feedback EW604 User manual

ELECTRONIC

WATTMETER

EW604

1160–00604

Feedback Instruments Ltd, Park Road, Crowborough, E. Sussex, TN6 2QX, UK.

Telephone: +44 (0) 1892 653322, Fax: +44 (0) 1892 663719.

email: feedback@feedback-instruments.com website: http://www.feedback-instruments.com

Manual: EW604 Ed01-1 122013

Feedback Part No. 1160–00604

ii

Product Use

All users must familiarise themselves with the following information.

This product is marked as CE compliant. This means that it complies with the relevant

European Directives for this product. In particular the Directives cover Low Voltage, EMC,

Machinery, Pressure and electronic waste disposal.

The equipment, when used in normal or prescribed applications and within the

parameters set for its mechanical and electrical performance, should not cause any

danger or hazard to health or safety.

If, in specific cases, circumstances exist in which a potential hazard may be brought about

by careless or improper use, these will be pointed out and the necessary precautions

emphasised.

This equipment is designed for use by students as part of the learning process who must

be under the supervision of a suitably qualified and experienced person in a laboratory

environment where safety precautions and good engineering practices are applied.

By the nature of its intrinsic teaching functionality, parts are visible and accessible that

might normally be covered up or encased in an industrial or domestic product.

For this reason students attention should be drawn to the need to operate the equipment

only in the manner prescribed in the accompanying documentation and supervisors must

make students aware of any particular risk. The equipment should not be operated by any

person alone.

We are required to indicate on our equipment panels certain areas and warnings that

require attention by the user. These have been indicated in the specified way by yellow

labels with black printing. The meanings of any labels that may be fixed to the instrument

are shown below:

CAUTION -

RISK OF

DANGER

CAUTION -

RISK OF

ELECTRIC SHOCK

CAUTION -

ELECTROSTATIC

SENSITIVE DEVICE

iii

Compliance with the EMC Directive

This equipment has been designed to comply with the essential requirements of the

Directive. However, because of the intrinsic teaching function it cannot be

electromagnetically shielded to the same extent as equipment designed for industrial or

domestic use. For this reason the equipment should only be operated in a teaching

laboratory environment where electromagnetic emissions in the immediate area might not

be expected to cause adverse effects. In the same way users should be aware that

operating the equipment near to an electromagnetic source may cause the experimental

results to be outside the range expected.

The Waste Electrical and Electronic Equipment Directive (WEEE)

If this equipment is disposed of it must be in accordance with the regulations regarding

the safe disposal of electronic and electrical items and not placed with ordinary domestic

or industrial waste.

Product Improvements

We maintain a policy of continuous product improvement by incorporating the latest

developments and components into our equipment, even up to the time of dispatch.

All major changes are incorporated into up-dated editions of our manuals and this manual

was believed to be correct at the time of printing. However, some product changes which

do not affect the teaching capability of the equipment, may not be included until it is

necessary to incorporate other significant changes.

Component Replacement

In order to maintain compliance with the Directives all replacement components must be

identical to those originally supplied.

Operating Conditions

This equipment is designed to operate under the following conditions:

Operating Temperature 10°C to 40°C (50°F to 104°F)

Humidity 10% to 90% (non-condensing)

WARNING:

This equipment must not be used in conditions of condensing humidity.

iv

Copyright Notice

© Feedback Instruments Limited

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form or by any means, electronic, mechanical, photo-

copying, recording or otherwise, without the prior permission of Feedback Instruments

Limited.

ACKNOWLEDGEMENTS

Feedback Instruments Ltd acknowledge all trademarks.

MICROSOFT, WINDOWS 8, WINDOWS 7, WINDOWS VISTA, WINDOWS XP,

WINDOWS 2000, WINDOWS ME, WINDOWS NT, WINDOWS 98, WINDOWS 95 and

Internet Explorer are registered trademarks of Microsoft Corporation.

MATLAB is a registered trademark of Mathworks Inc.

LabVIEW is a registered trademark of National Instruments.

v

Addendum

This manual is for the EW604 and EW1604 Electronic Wattmeter. The EW1604 design

includes a higher degree of immunity to radiated radio frequency fields in order to comply

with the EMC Directive. In all other respects the specification and operating instructions

for the EW604 and EW1604 are the same. The only other difference is that the protective

fuse in the input lines (not the mains fuse) has been moved from the rear to the front

panel.

vi

Electronic Wattmeter

CONTENTS

CHAPTER

1 Description

1.1

Introduction

1.2 Mechanical

1.3 Electrical specification

CHAPTER 2

Operation

2.1

Installation of EW604

2.2 Power supply voltage selection

2.3 Wire connections

2.4 Range selection

2.5 Connection of EW604

to

circuit under test

2.6 Measuring power

in

a three-phase system

2.7 Measuring systems with low power factor

2.8 Amplifier power measurement

2.9 Measuring power

in

audio frequency circuits

2.10 Audio frequency power comparison

2.11

Measuring radio frequency power

CHAPTER

3 Circuit Description

3.1

Multiplying circuit

3.2 Overload circuits

3.3 Power supply circuit

CHAPTER

4

Maintenance

4.1

Access

4.2 Alignment schedule

4.3 Component replacement table

3

METER

AMPS~

O/~

·S '

C

POWER

;q

REV

.j

Hi

SET

ZERO

FEEDBACK

ELECTRONIC

WATTMETER

EWS04

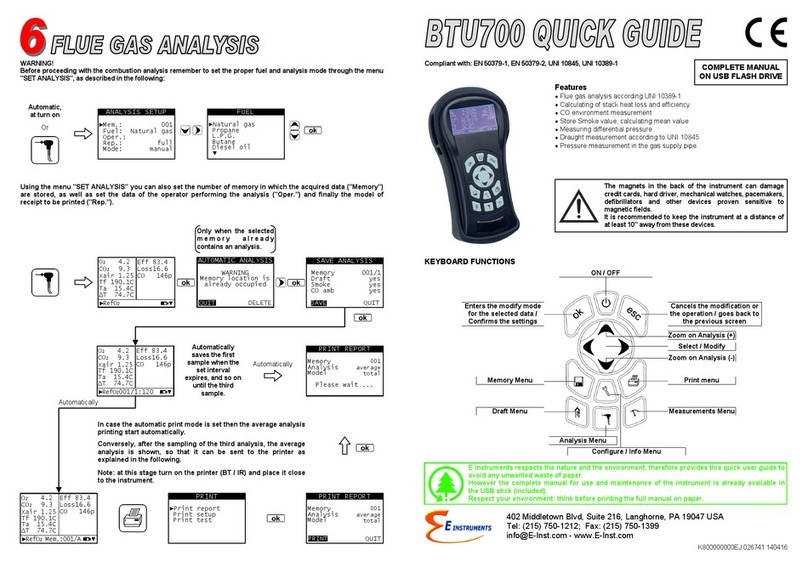

Fig

1.

1 Electronic Wattmeter

4

Electronic Wattmeter

VOLTS.

0/L

so

100

DESCRIPTION

1.1 Introduction

Electronic Wattmeter

CHAPTER 1

The Feedback EW604 Electronic Wattmeter is based

on

an

analogue multiplying circuit using the logarithmic voltage-to-

current transistor characteristic. The inputs to this multiplying

circuit are currents that are derived via range-scaling resistors

from the input voltage terminals and the input current terminals.

The output is displayed

on

the front panel moving-coil meter

calibrated

in

watts.

The wattmeter terminals are arranged as two pairs marked

'SUPPLY' and 'LOAD' to facilitate correct connection.

Separate warning lights are provided

on

the voltage input

and

current input to indicate when

an

overload might affect the

reading accuracy. Additional precautions are taken to prevent

damage to the instrument

in

the event of gross overload of

current or voltage.

Pushbuttons enable the meter deflection to

be

reversed to

measure reverse power flows and also to increase the meter

sensitivity

by

x2

to improve readability of small deflections.

The wattmeter contains its

own

partly-regulated power supply

for operation

on

normal line voltages.

The value of the wattage is displayed

on

the front panel meter

which responds to the true wattage or potential heating ability of

the current in the associated load.

In

a resistive load this

corresponds to:

2

2

(V

rmsl

. .

(I

rmsl

R or R

1rrespect1ve

of waveform*

and to: (Irmsl

(Vrmsl

cos

<jl,

in

a reactive circuit with sinusoidal

excitation

and

in

general to:

T

Limit T

1 Jv i dt

T->=

0

*High crest values applied to EW604 will illuminate the

0/L

lamp(s) if they are of such a value as to cause limiting

in

the

circuit

and

thus errors.

5

1.2 Mechanical

1.3 Specification

Electronic Wattmeter

Chapter 1

The EW604 is housed

in

an

ABS plastic case made

in

two

halves, each secured

by

two screws

on

each side. The case

provides the

main

structural strength of the instrument. Removal

of the case gives access to

all

components. Without the cover

the EW604 consists of a horizontal

PWB

fixed

by

small plastic

brackets to the front and rear panels, providing a structure

strong enough for normal handling

and

maintenance. The low-

power dissipation of the EW604 obviates the need for

ventilation holes.

The controls, situated

on

the front panel

(see

fig

1.1) are:

Power

Green pushbutton power switch

Separate green power

ON

indicator

Current

Eight-position rotary range selector

Voltage

Eight-position rotary range selector

Terminals

Four 4mm

red

socket binding posts (two for connection to

supply and two for connection to the load) with mimic showing

metering circuits.

Meter

Mirror-scale moving-coil meter calibrated

in

watts.

Zero-

separate knob for electrical meter zero.

x2-

Pushbutton to increase sensitivity

Rev

-Pushbutton

to

reverse deflection

On

the rear panel are:

Current circuit-protection fuse holder with spare fuses.

'Three-terminal wattmeter'

(one

terminal common to voltage

and

current ranges) connected to four front-panel binding posts

so

that two are for connection to the 'supply' and two for connection

to the 'load'.

Power range

250mW

to

1

OkW

fsd.

Voltage ranges

Nominal

5,

10, 20,

50,

100, 200,

500

and 1000 volts.

6

Burden

Meter

Accuracy

Scale Accuracy

Electronic Wattmeter

Chapter 1

No

more than 1.5kV peak should

be

applied between the upper

pair of terminals and either ground or the lower terminals. The

latter must not exceed 400V peak to ground.

Current ranges

Nominal 0.05, 0.1, 0.2, 0.5,

1,

2,

5 and 1

OA.

Overload Indication

Input peaks of voltage or current

in

excess of 1.5x the nominal

range can cause overload which is clearly indicated by the

appropriate voltage or current overload lamp.

Overload Protection

All current circuits

are

protected by a 1

OA

slow-blow 1/4" x 1 1/4"

fuse mounted

on

the rear panel. The circuit is designed

to

withstand the transient associated with normal rupturing of this

fuse

on

all

current ranges. The voltage circuit will withstand the

nominal 250V a.c supply indefinitely

on

any range.

Frequency range

DC

to

20kHz.

All voltage ranges; 5kQ/Volt

All current ranges; less than 60mQ

3 1/4" mirror scale graduated 0 to 1.0

in

50

divisions

Reading given by:

Watts=

(meter deflection) x (Voltage range) x (Current range)

Pushbutton to give x2 scale expansion and pushbutton meter

reversal.

Many factors control the final indication

on

any wattmeter. They

include voltage, current and power ranges, power factor,

temperature and frequency.

The possible permutations of these are

so

numerous that it

is

impracticable to specify or to test instruments under all likely

operating conditions. The figures below should

be

interpreted

in

the light of these comments.

All figures are at 50Hz, unity power factor, 25oc.

Typically better than 1.5% of fsd measured

on

1

OOV

and 0.5A

range at

20,

40,

60,

80

and 100% of fsd with a 200 ohm load

(guaranteed better than 2.5% of fsd).

Also typically better than 2% of fsd for all combinations of 0.25A,

0.5V,

0.

75A and 1A with 25V, 50V, 75V and 1

OOV

applied to the

1A and 1

OOV

ranges.

7

Range-to-range Accuracy

Reference Point Power

10kW

1kW

~

Q)

~

100W

0..

DC

Carrying Handle

Power Requirements

Fuse

Electronic Wattmeter

Chapter 1

Errors in the current and voltage range multipliers contribute a

combined error to power indication that is typically less than

1%

of reading (guaranteed less than 2.3% of reading).

This is at full-scale

on

the 1

OOV

and 0.5A range and is set

to

within 0.3% of 50W.

Note

1)

In

general, scale errors are not affected by choice of

range.

2)

Typical figures are determined from measurements

made

on

a single batch of instruments.

3)

Guaranteed figures

are

from measurements made

on

every instrument.

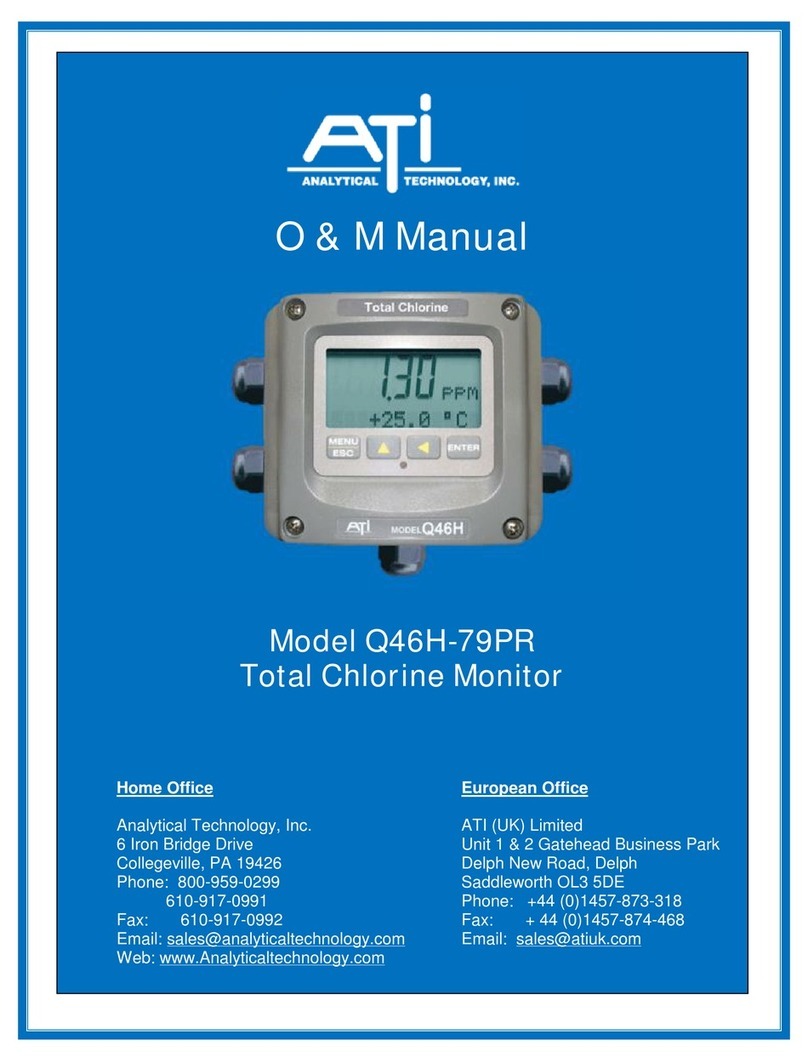

Fig 1.2 shows the area of operation within which the EW604

may

be

expected to give results accurate to better than ±5% of

fsd and should

be

interpreted

in

conjunction with the accuracy

figures given for the calibration frequency of 50Hz.

Area of operation

10

50

100

1k

10k 20k

Calibration Frequency Frequency

Hz----e.

Fig 1.2

A dual purpose handle is fitted for

use

in

carrying the instrument

or serving

as

a stable stand to present the instrument panel

at

a

convenient working angle.

Line voltage

200/250V or 100/125V rms

50

or 60Hz

Consumption

4

V.A.

315mA slow blow (200mm x 5mm) Littelfuse style 213

Beswick TTC123, Buss GMA

8

Dimensions and Weight Width

Depth

Height (with feet)

Weight

9

330mm (13in)

238mm (9.4in)

118mm (4.6in)

1.9kg

(4.31b)

Electronic Wattmeter

Chapter 1

Electronic Wattmeter

NOTES

10

OPERATION

2.1

Installation of EW604

2.2 Power Supply

Voltage Selection

2.3 Wire Connections

2.4 Range Selection

Electronic Wattmeter

CHAPTER 2

Inspect the EW604 and if any damage is evident, immediately

notify the carriers and your supplier.

Ensure that the instrument is set to the appropriate voltage

supply either

by

inspecting the tag (if fitted)

on

the power cable

or

by

removing the top cover of the instrument. See Chapter

4.1.

Before removing the covers, however, ensure that the mains

plug is disconnected.

The voltage selection is accomplished

by

a slide switch

on

the

printed circuit board. Set the switch to '115' for operation

from

100 to 125V

and

to '230' for 200 to 250V, 50/60Hz

AC.

The colour code of the power supply cable is:

Brown

Blue

Green/Yellow

Live

Neutral

Ground

The ground wire is connected to the graphite screening of the

case but is isolated from the front panel 'common' terminal.

The current

and

voltage ranges should

be

selected to suit

the

current voltage present

in

the circuit under test. This is

conveniently done

by

progessively increasing the sensitivity

by

means of the appropriate range switch until the corresponding

overload indicator lights, and then switching back one range.

This should

be

done with both the current ranges and voltage

ranges.

The table

in

fig

2.1

lists the full-scale power for the various

current and voltage range combinations.

1 1

Electronic Wattmeter

Chapter 2

Power for a given voltage range (Watts)

Current

Range

0.05

0.1

0.2

0.5

1

2

5

10

Working voltage limits

2.5 Connection

of

EW604

to Circuit under

Test

5

10

20

50

100

200

500

1000

0.25 0.5 1.0 2.5 5 10 25 50

0.5 1.0 2 5 10 20 50 100

1.0 2 4 10 20 40 100 200

2.5 5 10 25 50 100 250 500

5 10 20 50 100 200 500 1k

10 20 40 100 200 400 1k 2k

25 50 100 250 500 1k 2.5k 5k

50 100 200 500 1k 2k 5k 10k

Fig 2.1

It is recommended that the lower front panel 'COMMON'

terminals are operated

at

'neutral' potential and

in

no

case

at

a

potential exceeding 400V d.c

or

peak, and the upper terminals

at

no

more than 1500V d.c or peak, with respect to the normal

supply ground (green/yellow wire

in

the supply cable to the rear

of

the EW604).

The EW604 terminals

are

arranged

so

that two terminals can

be

connected to the supply and a separate two to the load

as

in

fig

2.2.

Live

Supply

Neutral

Fig 2.2

12

Supply

Electronic Wattmeter

Chapter

2

The current-sensing circuit is in the lower line and should

be

connected

in

the neutral line. (This is good practice since it

keeps low the operating potential of the wattmeter common

connection). However, if necessary, it is possible to operate with

the upper line at neutral. (This situation may occur where it is

not possible to break the neutral line or where a dangerous

situation would

be

created if the 1

OA

overload protective fuse

in

series with the current-sensing circuit were ruptured). The live

voltage must not then exceed 280V with respect to ground.

With conventional dynamometer wattmeters a decision has to

be made before connection whether to include the internally

consumed watts of the current coils or the voltage coils

in

the

power supply measured.

With the EW604 connected

as

in

fig 2.3(a) the power consumed

by the voltage circuit

at

(5000 ohms/V) is

so

small that it is

insignificant compared with load power. This enables the

prearranged connections as shown

on

the front panel

schematic to

be

used without need for correction.

However the EW604 may, if desired,

be

connected

as

in

fig

2.3(b). This introduces a small voltage drop (about 60mV/A)

in

the current sensing circuit. The reading can

be

corrected if

necessary

by

subtracting the

I2R

loss from the EW604 reading.

Wattmeter

'"

___________

,

Figs 2.3(a)

Load

WL

Wattmeter

... -----------,

I ' ,

__.,

l-r'----,

Warning

'

'

'

---

--------

Fig 2.3(b)

Load

WL

As

with

an

electrical measuring instrument care must

be

taken

to

avoid contact with supply voltages associated

with the test circuit. Switch off the supply voltage before

making connections to the wattmeter terminals and

avoid contact with these terminals during the test.

13

Electronic Wattmeter

Chapter 2

2.6 Measuring Power in

a Three-phase System

Balanced system

Polyphase measurements invariably require connection of the

common terminal of the EW604 to at least one live line. The

line

voltage must then not exceed 280V. For three-phase systems

this implies a maximum line voltage of 490V.

If both the supply and the load are balanced and either a neutral

is

available

on

the supply or a star point

on

the load, the power

can

be

measured by connecting as

in

fig 2.4 and multiplying the

reading obtained by three.

EW604

3phase

supply{----.:

8

::.._

y

~~-L~-.

a)

Supply neutral available

3 phase

JRB

supply

ty

b)

Star point of load available

Fig 2.4 Finding the power

in

a balanced load system

If the supply and load are balanced, both the power and the

power factor can

be

obtained from two readings using the

connections

of

fig

2.5. Two readings P1 and P2 are taken using

the two positions of the switch. The power is then given

by

P1 + P2, and the power factor

is

1 2

p1

1--

1+ 3

p2

p1

1+-

p2

14

Electronic Wattmeter

Chapter

2

3

phase

{~~'--~t_..--1

Balanced

supply 8 Load

:-"---L_.::.:::.:::..:::___J

Fig 2.5 Power andpower factor

in

a balanced load system

Unbalanced system If either the load or the supply is unbalanced (or both) it is

necessary to obtain the power as the sum of readings, taken

with the current terminals connected

in

series with each line

in

turn, except one, and the voltage connection is taken to that

one

in

each case. Connections are shown

in

fig

2.6 for three-wire

and four-wire three-phase systems. If only one wattmeter is

available it may

be

connected

in

each of the positions shown

in

turn. The power is the sum of all the readings. (This scheme

of

connections

can

be

extended

to

any number of wires, taking n -

1 readings

in

the n - wire case. Also it is not

in

principle

restricted

to

any particular current or voltage waveforms).

,-----l

1 load 1

I

I

I

I

I

I

I

I

I

L

_____

_j

Fig 2.6a Measuring power

in

a three-terminal load

1 5

Electronic Wattmeter

Chapter 2

N

Fig 2.6b Measuring power

in

an unbalanced star-connected load

2.7 Measuring Systems

with Low Power Factor

It

is

possible with conditions of low power factor or

high

crest

factor that only a small deflection is obtainable without

overloading. This is a direct result of the real power being

low

in

the circuit and thus it is unreasonable to expect a large

deflection.

In

practice low power factors are commonly

encountered when measuring, for example, the iron loss of

transformers.

In

this case the magnetising current

may

cause

overloading of the wattmeter when it is displaying a very small

deflection corresponding to a small iron loss. This difficulty

may

be

overcome

by

the use of power factor correction capacitors.

In

theory the use of such capacitors to 'tune' the transformer

inductance does not affect the power reading but

it

does

reduce

the supply current enabling a more sensitive current range

to

be

used without overloading the wattmeter, thereby providing a

more significant deflection.

The capacitor used

as

shown

in

fig 2.7 can

be,

for convenience,

a decade box of suitable voltage rating and value. The loss

angle of most commercial capacitor boxes is

so

small that

it

is

insignificant compared with normal power transformer loss

angles

and

so

requires

no

correction.

The value of the capacitors is not critical,

it

being adjusted

on

test

to

extinguish the current overload indication.

1 6

This manual suits for next models

1

Table of contents

Popular Measuring Instrument manuals by other brands

Neptune Technology

Neptune Technology CMIU Installation and maintenance guide

JAVS

JAVS X7-DAC Femto manual

DIDIESSE

DIDIESSE Baby Frog operating instructions

LEGRAND

LEGRAND 0 435 01 Instructions for installation and use

Delta F

Delta F NANOTRACE DF-745 instruction manual

Integra

Integra Ri3 Installation and operating instructions

TAC

TAC H2S/H2O/O2 instruction manual

Extech Instruments

Extech Instruments 475040 user guide

Schroeder Industries

Schroeder Industries HY-TRAX Operating and maintenance instructions

Omntec

Omntec FuelCheck Installation & operating manual

Major tech

Major tech MT760 manual

Thermo Scientific

Thermo Scientific ISE user guide