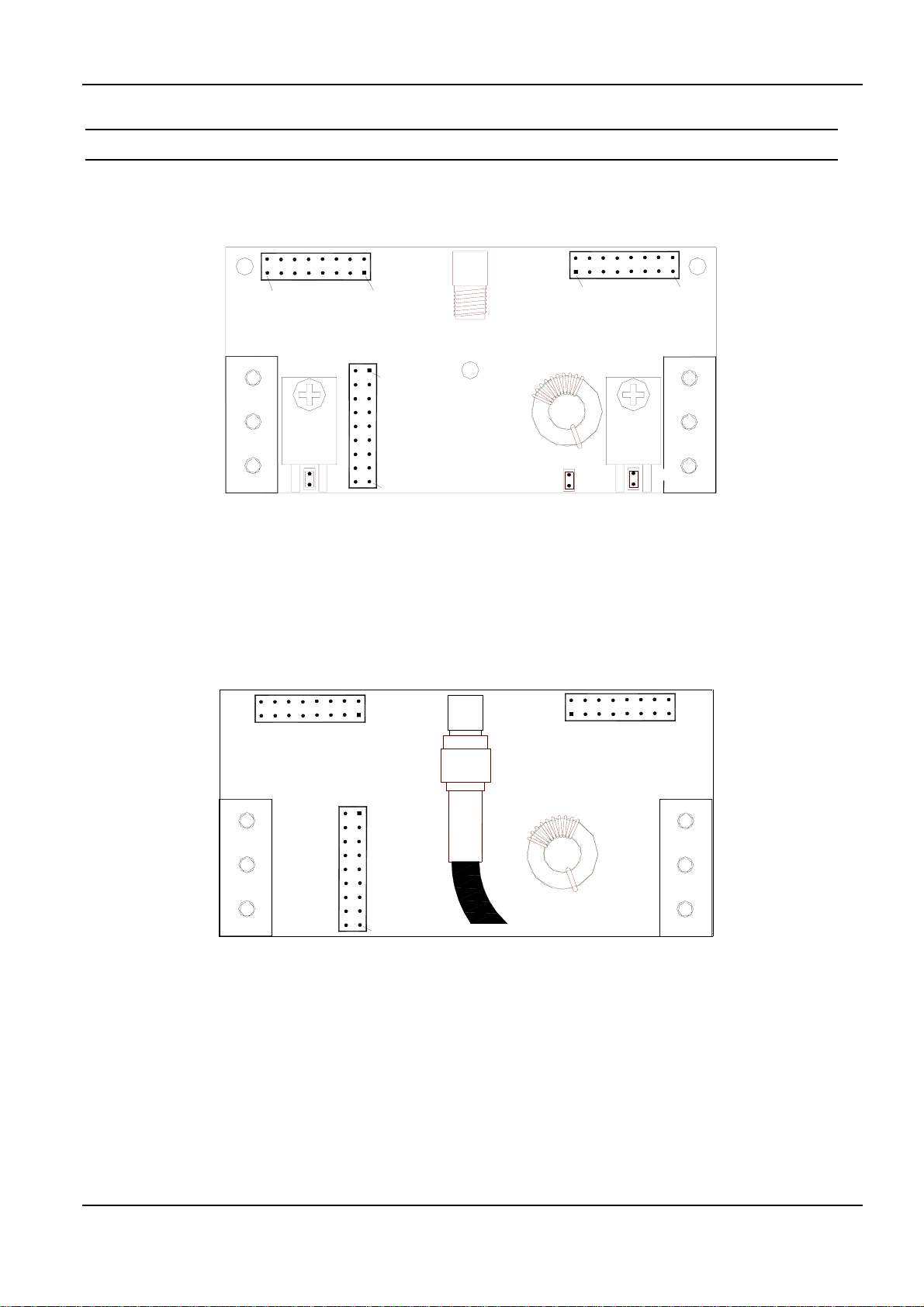

OBID i-scan®Montage / Installation ID ISC.MAT-B

FEIG ELECTRONIC GmbH Page 2 of 19 M70101-0e-ID-B.doc

Note

©Copyright 2007 by

FEIG ELECTRONIC GmbH

Lange Strasse 4

D-35781 Weilburg-Waldhausen

Tel.: +49 6471 3109-0

http://www.feig.de

With the edition of this document, all previous editions become void. Indications made in this manual may be

changed without previous notice.

Copying of this document, and giving it to others and the use or communication of the contents thereof are

forbidden without express authority. Offenders are liable to the payment of damages. All rights are reserved

in the event of the grant of a patent or the registration of a utility model or design.

Composition of the information in this document has been done to the best of our knowledge. FEIG

ELECTRONIC GmbH does not guarantee the correctness and completeness of the details given in this

manual and may not be held liable for damages ensuing from incorrect or incomplete information. Since,

despite all our efforts, errors may not be completely avoided, we are always grateful for your useful tips.

The instructions given in this manual are based on advantageous boundary conditions. FEIG ELECTRONIC

GmbH does not give any guarantee promise for perfect function in cross environments and does not give

any guaranty for the functionality of the complete system which incorporates the subject of this document.

FEIG ELECTRONIC call explicit attention that devices which are subject of this document are not designed

with components and testing methods for a level of reliability suitable for use in or in connection with surgical

implants or as critical components in any life support systems whose failure to perform can reasonably be

expected to cause significant injury to a human. To avoid damage, injury, or death, the user or application

designer must take reasonably prudent steps to protect against system failures.

FEIG ELECTRONIC GmbH assumes no responsibility for the use of any information contained in this docu-

ment and makes no representation that they free of patent infringement. FEIG ELECTRONIC GmbH does

not convey any license under its patent rights nor the rights of others.

OBID®and OBID i-scan®are registered trademarks of FEIG ELECTRONIC GmbH.