Fermator MOD MC PREMIUM PM User manual

COMMERCIAL

LIFTS

EXISTING INSTALLATION

MAN-MMP2P0000ENGHP-01.2022 ENG

MOD MC PREMIUM PM

INSTALLATION MANUAL

Automatic horizontal sliding car door

Development and production by Fermator.

Attention: Before taking any action, testing or modication not covered in this manual you should notify

to our Technical Department.

Fermator accepts no responsibility in the event of any damage to the equipment described in this manual

and associated installation if the instructions given have not been followed.

Fermator reserves the right to modify the product specications in this technical brochure without any

prior notication.

For further information please contact our product department:

product@fermator.com

3

MOD MC PREMIUM PM

1 General

1.1 General.................................................................6

1.1.1 Equipment and tools .................................................6

1.1.2 Statements .........................................................6

1.1.3 Stainless steel cleaning and maintenance instructions .......................7

1.1.4 Environmental awareness .............................................7

1.1.5 Abbreviations .......................................................8

2 C2

2.1 List of components .......................................................9

2.1.1 C2 door ..........................................................10

2.1.2 Electronic module assembling options...................................11

2.1.3 Accessories .......................................................14

2.1.4 Optional components ................................................19

2.2 Assembly instructions ...................................................21

2.2.1 Sill installation .....................................................22

2.2.1.1 Aluminium 15 mm at channel sill assembly ........................22

2.2.1.2 Aluminium 8 mm recess at channel sill assembly ...................23

2.2.1.3 Steel at channel sill assembly ..................................24

2.2.1.4 Massive at channel sill assembly ...............................25

2.2.2 Operator installation .................................................26

2.2.2.1 Operator assembly ...........................................26

P 2.2.2.2 Operator adjustment ..........................................30

P 2.2.3 Clear opening (PL) verication and validation .............................31

2.2.4 Sheet metal panel ..................................................33

2.2.4.1 Sheet metal panel installation ...................................33

P 2.2.4.2 Sheet metal panel verication and validation .......................37

P 2.2.5 Eccentric wheel verication and validation ...............................39

P 2.2.6 Panel verication and validation .......................................40

2.2.7 Toe guard installation ................................................41

2.2.8 Other adjustments ..................................................43

P 2.2.8.1 CDL / clutch verication and validation ............................43

P 2.2.8.2 CDL / clutch adjustment .......................................45

P 2.2.8.3 Electrical contacts verication and validation .......................49

P 2.2.8.4 Coupling lateral view ..........................................51

Step of special interest to verication and regulation operations.

INDEX

4MOD MC PREMIUM PM

INDEX

3 T2

3.1 List of components ......................................................53

3.1.1 T2 door...........................................................54

3.1.2 Electronic module assembling options...................................55

3.1.3 Accessories .......................................................58

3.1.4 Optional components ................................................63

3.2 Assembly instructions ...................................................65

3.2.1 Sill installation .....................................................66

3.2.1.1 Aluminium 15 mm at channel sill assembly ........................66

3.2.1.2 Aluminium 8 mm recess at channel sill assembly ...................67

3.2.1.3 Steel at channel sill assembly ..................................68

3.2.1.4 Massive at channel sill assembly ...............................69

3.2.2 Operator installation .................................................70

3.2.2.1 Operator assembly ...........................................70

P 3.2.2.2 Operator adjustment ..........................................74

P 3.2.3 Clear opening (PL) verication and validation .............................75

3.2.4 Sheet metal panel ..................................................77

3.2.4.1 Sheet metal panel installation ...................................77

P 3.2.4.2 Sheet metal panel verication and validation .......................81

P 3.2.5 Eccentric wheel verication and validation ...............................83

P 3.2.6 Panel verication and validation .......................................84

3.2.7 Toe guard installation ................................................85

3.2.8 Other adjustments ..................................................87

P 3.2.8.1 CDL verication and validation ..................................87

P 3.2.8.2 CDL adjustment..............................................88

P 3.2.8.3 Electrical contacts verication and validation .......................89

P 3.2.8.4 Coupling lateral view ..........................................91

4 Optional components

4.1 Optional components C2 .................................................93

P 4.1.1 Egress device (From pit) .............................................94

P 4.1.2 Fixings to car roof operator assembling rails ..............................95

Step of special interest to verication and regulation operations.

5

MOD MC PREMIUM PM

4.2 Optional components T2 .................................................97

P 4.2.1 Egress device (From pit) .............................................98

P 4.2.2 Fixings to car roof operator assembling rails .............................99

5 Electronic module

5.1 VF7+ Relay electronic module ............................................101

5.1.1 Connections ......................................................102

5.2 VF7+ CAN electronic module.............................................105

5.2.1 Connections ......................................................106

5.3 VF5+ Electronic module .................................................109

5.3.1 Connections ......................................................110

5.4 Emergency power supplier ..............................................113

5.4.1 Connections ......................................................115

6 EU Declaration of conformity

6.1 EU Declaration of conformity.............................................117

INDEX

Step of special interest to verication and regulation operations.

6MOD MC PREMIUM PM

17 mm

13 mm

13 mm

4 mm

5 mm

19 mm

13 mm

15 mm

10 mm

+

-

mm

2.1.1 1.000,0

PRE START RECOMMENDATIONS

TOOLS

ICONS

SAFETY EQUIPMENT

1.1 GENERAL

11.1.1 EQUIPMENT AND TOOLS

1.1 GENERAL

11.1.2 STATEMENTS

Torque indicator. Optional. Verication and validation.

SUBSECTION NUMBER

Each step is numbered and

displayed under this format,

you will nd it at the upper-left

corner of the page.

DIMENSIONS

All dimension

measurements

are stated in mm.

THOUSANDS

In Fermator documentation,

the thousand symbol

is always a dot.

CAUTION

Before performing any action

on the existing operator, it

is imperative to disconnect

the electricity supply.

7

MOD MC PREMIUM PM

Use neutral liquid soap or products for glass cleaning (without bleach).

Use soft cloths and warm water.

Always clean following brush direction.

Do not use cleaning products that

contain bleach.

Do not rub or use scouring pads

or rough cloths.

1.1 GENERAL

11.1.3 STAINLESS STEEL CLEANING AND MAINTENANCE INSTRUCTIONS

1.1 GENERAL

11.1.4 ENVIRONMENTAL AWARENESS

To prevent possible damage to the environment when you decide to dispose of the packaging the waste should be disposed

of responsibly in accordance with the applicable environmental legislation.

Preventive cleaning to avoid corrosion: Regular cleaning will help in the removal of impurities and contaminants

which can cause corrosion. Marine, industrial, polluted and other corrosive climates require regular maintenance

to avoid excessive accumulation of dirt. Before cleaning the stainless steel remove any dust particles in order to

prevent friction of the particles on the surface.

8MOD MC PREMIUM PM

1.1 GENERAL

11.1.5 ABBREVIATIONS

DOOR

PARAMETERS

AFO Operator fastening point.

CDL Car door lock.

HL Clear height.

PL Clear opening.

DOOR

OPENING T2 2 panel side opening door.

ELECTRONIC

COMPONENTS

PM Permanent magnet motor.

VF Inverter.

MOD MC PREMIUM PM

LIST OF COMPONENTS

C2

2

10 MOD MC PREMIUM PM

1

Illustrative image,

see other options

in this manual.

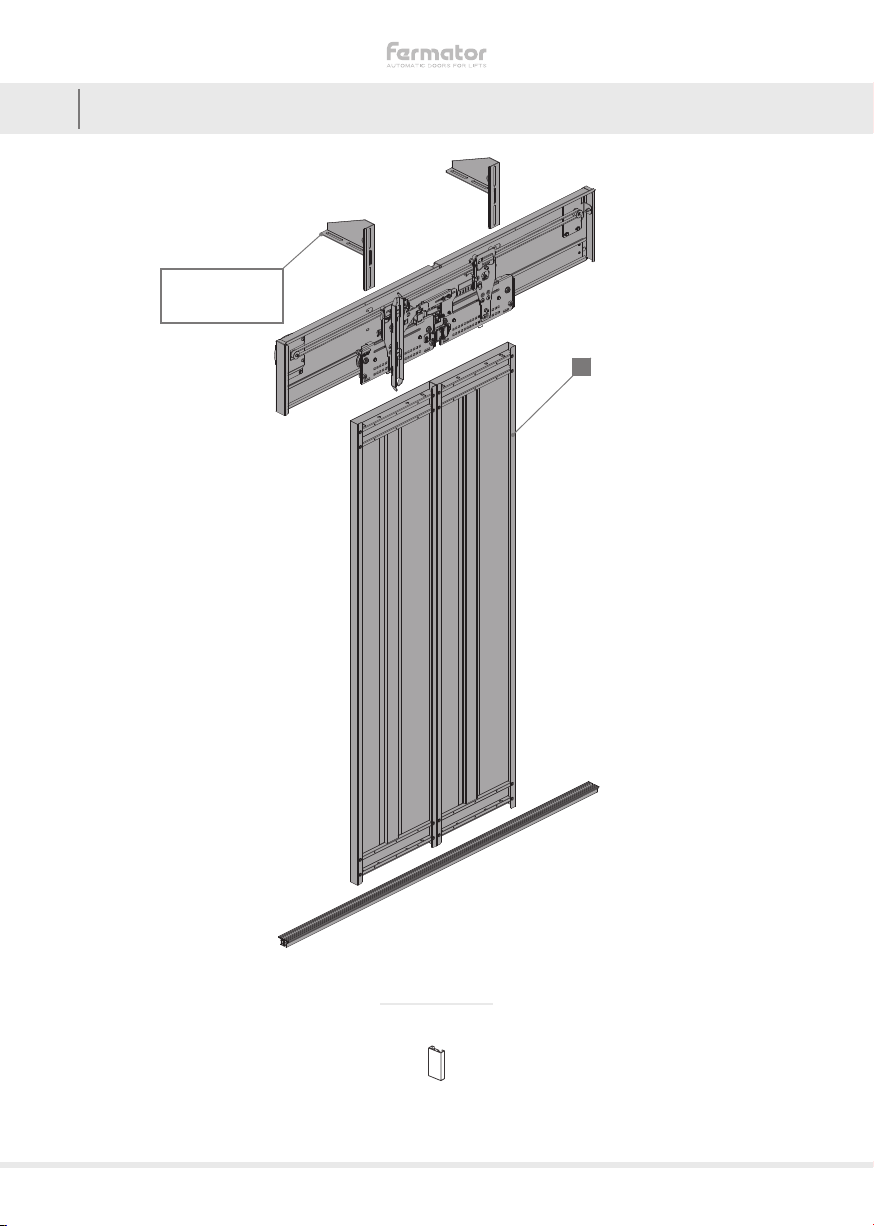

22.1.1 C2 DOOR

2.1 LIST OF COMPONENTS

STEEL PANELS

1

SHEET METAL

11

MOD MC PREMIUM PM

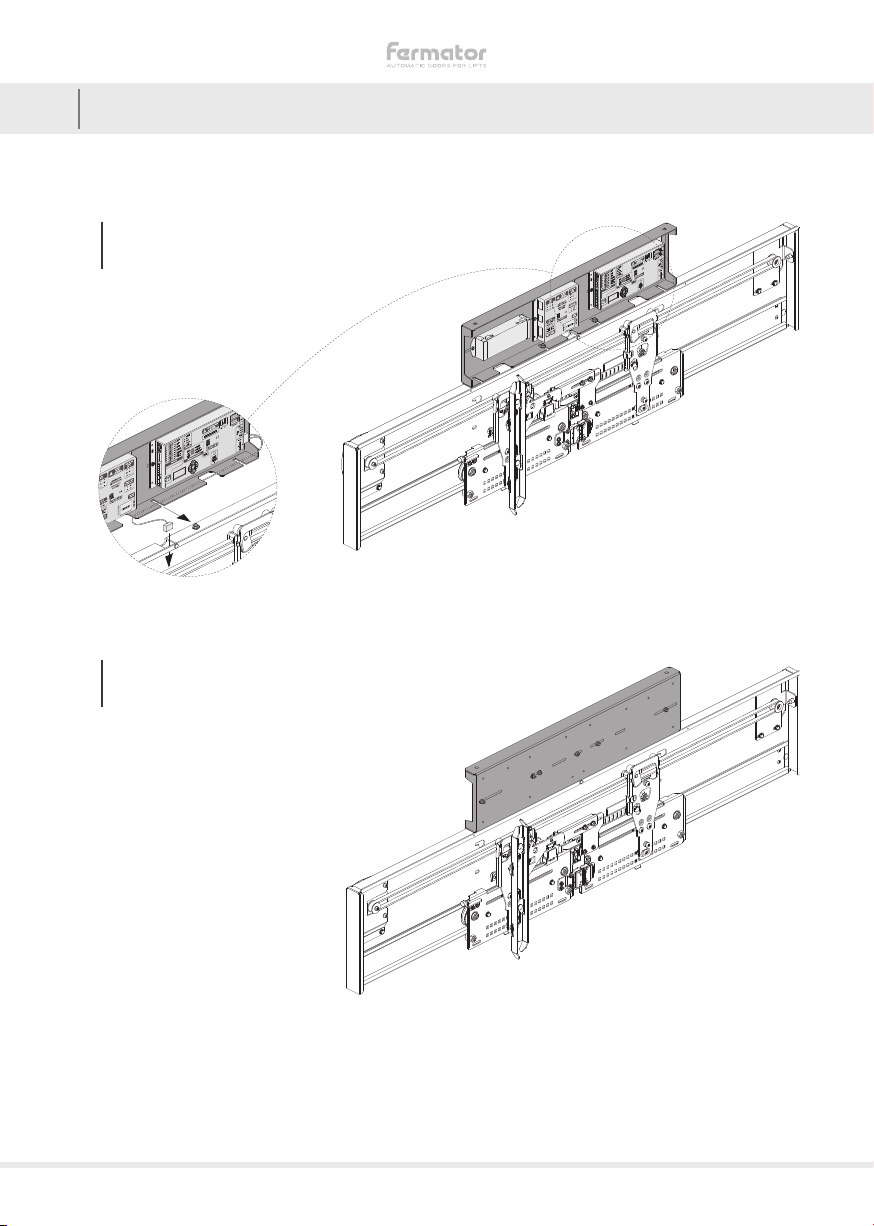

2.1 LIST OF COMPONENTS

22.1.2 ELECTRONIC MODULE ASSEMBLING OPTIONS

AABOVE THE

OPERATOR FACING

THE LANDING DOOR

BABOVE THE

OPERATOR FACING

THE CAR ROOF

12 MOD MC PREMIUM PM

2.1 LIST OF COMPONENTS

22.1.2 ELECTRONIC MODULE ASSEMBLING OPTIONS

BABOVE THE

OPERATOR FACING

THE CAR ROOF

AABOVE THE

OPERATOR FACING

THE LANDING DOOR

13

MOD MC PREMIUM PM

2.1 LIST OF COMPONENTS

22.1.2 ELECTRONIC MODULE ASSEMBLING OPTIONS

BABOVE THE

OPERATOR FACING

THE CAR ROOF

AABOVE THE

OPERATOR FACING

THE LANDING DOOR

14 MOD MC PREMIUM PM

2.1 LIST OF COMPONENTS

22.1.3 ACCESSORIES

BRACKET ST ACCESSORIES PER SET

PL 700 - 950

PL 1.000 - 1.400

x2

x4 AM8 x 25

DIN 933 BM8 x 25

REDUCED HEAD CM8

NF E25-511 M DNUT M8

x4 x2 x6 x6

NUMBER OF SETS

PL 700 - 950 x1

PL 1.000 - 1.400 x2

BRACKET SD ACCESSORIES PER SET

PL 700 - 950

PL 1.000 - 1.400

x2

x4 AM8 x 25

DIN 933 BM8 x 25

REDUCED HEAD CM8

NF E25-511 M DNUT M8

x4 x2 x6 x6

NUMBER OF SETS

PL 700 - 950 x1

PL 1.000 - 1.400 x2

BRACKET EF ACCESSORIES PER SET

PL 700 - 950

PL 1.000 - 1.400

x2

x4 AM8 x 25

DIN 933 BM8 x 25

REDUCED HEAD CM8

NF E25-511 M DNUT M8

x4 x2 x6 x6

NUMBER OF SETS

PL 700 - 950 x1

PL 1.000 - 1.400 x2

BRACKET SE ACCESSORIES PER SET

PL 700 - 950

PL 1.000 - 1.400

x2

x4 AM8 x 25

DIN 933 BM8 x 25

REDUCED HEAD CM8

NF E25-511 M DNUT M8

x4 x2 x6 x6

NUMBER OF SETS

PL 700 - 950 x1

PL 1.000 - 1.400 x2

BRACKET ER ACCESSORIES PER SET

PL 700 - 950

PL 1.000 - 1.400

x2

x4 AM8 x 25

DIN 933 BM8 x 25

REDUCED HEAD CM8

DIN 125-A DM8 NUT

DIN 6923

x4 x2 x6 x6

NUMBER OF SETS

PL 700 - 950 x1

PL 1.000 - 1.400 x2

15

MOD MC PREMIUM PM

2.1 LIST OF COMPONENTS

22.1.3 ACCESSORIES

BRACKET EG ACCESSORIES PER SET

PL 700 - 950

PL 1.000 - 1.400

x2

x4 AM8 x 25

DIN 933 BM8 x 25

REDUCED HEAD CM8

NF E25-511 M DNUT M8

x4 x2 x6 x6

NUMBER OF SETS

PL 700 - 950 x1

PL 1.000 - 1.400 x2

REINFORCED

ALUMINIUM 15 mm

TRACK SILL

ACCESSORIES PER SET

AM10 x 16

DIN 933 BM10

DIN 6923

x4 x4

NUMBER OF SETS

700 ≤ PL ≤ 850 x1

900 ≤ PL ≤ 1.400 x2

REINFORCED

ALUMINIUM 8 mm

TRACK SILL

ACCESSORIES PER SET

AM10 x 16

DIN 933 BM10

DIN 6923

x4 x4

NUMBER OF SETS

700 ≤ PL ≤ 850 x1

900 ≤ PL ≤ 1.400 x2

ALUMINIUM 8 mm

TRACK SILL

ACCESSORIES PER SET

AM10 x 16

DIN 933 BM10

DIN 6923

x4 x4

NUMBER OF SETS

700 ≤ PL ≤ 850 x1

900 ≤ PL ≤ 1.400 x2

ALUMINIUM 15 mm

TRACK SILL

ACCESSORIES PER SET

AM10 x 16

DIN 933 BM10

DIN 6923

x4 x4

NUMBER OF SETS

700 ≤ PL ≤ 850 x1

900 ≤ PL ≤ 1.400 x2

16 MOD MC PREMIUM PM

2.1 LIST OF COMPONENTS

22.1.3 ACCESSORIES

MASSIVE SILL

ACCESSORIES PER SET

AM8 x 16

DIN 963 BM8

DIN 6923

x6 x6

NUMBER OF SETS

700 ≤ PL ≤ 950 x1

1.000 ≤ PL ≤ 1.400 x2

STEEL SILL

ACCESSORIES PER SET

AM8 x 16

DIN 6921

x6

17

MOD MC PREMIUM PM

2.1 LIST OF COMPONENTS

22.1.3 ACCESSORIES

SHEET METAL

PANEL

ACCESSORIES PER PANEL

A

85 mm REGULATION

SUPPORT

BM10

DIN 6923 CRECTANGULAR

WASHER DM10 x 25

DIN 6334

x2

700 ≤ PL ≤ 1.150 x2

1.200 ≤ PL ≤ 1.400 x3

700 ≤ PL ≤ 1.150 x2

1.200 ≤ PL ≤ 1.400 x3

700 ≤ PL ≤ 1.150 x4

1.200 ≤ PL ≤ 1.400 x6

700 ≤ PL ≤ 1.150 x2

1.200 ≤ PL ≤ 1.400 x3

E8 mm

GUIDE SHOE FM8 x 20

DIN 603 GM8

DIN 934

x2 x2 x2

HSEPARATOR IANTITURN

x2 x2

J15 mm

GUIDE SHOE

KWASHER M8 LM8 X 16

DIN 933 MM8

NF-E25-511 M

x2 x2 x2 x2

N0,8 mm SHIM

THICKNESS O0,5 mm SHIM

THICKNESS

x2 x4

18 MOD MC PREMIUM PM

2.1 LIST OF COMPONENTS

22.1.3 ACCESSORIES

CM6 x 15

BOLT DM6 x 5

DIN 966

x2 x2

NUMBER OF SETS

700 ≤ PL ≤ 1.400 x1

700 ≤ PL ≤ 850 x2

900 ≤ PL ≤ 1.150 x3

1.150 ≤ PL ≤ 1.400 x4

TOE GUARD ACCESSORIES PER SET

x1

AM6 x 10

DIN 966 BM6

DIN 6923

x6 x8

19

MOD MC PREMIUM PM

2.1 LIST OF COMPONENTS

22.1.4 OPTIONAL COMPONENTS

RAIL ACCESSORIES PER SET

AM12 x 40

DIN 603 BFIXATION

PLATE CM12

NF E25-511 M DM12

DIN 934

x4 x4 x4 x4

NUMBER OF SETS

PL 700 - 950 x1

PL 1.000 - 1.400 x2

Table of contents

Popular Garage Door Opener manuals by other brands

Craftsman

Craftsman 139.53976SRT owner's manual

Guardian

Guardian DCR2 Installation instructions and owner's manual

Sears

Sears Craftsman 139.54920 owner's manual

tau

tau 650ESE installation guide

Chamberlain

Chamberlain LiftMaster LM60 Assembly and operating instructions

Brano

Brano Pro-Alpha Infinity Setup instructions

Wayne-Dalton

Wayne-Dalton Flush 42 quick start guide

Craftsman

Craftsman 139.53990D owner's manual

Automatic Technology

Automatic Technology SecuraLift GDO-7V1 Owner's installation instructions

Craftsman

Craftsman 139.53993DM owner's manual

Proteco

Proteco Q80S instruction manual

MyQ

MyQ CHAMBERLAIN B4603TC user guide