Fernstrum GRIDCOOLER Manual

GRIDCOOLER®

KEEL COOLER

Installation and

Maintenance Manual

Form 185

R.W. Fernstrum & Company

Installation and Maintenance Manual form 185 Page 1

1.0 PLANNING & LOCATION 2

1.1 Determining Proper Location -

Typical 2

1.2 Determining Proper Location –

Displacement Vessels 2

1.3 Determining Proper Location –

Planing Vessels 3

1.4 Improper (Not Recommended)

Locations 3

1.5 Mounting Considerations - Typical 3

1.6 Mounting Considerations -

Displacement Vessels 4

1.7 Mounting Considerations -

Planing Vessels 4

1.8 Bonding or Isolation 4

2.0 INSTALLATION 5

2.1 Making Holes 5

2.2 Fitting Up 5

2.3 Copper-Nickel Installation 5

2.4 Aluminum Installations 6

2.5 Plumbing 6

2.6 Filling & Testing 7

3.0 SPECIAL INSTALLATIONS 8

3.1 Coerdam Installation

with Compression Sealing Kit 8

3.2 Z Option™ Installations 9

3.3 L Option™ Support Plate Installation 10

3.4 Mounting Copper-Nickel Coolers

on an Aluminum Hull 11

4.0 FORMING THE GRIDCOOLER®

KEEL COOLER 12

5.0 PERFORMANCE ISSUES 13

6.0 MAINTENANCE 14

7.0 REPAIR 15

8.0 STRAY-CURRENT CORROSION 16

9.0 REPLACEMENT PARTS 17

10.0 LIMITED WARRANTY 19

11.0 RECOMMENDATION FORM 20

Contents

Page 2 Installation and Maintenance Manual form 185

1.0 PLANNING & LOCATION

To function properly, the FERNSTRUM® GRIDCOOLER® Keel

Cooler must be properly located on your vessel’s hull. Please

consider the following before installing your keel cooler on

most types of vessels. For additional details on displacement

or planing hulls, refer to the appropriate sections.

1.1 DETERMINING PROPER LOCATION –

TYPICAL

1.1.1 Sea water must flow over the entire length of the

unit.

1.1.2 Always install the unit parallel, not transverse, to the

skeg or keel. See Figures 1 & 2.

FIG.1 External type installation with E1 OPTION

end-mounted anodes using fairing blocks for

protection and streamlining.

FIG.2 Recess type installation with E1 OPTION end-

mounted anodes.

1.1.3 When using a two-circuit cooling system, consisting

of a high temperature jacketwater circuit and a low

temperature aftercooler circuit, make certain the

aftercooler circuit cooler is placed forward of the

jacketwater circuit cooler. When room allows, they

can be installed side by side with the aftercooler

circuit lower on the hull (i.e. closer to the skeg or

keel) and a divider plate between the high and low

temperature units.

1.1.4 When the GRIDCOOLER unit is used on a generator

set or if your application requires sizing for a hull

speed of 0 knots, make sure that sea water can

freely circulate past the cooler tubes. Do not recess

a generator set unit on the bottom of a flat bottom

boat unless the hull section where the unit will be

mounted inclines a minimum of 20 degrees (from

forward to aft) to avoid entrapment of heated water

around the tubes. See Figure 3.

1.2 DETERMINING PROPER LOCATION –

DISPLACEMENT VESSELS

1.2.1 On vessels performing pushing, towing, dragging

or pulling operations, the unit may be installed near

the propeller, but not directly above it. See Figure 3.

Install the unit to avoid the full impact of the propeller

wash as this could cause damage to the unit.

FIG.3 Recessed installation is made by welding in

a box-shaped recess in the hull. Note aft end

of recess is tapered to prevent hot water

entrapment.

1.2.2 When installing a unit on the side of a hull, position

it well below the water line to avoid aerated surface

water. Take the bow wave into consideration. Aeration

reduces heat transfer and can cause overheating.

Installation and Maintenance Manual form 185 Page 3

1.3 DETERMINING PROPER LOCATION –

PLANING VESSELS

1.3.1 For planing hull vessels, locate the unit as far aft as

possible to avoid aeration and impact shock in heavy

seas.

1.4 IMPROPER (NOT RECOMMENDED)

LOCATIONS

1.4.1 The area of the hull where the GRIDCOOLER® Keel

Cooler is installed must not vibrate or flex severely.

1.4.2 To eliminate unnecessary stress and vibration on the

cooler, do not locate the unit directly below engine

mounts or above the propeller(s).

1.4.3 Make sure that hot water is not discharged on or

near the unit.

1.4.4 Do not locate the unit on the front 1/3 of the hull for

displacement hulls. Bowthruster coolers could be an

exception, depending on the vessel.

1.4.5 The GRIDCOOLER Keel Cooler is designed to be

mounted directly to the hull. Do not mount the unit

to any external structure without first consulting the

factory.

1.5 MOUNTING CONSIDERATIONS – TYPICAL

1.5.1 Some classed vessels (ABS or Coast Guard, for

example) may require coerdams, check with your

local ocials for more information. For this type of

installation, see Coerdam Installation in Section 3.1.

1.5.2 The GRIDCOOLER unit can be canted from the hull

(sideways) to vertically align the nozzles. This can

reduce interference problems with stringers on

coerdam installations. See Figure 4. (referred to

section 3.1 for coerdam installation)

FIG.4 Canted Installation with Coerdam.

1.5.3 If the unit is recessed into the hull, make sure that

there is 1-1/2 in. (38 mm) minimum clearance on all

sides (this does not include between the hull and the

top of the cooler). The recess should be no deeper

than 1/2 in. (13 mm) plus the hull projection (listed on

installation drawing) of the cooler.

1.5.4 In extreme cases, where logs, debris, or dragging

bottom may endanger the unit, a protective guard

may be mounted over the unit. Make certain the

guard does not cover more than 25% of the face

opening. For examples of protective guards and

dierent installations that have been used, see

Figures 5 and 6.

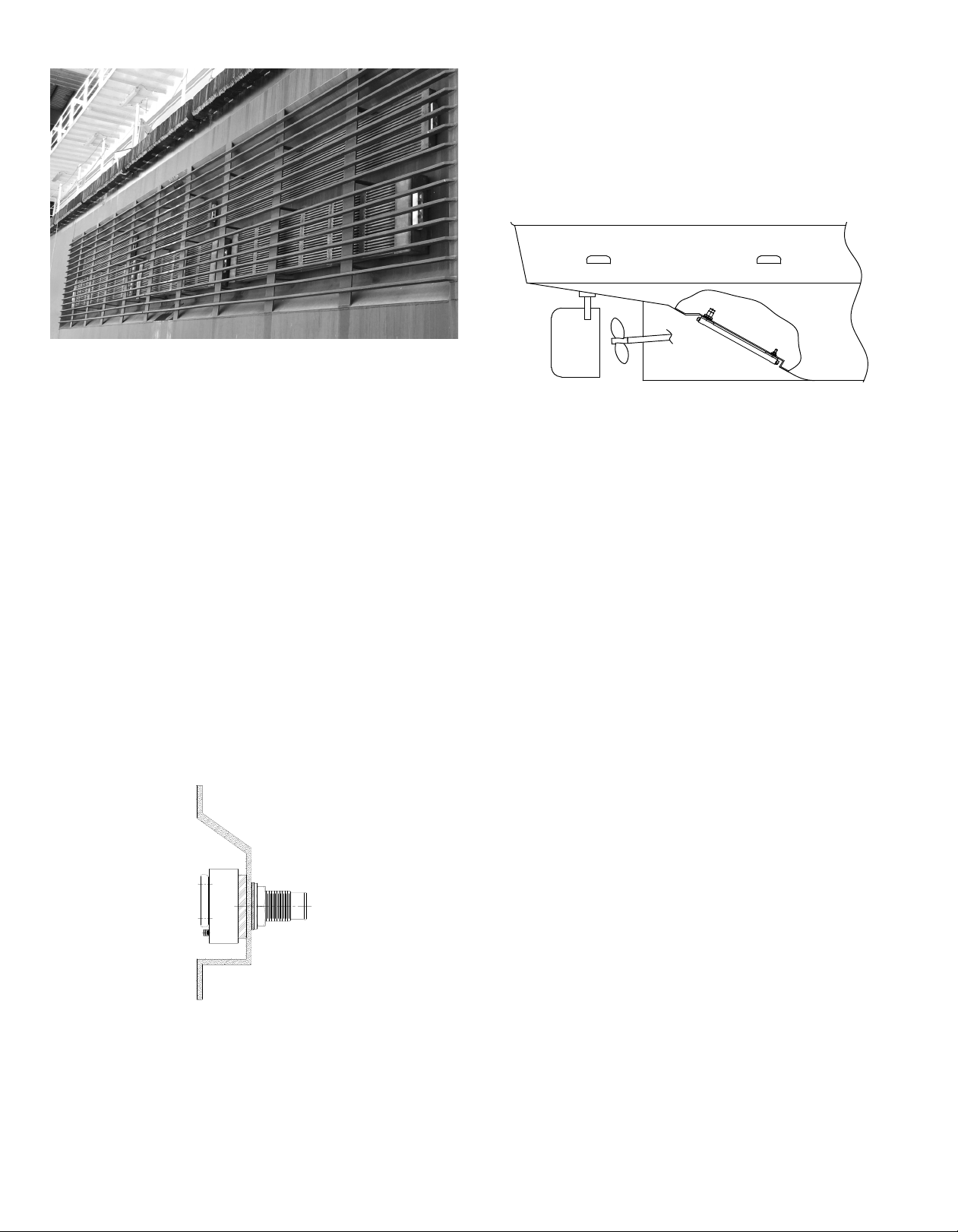

FIG.5 Example of external guarding

Page 4 Installation and Maintenance Manual form 185

FIG.6 Side mounted coolers

1.5.5 Copper-nickel units can be bent to conform to

the hull. The bending can be done at the yard or

by R. W. Fernstrum & Company. Contact us if you

are considering bending a unit. See Section 4.1 –

Bending A GRIDCOOLER® Keel Cooler. The bending

of aluminum keel coolers is not recommended.

1.6 MOUNTING CONSIDERATIONS –

DISPLACEMENT VESSELS

1.6.1 Owners of vessels with displacement hulls moving

at less than 10 knots may find an external mounting

with fairing blocks to their advantage; provided

there isn’t much chance of the unit being damaged

in their operating environment

1.6.2 When recessing the unit into the side of the hull

for generator sets and/or equipment operating at

dockside, angle the top of the recess box to improve

convection current over the cooler. See Figure 7.

FIG.7 Side Mounted Recess.

NOTE: Recess box with angled top suggested for

generator set and equipment operating at

dock side only. NOT required for propulsion

engines.

1.6.3 When installing a multiple-pass unit on an incline,

make sure that the nozzles are at the high end to

avoid air entrapment. See Figure 8.

1.6.4 If coolers must be installed with the nozzles at the

low end, special units can be ordered with additional

vents in the stud end of the cooler.

FIG.8 U-Flow unit with E1 OPTION end mounted

anodes mounted on rake of vessel with

nozzles positioned to avoid air entrapment.

1.6.5 If side plates and fairing blocks are used, make sure

that the side plates are scalloped (notched) out so

they will not entrap water. Fairing blocks are most

eective when installed with a 4 to 1 slope. See

Figures 1 & 5.

1.7 MOUNTING CONSIDERATIONS – PLANING

VESSELS

1.7.1 We recommend using a recess on planing hulls and

vessels moving at 10 or more knots.

1.7.2 High speed applications (10+ knots) can reduce the

1-1/2 in. clearance recommendation in section 1.5.3

to 1/2 in. minimum due to increased raw water flow

over the cooler at high speed.

1.7.3 High speed applications and others that use E1

OPTION™ coolers should take into consideration the

removal and replacement of anodes and drain plugs

when sizing the length of a recess. See Figure 2.

1.8 BONDING OR ISOLATION TO MINIMIZE

CORROSION

1.8.1 It is recommended that the installer consult with a

corrosion engineer to review the corrosion protection

system of the vessel to determine the best mode of

installation for their particular situation.

1.8.2 Typically, it is common practice to isolate the keel

cooler from the hull. This ensures that the antifouling

property of the copper-nickel is at full potential.

However, there are other variables that may aect

the decision whether to isolate or bond the unit.

Installation and Maintenance Manual form 185 Page 5

2.0 INSTALLATION

Once you have decided on the correct location, use

the following steps as a guideline for installing your

GRIDCOOLER® Keel Cooler.

2.1 MAKING HOLES

2.1.1 Measure the distance between the inlet & outlet

nozzles from center to center (also measure to the

centers of the support studs when applicable) before

cutting holes for them in the ship’s hull.

2.1.2 Make the holes through the hull 1/4 in. (6.4 mm)

diameter oversized.

2.1.3 Make sure that the hull surfaces where the unit will

be mounted are smooth and properly aligned (on

steel hulls, if you burn the holes, grind the edges

smooth afterwards). This will allow the gaskets to

seal properly and ensure that no undue stress will be

placed on the cooler.

2.2 FITTING UP

2.2.1 Under normal conditions, the compression of the

mounting gaskets puts sucient tension on the

nozzle nuts (and support bolt nuts when applicable)

to prevent them from working loose. To seal out

water, apply a bead of sealant to the exterior of the

gaskets, and around the points where the nozzles

and support bolts penetrate the hull before assembly.

2.2.2 Remember to tighten the nuts again, after the

caulking has set.

2.3 COPPER-NICKEL INSTALLATION

2.3.1 Mounting gaskets supplied with the GRIDCOOLER

Keel Cooler must be used to provide proper spacing

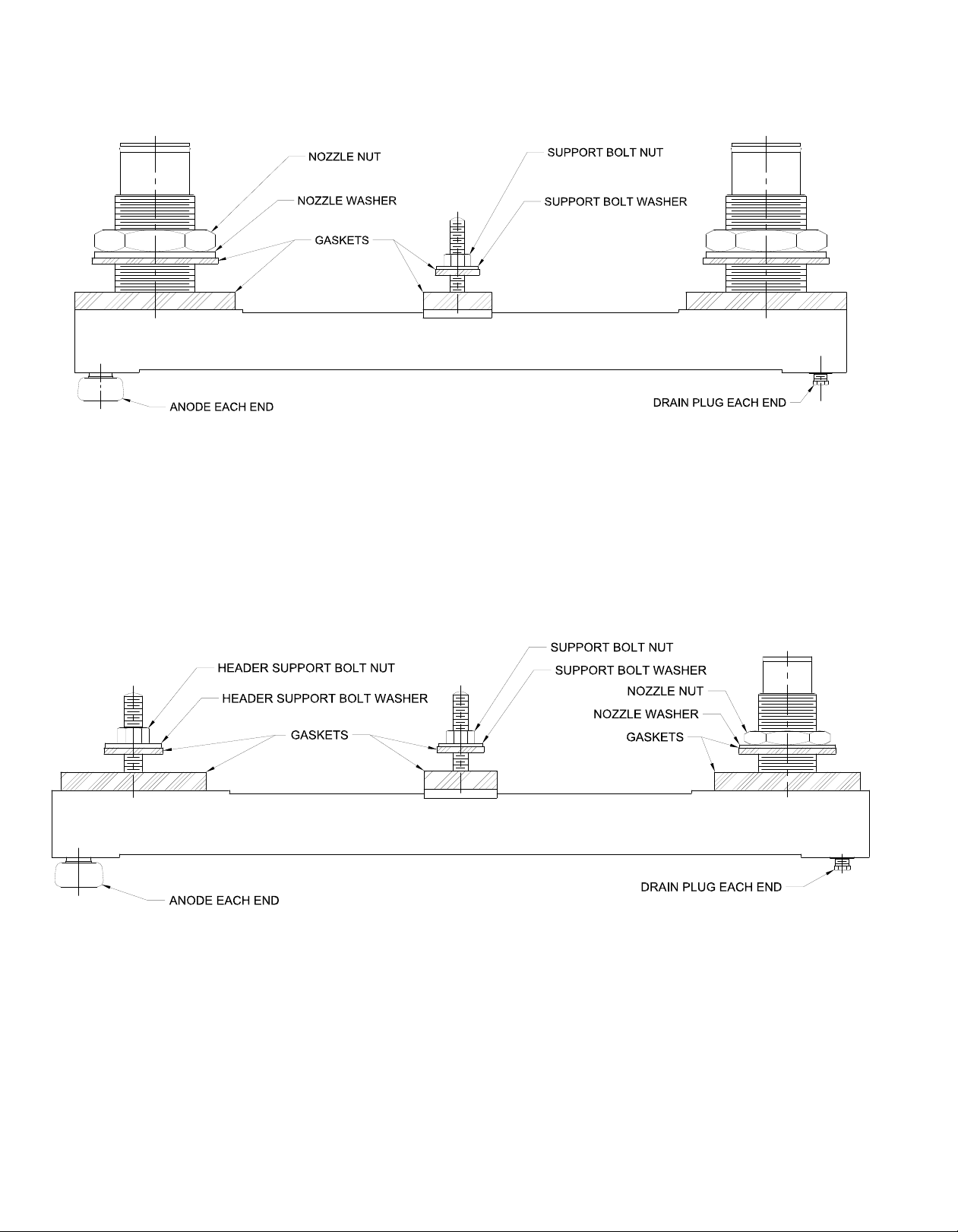

between the unit and the ship’s hull. See Figure 9.

For exterior gasket thickness see the chart below, all

exterior gaskets are available in ¼” on request

NOTE: INSULATORS: Insulators for galvanic isolation

of through-hull installation studs and nozzles

are available upon request at time of purchase.

When requesting the insulators, provide hull

thickness so the insulators can be supplied at

the proper length.

FIG.9 Mounting Parts Placement

NOTE: IF CONCAVE WASHERS ARE

USED, MAKE SURE CONCAVE SIDE

IS DOWN ON GASKET. FOR NIPPLE

WASHERS THAT ARE CAST, PLACE THE

ROUGH SIDE AGAINST THE GASKET.

EXTERIOR GASKET THICKNESS

B

¼”

6.4mm ½”

12.7mm ¼”

6.4mm

½”

12.7mm

BN C CN D

¾”

19mm

Page 6 Installation and Maintenance Manual form 185

2.3.2 To avoid over-tightening any of the supporting nuts,

we recommend the following torques for all standard

installations:

2.3.3 Anodes are standard equipment with copper-nickel

units. They minimize the eects of galvanic corrosion

and should be replaced when deteriorated. The life

of these plates varies with localities.

2.3.4 Attach the anodes using the special bolts and

washers supplied with the unit. They can be found

in a cardboard box inside the unit shipping box. See

Figure 10.

FIG.10 Anode Attachment Detail

NOTE: Anode replacement kits, including anodes,

screws, and washers, can be ordered from

the factory. They are available with zinc

anodes or aluminum anodes upon request.

Please provide the model number of your

GRIDCOOLER® Keel Cooler to ensure the

proper replacement anodes are sent.

2.4 ALUMINUM INSTALLATIONS

2.4.1 Aluminum GRIDCOOLER Keel Coolers should be

installed on unpainted aluminum hulls only.

2.4.2 The 1/4-inch mounting gaskets supplied with the unit

must be used to provide proper spacing between

the cooler and the ship’s hull.

2.4.3 To avoid over-tightening any of the supporting nuts,

we recommend the following torques for all normal

installations:

2.4.4 Most aluminum units have tapered threads on the

nipples and no hose connectors (see installation

drawing). These units can be piped directly to the

engine, provided flexible couplings are used to

remove engine vibration between the engine and

the cooler.

2.4.5 If a wire reinforced rubber hose is used to connect

the unit to the engine, put a screw-on coupling over

the cooler nozzle threads.

2.4.6 Aluminum GRIDCOOLER Keel Coolers do not use

anodes.

2.5 PLUMBING

NOTE: Prior to installing cooler, flush entire piping

system to remove any debris.

2.5.1 Remove the orange nozzle plugs from the

GRIDCOOLER unit before hooking up the plumbing

to the cooler.

2.5.2 Engines equipped with inboard raw water heat

exchangers may not be able to be converted to

keel cooling, please consult your engine dealer and

Fernstrum representative for guidance.

2.5.3 As a rule-of-thumb, the expansion tank for your

cooling system should be able to hold approximately

COPPER-NICKEL UNIT

NUT TORQUES FT.-LBS. (KG-M)

NOZZLE THREAD SIZE

¾”

19mm

50 - 60

(7 - 8)

HEADER STUD SUPPORT BOLT

1 - 1 ½”

25 - 38mm

75 - 100

(10 - 14)

2”

51 mm

125 - 150

(17 - 21)

2 ½ - 3 ½”

63 - 89mm

200 - 250

(28 - 35)

⅝ - ¾”

16 - 19mm

35 - 40

(5 - 5 ½)

1”

25 mm

50 - 60

(7 - 8)

½ - ¾”

13 - 19mm

20 - 25

(3 - 3 ½)

ALUMINUM UNIT

NUT TORQUES FT-LBS (KG-M)

NOZZLE THREAD

1 ½ - 3”

38 - 76mm

125 - 150

(17 - 21)

⅝”

16mm

20 - 25

(3 - 3 ½)

1”

25 mm

75 - 100

(10 - 14)

SUPPORT BOLT

Installation and Maintenance Manual form 185 Page 7

10% of the total cooling system coolant. Contact

your engine dealer for the exact size.

2.5.4 When piping, do not use tubing or fittings smaller

than the engine or keel cooler connections. If those

on the engine are larger than those on the keel cooler,

reduce the piping at the keel cooler, not the engine.

Use a minimum of elbows and check all connections

for leaks. All high areas in piping must be vented.

2.5.5 To avoid transmitting engine vibrations to the

GRIDCOOLER unit, use wire reinforced rubber

hoses and clamps at the engine and keel cooler

connections.

2.5.6 When installing a multiple-pass unit in a side mounted

position, the inlet line should be connected to the

lower nozzle to force air up and out of the cooling

system. Special units can be ordered with additional

air bleeding vents in the stud end of the cooler.

2.5.7 To avoid air pockets that would restrict coolant flow

through the system and cause overheating, install

the piping between the engine and the cooler so

that it is self- venting.

NOTE: Depending on installation, special air bleeding

vents are available as an option.

2.5.8 For piping diagrams for multiple cooler installations,

see Figures 11 through 14.

FIG.11 Coolers connected in parallel

FIG.12 Multiple-pass coolers connected in parallel

FIG.13 Coolers connected in series

FIG.14 Coolers connected in series parallel

2.6 FILLING & TESTING

NOTE: Do not exceed 35 PSI (2.41 Bar) when pressure

testing a GRIDCOOLER® Keel Cooler.

2.6.1 Always premix ethylene glycol (antifreeze) with

water before adding it to the cooling system. Contact

your engine dealer for the proper antifreeze type and

percentage for your engine. We do not recommend

the use of propylene glycol in your cooling system.

2.6.2 Never mix ethylene and proplyene glycol-based

antifreezes in your cooling system.

2.6.3 When installing a GRIDCOOLER Keel Cooler in a

side mounted position, it is important that the unit

is completely filled with coolant before launching

the vessel. This can be accomplished by using the

following procedure:

2.6.4 At the outlet end of the unit, remove the upper drain

plug and fill the unit with coolant

2.6.5 When coolant runs out of the upper drain, replace

the plug.

2.6.6 The unit is now filled with coolant. If the system is

ever drained, you must repeat this procedure.

Page 8 Installation and Maintenance Manual form 185

3.0 SPECIAL INSTALLATIONS

3.1 COFFERDAM INSTALLATION WITH

COMPRESSION SEALING KIT

3.1.1 Place a continuous bead of sealant around the

header gasket that separates the GRIDCOOLER®

unit from the outer hull. Customers have reported

good success with polysulfide rubber sealants.

3.1.2 Place a second continuous bead of sealant on the

inner hull around the nipple. This bead must be in

contact with the hull and the nipple.

3.1.3 Hoist the unit up into the mounting position. The

exterior header gasket must be in full contact with

the hull.

3.1.4 Place the nipple gasket (harder of the two interior

gaskets) down over the nozzle as far as possible.

3.1.5 Place the unfinished cast washer down over the

nipple as far as possible. The side of the washer

marked “up” must face away from the hull.

3.1.6 Place the compression gasket (softer of the two

interior gaskets) down over the nipple as far as

possible.

3.1.7 Place the semi-finished washer down over the nipple,

finished side away from the hull.

3.1.8 Run the nut down over the nipple and torque to

spec. (See chart in Section 2.3.2)

3.1.9 Torque the nut to spec a second time after the

sealant has set.

FIG.15 Compression Sealing Parts Replacement

Installation and Maintenance Manual form 185 Page 9

OPTION: For ease of installation and maintenance,

pipe to the side of the coerdams. (see Figure

16)

FIG.16 Pipe to side of coerdam

3.2 Z OPTION™ INSTALLATIONS

3.2.1 The Z OPTION GRIDCOOLER Keel Cooler replaces

the standard through-hull nozzle mounting/

connecting means with a copper-nickel flange,

fused to the header. This flange utilizes a plurality of

stainless-steel mounting studs locked in place by set

screws to allow replacement in the event of damage.

3.2.2 The unit is also supplied with mating ASTM steel

flanges and flange mounting hardware. The supplied

hardware illustrated in Figure 17 includes nylon

shoulder washers combined with neoprene gaskets

to allow isolation from the vessel’s hull. Special extra

heavy lock nuts and washers are provided for a

secure installation.

3.2.3 Flange mounting hardware can be found in a

cardboard box inside the unit shipping box.

3.2.4 The mating steel flange is welded to a pipe stub

extending from the hull of the vessel. This pipe stub

must be long enough to allow access to the flange

lock nuts for tightening. Alignment of the flanges

on the hull is critical. We suggest that a template be

made of the cooler to aid with the proper alignment

of the flanges.

NOTE: Temporarily remove nylon shoulder washers

while welding. Re-insert prior to mounting

cooler

The torque specification for the flange nuts is as follows:

NOTE: Z OPTION units utilize our L OPTION™ support

plates for intermediate mounting of the cooler.

See the next section for L OPTION mounting

instructions.

FLANGE NUT TORQUE SPECIFICATIONS

⅝” diameter or

larger stud

35 - 40 FT. LBS.

½” diameter stud

20 - 25 FT. LBS.

FIG.17 Z OPTION mounting detail

Page 10 Installation and Maintenance Manual form 185

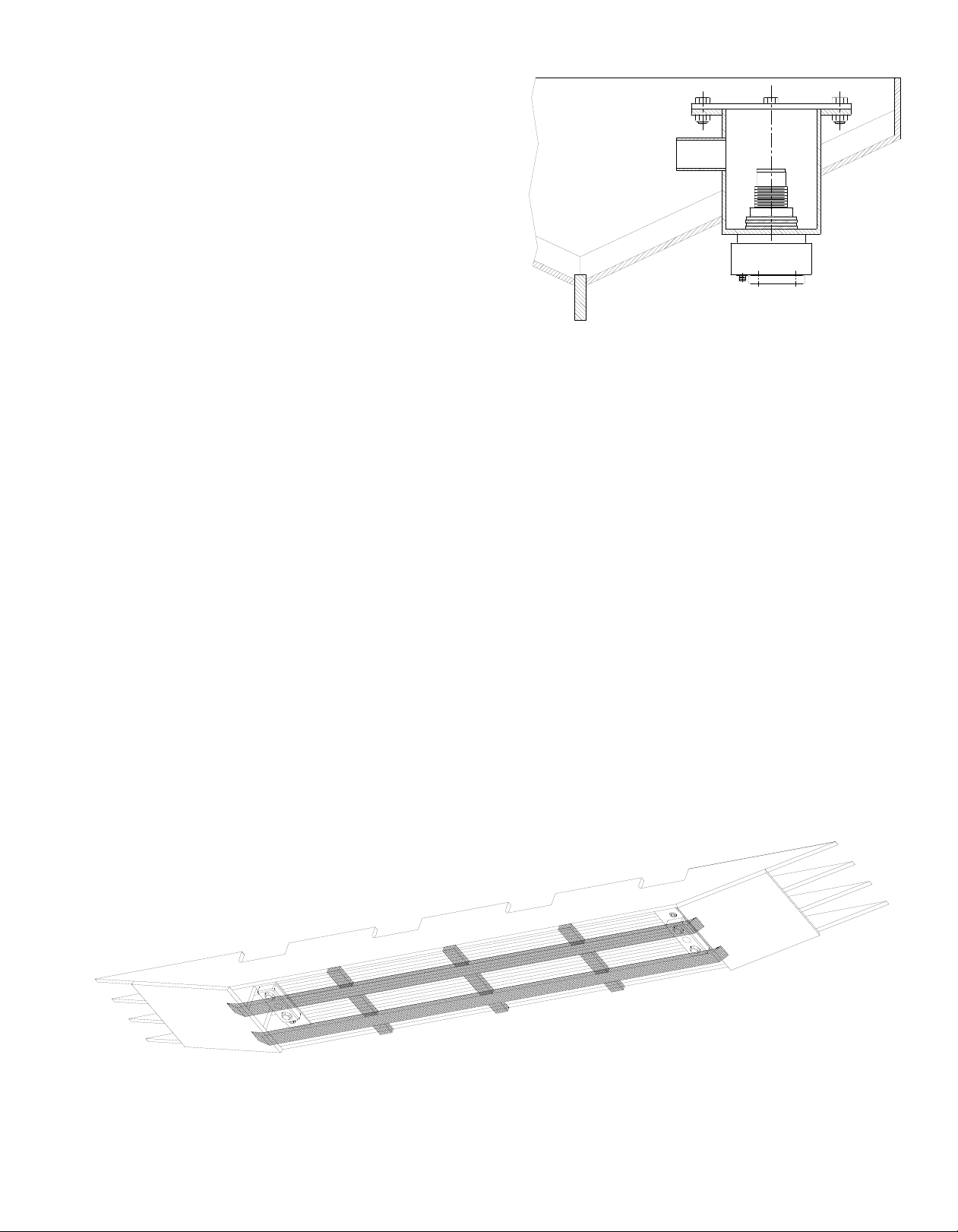

3.3 L OPTION™ SUPPORT PLATE INSTALLATION

The L OPTION support plates do not require a through-hull

penetration. These support plates extend beyond the sides

of the keel cooler allowing the customer the option to weld

a mounting stud directly to the hull or to weld a short piece

of angle to the hull as a securing means. The customer can

then install the appropriate fasteners for the support plates.

Figures 18 and 19 show examples of this style of mounting.

The combination of the neoprene gasket and the nylon

shoulder washer provide isolation of the cooler from the hull.

NOTE: Do not cut o the center stud on your

GRIDCOOLER® Keel Cooler. The center stud is

there to provide necessary support for your

keel cooler when it is attached to the hull.

FIG.18 L OPTION support plate with stud welded to hull

FIG.19 L OPTION support plate with angle welded to hull

Installation and Maintenance Manual form 185 Page 11

3.4 MOUNTING COPPER-NICKEL COOLERS ON

ALUMINUM HULLS

3.4.1 An electrical barrier must be placed between the

GRIDCOOLER® unit and the hull. R. W. Fernstrum &

Company does not formally approve any method of

installing a copper-nickel GRIDCOOLER Keel Cooler

on unpainted aluminum hulled vessels. However, the

following technique has been used on hundreds of

boats.

3.4.2 Sandblast the area of the hull where the unit will be

installed.

3.4.3 Coat the sandblasted area with a two-part fiberglass

epoxy resin.

3.4.4 Spray the resin on in four separate coats. Do not use

any matting. Spray each coat just heavy enough so

that it does not start to run o.

3.4.5 After spraying on the fourth coat, and while the

resin is still tacky, prime the entire area with the hull

priming paint used on the rest of the vessel’s hull.

3.4.6 Apply the final bottom paint, and then install the

cooler.

Page 12 Installation and Maintenance Manual form 185

4.0 FORMING THE GRIDCOOLER® KEEL COOLER

BENDING A GRIDCOOLER KEEL COOLER

When bending a cooler in a press, support the cooler from

underneath with wood blocking across the entire width of

the unit. Blocking is also placed on top of the cooler, centrally

located between the wood blocking underneath the cooler.

The location of the wood blocking on the top of the cooler

will determine the location of the bend. Since this method

of bending exerts pressure on only a small area, the cooler

will need to be repositioned multiple times to produce an

even bend over the length of the cooler. Care must be taken

to ensure that the unit is not bent too far at any one point.

A tape measure or other measuring instrument, along with

a template of the hull profile can be used to measure your

progress. See Figures 20 and 21.

TWISTING A GRIDCOOLER KEEL COOLER

To produce a twist, first fabricate a hook onto the end of a

short length of pipe using barstock. Hook this bar across the

header as close to the nipple or stud as possible. The cooler

may be secured in a press or placed on sawhorses with a

person at each end. By placing your weight on the end of

the pipe, you can produce a twist in the cooler. See Figures

22 and 23.

NOTE: Do Not Bend greater than 1” (25 mm) over

12” (305 mm) of cooler length. Do Not Twist

beyond 1° over 12” (305 mm) of cooler length.

Do Not Tension Bend the keel cooler.

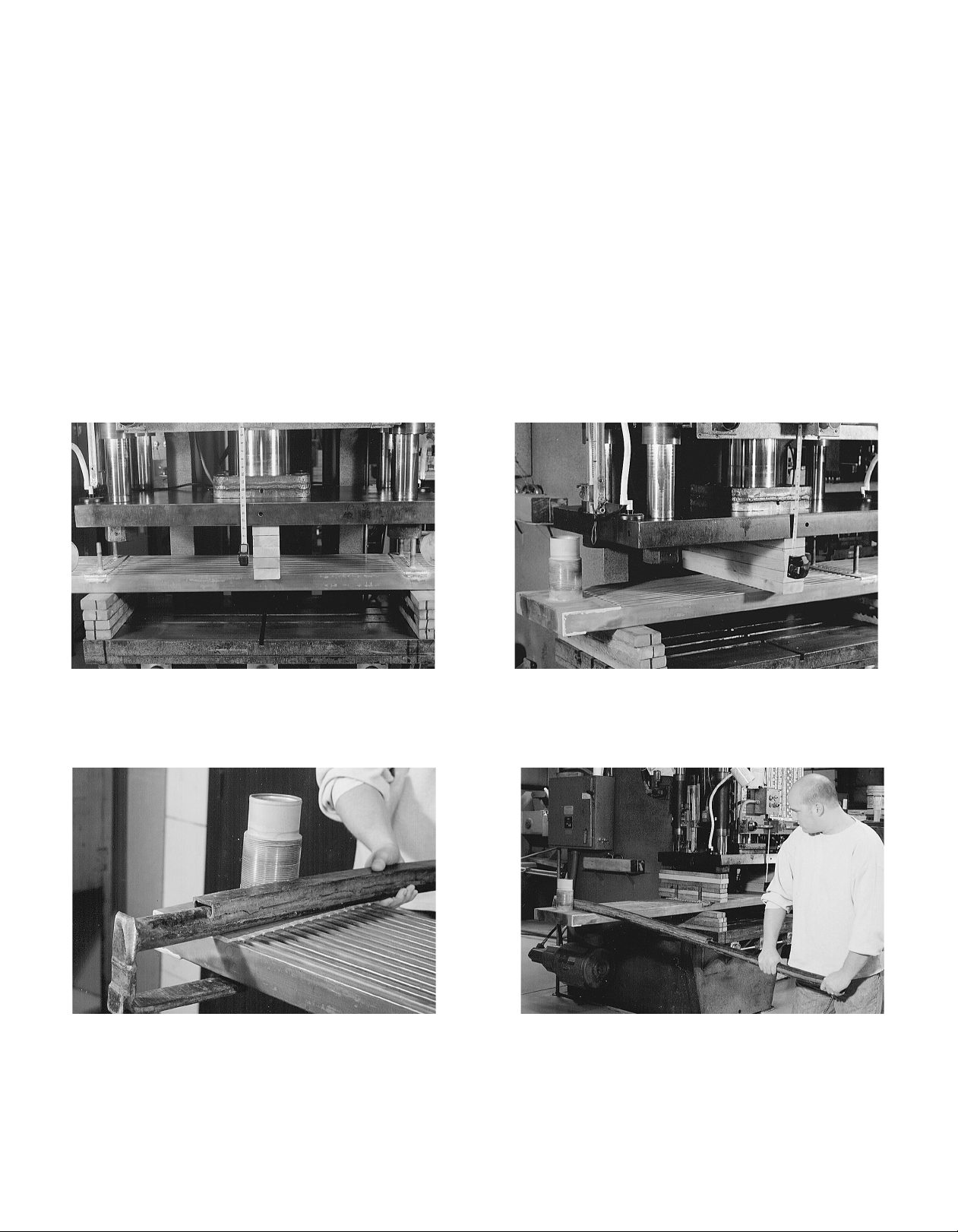

FIG.20 Creating a bend in a cooler using a

hydraulic press

FIG.21 Creating a bend in a cooler using a

hydraulic press

FIG.23 Carefully apply downward force to

impart a twist in the cooler

FIG.22 Locate twisting hook as close as

possible to the nozzle or stud

Installation and Maintenance Manual form 185 Page 13

5.0 PERFORMANCE ISSUES

Determining the cause of overheating can be dicult. Here

are some things to look for:

WIRE REINFORCED RUBBER HOSE:

Could the rubber hose connecting the engine piping and the

cooler be collapsed? This could cut the cooling water supply

to the unit and reduce its eciency. Be sure you are using

wire reinforced rubber hose.

PIPING:

Is the piping between the engine and the cooler as large or

larger than the engine and cooler connections? (See section

2.5.4 under plumbing.) The piping should also be self-venting

and arranged so that a minimum number of elbows are used.

JACKETWATER:

Is the coolant circulating through the cooler? It may be taking

a path of least resistance through the bypass (if one exists).

THERMOSTAT:

Could the thermostat be stuck, or could the wrong thermostat

be in use? If so, it could give you a faulty temperature.

CIRCULATING PUMP:

Is the circulating pump working properly? If not, it could

reduce the cooling systems eciency.

AIR IN THE SYSTEM:

Was the unit installed in a way to allow all the air in the system

to escape? When a multiple-pass unit is mounted on the rake

of the vessel, make sure that the nozzles are mounted in the

up or high position. See sections 1.6.3, 2.5.6, 2.5.7, & 2.6.3

under Installation. See Figure 8

FOREIGN MATTER:

Could anything have gotten into the cooler nozzles? Make

sure that the orange plastic cap plugs covering the ends

of the hose connectors were removed and that no foreign

matter, such as a rag, was dropped into the cooler nozzles.

EXPANSION TANK:

Could the water level be too low in the expansion tank? This

can reduce the cooling system’s eciency.

EXTERNAL COATING:

Is the cooler painted or covered with any other coating? This

will have an insulating eect and will greatly reduce the heat

transfer rate of the unit. The standard recommendation is to

not coat the keel cooler.

WATER AERATION:

Could the water around the cooler be aerated in any way?

Aeration will reduce the heat transfer rate of the keel cooler.

MOORED AT DOCK:

Is the engine temperature rising while the vessel is moored

in dock? If the unit is installed near the propeller, engage

the propeller to circulate water past the unit, after taking the

proper safety precautions.

PLACEMENT:

Is an aftercooler circuit overheating? Make sure that the low

temperature cooling circuit is mounted forward of or closer

to the skeg or keel than the jacketwater coolers.

MOUNTING GASKETS:

Were the mounting gaskets put in place when the unit was

installed? The mounting gaskets supplied with the cooler

must be used to provide adequate spacing between the unit

and the ship’s hull. This will allow water to flow freely over

the cooler tubes.

GLYCOL:

How much glycol (antifreeze) is in the system? Perhaps the

cooler was not sized for the use of glycol in the system.

NOTE: Always premix glycol with water before adding

it to the cooling system.

NOTE: Never mix ethylene and propolyene glycol.

CRUSHED TUBES:

Have the rectangular tubes on the cooler been crushed or

pinched? This could restrict the internal water flow.

BLOWN TUBES:

Could the rectangular tubes on the unit have been blown or

bulged by unusually high pressures? If so, the exterior water

flow past the unit tubes could be impaired, retarding heat

transfer.

MARINE GROWTH:

Has your vessel been in dock for several months? You may

find marine growth on the unit which will hinder the unit’s

heat transfer rate. See Maintenance Section.

OIL DEPOSITS:

Have you had engine problems? Oil may have gotten into the

cooling water system and collected in the cooler, coating it

with an oil film. See Maintenance Section.

MINERAL DEPOSITS:

Could you be using hard water in the system? Mineral

Deposits can collect on the tube in the cooler, lining the

inside with lime, calcium, etc. See Maintenance Section.

Page 14 Installation and Maintenance Manual form 185

6.0 MAINTENANCE

A GRIDCOOLER® Keel Cooler that is clean inside and out

will dissipate heat most eciently. To keep your unit clean, a

periodic check of the cooling system is recommended. What

follows are some ways to clean your GRIDCOOLER unit.

EXTERIOR

If the GRIDCOOLER Keel Cooler is used regularly, the 90/10

copper-nickel alloy in conjunction with the unit’s operating

temperature will tend to keep the exterior of the unit

relatively free of marine growth. However, if the unit is not in

operation for extended periods of time, marine growth may

result. Below are some ways of removing marine growth,

paint, etc. from the exterior of the GRIDCOOLER unit:

SCRAPE:

Scraping is an eective way of removing larger matter from a

cooler. The use of a rectangular instrument works best.

PRESSURE WASHING:

Pressure washing is eective in cleaning many things o of a

cooler. Do not exceed 3000 psi (206.84 bar).

SANDBLAST:

Sandblasting is also very eective, but very fine sand such as

40 to 60 grit blasting media should be used.

For suction blast do not exceed 90 psi (6.21 bar).

For pressure pot blasting do not exceed 35 psi (2.41 bar).

NOTE: Never sandblast an ALUMINUM GRIDCOOLER

unit.

PAINTING:

Coolers do not require painting. Doing so will decrease the

unit’s eciency.

ANODES:

Anodes are standard equipment with most copper-nickel

units. They minimize the eects of galvanic corrosion and

should be replaced when deteriorated. The life of these

anodes varies with localities.

Anode replacement kits, including anodes, screws, and

washers, can be ordered from the factory. When contacting

our sales representatives, provide the model number of your

GRIDCOOLER Keel Cooler. Anodes are available in aluminum

or zinc material.

NOTE: Anodes installed on coolers provide immediate

protection to the cooler only. When using an

active protective system, the cooler should be

taken into consideration during the hull survey.

INTERIOR

The interior of your GRIDCOOLER unit may need periodic

cleaning to remove oil, old glycol, mineral deposits, etc. The

easiest and most convenient way of doing this is the use of

a radiator flush. Contact your engine dealer for the proper

radiator flush type for your engine.

PRESSURE TESTING

Do not exceed 35 psi (2.41 bar) when pressure testing a

GRIDCOOLER® Keel Cooler.

Installation and Maintenance Manual form 185 Page 15

7.0 REPAIR

For a unit in warranty, attempt no repairs without first

contacting the manufacturer, otherwise your warranty will

be void.

For a unit out of warranty, if the unit is accidentally damaged

while in use, you can make minor shipyard repairs as follows:

STRAIGHTENING

If the tubes are accidentally bent, they can be straightened

with a hard wood block and a mallet. See Figure 24.

FIG.24 Straightening tubes with a wooden block &

mallet

COPPER-NICKEL GRIDCOOLER® KEEL COOLER

REPAIRS

BRAZING:

Drain the cooler before brazing. Clean the area or joint to be

brazed thoroughly with a good degreasing solvent followed

by wire brushing. The braze wire should be 56% silver, AWS

A5.8 BAg-7. See Figure 25.

FIG.25 Brazing repair

TIG WELDING:

C70600 copper-nickel or monel 67 wire may be used.

TEMPORARY REPAIR

For temporary repairs, liberally apply an epoxy compound.

Before applying the epoxy compound, clean the surface of

the GRIDCOOLER unit and relieve any internal pressure.

For major repairs not covered by our Limited Warranty,

contact us. Give us a complete description of the damage,

and we will tell you if and how your unit can be repaired.

TUBE COUPLING REPAIRS

A damaged section of D or C tube can be replaced with two

couplings and a replacement length of tube brazed in place.

FIG.26 Replacing a section of tube

A single coupling can be cut or split, slid over the tube, and

brazed into place to patch a hole in a tube.

FIG.27 Patching a hole in a tube

ALUMINUM GRIDCOOLER KEEL COOLER REPAIRS

TIG WELDING:

Drain the cooler before welding. Clean the area or joint to be

welded thoroughly with a good degreasing solvent followed

by stainless steel wire brushing. The aluminum filler rod used

in the GRIDCOOLER Keel Cooler is R 5554 aluminum wire.

Page 16 Installation and Maintenance Manual form 185

8.0 STRAY-CURRENT CORROSION

Since Fernstrum’s involvement in the design of any particular

marine vessel is limited to the heat transfer requirements of

the vessel, grounding or bonding of the keel cooler is best

left to the person responsible for the design of the corrosion

protection system. If the customer needs guidance on this

issue it is suggested to isolate the cooler from the hull and

monitor closely the condition of the cooler, anodes and

surrounding hull area for the first few months. This is for the

simple fact that it is easier to ground a cooler after installation

than it is to isolate it.

When welding is taking place on the hull while in the water,

steps should be taken to monitor the keel cooler for any

possible stray current corrosion. For guidance on proper

welding equipment connections for waterborne vessels,

we suggest consulting either NAVSEA S9086-CH-STM-010/

CH-074R4 Welding and Allied Processes, Naval Ships’

Technical Manual Chapter 74 - Volume 1, or ANSI/AWS

D3.5:1993(R2000) Guide for Steel Hull Welding, Section 6

Stray Current Protection. Note that the Section 6 of the ANSI/

AWS D3.5:1993 standard comes directly from the document

provided by NAVSEA.

If an impressed current system is used, it is best to consult

the manufacturer of the system for their recommendations

as to grounding or bonding of equipment mounted to the

hull.

The product warranty is not aected by how the keel cooler

is configured into the corrosion protection system, as it

covers defects in material and workmanship, not failure due

to galvanic or stray current corrosion.

The best plan of action is to have a corrosion engineer

evaluate the corrosion protection scheme of the vessel and

verify its proper function.

Installation and Maintenance Manual form 185 Page 17

9.0 REPLACEMENT PARTS

FIG.28 Single Pass Gridcooler Keel Cooler

FIG.29 Multi Pass Gridcooler Keel Cooler

Page 18 Installation and Maintenance Manual form 185

FIG.30 Z-Option Single Pass Gridcooler Keel Cooler

FIG.31 Z-Option Multi Pass Gridcooler Keel Cooler

NOTE: All gaskets are sold in complete sets. Gasket

sets include all internal gaskets, exterior

gaskets and isolators.

NOTE: Anodes are sold in kits consisting of anodes

and mounting hardware. Most Keel Coolers

require one (1) anode kit. Larger Keel Coolers

may require two (2) anode kits. Keel Cooler

model number is needed to identify correct

kit. Anodes are standardly sold in zinc, but

can be aluminum upon request.

9.0 REPLACEMENT PARTS

Table of contents

Popular Accessories manuals by other brands

PCB Piezotronics

PCB Piezotronics 113B03 Installation and operating manual

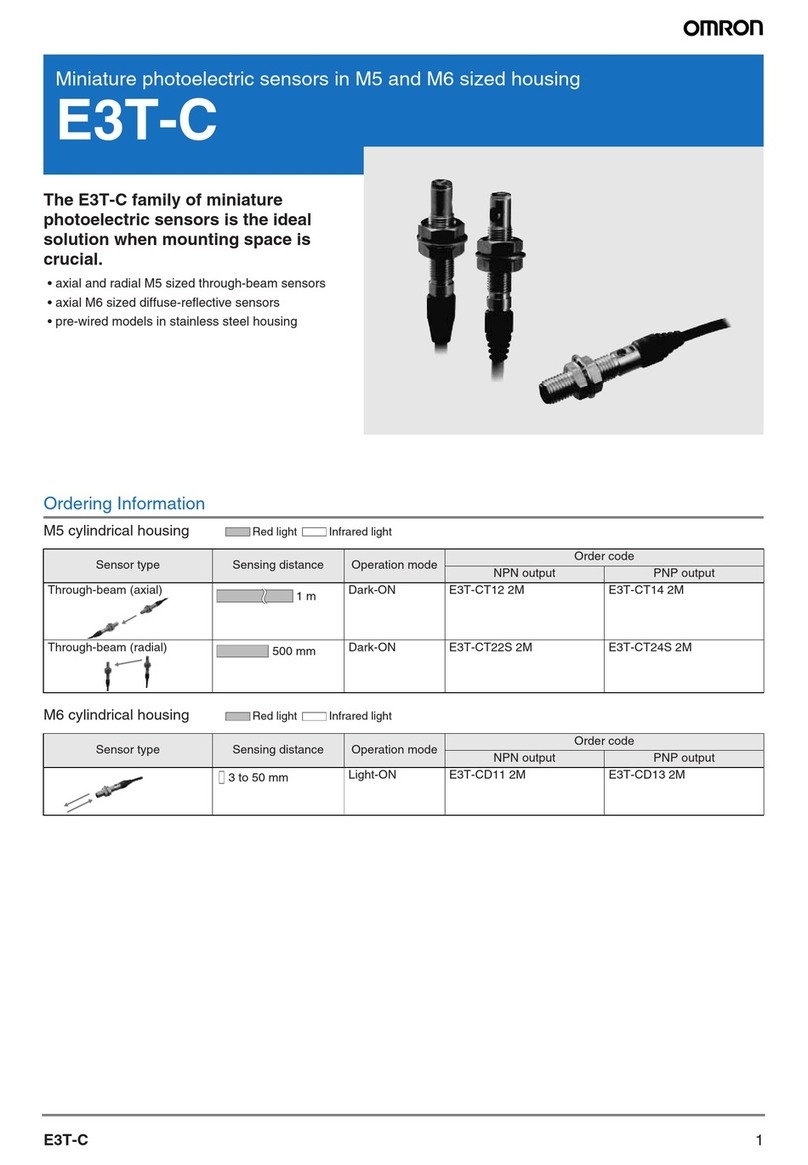

Omron

Omron E3T-C datasheet

MIXX CHARGE

MIXX CHARGE Powerlife C10 quick start guide

BEA

BEA ACTIV8 THREE F instructions

TEKTELIC Communications

TEKTELIC Communications T0005982 user guide

Siemens

Siemens SITRANS CU02 operating instructions

IFM

IFM UIT510 operating instructions

EVA Logik

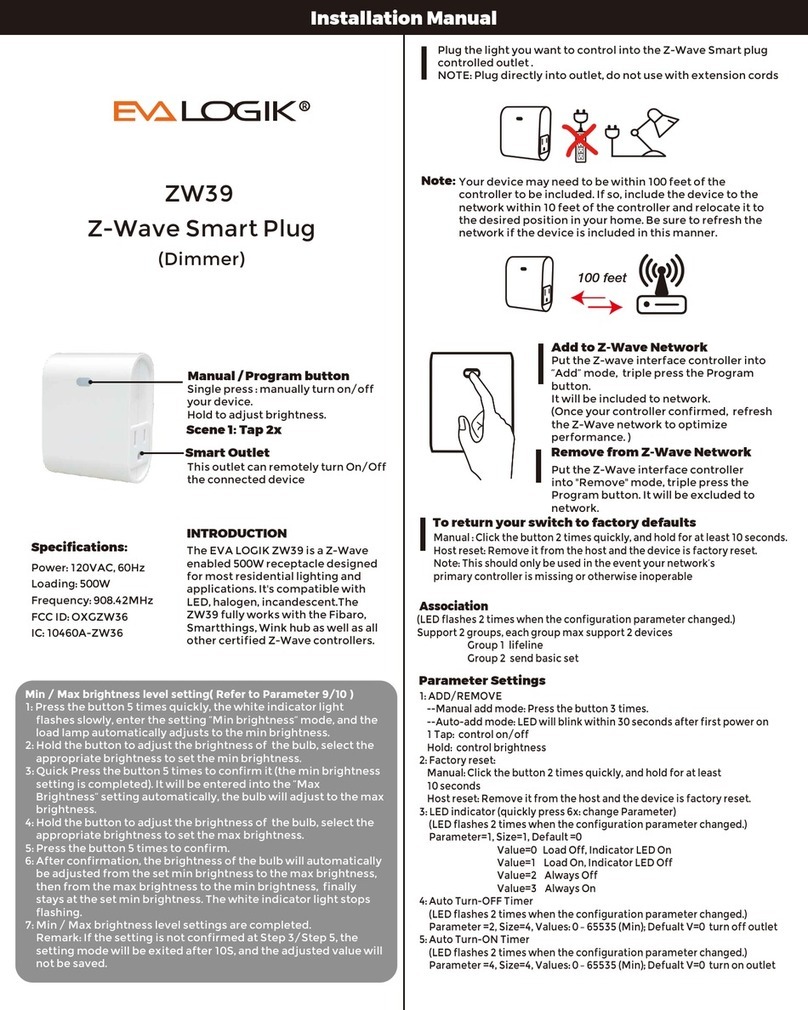

EVA Logik ZW39 installation manual

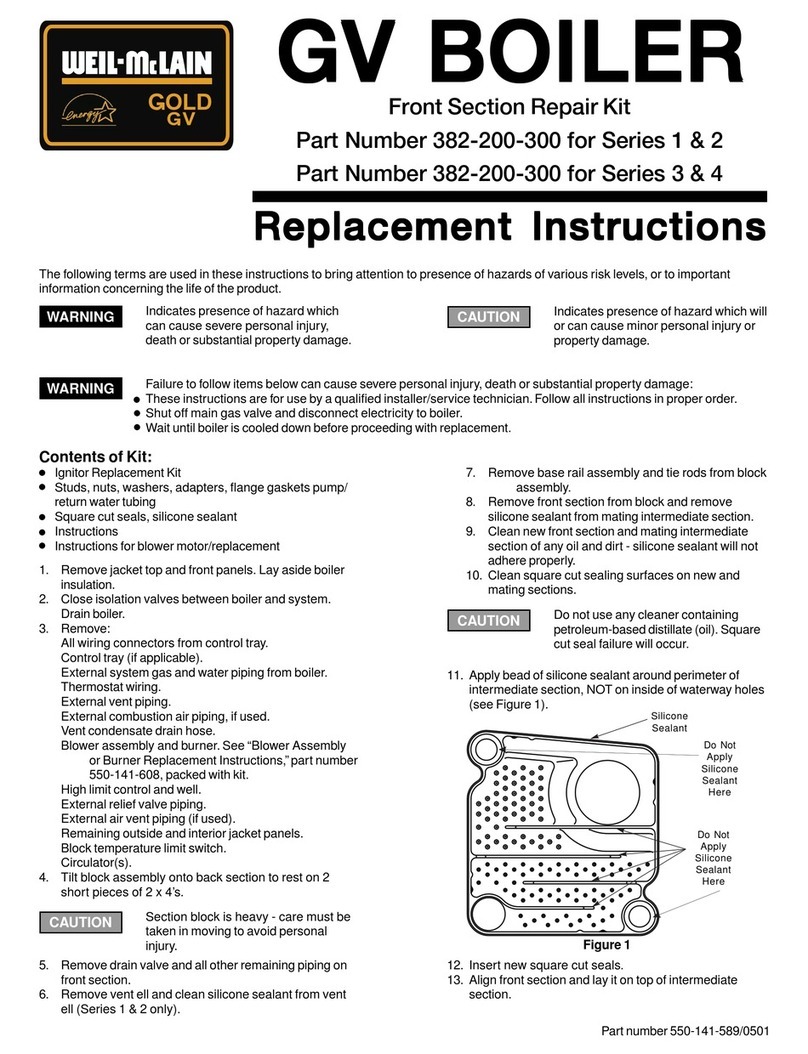

Weil-McLain

Weil-McLain Gold GV 2 Series Replacement instructions

Ace

Ace Lighted Wireless Push Button Accessory... owner's manual

Galvin Engineering

Galvin Engineering CliniMix CMV2 Product installation guideline

Panasonic

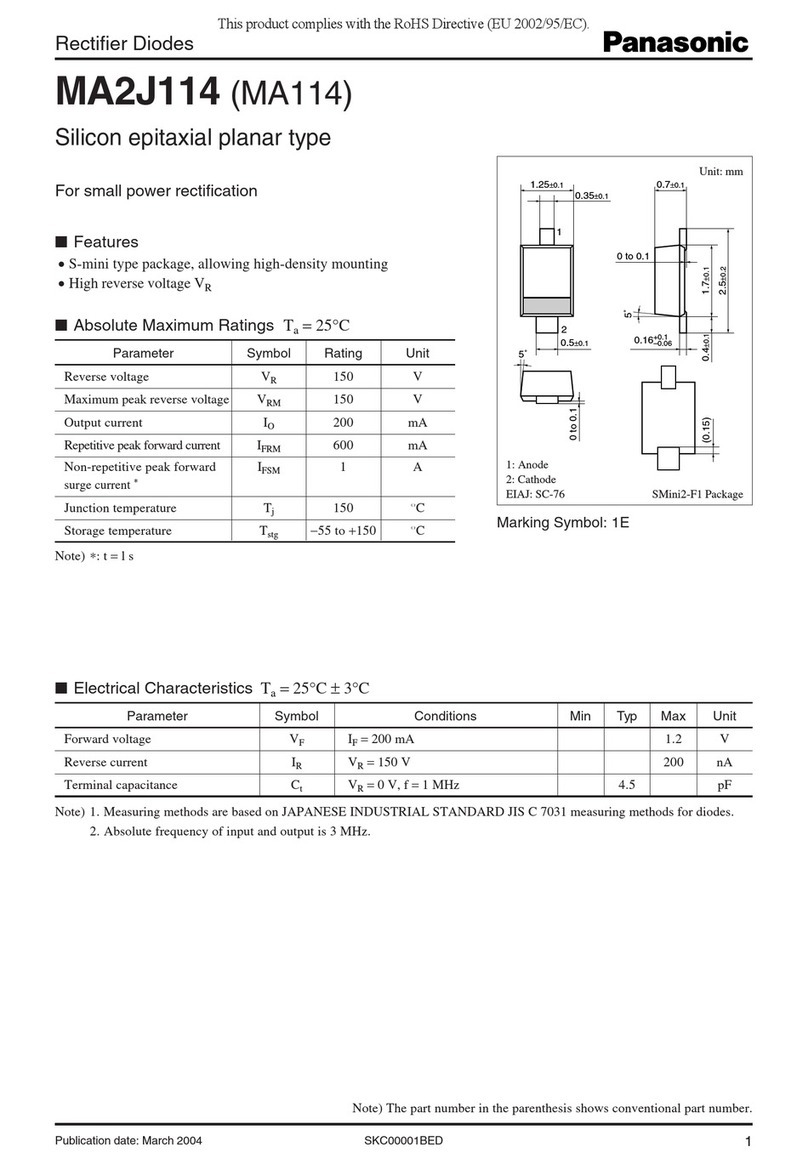

Panasonic MA2J114 (MA114) Specifications