Thereisariskassumedbyindividualswhousethistypeofequipment.

Amoment’slackofattentioncanresultinanaccident,ascanfailureto

observecertainsimplesafetyprecautions.

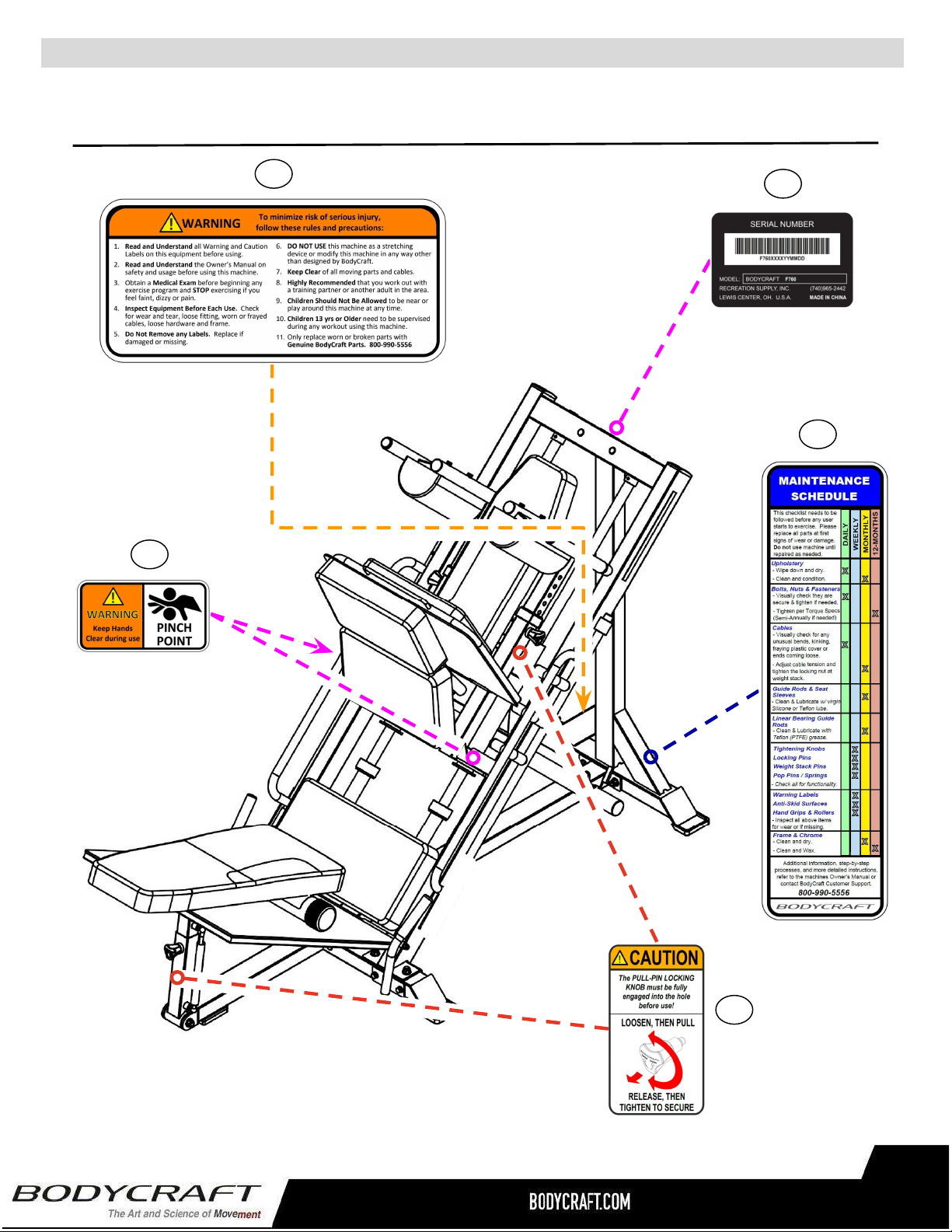

Read,studyandunderstandtheAssemblyInstructionsandallthewarninglabelson

thisproduct.Furthermore,itisrecommendedtofamiliarizeyourselfandotherswith

theproperoperationandworkoutrecommendationsforthisBODYCRAFTproduct

priortouse.

● Beforebeginningthisoranyotherexerciseprogram,consultyourphysician.Thisis

especiallyimportantforindividualsovertheageof35orpersonswithpreexistinghealth

problems.RecreationSupply,Inc.assumesnoresponsibilityforpersonalinjuryor

propertydamagesustainedbyorthroughuseofthisproduct.

● Exercisewithcaretoavoidinjury.Donotattempttoliftmoreweightthanyoucancontrol

safely.

● Thisproductmustbeassembledonaflat,levelsurfacetoassureitsproperfunction.

● Cleanpadsandframeonaregularbasis.Werecommendwarm,soapywater.Donot

useharshorabrasivechemicals.

● Inspectandtightenallpartsbeforeeveryuse.Replaceanywornpartsimmediately.

Failuretodosomayresultinseriousinjury.

● KeepchildrenawayfromanyBODYCRAFTstrength

machinesatalltimes.

● Keepyourhandsawayfromcablesandpulleysduring

operation,otherthanthedesignatedhandles.

● Keephands,limbs,looseclothingandlonghairwelloutofthewayofmovingparts.

● Inspecttheunitforanysignofwearonparts,hardwarebecominglooseorcrackson

welds.Ifaproblemisfound,donotuseorallowthemachinetobeuseduntilthedefective

partisrepairedorreplaced.

● ItisimperativethatyouretaintheseAssemblyInstructionsandbesureallwarninglabels

arelegibleandintact.ReplacementAssemblyInstructionsandlabelsareavailablefrom

BODYCRAFT.IfyouareunsureabouttheproperuseoftheBODYCRAFTstrength

machinecallyourlocalBODYCRAFTdealerorourCustomerServiceDepartment.

ContactBODYCRAFTat800-990-5556orsupport@bodycraft.com

ProductSafety-Benches&Racks

4