FEICHTNER RP-3000 User manual

Operation Manual Universal Gluing Press “

RP-3000

”

Release 10/2017 - We reserve the right to make technical changes in the interests of further development

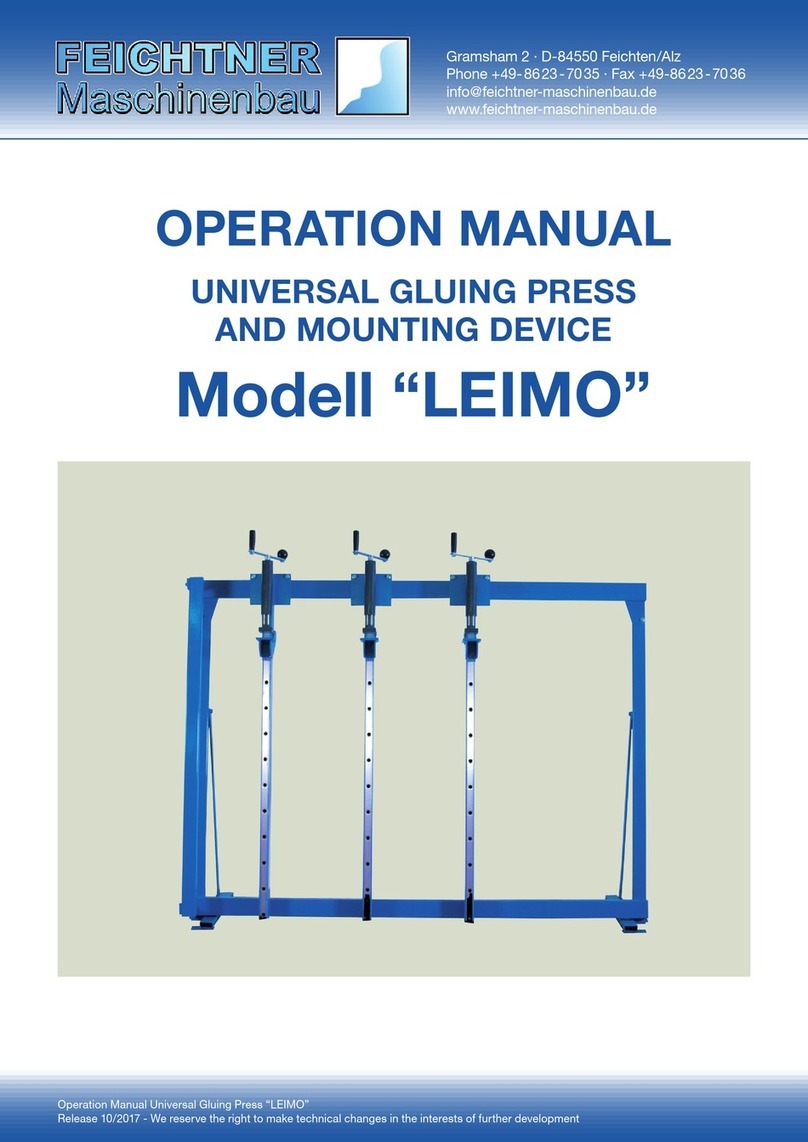

OPERATION MANUAL

UNIVERSAL GLUING PRESS

AND MOUNTING DEVICE

Modell “RP-3000”

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

Contents Release 10/2017 – We reserve the right to make technical changes in the interests of further development

Contents

ITEM: Page

Contents

Introduction 3

General information 4

Intended usage 5

Safety instructions 6

Device view / Main controls 7

Set up / Operation 8 –13

Version RP-3000 13

Preventive Maintenance 14

Warranty conditions 15

EU-declaration of conformity 16

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

Release 10/2017 - We reserve the right to make technical changes in the interests of further development 3

Introduction

Dear Costumer!

With the purchase of this frame press you acquired a high quality product, to which we can

congratulate you.

It shows us, that you appreciate quality and technical leadership.

By purchasing the Feichtner frame press you have the following advantages:

Optimized pressure control

Angle accurate pressing of large-format parts

Very good price / performance ratio

Small space requirement

3 press units in the basic equipment

Read the following instructions carefully.

It will provide you a valuable help in the assembly and operation of the new frame press.

Please keep this manual for future reference.

We wish you much pleasure with your new frame press.

Josef Feichtner

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

4Release 10/2017 – We reserve the right to make technical changes in the interests of further development

General information

Before starting and operating the new machine, please read this operation manual carefully and follow

the instructions.

Operation of the machine is only permitted with devices and spare parts which are included in the

scope of delivery or are listed in the spare and wear parts list.

Accessories must be matched to the basic unit (safety and operability). For more detailed information,

please contact the manufacturer or his contractual partner.

For ease of understanding, the following symbols have been used:

This area represents a special danger to the operating personnel or maintenance

personnel, if the operating instructions are not observed.

Maintenance work must be carried out at certain intervals in these areas.

Note or information on individual components of the machine which make the use

easier or more understandable.

Disregarding this instructions may cause personal injury or property damage.

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

Release 10/2017 - We reserve the right to make technical changes in the interests of further development 5

Intended usage

The universal gluing press “RP-3000” is used for gluing applications in the wood processing industry.

Thanks to its easy handling and versatile extras, this press is extremely economical and time-saving to

use.

Observe the instructions given in this operating manual. Use of this device for other than its intended

is unsafe.

The manufacturer does not assume any liability for resulting personal injury and / or material damage

from improper use.

It is recommended to consult a person who already has experience with such a machine when

assembling and setting up the machine.

Only original accessories or spare parts ensure perfect functioning of the machine.

No liability is assumed for damage resulting from the use of external components.

The device should only be operated, maintained and repaired by persons who are

familiar with the intended use and the dangers of the device!

Failure to observe the operating and maintenance instructions described by the manufacturer in these

operating manual excludes any liability on the part of the manufacturer in the event of a defect.

The Feichtner ** UNIVERSAL GLUING PRESS “RP-3000” ** may only be used for gluing

wood and wood joints.

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

6Release 10/2017 – We reserve the right to make technical changes in the interests of further development

Safety instructions

4.1 General safety instructions:

Any person charged with setting up, operation,

maintenance and repair must have read and understood

the operating instructions and, in particular, the chapter on safety.

It is recommended to the machine user to provide in-house operating instructions, prepared by a

person with professional skills and qualifications to train particular operators. The participation of the

instruction and training has to be confirmed by all participants in a written protocol.

Safety instructions to the machine user and / or operators:

– Any operation, that affects the safety of the equipment, must be omitted.

– The operator must ensure that no unauthorized persons work with or on the machine.

– The operator is obliged to check safety-relevant parts, f. e. protective devices before setting up

and in case of defects to have them repaired before start up the machine.

– The operator has to take care that a holding-down device is used for surface gluing so that the

workpiece cannot fall out of the frame due to the pressing pressure.

– When moving the press arm, hold the pad shoe, so that it cannot fall downwards.

– The pressure elements should only be actuated by means of pure muscular strength and

without the aid of any tools. A violation of the regulations will result in a damage to the gluing

press (bent profiled pipe, broken rack-and-pinion gears) which is excluded from the guarantee.

– It is important to ensure, whether there is any other person in the working area or danger area.

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

Release 10/2017 - We reserve the right to make technical changes in the interests of further development 7

Device view/ Main controls

3

1

8

9

10

2

4

5

6

7

1) Hand-hydraulic cylinder

2) Base frame

3) Swivel pressure shoe (accessory)

4) 90°-stop device

5) Press arm

6) Height adjustable pad shoe

7) Side pressure with 2 rack-and-pinion gears

8) Lifting device for side pressure

9) Holding down clamp (Accessory)

10) Rack-and-pinion gear

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

8Release 10/2017 – We reserve the right to make technical changes in the interests of further development

Set up / Operation

Installation:

Place the press in an accessible place with flat ground.

The frame is then anchored to the ground.

Before starting work:

¾Always check whether all the controls on the gluing press are okay.

¾Check that the rack-and-pinion gears and hydraulic cylinders are free from dirt.

Remove possible glue residues from 90°-stop and pad shoes, so that a clean gluing (bond)

is guaranteed.

Always check, that all pressure elements are properly hooked and clamped before

starting work!

Calculate the dimensions of the finished wooden board or the finished frame so that

you can adjust the press arms, support shoes and hydraulic cylinders accordingly.

Adjust the press arms in such a way (horizontally move) that a uniform distance and thus a uniform

pressing pressure is produced.

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

Release 10/2017 - We reserve the right to make technical changes in the interests of further development 9

Set up / Operation

Make sure that the hydraulic pumps are fully retracted. Now adjust the pad shoes in such a way that

the finished wooden board or frame still receives sufficient pressure (observe the max. way of the

hydraulic pumps!). If necessary, the hydraulic pumps can also be adjusted in their position. For this

purpose, the screw handles are released, the hydraulic pumps are moved upwards or downwards and

the screw handles are tightened again.

Pull up the pad shoe to release the locking pin.

The pad shoe can now be moved freely.

Then release the pad shoe just before the desired

position and push it until the bolt snaps back into place.

Loosen the screw handle,

move the hydraulic pump,

tighten the screw handle

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

10 Release 10/2017 – We reserve the right to make technical changes in the interests of further development

Clamping and gluing process:

Once pad shoes, press arms and hydraulic cylinders have been positioned, the actual working

process can be started.

Equip the press with the glued work pieces so that they stand on the stop rail. Now pump the

hydraulic cylinders downwards until the desired pressing pressure is reached. Now place the side

pressure pipe in position. This is done by actuating the lifting mechanism and thus lifting the side

pressure pipe.

Make sure that the snap-in pins of the side pressure pipe snap into the rowes of holes above and

below, so that the resulting side load can be discharged optimally.

When gluing frames, ensure that the press shoes are seated at the corner points of

the frame so as to avoid deflection and possible damage to the workpiece.

Set up / Operation

Pump the hydraulic

cylinders downwards

Actuation of the lifting device,

move the side-pressure unit,

reduce the side-pressure unit

using the lifting device.

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

Release 10/2017 - We reserve the right to make technical changes in the interests of further development 11

Crank the racks of the rack-and-pinion gear on the side pressure pipe to the left until the desired side

pressure is reached.

In the case of angle gluing, the swivel pressure shoes, available as accessories, can be pushed

onto the press shoes of the hydraulic pumps.

Set up / Operation

Crank the racks of the rack-and-pinion

gears to the left at the side pressure

device until the desired pressing pressure

is reached.

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

12 Release 10/2017 – We reserve the right to make technical changes in the interests of further development

Set up / Operation

How to use the holding-down device (clamping device) (accessory):

Use a clamping device for surface gluing so that the workpiece does not bend forward during pressing

and the surface becomes even.

¾The holding-down device (clamping device) is simply to be mounted from above at the upper and

lower cross-tubes in the desired position.

¾Then crank the hold-down profile in the direction of the wood plate until the workpiece is evenly

against the press arms.

The holding down clamp serves only to prevent a deflection of the workpiece,

and not as an additional pressing device.

Place the clamping device on the top

Mount the clamping device

on the lower position

Place the clamping device on the work piece by means

of a crank

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

Release 10/2017 - We reserve the right to make technical changes in the interests of further development 13

Set up / Operation

Version RP-3000

Relief of the hydraulic pumps:

To release or push up the press shoes, press the

pump lever at the hydraulic pump all the way up.

By doing so, the pump lever on his part presses on

a valve, which allows the ram (plunger) to be driven

up independently with the press shoe.

With hand hydraulic cylinder – 2 tons of pressure

Basic equipment with 3 press units

Clamping dimensions (H x W): 1600x 2900 mm

Accessories: Side-pressure unit with 2 rack-and-pinion gears

or cylinder – clamping device – landing gear (chassis) – mitre

gluing device - swivel pressure shoe

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

14 Release 10/2017 – We reserve the right to make technical changes in the interests of further development

Preventive Maintenance

With the Feichtner frame press you have acquired an extremely low maintenance

– almost maintenance free device. However, in order to guarantee an optimal

performance sequence and to extend the service life of the machine, the following

maintenance instructions should be observed.

1) Allow glue residues to harden and then scrape them off.

2) Clean or remove dust from the surface of the upper profile, the rollers and the hydraulic cylinders

occasionally.

3) The gauge screws are used to adjust the press arms and can be adjusted by means of an Allen key.

4) Occasionally the fastening screws on the frame

and on the press arms should be inspected and,

if necessary, retightened.

5) Regularly grease the rack-and-pinion gears by

means of a grease gun on the lubrication nipples

provided for this purpose.

At this point regularly

lubricate using a

grease gun

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Operation Manual Universal Gluing Press “

RP-3000

”

Release 10/2017 - We reserve the right to make technical changes in the interests of further development 15

Warranty conditions

Warranty claims according to our general terms and conditions:

¾The supplier gives a guarantee for his machines of 2 years. However, this only applies to visible

design errors and material defects. The supplier shall only be liable for defects of the delivery in

such a way that he has to remedy any defective parts of his product free of charge or to deliver it at

his own discretion.

¾The warranty period begins on the day of delivery.

¾The defects must be reported to the supplier immediately in writing and the parts concerned must

be sent to him on request. Regarding liability for faulty design or defective design; for material

defects, the supplier is only liable to the extent that he should have been aware of the defect in the

case of application of professional diligence.

¾The supplier is not liable for damages that have arisen for the following reasons:

– Faulty assembly or setup by the customer or third parties

– Unsuitable or improper use

– Normal wear

– Faulty or careless handling of the machine

– Excessive use

The supplier is not obliged to remedy defects, if the customer has not fulfilled his payment

obligation.

¾Further claims by the customer, in particular a claim for compensation for damages, which are not

caused by the equipment itself, do not exist.

Handling of spare parts deliveries during guarantee period:

The customer himself sends the defective part back to us free of charge. The workshop manager

assesses the damage and checks whether there is a guarantee claim according to the above

mentioned terms and conditions. The spare part is also sent free to the customer when the warranty is

granted.

Operation Manual Universal Gluing Press “RP-3000”

16 Release 10/2017 – We reserve the right to make technical changes in the interests of further development

EU-declaration of conformity

The manufacturer

Feichtner Maschinenbau

Gramsham 2

D-84550 Feichten an der Alz

declares that the machine described in the enclosed operating manual:

Type: Universal gluing press and mounting device “RP-3000”

Brand: Feichtner

Serial number: __________________________

Manufacture year: __________________________

complies with the guidlines of Directives 2006/42/EC (for machinery).

Applied harmonized standards, in particular:

DIN EN ISO 12100-1

DIN EN ISO 12100-2

Gramsham, __________________________

_____________________________

Signature/Stamp

Gramsham 2 · D-84550 Feichten/Alz

Phone +49- 8623-70 35 · Fax +49-8623 -7036

info@feichtner-maschinenbau.de

www.feichtner-maschinenbau.de

Table of contents

Other FEICHTNER Power Tools manuals