Fender Super Champ XD >> DSP (Digital) Board Bypass Instructions

PLEASE READ EVERYTHING ENTIRELY BEFORE YOU START!

This instruction is designed to modify a Fender Super Champ XD amplifier such that the DSP

board will be eliminated from the circuit. Typically, it would apply in those cases where trouble

with the digital portion of the amp is experienced yet the remainder (analog/tube portion) is

working. But, before blaming the digital board, it is good practice to verify that the tubes are good

or there is not some other problem such as a disconnected speaker wire or blown fuse.

Although I modified a Super Champ XD, other amps (such as the Vibro Champ XD) may be good

candidates for this modification as well.

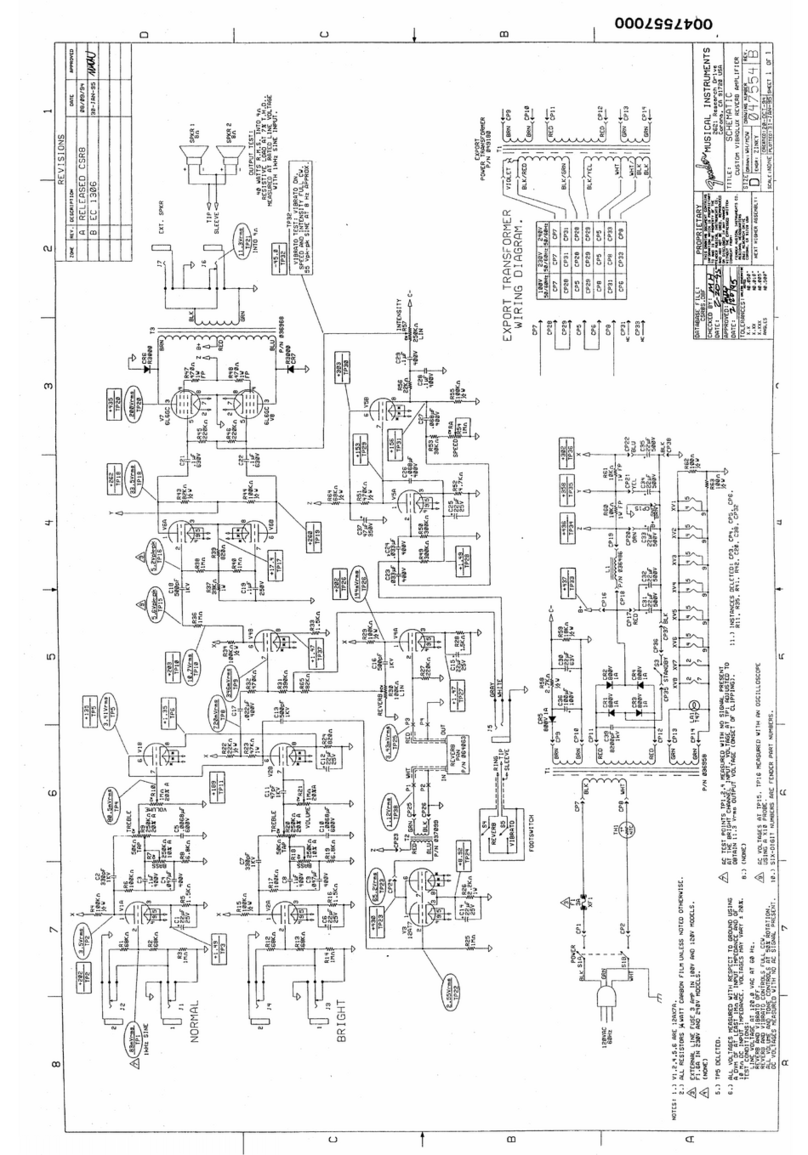

Understand that what is being accomplished here is to (1) bypass the DSP (digital) board and (2)

create a tone control (unfortunately, the factory tone adjustment was handled in the DSP board).

To accomplish this, R84 (“GAIN”) and R85 (“VOLUME 1”) are re-purposed.

See Appendix 1 - Schematic.

When completed, the procedure described below will allow you to adjust VOLUME and

BRIGHTNESS (TONE) –nothing else! It assumes that you want to retain the “tube amp” sound

and that any added effects will be inserted between the instrument output and the amp input.

See Appendix 2 –Frequency Response Data to see the effect of the Brightness Control.

I accept no responsibility in the outcome of your project (since you are the one doing it), but I am

confident that if you follow these directions studiously, you will end up with a reliable great Fender

tube amp!

If you should have questions, comments, or you have adapted this procedure to another amp,

please email me at: dbtech@brasherweb.com

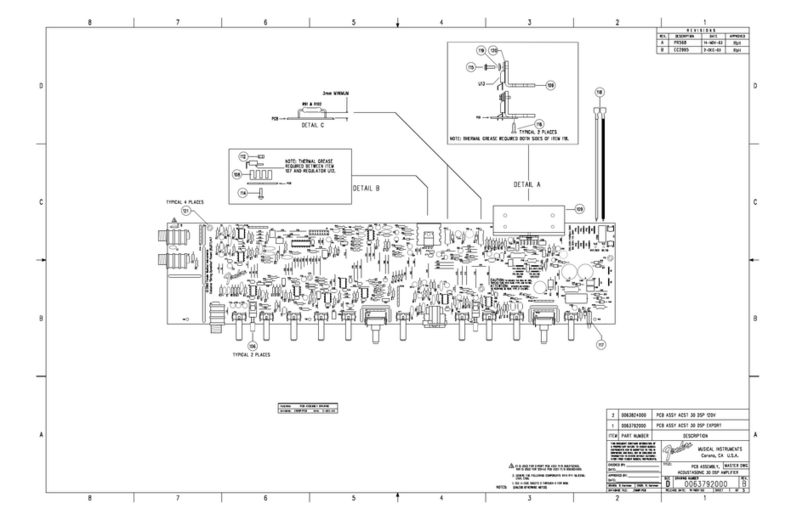

This procedure expects the technician to have good workmanship/soldering skills and the

necessary tools to work on printed-circuit assemblies and leaded parts, including

low/medium power soldering iron and heat gun. Additionally, a Dremel type cutting tool or

X-Acto type knife is required. An ohm-meter/multimeter is desirable.

Please be safe and wear protective eyewear!

PARTS LIST:

1 ea. 10,000 ohm, ⅛, ¼, or ½-watt resistor

1 ea. .03 micro-farad (µF) capacitor, 100 VDC or more –can be fabricated and material is not

important. Below are examples of two combinations that may be used:

A) Use a .01 µF and a .02 µF (100V or more each), see Figure 10a

B) Use three .01 µF (100V or more each), see Figure 10b

C) Any other combination that is equivalent to .03 µF total at 100V or more

1 ea. 4.7 or 5.0 µF capacitor, 100 VDC or more

1 ft. 24 or 26 gauge hookup wire (color not important; I used blue)

1 ft. Heat shrink tubing (HST), size 3/32” or 1/8”

3 tie wraps or some lacing twine

Label maker (if you want to re-label front-panel controls)

STEP-BY-STEP INSTRUCTIONS:

NOTE –where the cutting of PCB traces is indicated, use a Dremel type tool or an appropriate X-

Acto type knife and blade.