felfil evo User manual

User Manual

Spooler Manual

User Manual

2

DC input 12V

30W

3,8Kgweight

average power usage (while working)

175 mm

348 mm

50 mm

240 mm

Thank you and congratulation for choosing the Felfil Evo Spooler.

Felfil Spooler is a plastic filament extruder, able to produce filaments for 3D printers starting

from industrial pellets or plastics wastes.

This guide is designed to allow you a good experience with Felfil Spooler, please read this

manual in all its parts before connecting and operating.

Felfil Spooler is suitable for domestic, research or business use; is wary of improper use.

Spooler Manual 3

Warnings

!Warnings

Felfil S.r.l. does not assumeresponsibilityandexpressly disclaimliabilityforloss,inju-

ries,damage,orexpensearisingoutoforinanywayconnected withtheassembly,han-

dling,storage, wrong useordisposaloftheproduct. Please, read this document before use

Felfil Spooler.

Any kind of modification will be at your own risk, and will result in the decay of the warranty.

Felfil S.r.l. does not take any responsibility for damage occurred to people or object, caused by

such modifications or improper uses.

- Do not use vinyl and PVC, they will produce toxic emissions.

- Do not eat or inhale the filament.

- Do not use the machine if any parts are missing or damaged. If you notice any damage to the

unit, unplug the device immediately and contact the Felfil team for guidance.

Use the device only with specified input power. Using the device with any other input power is

likely to damage the electrical and/or electronic parts of the device.

Remind to keep the equipment out of children’s reach.

Use this device only to spool plastic filament for 3D printing. No other use has been tested.

- Do not insert your fingers in the moving parts.

- Do not throw water on the spooler.

- Do not hit the spooler and its accessories or you could damage the spooler.

- Please, never try to spool a plastic unless you are absolutely certain you know what type it is.

- Some polymers can undergo thermal decomposition resulting in potentially toxic fumes. So

always use the Felfil Spooler in a well ventilated area, or inprecence of a suction hood (not your

bedroom or inside your house), and understand the thermal decomposition properties of the

polymer you are extruding.

- Be sure to check in on it periodically.

The Felfil Spooler is a first-generation, experimental piece of hardware. Treat it as such.

Basically, use common sense.

Caution

Spooler Manual

User Manual

4

6

5

2

4

3

1

8

7

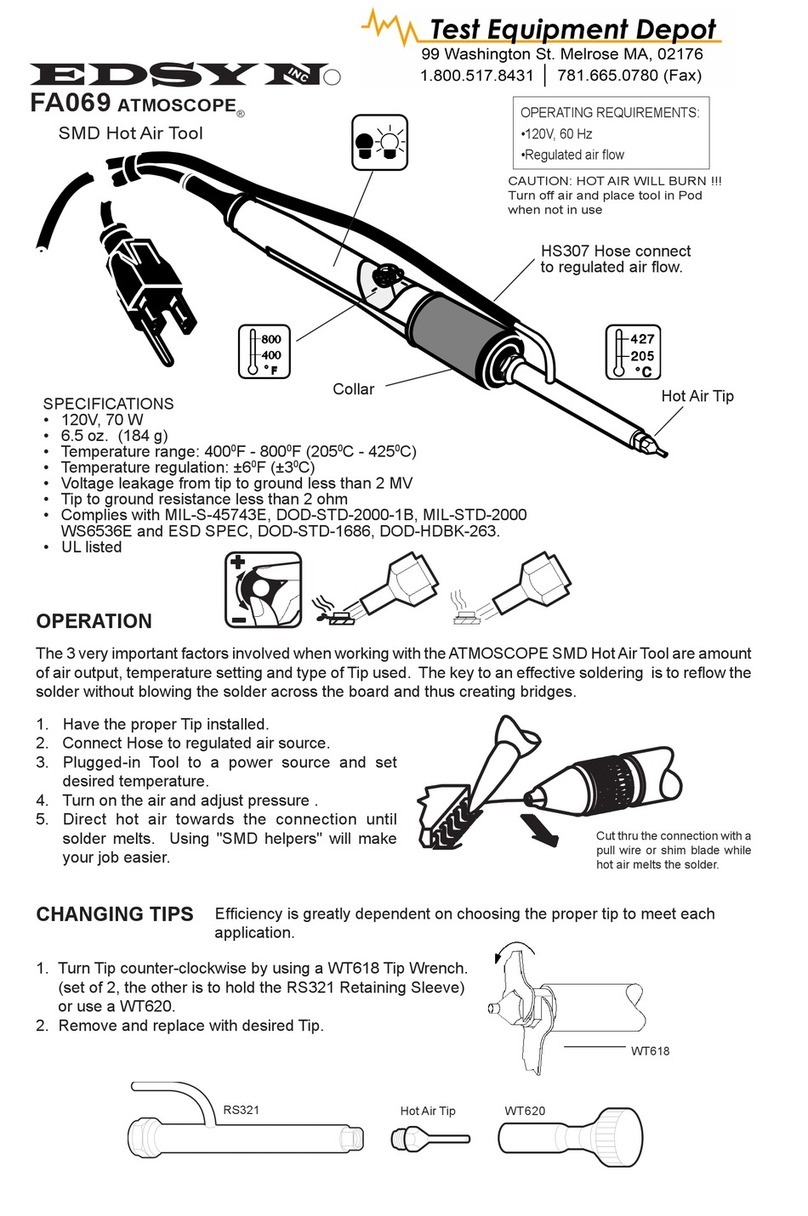

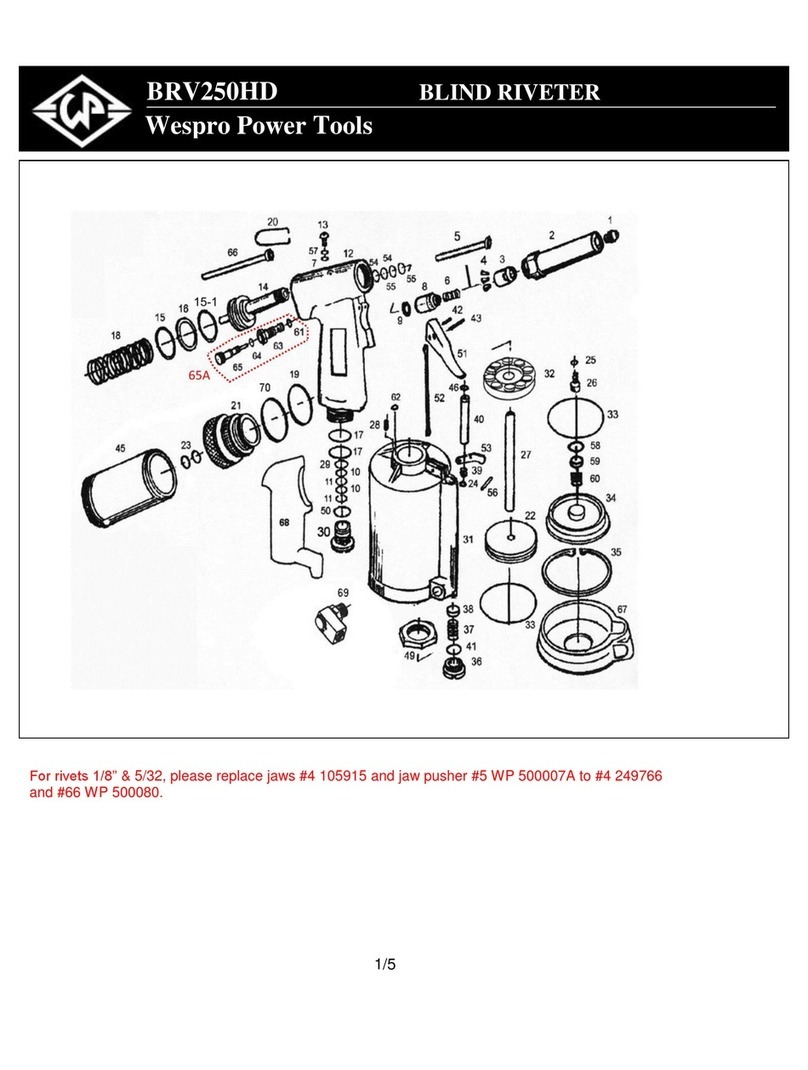

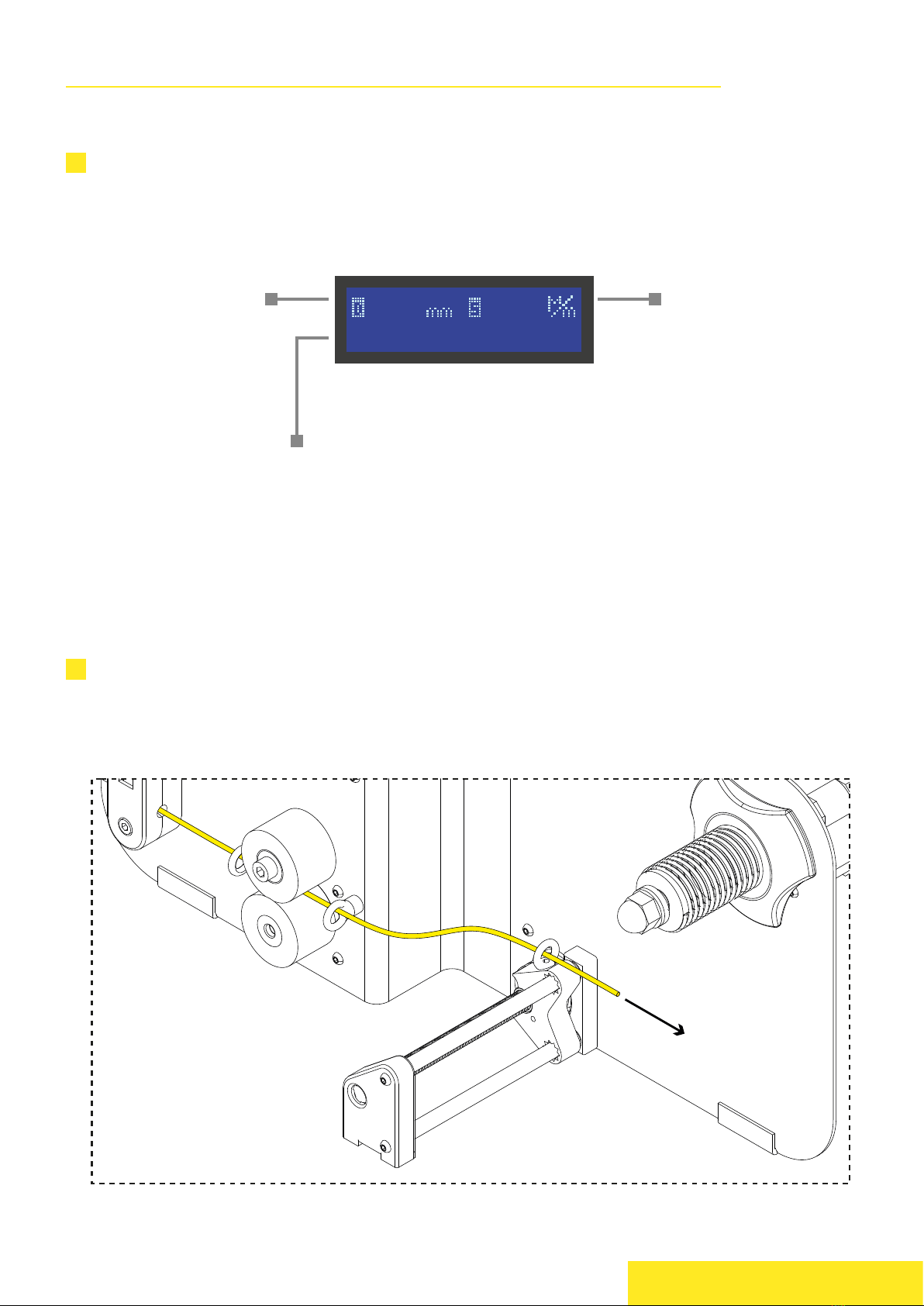

1Electronic Cover/Connection

2Input / Output Interface

3Misuring System

4Pulling System

5Distributing System

6Spool Holder / Spinner

7Fan Array

8Fan Array Connection

Spooler Manual 5

Connection

Before using Felfil Spooler some steps are required. Please use the following in

Insert the leadscrew shaft stepper 5A into its place. And fix it using two M3 screws, only

the left side. The connector must be on the top.

5A

Spooler Manual 6

Connections

5D

5B

5C

Insert the sliding part 5D in the shaft turning the shaft by hand.

Insert the two slideguide 5C into 5B component. Then screw them to the rigt side of the

leadscrew shaft stepper.

Spooler Manual 7

5E

Connections

Connect the leadscrew shaft stepper to its wires connector.

Fix the 5E component using 2 M3 screws.

Spooler Manual 8

Connections

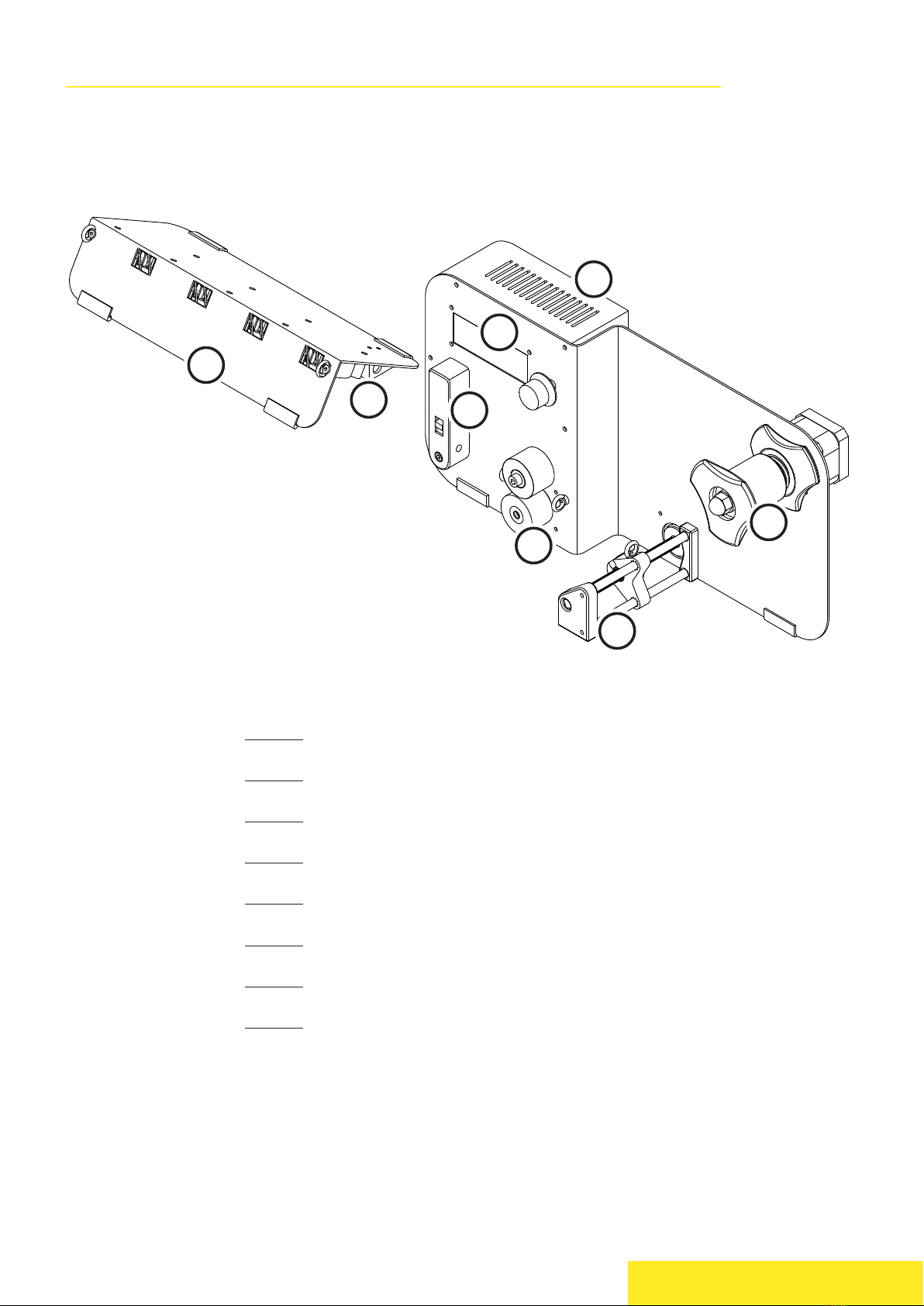

AC

Plug

AC/DC

Power

Supply

Spooler

Back

Spooler

Side

Fan Array

Side

Connect Felfil Spooler to the fan array using the DC jack to jack cable.

Connect the power supply.

Spooler Manual

User Manual

9

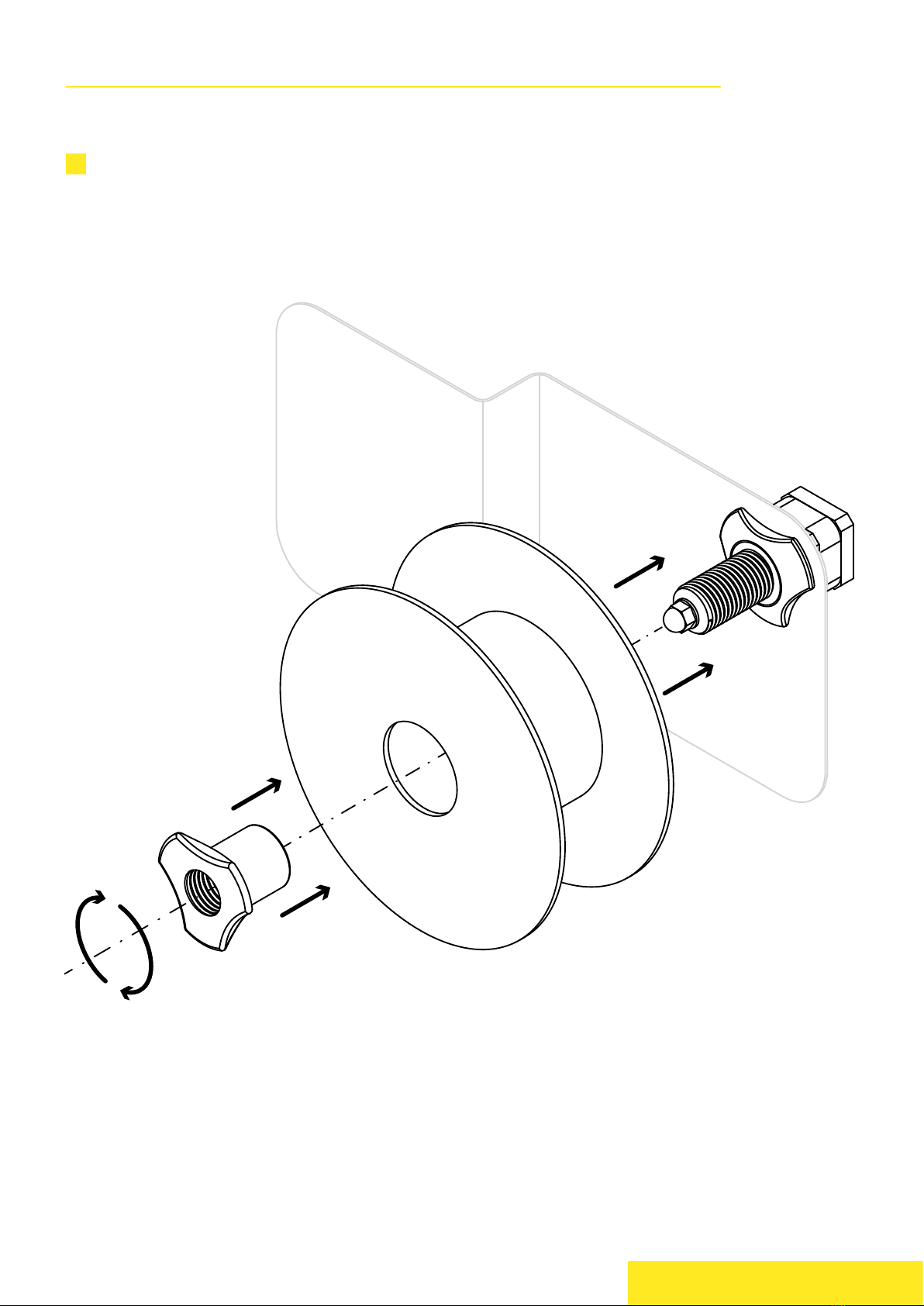

Insert your empty spool in its support and lock it.

Please note that max size of the spool is 10cm width and 22cm diameter.

Spooler Manual

User Manual

10

from 3cm

to 10cm

from 3cm

to 10cm

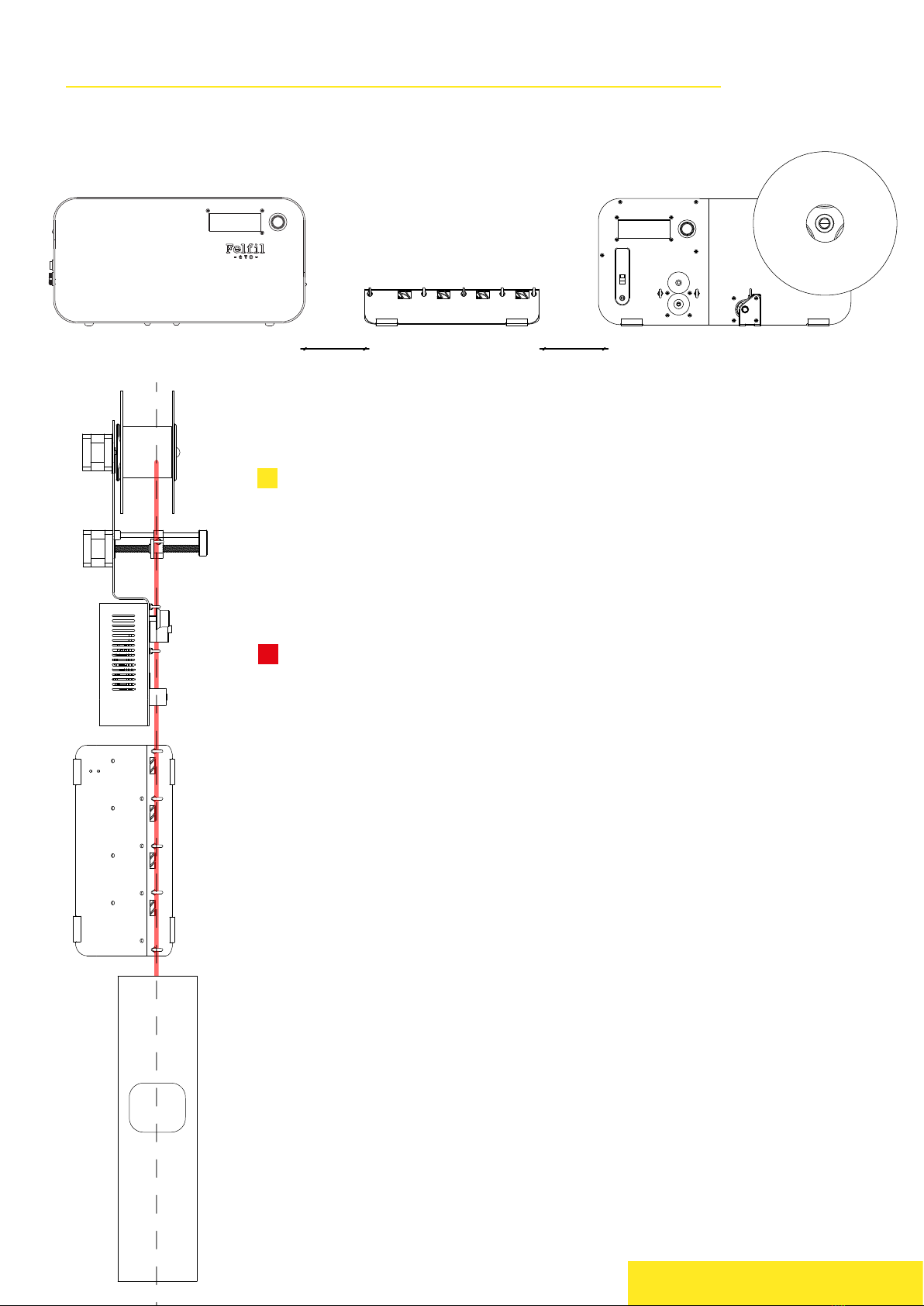

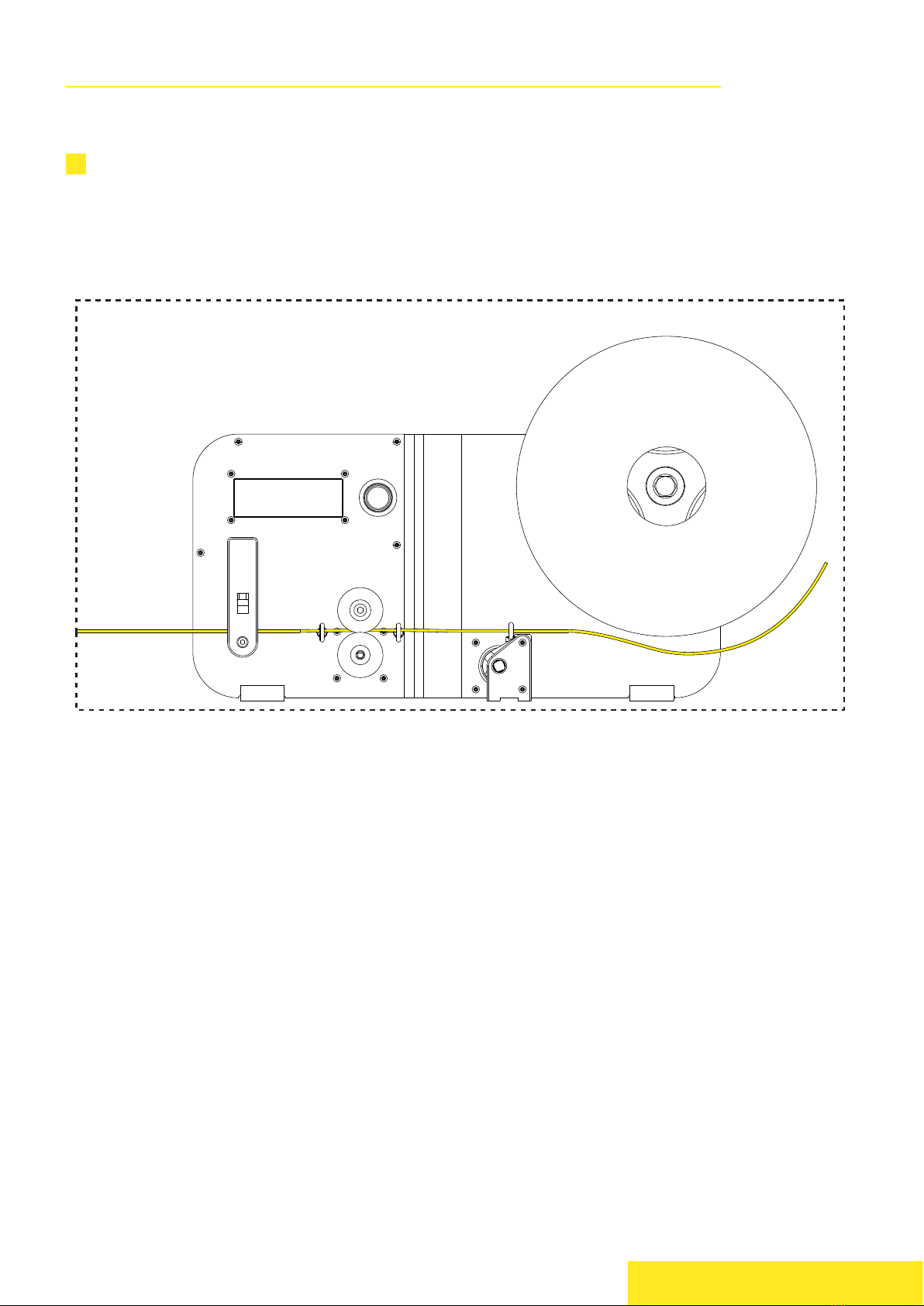

Place Felfil Evo, Fan Array and Felfil Spooler on a table and arrange

them like in the pictures.

All the machines must be alligned: allign the Felfil Evo nozzle with

the filament support placed on the Fan Array and Felfil Spooler.

The filament has to be streight ahead, or the extrusion will result

compromised.

!

Spooler Manual 11

Connections

Main Switch

!

Turn on the main switch placed on the back of the spooler, near the DC Jack connector.

!The measuring system must be empty!

Otherwise the measure read will be compromised.

Check it, please.

Spooler Manual

User Manual

12

Felfil Spooler

Calibrating...

Set Mode:

> Soft

Set Mode:

> Medium

Set Mode:

> Hard

Set Mode:

> Manual

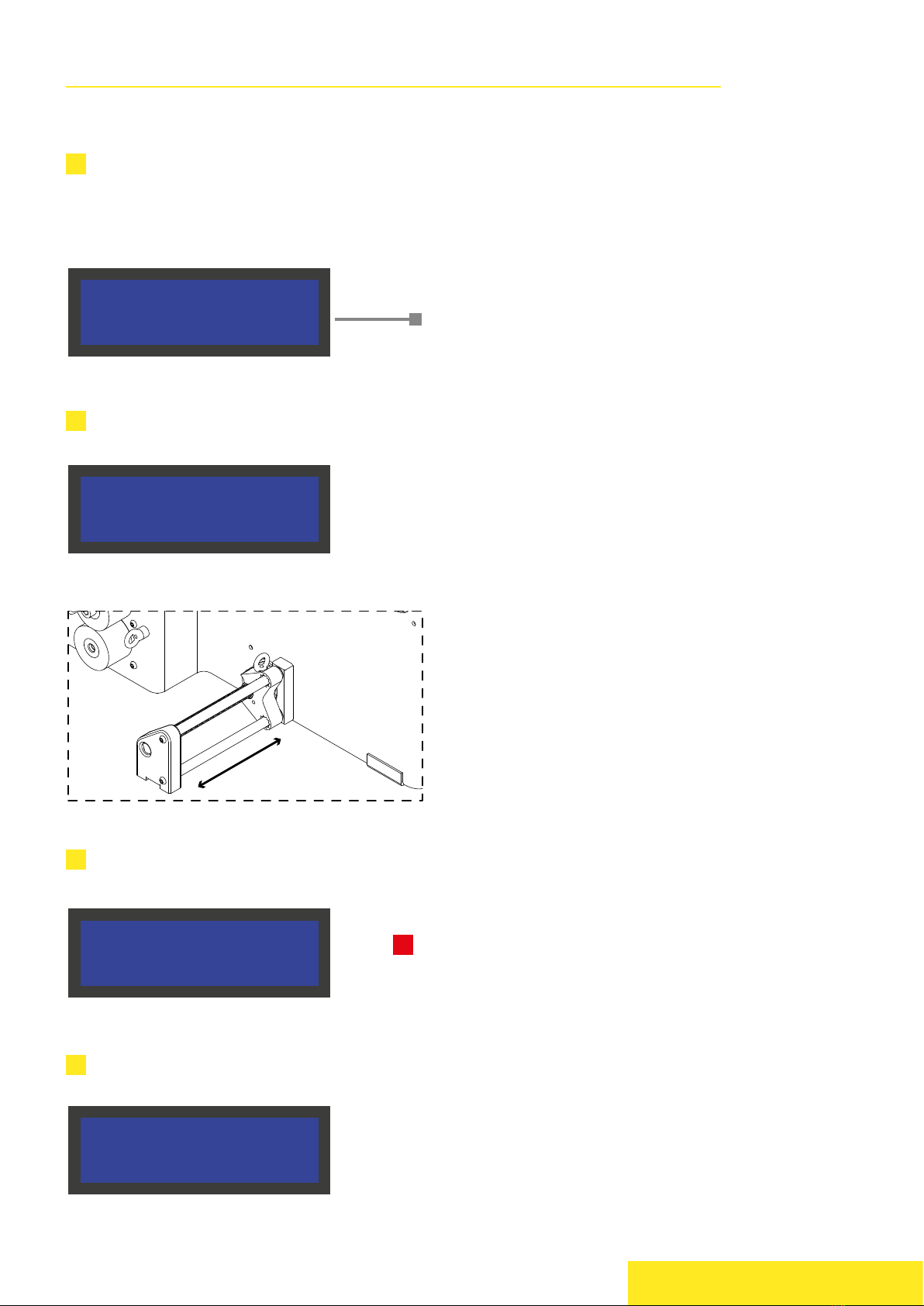

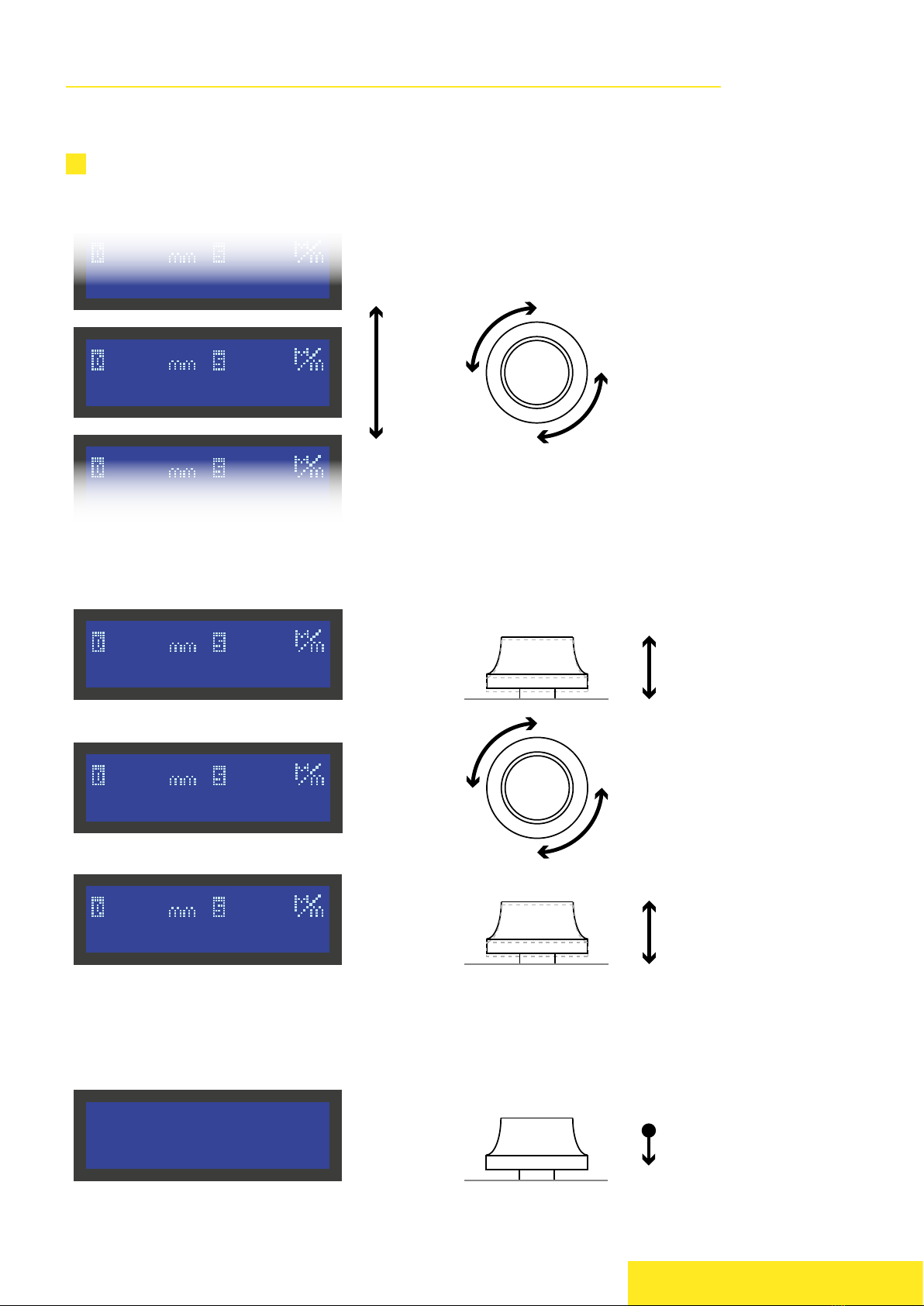

The first screenshot shows a calibration. During this step, you will see the distribution

reset. Indeed, every spooling session will start from the left side of the distribution.

Once the calibration is finished, a guided interface leads you to the spooling session.

Rotate the knob in order to switch settings and click it to confirm.

The first parameter that you can select is “Set Mode” which indicates the presets

used for the diameter control. Every mode is suitable for different materials.

Do not click anything during the calibration

process.

Tested with these materials:

ABS, HIPS

Tested with these materials:

PETG, TPU (2,85mm needed)

Tested with these materials:

PLA, Nylon

In Manual mode the diameter autocalibration is

disabled, it will operate at constant speed.

This mode is useful for sperimental materials.

!

Felfil Spooler

Calibrating...

Set Mode:

> Soft

Set Mode:

> Medium

Set Mode:

> Hard

Set Mode:

> Manual

Spooler Manual

User Manual

13

Set Diameter:

1.75

Set PullSpeed:

1.18

Spooler ready!

> Diameter: 1.75

Set Travel:

80

80mm

The second parameter is the diameter you would like to obtain.

The sysytem will remember your last choice for the next extrusion.

Click to confirm.

This parameter is about the spool width. Measure it and set the distance.

Click to confirm.

If you are working in “Manual Mode” this parameter indicates the puller whells constant

speed (meter per minute). Adjust it according to your extrusion flow.

Felfil Spooler is ready to be used.

You can set it form a minimum of 0.5mm to a

maximum of 3mm.

This parameter is settable only in “Manual

Mode”

!

Spooler Manual

User Manual

14

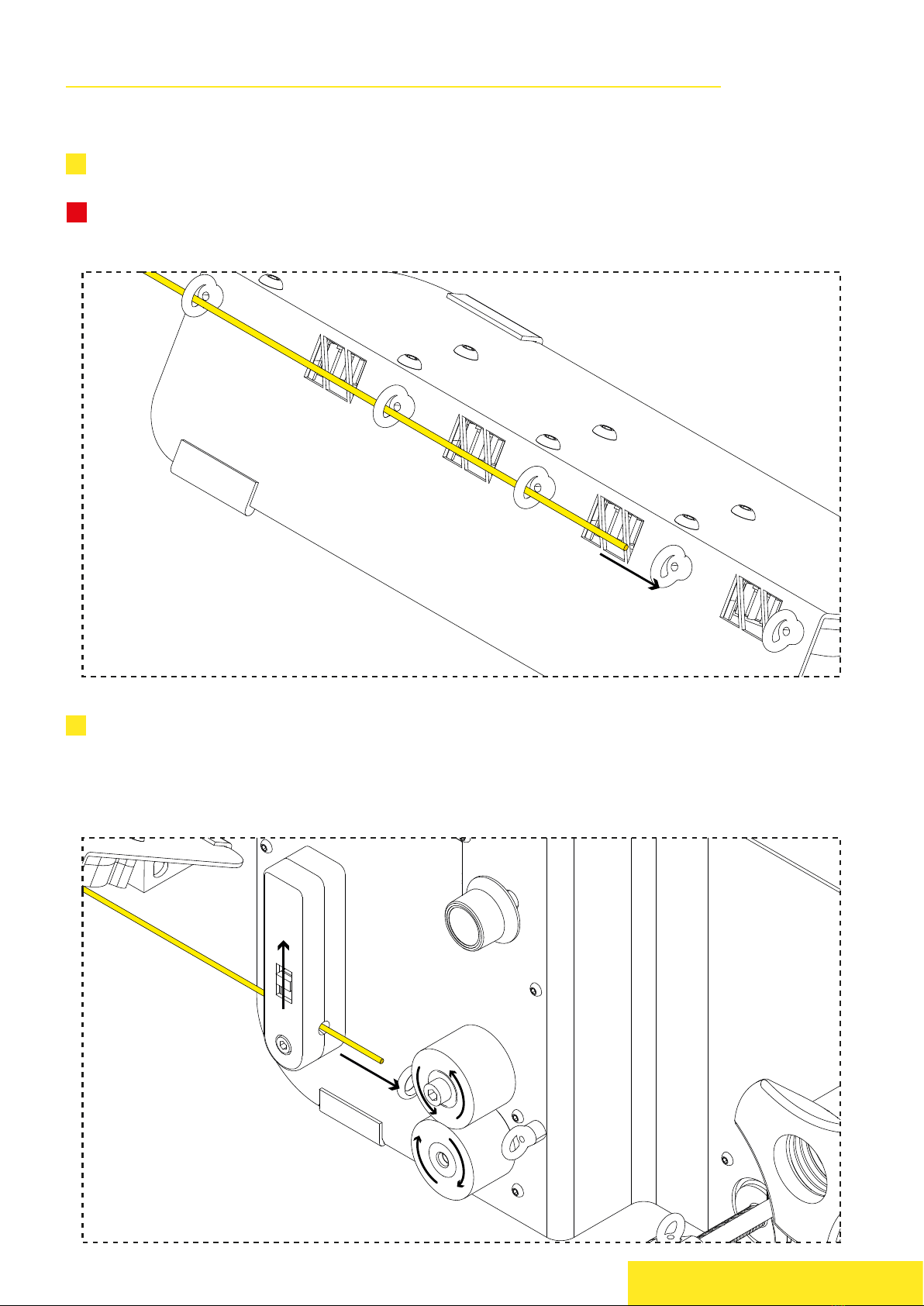

Insert the filament through the proper supports placed on the fan array.

Insert the filament into the measuring system sliding up the little lever.

Once the filament is in position the puller wheels will start rotating.

!Use gloves to do this operation. The filament is still hot.

Do not stretch the filament, do this operation slowly.

Spooler Manual

User Manual

15

> Diameter: 1.75

1.74 0.69

Let the filament pass through the supports and between the puller wheels. Then guide it

in the distribution support.

Once the filament is pushed in the measuring system the puller wheels will start to rotat-

ing and the following information will appear. This is the main working interface of Felfil

Spooler.

This is the read

diameter, it will

constantly change

during extrusion

This is a menù item. This will

change rotating the knob. More

info on next pages.

This is the extrusion

speed (meter per

minute).

> Diameter: 1.75

1.74 0.69

Spooler Manual

User Manual

16

> Diameter: 1.75

1.74 0.69

The filament must pass under the empty spool. Let it go until the diameter will remain

quite constant. Then you can fix the filament to the spool.

Spooler Manual 17

Powering On

> Diameter: 1.75

1.74 0.69

SetDiameter 1.72

1.74 0.69

Set Mode:

> Soft

> Diameter: 1.75

1.74 0.69

> Diameter: 1.75

1.74 0.69

> Mode: Soft

1.74 0.69

> Travel: 80

1.74 0.69

Use the following gestrures to navigate into the menu.

Push to enter in

menu item

Rotate to select the

parameter

Rotate to navigate

between menu items

Long push to reset

the machine

Push to confirm

Spooler Manual 18

User Interface

> Diameter: 1.75

1.74 0.69

> Mode: Soft

1.74 0.69

> Travel: 80

1.74 0.69

> PullSpd: 1.18

1.74 0.69

> TravSpd: Auto

1.74 0.69

> SpoolSpd: 12

1.74 0.69

> FanSpd: 255

1.74 0.69

Listed below there are all the parameters (menu items) that you can modify every time

you need during the extruding session.

Filament diameter desired.

From 0.5mm to 3mm

Preset for auto measuring and calibration.

See page 12 for more information.

Puller wheels constant speed. Adjust this parameter

according to your extrusion flow.

Available only in “Manual Mode”

Travel distribution width, modify this parameter

according to your spool width.

Travel distribution Speed. By default is set on

“auto” mode. This parameter can affect the filament

distribution.

Spool Speed. Modify this parameter if the spool

clutch is not working properly for your material, or if

your extrusion flow is over 1,5m/m

Fan Speed. You can modify the airflow of fan array if

necessary.

Spooler Manual 19

Usage

For a correct usage of Felfil Spooler please follow these suggestions:

- Place it on a flat and stable surface before operating (a table is quite good);

- Do not place anything near Felfil Spooler, it requires unrestricted airflow, for cooling,

proper operation and to protect the electronic components from overheating;

- Do not operate the machine for more than 4 hours. After that cycle, please could it down for

2 hours;

The first meters of filament will be inconsisten on diameter. Do not use this filament in your 3D

printer.

Felfil Spooler needs some occasional maintenance:

- Clean it regulary

- Be sure that every part can spin properly

- Use always gloves while working on still hot components.

?Usage

?Maintenance

Spooler Manual 20

Polymers Guide

In this section you can find some information about the plastics you can extrude with Felfil

System.

When using commercial pellets, rely on the maker’s identification of the type of plastic.

When using recycled plastic, check the markings on the item(s) to determine which type of

plastic you are using.

Do not mix types of plastic, as this may affect processing times, both in the extruder and in

the printer.

The following is a table of general processing temperatures. Notice that the processing tem-

perature may not be the same as the melt temperature.Temperatures will vary based on:

humidity, ambient temperature and chemical composition of the polymers.

NOTE: The temperature ranges in the chart are approximate. It will require some trial and error

to determine the right processing temperatures. Keep notes of actual temperature settings

with different types of plastics, along with other operational notes, to develop a procedure that

works well in your situation.

PLA

ABS

HIPS

TPU (2,85 nozzle)

T45 (pc+abs)

T [°C]

187 6

190 9

205 8

200 9

205

6

4

-

4

19

1,3

-

1,22

1.04

1,04 9

Speed [rpm]MFR Density [g/cm3]

HDPE 200 9- 0,94

PETG 209 68 1,23

Nylon 240 9- -

Other manuals for evo

1

Table of contents