FERRI T380D Series User manual

T380D-T430D

ENGLISH

EN-GB

HYDRAULIC FLAIL HEDGE MOWER ARM

Translation of Original Instructions Rev. 1.0

UM0100 - 06/03/2015

USE AND MAINTENANCE MANUAL

Model Serial number

T380D right 01

T430D right 01

T380D left 01

T430D left 01

3

Rev. 1.0 T380D-T430D

TABLE OF CONTENTS

INDICE

1 GENERAL INFORMATION 13

1.1 Purpose and contents of the manual 13

1.1.1 Who should read this manual................................................................................................................................13

1.1.2 Updates to the manual..........................................................................................................................................13

1.1.3 Conservation.........................................................................................................................................................13

1.1.4 Copyrights.............................................................................................................................................................13

1.2 Spare parts 14

1.3 Machine versions 15

2 SAFETY RULES 16

2.1 General safety rules 16

2.2 Safetyrulesconcerningroadtrafc 20

2.3 Safety rules during use 21

2.3.1 Responsibility of the operator or the owner...........................................................................................................22

2.4 Safety rules concerning the hydraulic system 23

2.5 Fire-prevention methods 24

2.6 Overhead hazards 25

2.7 Protection and equipment for the operator 26

2.7.1 Maintenance: safety rules.....................................................................................................................................27

2.8 Working range of the machine 28

2.9 Safety decals 29

2.9.1 Replacing safety decals........................................................................................................................................33

3 TECHNICAL CHARACTERISTICS 34

3.1 General description of the machine 34

3.1.1 Proper and improper use of the machine..............................................................................................................34

3.2 Machineidentication 35

3.3 Description of the parts 36

3.4 Technicalspecications 37

3.5 Noise level 38

3.6 Radius of work 39

3.7 End tools 41

3.7.1 Flail heads.............................................................................................................................................................41

3.7.2 Cutter bar..............................................................................................................................................................42

3.8 Optional equipment 43

3.8.1 Flails......................................................................................................................................................................43

4 INSTALLATION AND HANDLING 44

4.1 Lifting 44

4.2 Tractor hitch 45

4.2.1 Position of the centre of gravity.............................................................................................................................47

4.2.2 Attaching Without a Quick Hitch............................................................................................................................48

4.2.3 Attaching Without a Quick Hitch............................................................................................................................49

4.2.4 DELTA coupling ....................................................................................................................................................50

4.3 Fitting the PTO shaft 52

4.4 Tractor stability 55

4.5 Electrical connections 56

4.6 Assembling the end tool 59

4.6.1 Connectingtheailhead.......................................................................................................................................60

4.6.2 Disconnectingtheailhead ..................................................................................................................................61

4.6.3 Cutter bar connection............................................................................................................................................62

4.7 Detachment from the tractor 63

4.7.1 Detachment with head resting on the ground (TSA530-550-610) ........................................................................63

4T380D-T430D Rev. 1.0

TABLE OF CONTENTS

INDICE

5 ADJUSTMENTS 64

5.1 Working speed adjustment 64

6 USE AND OPERATING RULES 66

6.1 Controls 66

6.1.1 Cable controls (CLASSIC) ....................................................................................................................................67

6.1.2 Electronic controls (ELECTRA version)................................................................................................................69

6.1.3 Controls (FULL ELECTRA version).......................................................................................................................71

6.2 Starting up 73

6.2.1 Preliminary checks................................................................................................................................................73

6.2.2 Starting up the machine........................................................................................................................................74

6.2.3 Startingtheailhead ...........................................................................................................................................75

6.2.4 Starting the cutter bar ..........................................................................................................................................76

6.2.5 Startinguptheailhead(FULLELECTRAversion) .............................................................................................77

6.2.6 Starting up the cutter bars (FULL ELECTRA version)...........................................................................................77

6.3 Working mode 78

6.3.1 Rotational direction of the rotor.............................................................................................................................79

6.3.2 Rotor's direction of rotation (FULL ELECTRA version).........................................................................................80

6.3.3 Arm safety.............................................................................................................................................................81

6.3.4 Work with arm close to a vertical position.............................................................................................................82

6.4 Stopping 85

6.5 Stopping (FULL ELECTRA version) 86

6.6 Transport position 87

7 ROUTINE MAINTENANCE 89

7.1 General information 89

7.2 Checklist 90

7.2.1 Every 8 working hours or daily..............................................................................................................................90

7.2.2 Every 50 working hours or every month................................................................................................................91

7.2.3 Every 200 working hours.......................................................................................................................................92

7.2.4 Every 500 working hours or every month..............................................................................................................93

7.3 Oil table 94

7.4 Greasing 95

7.5 Changing the gearbox oil 96

7.6 Replacingtheoilandthelters 99

7.6.1 Replacingoilltercartridge.................................................................................................................................100

7.7 CleaningtheHeatExchanger 101

7.8 Electricalsystem 102

7.9 Electricsystemdiagnostics 103

7.9.1 Procedure for movement operation in case of electrical failure..........................................................................105

7.10 Instructionsforpreloadingthehydropneumaticaccumulators 107

7.11 Fasteningthehydraulichosecouplings 108

7.12 Bolttightening 110

7.13 Parking or storage 112

8 EXTRAORDINARY MAINTENANCE 113

8.1 Pipe replacement 114

8.1.1 Replacing the pipes in the hydraulic stopping devices .......................................................................................115

8.2 Pin replacement 116

9 TROUBLE SHOOTING CHART 117

9.1 Trouble shooting chart 117

9.1.1 General ...............................................................................................................................................................117

10 SCRAPPING AND DISPOSAL 123

5

Rev. 1.0 T380D-T430D

TABLE OF CONTENTS

INDICE

11 WARRANTY 125

11.1 Voiding of the Warranty 125

12 OPTIONAL UNITS 126

12.1 Air-oil heat exchanger 127

12.1.1 Assembly instructions .........................................................................................................................................128

12.2 Boom hydro-pneumatic suspension 132

12.2.1 Assembly instructions .........................................................................................................................................133

12.3 1st boom dual effect kit 135

12.3.1 Assembly instructions .........................................................................................................................................135

6T380D-T430D Rev. 1.0

TABLE OF CONTENTS

Page left intentionally blank

INDICE

7

Rev. 1.0 T380D-T430D

DECLARATION OF CONFORMITY

Dichiarazione di conformità

DECLARATION OF CONFORMITY

TheCE Declaration of Conformity, providedtogether withthemachine,is the documentwithwhichthe Manufacturer

certies, under its own responsibility, that it has complied with observance of the European Directives, the Standards

and Technical Specications necessary (specied in said Declaration) in order for the machine to conform to the basic

requirements for sale and use in the European Union.

The Declaration of conformity must be considered as an integral part of the machine and must always accompany

the machine until it is scrapped.

If this document is not delivered together with the machine or gets lost, please request a copy from the

Manufacturer.

N°

CE Declaration of Conformity

According to 2006/42/CE Directive

(that abrogate 98/37/CE Directive)

The undersigned FERRI s.r.l. state on its own responsibility that the machine

description of machine code series (flail head/series) serial no.

complies with the Essential Safety and Health Protection Requirements of the 2006/42/CE Directive and to

the electromagnetic compatibility for models equipped with electro/electronic devices according the

2004/108/CE Directive.

To answer to Conformity, according to the above mentioned Directives, following rules have been

considerated:

As well as the technical detailed list:

(Name and qualification of the delegate of the manufacturer)

Signature of the delegate

Tamara,

Person authorised to form the Technical file

Dr. Sandro Ferri

(Place and date)

FERRI s.r.l. – Via Govoni, 30 – 44034 Tamara (Ferrara) – Italia - Tel. +39.0532.866 866 - Fax +39.0532.866 851

(to cut along the outlined line)

To fill out by the Distributor with user’s details

Date

ata

WARRANTY COUPON

Surname Name

Series

Date

Company Ragione Sociale User Signature

Address

City or Town State/Prov

Postal

Code

Machine Model

Serial N°

Telefono Fax

Serial N° Series

Distributor stamp and signature

Machine Model

Taken note of the Use and Maintenance Book and

of the use’s rules (Safety Rules included)

Distributor Stamp

User Signature (legible)

FAC-SIMILE

The bottom part of the Declaration of Conformity contains the Warranty Coupon which must be completed in full and

returned to the Manufacturer in order for the rights under the warranty to be valid (see Chapter 11).

8T380D-T430D Rev. 1.0

DECLARATION OF CONFORMITY

Norme DECESPUGLIATRICI

The machine described in this manual complies with:

European Directives

2004/108/EC Electromagnetic compatibility of machines with internal electrical power supply

2006/42/EC Machinery directive

Harmonised standards

UNI EN ISO 13857 2008 Safety of machinery – Safety distances to prevent hazard zones being reached by upper and

lower limbs

UNI EN 13524 2014 Highway Maintenance Machines - Safety Requirements

UNI EN ISO 4254-1 2010 Agricultural machinery - Safety - Part 1: General requirements

UNI EN ISO 12100 2010 Safety of machinery - General principles for design – Risk assessment and risk reduction

Technical Specifications

UNI EN ISO 3767-2 1998 Tractors, machinery for agriculture and forestry, powered lawn and garden

equipment – Symbols for operator controls and other displays - Part 2: Symbols for agricultural

tractors and machinery

ISO 11684 1995 Tractors, machinery for agriculture and forestry, powered lawn and garden

equipment – Safety signs and hazard pictorials – General principles

IEC EN 60204-1 2006 Safety of machinery. Electrical equipment of machines.

9T380D-T430D Rev. 1.0

DECLARATION OF CONFORMITY

Page left intentionally blank

Norme DECESPUGLIATRICI

10 T380D-T430D Rev. 1.0

PREFACE

Prefazione

PRELIMINARY DECLARATION

SAFETY RULES

The safety instructions provided in this manual are preceded by a hazard symbol and a caution (CAUTION, WARNING

and DANGER).

Theseprecautionsareintendedto protect personalsafetyand the safety of thoseworkingand/orpresentin the danger

zone of the machine.

Carefully read all the instructions provided in this manual.

THE WORD “CAUTION” REFERS TO SAFE CONDUCT PRACTICES BOTH IN OPERATING

AND MAINTENANCE TO BE IMPLEMENTED FOR ALL PERSONS PRESENT IN THE

DANGER ZONE OF THE MACHINE IN ORDER TO PREVENT ACCIDENTS.

CAUTION

THEWORD“WARNING”DENOTESAPOTENTIALORHIDDENDANGERTHATCANCAUSE

ACCIDENTS OR DEATH.

IT IS USED TO ENCOURAGE OPERATORS AND THE OTHER PERSONS TO USE

APPROPRIATE MEANS IN ORDER TO AVOID POSSIBLE ACCIDENTS.

WARNING

THE WORD “DANGER” DENOTES A NON-PERMITTED PRACTICE THAT CAN CAUSE

ACCIDENTS OR DEATH.

DANGER

FAILURE TO OBSERVE THE INSTRUCTIONS, ESPECIALLY THOSE PRECEDED BY CAUTION, WARNING

AND DANGER PRECAUTIONS, CAN CAUSE SERIOUS ACCIDENTS OR DEATH.

11

Rev. 1.0 T380D-T430D

PREFACE

Prefazione

PREFACE

To operate safely it is necessary to:

1) Observe the general use precautions for all mechanical equipment, which are described in Chapter 2;

2) Always follow the use instructions contained in this manual.

3) In the case of difculties in the installation, use or maintenance of the machine, contact specialised technical

personnel (Manufacturer, Dealers, Technical Assistants, etc);

4) Never remove, tamper with or modify any part of the machine unless allowed specically by this manual;

5) Repair or replace the protections and any worn or broken parts in the manner described in this manual;

6) Keep the safety decals perfectly legible;

7) Carry out maintenance operations in compliance with the instructions included in this manual;

8) Observe the safety rules established by law;

9) Always refer to qualied, authorised, adequately instructed and trained personnel.

10) Maintain all the guards in a perfect state of efciency.

All the technical measures for preventing the expulsion of objects adopted in the design

of the machines do not allow absolute safety to be achieved.

Even if the machine is used correctly, there is always the possibility that small stones,

splinters or other objects will get past the safety barriers and will be hurled a long

distance.

It is absolutely mandatory to make sure that THERE IS NOBODY INSIDE THE WORKING

RANGE OF THE MACHINE (AT LEAST 50 METRES) WHILE IT IS OPERATING.

Pay particular attention when working close to roads and/or buildings.

WARNING

Formachinesequippedwith electrical/electrohydrauliccontrolsand/oraheatexchanger

IT IS ABSOLUTELY NECESSARY to consult the assembly instructions for electrical

connection before mounting them on the tractor.

Failure to observe the above-mentioned instructions can damage the electrical system

and invalidate the warranty.

CAUTION

12 T380D-T430D Rev. 1.0

PREFACE

Page left intentionally blank

Prefazione

13

Rev. 1.0 T380D-T430D

GENERAL INFORMATION

01-INFORMAZIONI GENERALI

1 GENERAL INFORMATION

1.1 Purpose and contents of the manual

The purpose of this manual is to provide the customer with all the information necessary in order to use and manage

themachineina correct,independentandsafe manner.Themanualcontainsinformationon safety,technicalaspects,

operation, maintenance and spare parts.

Read this manual carefully and scrupulously observe the instructions provided before any use, check or operation of

the machine.

Correct use and correct maintenance contribute to the good operation and the duration of the machine.

In the event of doubts or questions, please contact the Manufacturer.

This Manual has been drawn up according to the regulations in force at the time of

printing.

CAUTION

The illustrations have a purely indicative value.

Some elements might not graphically correspond to those actually fitted on the

machine.

CAUTION

1.1.1 Who should read this manual

The Manual is intended for the operator and the technicians responsible for the maintenance of the machine.

Operators must not carry out operations meant for qualied technicians.

The instructions contained in this manual are intended for an authorised qualied technician, appropriately instructed

and trained on how to drive the tractor to which the machine is connected.

1.1.2 Updates to the manual

The information, descriptions, and illustrations contained in this manual reect the state of the art at the moment of

machine sale.

As part of the continuous commitment to improving its products and/or for market reasons, the Manufacturer reserves

the right to modify the machine for technical or commercial reasons at any moment whatsoever without prior notice

and without giving the purchaser any legal right to resolve the contract.

Any supplements must be conserved together with the manual and are to be considered as an integral part of the

manual.

1.1.3 Conservation

This manual must be kept close to the machine and away from liquids and any other substance which could cause

it to become illegible.

This manual and the Declaration of Conformity constitute an integral part of the machine up to the moment of its

disposal. If the manual is lost or becomes unreadable, request a new copy from the Manufacturer.

1.1.4 Copyrights

The copyrights for this manual are the exclusive property of FERRI srl.

The technical texts, drawings and illustrations in this manual may not be disclosed or transmitted to third parties, not

even in part, without the prior written authorisation of FERRI srl.

14 T380D-T430D Rev. 1.0

GENERAL INFORMATION

01-INFORMAZIONI GENERALI

1.2 Spare parts

It is strongly recommended to use original “FERRI” spare parts to avoid altering the technical features of the

machine.

FERRI is not responsible for any damage or injuries to the machine, persons or things due to the use of non-original

parts.

We recommend always using original spare parts and accessories.

Inadditiontoinvalidatingwarrantycoverage,theuseofnon-originalpartsandaccessories

will reduce the duration and performance of the machine.

CAUTION

15

Rev. 1.0 T380D-T430D

GENERAL INFORMATION

1.1

01-INFORMAZIONI GENERALI (Versione della macchina)

A A

A A

A

1 2

3

45

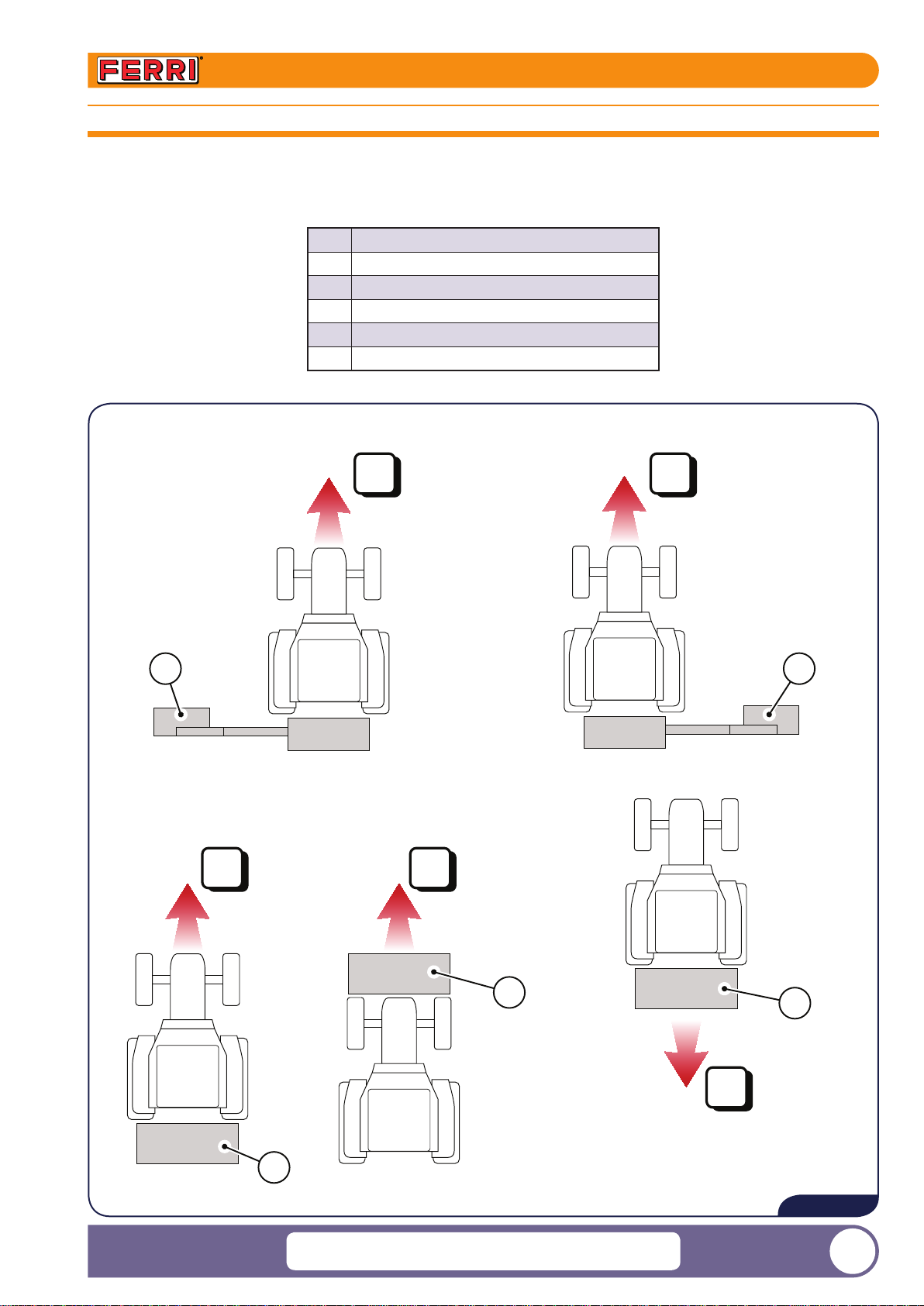

ADirection of movement

1Left machine

2Right machine

3Rear version

4Front version

5Back-face version

1.3 Machine versions

Duringwork, the machineversion variesdepending on the runningdirectionand the positionof themachinein relation

to the tractor.

16 T380D-T430D Rev. 1.0

SAFETY RULES

02-SICUREZZA GENERALE

2 SAFETY RULES

2.1 General safety rules

The machine was designed and manufactured according to appropriate safety standards. Before using the machine,

carefully follow all the precautions and instructions contained in the manual in order to avoid accidents.

►Ensure that, on the ground where you are to work, there are no large stones or rocks, protruding tree stumps,

metal elements of any kind (mesh, wires, cables, chains, tubes, etc.).

►Carefully follow the instructions for the adjustment of the machine height above ground.

►While working with the machine, ensure that there are no persons or animals within a radius of at least 50

metres.

►Never work “ush to the ground” on wet terrain. In these conditions, in fact, there is a risk of taking too much

power from the motor, lling the rotor protective casing with pressed mud, and causing excessive wear on the

ails and the drive belts, thereby compromising machine output and equilibrium.

►A tractor of appropriate power must be adopted for each machine. If a tractor with a power greater than the

machine maximum absorbable power is used, use a PTO shaft with a clutch (torque limiting device), without

which damage can be caused to the drive unit and the ail shaft.

►Examine the safety decals applied on the machine and described in this manual. To work safely, clean them

and, if they are not legible, replace them with new decals.

FERRI declines all liability for damage caused by improper use of the machine.

WARNING

Carefully check the machine before each start-up.

CAUTION

Before starting up the machine or carrying out maintenance work, carefully read all the

instructions and safety messages contained in the manual and on the machine. Carefully

follow all the accident prevention and safety rules.

CAUTION

►Before starting to use the machine you must be familiar with all its devices, controls and functions.

►Make sure that all the safety devices are in good condition and in the correct position. In the event of faults or

damage, replace them immediately.

►Before getting off the tractor and before each maintenance operation, apply the parking brake, switch off the

engine and remove the ignition key from the dashboard.

►The user is responsible for the maintenance of the machine.

►It is the responsibility of the owner to provide all the instructions to operators or employees before operating on

the machine, according to regulations of the destination country.

►Only an operator who is adequately trained and instructed on the safety rules can operate on the machine.

17

Rev. 1.0 T380D-T430D

SAFETY RULES

02-SICUREZZA GENERALE

DO NOT OPERATE on the machine if there are any persons and/or animals present within

the working range of the machine.

DANGER

Start the machine only when properly seated.

Read the instructions for starting up the machine that are contained in the operator’s

manual.

DANGER

►Always keep the manual at hand so that you can consult it quickly. If the manual is lost or damaged, request a

replacement copy from the Manufacturer.

►Disengage the power takeoff of the tractor (or self-propelled machine) before starting the motor of the

machine.

►The machine is designed to be used by only one operator.

►It is strictly prohibited to work in poor physical conditions, or under the inuence of alcohol, drugs or

medicines.

►Keep the machine clean and free from foreign bodies (debris, tools, other objects), which could cause harm to

the operator or damage to the machine.

Always wear the seat belts. Falls or overturning of the machine can cause serious

injury or death.

WARNING

This machine has been designed for use only with closed-cab tractors and/or self-

propelled machines!

In the case of a tractor with an open cab, the following are required:

1) Personal protection equipment for the operator;

2) Shielding from thrown objects;

3) Roll Over Protective Structure (ROPS) for the self-propelled vehicle.

DANGER

►Prolonged operations can cause physical and mental fatigue. Never operate the machine and tractor when

tired or in a bored mental state.

It is absolutely forbidden to climb or to ride on the machine when it is moving.

DANGER

►Ensure that the PTO shaft is correctly tted after each operation of connecting the machine.

►Disconnect the machine from the tractor only on compact level ground, ensuring that it is still and stable.

Check that the guards of the PTO transmission shaft are in good condition.

When the machine is not coupled to the power unit, place the hydraulic pipes in the

supports provided.

DANGER

►In the event of breakage or deterioration of the PTO shaft guards, replace them immediately.

►Do not use the controls or the exible pipes as handholds. These components are movable and do not offer

steady support.

►Neverwork,walkorstandundertheliftedarm.Toavoidaccidentalfalls,donotcarryout maintenanceoperations

under raised arm unless it is properly supported.

►Never use the arm to raise people or objects.

Do not, for any reason, get in between the tractor (or self-propelled machine) and the

machine with the engine running and/or the power takeoff switched on.

DANGER

18 T380D-T430D Rev. 1.0

SAFETY RULES

02-SICUREZZA GENERALE

Avoid contact with hot surfaces including:

1) Oil tank;

2) Pumps;

3) Motors;

4) Valves;

5) Gearbox;

6) Hydraulic pipe joints.

To avoid scalds and/or burns, use protective gloves and goggles during maintenance

work on hot surfaces.

WARNING

Preferably use the machine in daytime.

In conditions of reduced visibility, use the lighting system of the tractor.

If the machine is used at night:

1) Provide an auxiliary lighting system in order to guarantee good visibility in the whole work area;

2) Do not create dangerous reections for the operator;

3) Have sufcient lighting in the cab in order to guarantee identication of the controls.

Operate only in environments that are well lit by natural or articial light.

During work the operator must have visibility of at least 100 metres.

WARNING

Avoid contact with guard-rails or concrete structures so as not to damage the ails.

DANGER

Replace bent or broken ails with new ails.

Never straighten or weld the ails because doing so can reduce their strength and

compromise safety.

DANGER

Carefully inspect the area in which you will be operating and remove all debris or

foreign material in order to avoid damage to the machine, to persons and/or things.

Any objects that cannot be removed must be clearly marked and avoided by the

operator. Stop cutting immediately if the ails strike a foreign object.

WARNING

Never run the tractor engine in a closed location without adequate ventilation. The

exhaust fumes can be hazardous to health.

DANGER

ENSURE THAT THE CUTTING FLAILS HAVE STOPPED COMPLETELY BEFORE

APPROACHING THE MACHINE.

DANGER

Before leaving the tractor seat and before each maintenance operation, always engage

the parking brake and disengage the PTO. Stop the engine, remove the key from the

dashboard, and wait for all moving parts to stop.

DANGER

Never let children or other people up on top or operate the tractor or the machine. Falls

can cause serious injury or death.

DANGER

19

Rev. 1.0 T380D-T430D

SAFETY RULES

02-SICUREZZA GENERALE

The user may carry out only those maintenance operations that are described in this

manual.

WARNING

Makesuretoperformallmaintenanceoperations(routineandextraordinary)onthetractor

(or self-propelled machine) to which the machine will be connected.

WARNING

►Do not modify the equipment in any way. Unauthorised modication may impair the function and/or safety of the

machine and could affect the life of the equipment. In such a case, the user will be the only party responsible

in case of damage or injury.

Do not tamper with, remove or make inefcient the guards and/or safety devices of the

machine.

DANGER

►Use exclusively original “FERRI” spare parts.

FERRI declines all responsibility in case of:

►Improper use of the machine or use by untrained personnel;

►Serious shortcomings in the required maintenance;

►Unauthorised modications or interventions;

►Use of non-original spare parts or parts not specically intended for this model;

►Total or partial failure to observe the instructions;

►Failure to observe the common rules for safety at work;

20 T380D-T430D Rev. 1.0

SAFETY RULES

02-Norme per la circolazione stradale

2.2 Safetyrulesconcerningroadtrafc

Whenever the public road network must beused, scrupulously respect the highway code.

Pay particular attention to the speed limit.

WARNING

Observe the following rules when using the public road network with the machine coupled to the tractor (or self-

propelled machine):

►Make sure that all the lights and reectors are correctly working and positioned, clean, and clearly visible as

required by local regulations.

►Before heading out onto the road, consider installing optional light bars.

►When driving on public roads, observe all road regulations.

►Before entering public roads from muddy or unpaved terrain, clean the tires of the tractor (or self-propelled

machine) thoroughly of any residual mud.

Makesurethesteeringandbrakesofthetractor(orself-propelledmachine)areinexcellent

condition and operate properly.

DANGER

►Switch off the tractor PTO.

►Never transport the machine with the moving ail holder shaft, not even for short distances. Make sure that the

rotor control is disengaged and the moving parts of the machine have all come to a complete stop.

►Lock the machine with the safety devices provided.

►If the machine is used for verge maintenance on public roads:

1) The machine must only be driven by personnel specically instructed in safe use;

2) The safety procedures imposed by the competent Body must be adopted;

3) Follow the machine with a vehicle, positioned at a distance of approximately 20-30 metres, in order to

notify road trafc of the possible danger;

4) Place appropriate notices ahead of the machine so that vehicles arriving on the other side of the road will

be able to stay at a safe distance from the working range of the machine;

►Do not allow anyone to ride on the tractor (or self-propelled machine) or on the machine during transport.

►Reduce speed on rough roads and surfaces.

►Use rotating ashing lights on the tractor (or self-propelled machine) during the transport, unless they are

prohibited by local safety regulations.

►Make sure that the machine has been correctly installed on the tractor (or self-propelled machine) and that all

the safety pins have been mounted correctly.

►Use the lifting device of the tractor (or self-propelled machine) to raise the machine coupled to the 3-point

coupling to the maximum height above the ground.

►Test the tractor (or self-propelled machine) at low speed and then increase it slowly. Try the brakes gently to

determine the stopping characteristics of the tractor (or self-propelled machine) with the machine coupled.

Always proceed at a moderate speed, especially on rough surfaces and steep gradients,

to avoid overbalancing. The weight of the machine alters the stability of the tractor (or

self-propelled machine) and inuences its behaviour on the road, steering and braking

capacity.

Check the lifting capacity and the stability of the tractor (or self-propelled machine) to

avoid its tipping over and/or losing the grip of the steering wheels.

WARNING

This manual suits for next models

5

Table of contents

Other FERRI Lawn Mower manuals