1

RM4000 Series 1

Chapter 1: Getting Started

This guide explains how to install and configure Bullhorn RM4000 Series units for service. This guide

includes instructions for installing and configuring units, optional equipment that is available to be

installed with select units, technical specifications for different unit types, and other related

information.

This chapter includes the following topics:

lRM4010, RM4014, RM4011, RM4015, RM4013, RM4016, and RM4020 Unit Overview on page 1

lRM4150 and RM4151 Unit Overview on page 2

lRM4210 and RM4211 Unit Overview on page 3

lBullhorn Information Line on page 3

lTechnical Services on page 4

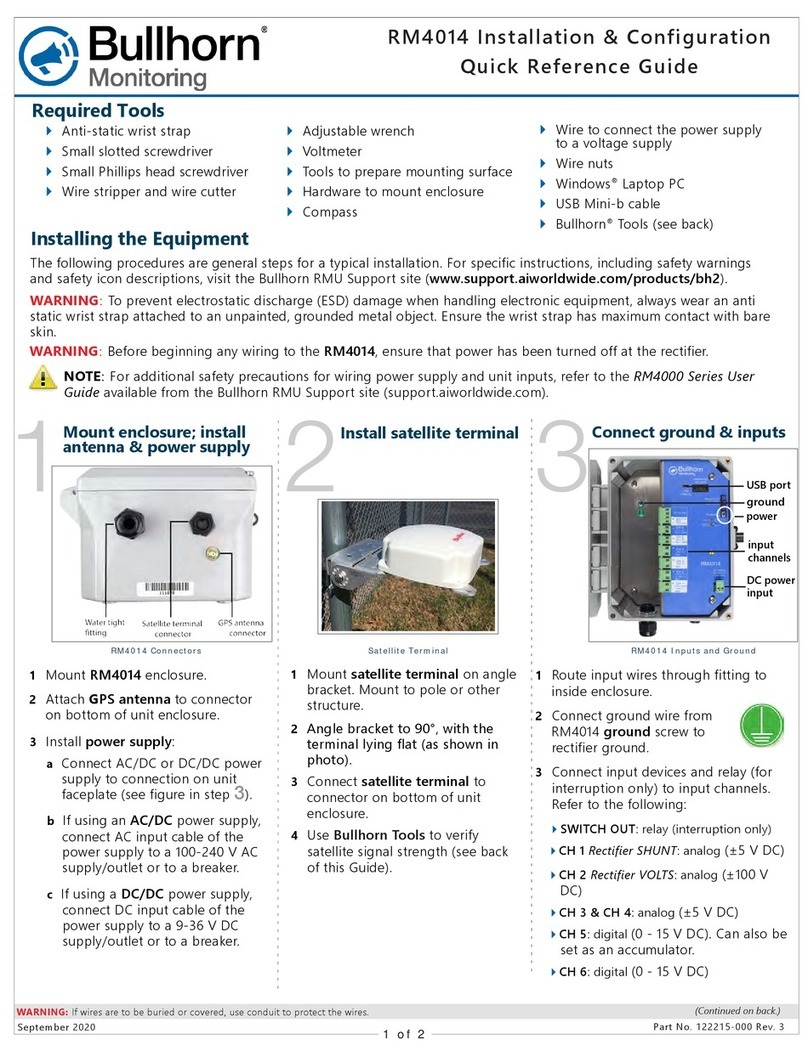

RM4010, RM4014, RM4011, RM4015, RM4013, RM4016,

and RM4020 Unit Overview

The RM4010, RM4014, RM4011, RM4015, RM4013, RM4016, and RM4020 units monitor oil and gas

assets in cathodic protection (CP) applications. The RM4010 and RM4014 measure the output of

rectifier current across shunt resistors. The RM4014, RM4015, and RM4016 are identical to the

RM4010, RM4011, and RM4013, respectively, except for the use of the SkyWave IDP-680 satellite

terminal, which is replacing the DMR-800 series terminals.

Remote monitoring units use satellite networks for communication with Bullhorn Web. RM4010,

RM4014, RM4011, RM4015, RM4013, and RM4016 (with the capability of two-way communication)

use the SkyWave-Inmarsat satellite network; RM4020 uses the ORBCOMM satellite network. Units

transmit channel measurements and alarms to your website account.

NOTE: Satellite coverage maps are available through the carrier websites, such as ORBCOMM

Satellite.

These units provide built-in surge protection, rectifier interface, and test point filtering functionality.

Additionally the RM4010, RM4014, RM4011, and RM4015 also support GPS synchronized current

interruption, either factory-installed or field-upgraded. These units support six (6) configurable

inputs with the following specifications: