REFRIGERATION OPERATION...................................................................................13

Self-Contained Refrigeration Operation..........................................................13

Dual Pressure Control ( Self-Contained Models Only )...................................13

Remote Refrigeration .....................................................................................14

Electronic Expansion Valve (EEV).............................................................14

Remote Refrigeration Operation.....................................................................15

CLEANING INSTRUCTIONS........................................................................................16

Cleaning The Condenser Coil.........................................................................16

Cleaning The Condensate Pump....................................................................16

Cleaning The Acrylic Air Deflector..................................................................17

Daily Cleaning.................................................................................................17

Weekly Cleaning.............................................................................................18

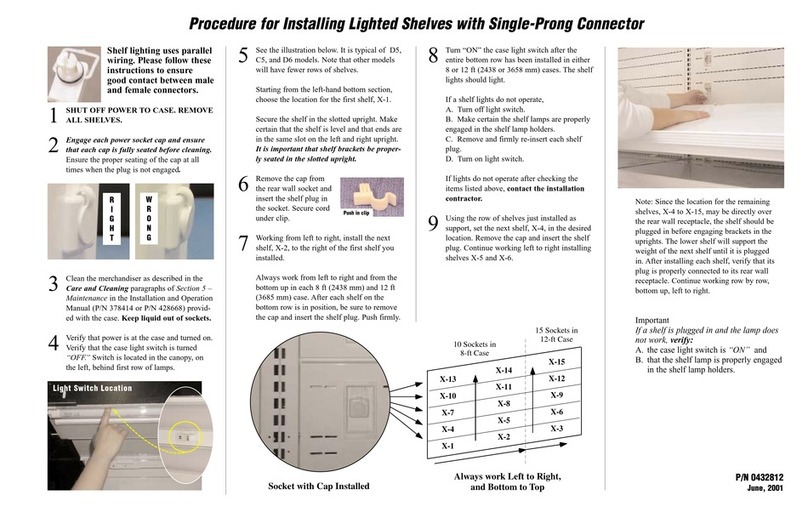

SHELVES......................................................................................................................19

Installation & Removal ....................................................................................19

SERVICE INFORMATION.............................................................................................20

Pre-Service Checklist................................................................................................21

Special Service Situations.........................................................................................22

SALE & DISPOSAL......................................................................................................22

Owner Responsibility................................................................................................22

REFRIGERATION & ELECTRICAL DATA .............................................................................23

RSSL378 ...................................................................................................................23

RSSL478 ........................................................................................................ 24 & 24A

RSSL578 ........................................................................................................ 25 & 25A

RSSL678 ........................................................................................................ 26 & 26A

NSSL378, NSSL478, NSSL578, NSSL678................................................................27

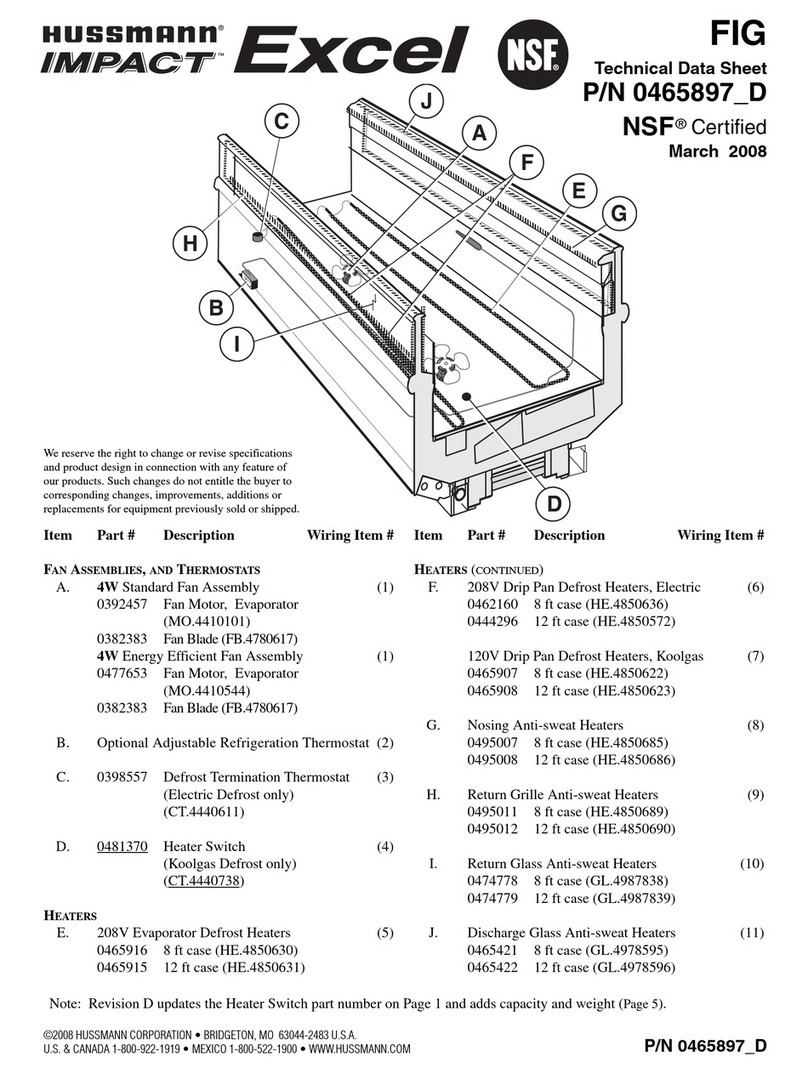

REPLACEMENT PARTS .........................................................................................................28

RSSL378 / NSSL378 ...................................................................................... 28 & 28A

RSSL478 / NSSL478 ...................................................................................... 29 & 29A

RSSL578 / NSSL578 ...................................................................................... 30 & 30A

RSSL678 / NSSL678 ...................................................................................... 31 & 31A

RSSL DISPLAY AREA & VOLUME.........................................................................................32

WIRING DIAGRAMS................................................................................................................33

RSSL3, 4, 5, 6 208-240V - Self-Contained After 01/01/20.........................................33

RSSL3, 4, 5, 6 208-240V –Remote After 01/01/20....................................................34

RSSL3 120V Self-Contained After 01/01/20...............................................................35

RSSL3 120V Remote After 01/01/20..........................................................................36

NSSL3, 4, 5, 6 120V ..................................................................................................37

Wiring Diagrams Prior to 01/01/2020 .............................................................38 thru 40

Refrigerated Self-Serve Merchandiser (High Profile)