Ferve F-1860 User manual

1

FERVE F-1860

WARNING

♦ Engines produce carbon monoxide which is odourless, causes slower

reaction time, and can lead to serious injury through inhalation. Keep service

areas WELL VENTILATED while the engine is running!

♦ Activate the handbrake and block the wheels be ore testing or repairing the

vehicle. It is especially important to block the wheels on ront-drive vehicles,

as the handbrake does not lock the drive wheels.

♦ Wear an eye shield when testing or repairing vehicles. Exceeding the limits

o the F-1860 is dangerous. It will expose you to serious or possibly atal

injury. Care ully read and take heed o the precautions described in this

instruction manual, and make sure that the established limits o the F-1860

are never exceeded.

♦ Under absolutely no circumstances must voltage exceed 1000 VDC or 750

VDC between any terminal or ground.

♦ Extreme caution must be exercised when measuring voltage above 25 VAC

or VDC.

♦ Circuits to be tested must be protected by a 20A use or circuit breaker.

♦ Do not use the F-1860 i it has been damaged.

♦ Do not use the test leads i the insulation is damaged or the cable is

exposed.

♦ Use adequate current clamps when measuring circuits in excess o 10A.

♦ To avoid electrical shock, never touch the test leads, tips or circuit while

testing.

♦ Do not make a voltage measurement with the test leads in the 20A or mA

terminal.

♦ When testing or voltage or current, make sure that the corresponding

unction o the F-1860 is the correct one. We recommend you take a test

reading o a known voltage or current be ore carrying out a speci ic unction.

♦ Choose the proper range and unction or the measurement. Do not try to

take voltage or current measurements that may exceed the ratings marked

on the unction /range switch or terminal.

♦ When measuring current, connect the F-1860 in series with the load.

♦ Never connect more than one set o leads to the F-1860.

♦ Disconnect the live test lead be ore disconnecting the common test lead

(COM).

♦ The mA and 20A terminals are protected by uses. In order to avoid possible

injury or damage, use only in circuits not exceeding 400mA, 10A continuous

or 20A or a maximum15 seconds.

IMPORTANT

♦ In order to maintain the accuracy o the F-1860, replace the battery as soon

as the battery symbol appears on the display.

♦ Avoid measuring errors rom external inter erence: keep the F-1860 away

rom spark plug cables or wire coils.

2

♦ Avoid damage to the F-1860 when testing: disconnect the test leads rom

the test points be ore changing unctions.

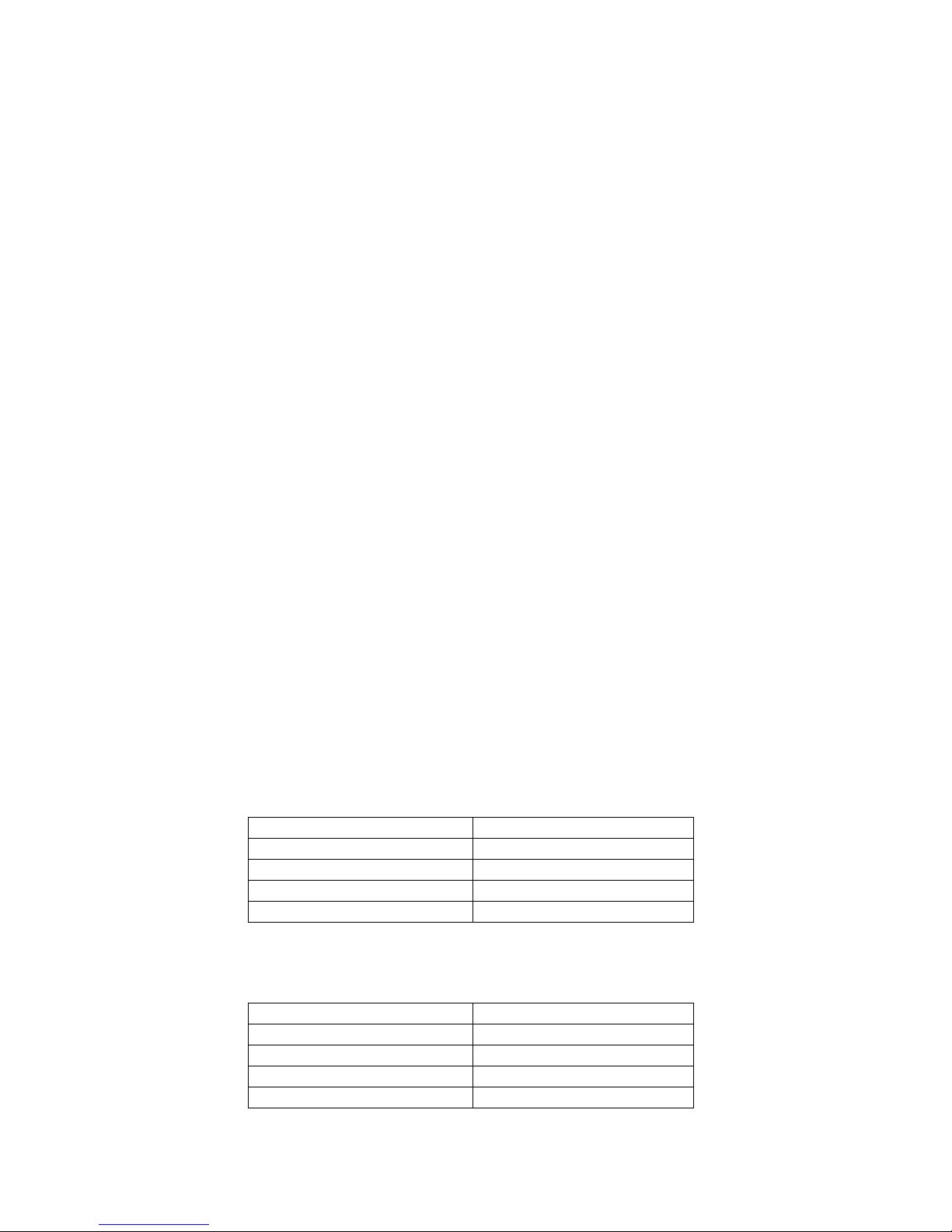

♦ Do not exceed the limits shown in the table below:

Function Terminal Input Limit

AC Volts 750 V AC rms

DC Volts V/ Ω / RPM 1000 V DC

Frequency

Ohm (resistance)

Diode

V/ Ω / RPM 500 V AC/DC

AC/DC 400 mA mA 400 mA AC/DC

AC/DC 20 A 20 A *20 A AC/DC

RPM

Duty Cycle (%)

Dwell angle

V/ Ω / RPM 500 V AC/DC

*10A continuous measurement or 20A or a maximum15 seconds

Ohms cannot be measured when voltage is present. They can only be

measured in a non-powered circuit. However, the F-1860 is protected up to

500V.

MEASURING BASICS

Protecti e Rubber Casing

The rubber casing has been designed to protect the F-1860 when accidentally

dropped. Additionally, it provides a convenient storage method or the test

probes. It is also use ul or holding one o the test probes, while leaving another

hand ree to operate the other test probe while holding the F-1860 in the other

hand. (see igure x).

3

1. Digital and Analogue Display

Display eatures:

a. Four character digital display

b. Symbols indicating unctions

c. Analogue bar graph

2. Function buttons

Press the button to select the desired unction. A

symbol con irming your selection will appear.

3. Rotary Selector Switch

Use this switch to select a unction or to turn o

the F-1860.

4. Temperature terminal

Insert the temperature probe into this terminal.

5. Test lead terminals

The black (-) test lead is used in the COM terminal

or all tests. The red (+) test lead is used to

measure Amps or Volts.

Automatic Deactivation eature

♦ Automatic Power O a ter 30 minutes o inactivity.

♦ Automatic Power can be disactivated. This eature must be set when the

F-1860 is to record data over a period o time in excess o 30 minutes. In

order to disactivate the “Power O ” mode, keep the yellow “PWR RST”

button pressed while switching on the F-1860.

Digital and Analogue Display

∗ Press HOLD to maintain data on the display

∗ Press MAX/MIN to read maximum or minimum stored values

∗ Press REL∆ to read the di erences between currently displayed reading

and stored reading.

∗ Press CYL to select number o cylinders a ter DWELL has been selected

with the rotary switch.

∗ Diode or continuity test.

∗ The F-1860 automatically selects the best range.

∗ Analogue bar graph with polarity display

∗ Press ºC / ºF to choose between degrees Celsius (ºC) or degrees

Fahrenheit (ºF).

4

∗ Negative Polarity indicator

∗ Press the blue button to choose between AC or DC current

∗ Press TRIG± to select positive (+) or negative (-) Trigger level

∗ Low battery: change the F-1860 battery when this symbol is displayed

Function and Range Selection

Turn the rotary switch in either direction to select desired unction.

The F-1860 automatically selects the range. However, you can also manually

select a speci ic unction by pressing the range button.

Always select a range higher than the expected current or voltage. A terwards a

lower range can be selected or improved accuracy.

♦ The higher the range selected, the lower the accuracy

♦ I the range is too low, the F-1860 blinks “OL” (Over Limit) and beeps.

PUSH-BUTTON FUNCTIONS

Alternate Function

The blue-coloured button is the Alternate Function button. Press this button to

alternate between AC, audible and capacitance unctions, shown in blue on the

ront o the F-1860.

REL∆

∆∆

∆ Function

Press the REL∆ Function button. The F-1860 will display the reading and store

it as a re erence value. Keep the button pressed or two seconds to exit this

mode.

In REL∆ mode, the indicated value is always the di erence between the stored

reading and the present reading. For example, i the re erence value is 24.00 V

and the present reading is 12.50 V, the F-1860 will show -11.50 V. I the new

reading is the same as the re erence value, the F-1860 will display 0.

DATA STORING

The Data Storage eature stores the highest or lowest reading in the memory.

♦ First connect the F-1860 test leads to the points to be tested. Press the

MAX/MIN key once to start MIN data storage, which will be displayed.

♦ Press the MAX/MIN key twice to start MAX data storage, which will be

displayed.

♦ Press the HOLD button to stop data storage; press again to restart the

storage.

5

Range Selection

The range is automatically selected by the F-1860. However, should you wish to

select the range manually, this can be done by pressing the RANGE button.

Range Exit

To exit the manual RANGE unction and return to automatic mode, keep the

RANGE button pressed or 2 seconds.

NOTE:

♦ I the range is too high, the readings will be less accurate.

♦ I the range is too low, the F-1860 will blink and show OL (Over Limit)

DATA HOLD

The Data Hold eature stores the last reading in the F-1860’s memory.

♦ Press the DATA HOLD button once to hold the present reading.

♦ Press the DATA HOLD button again to exit and resume readings.

Power Reset (PWR RST)

The Power Reset button switches the F-1860 back on when it has automatically

switched itsel o .

Power Off Disable

To disable the automatic power o unction, keep the PWR RST button pressed

while switching on the F-1860.

Temperature (ºC/ºF)

The temperature can be displayed in degrees Celsius (ºC) or in degrees

Farenheit (ºF).

Press the ºC/ºF button to choose between degrees Celsius (ºC) or degrees

Farenheit (ºF).

CYL Cylinder

Select the DWELL unction, then press the cylinder button to choose between

the 4, 5, 6 or 8 cylinder scale.

Trigger

Select the Duty Cycle and Pulse Width unction, then press the ±Trigger button

to choose between the negative (-) or positive (+) slope.

6

RPM / DIS

In the RPM unction the F-1860 de aults to RPM (2) or conventional 4-cycle

engines.

BASIC DIAGNOSTIC TESTING

This section takes you through a systematic series o tests that check the

vehicle’s electrical system. These tests should be carried out be ore testing

individual components.

Electrical System Diagnostics

It is important to diagnose vehicle electrical problems thoroughly and e iciently.

The series o tests that ollow check primary areas that are responsible or the

majority o the electrical problems ound in an automobile. These basic tests

should always be carried out, even i the vehicle has a trouble-shooting code

set in the computer. A component mal unction can be caused by a basic

problem in the electrical system. Simply replacing a ailed component will not ix

the problem i a de ective ground caused the component ailure.

The tests begin by checking the main source o power and the chassis ground

circuit connections. Ground circuits are are one o the least understood but

potentially most troublesome areas o automotive electronics. An excessive

voltage ground in a circuit a ects the entire electrical circuit. That is why it is o

the utmost importance that the basic circuit is checked be ore consulting

computer trouble codes and individual components.

Battery Testing

(1) Battery Surface Discharge Test

IMPORTANT:

The ignition must be switched OFF in order to avoid damage to the vehicle’s

computer while connecting or disconnecting battery cables.

Remove the positive and negative battery cables and clean the cable clamps

and the battery terminals. Reassemble and begin testing.

This ollowing test checks or a low current discharge on the battery sur ace:

♦ Set the F-1860’s rotary switch to the voltage position (V).

♦ Insert the black lead o the F-1860 into the COM socket, and the red

cable into the V/Ω

ΩΩ

Ω/RPM socket.

♦ Connect the negative (-) test lead to the negative (-) battery terminal.

7

♦ Press the F-1860’s MAX/MIN button.

♦ Move the positive (+) test lead o the F-1860 around the positive (+)

battery terminal, without touching the terminal, but skimming the

surrounding battery sur ace. Readings o more than 0.5 V indicate

excessive battery sur ace discharge. Dirt, dust, moisture and corrosion

are all common causes o battery discharge. Clean the battery sur ace

with a baking soda and water solution, taking care that none o the

solution makes its way into the battery.

(2) Static Battery Test (No load)

This test checks the battery charge state.

Turn the vehicle’s headlights on or 15 seconds to dissipate battery sur ace

charge.

IMPORTANT:

The ignition must be switched OFF in order to avoid damage to the vehicle’s

computer while connecting or disconnecting battery cables.

Disconnect the negative (-) battery cable rom the battery.

♦ Set the F-1860’s rotary switch to the voltage position (V).

♦ Insert the black lead o the F-1860 into the COM socket, and the red

cable into the V/Ω

ΩΩ

Ω/RPM socket.

♦ Connect the positive (+) test lead to the negative (-) battery terminal.

Readings under 12.4 V indicate an undercharged battery. Recharge the battery

be ore urther testing.

NO LOAD TEST FOR STANDARD BATTERIES

F-1860 Reading Battery charge

12.70 V 100%

12.54 V 75%

12.30 V 50%

12.18 V 25%

NO LOAD TEST FOR GEL BATTERIES

F-1860 Reading Battery charge

13.00 V 100%

12.75 V 75%

12.50 V 50%

12.25V 25%

8

(3) Battery Test (Parasitic Load)

NOTE:

Keep the battery disconnected for this test.

This test is or excessive parasitic drain on the battery.

Keep the ignition OFF.

IMPORTANT:

Do not start the vehicle during this test; the F- 860 may be damaged as a

result.

♦ Set the F-1860’s rotary switch to the 20A position.

♦ Insert the black lead into the COM socket and the red cable in the F-1860’s

20 A terminal.

♦ Disconnect the positive (+) cable rom the battery.

♦ Connect the positive (+) test lead o the F-1860 to the positive (+) battery

terminal.

♦ Connect the negative (-) test lead o the F-1860 to the negative (-) battery

terminal.

♦ Press the MAX/MIN button on the F-1860.

Parasitic readings should not exceed 100 mA.

I parasitic readings are in excess o this value, remove the circuit uses one by

one, until the ault is located. Also check all non- used applications such as

headlights, relays and capacitors in the instrument panel.

Reconnect the battery cable or the next test.

(4) Battery Test (Load)

This tests the battery’s capacity to deliver su icient cranking voltage.

♦ Set the F-1860’s rotary switch to the voltage position (V).

♦ Connect the positive (+) test lead to the positive (+) battery terminal.

♦ Connect the negative (-) test lead to the negative (-) battery terminal.

♦ Press the MAX/MIN button on the F-1860.

9

♦ Disable the ignition; crank the engine or 15 seconds.

Check the Min. reading. I this reads less than 9.60 V at 21ºC, the battery is

weak. Recharge or replace be ore urther testing.

F-1860 Minimum reading Ambience temperature

10.0 V 33ºC

9.8 V 27ºC

9.6 V 21ºC

9.4 V 16ºC

9.2 V 10ºC

9.0 V 4º C

8.8 V -1ºC

8.6 V -7ºC

NOTE:

For each 6ºC above or below 2 ºC, add or subtract 0.2 V.

Voltage Drop Testing

Resistance; what is it?

Resistance is an opposing orce to the low o electrical current, created by a

circuit or component.

A small amount o natural resistance is encountered when voltage lows through

wires, switches, grounds, or connections. This resistance increases beyond

acceptable limits i corrosion develops, ittings become loose or wires ray.

Resistance increases every time that something is added to the circuit, such as

wire, switches, connections, ground, etc.

Voltage Drop; what is it?

Voltage drop is the di erence in voltage potential when measured across a

circuit or component creating resistance.

The resistance decreases the amount o voltage available. Bulbs will not light

up nor will the engine turn over i the voltage is too low.

Maximum Voltage Drop

Maximum voltage drop should not be more than 0.1 V per wire, ground,

connection or solenoid.

What should be tested?

Each wire, ground, connection or solenoid as well as the complete circuit should

be tested. Each connection point is a potential source o increased resistance.

Voltage Drop Testing

(1) Negati e (-) Engine Ground

10

This test checks or e iciency o engine ground.

♦ Set the F-1860’s rotary switch to the voltage position (V).

♦ Insert the black lead o the F-1860 into the COM socket, and the red

cable into the V/Ω

ΩΩ

Ω/RPM socket.

♦ Touch the positive (+) lead to the positive (+) battery terminal and the

negative (-) lead to the negative (-) battery terminal. Take note o the

reading, which will be the starting re erence or uture readings.

♦ Conect the positive (+) lead o the F-1860 to a clean screw on the engine

block.

♦ Connect the negative (-) lead o the F-1860 to the negative (-) battery

terminal.

♦ Press the MAX/MIN button on the F-1860.

♦ Disable the ignition so the engine doesn’t start; crank the engine or 2-3

seconds.

A voltage drop in excess o 0.5 V indicates de ective ground.

Clean and inspect the battery cable connections and the ground, and test again.

IMPORTANT:

Repeat this test when the engine is completely warmed up. Heat expansion

may cause increased resistance.

(2) Negati e (-) Chassis Ground

This test checks or chassis ground e iciency.

♦ Set the F-1860’s rotary switch to the voltage position (V).

♦ Insert the black lead o the F-1860 into the COM socket, and the red

cable into the V/Ω

ΩΩ

Ω/RPM socket.

♦ Keep in mind the commented re erence reading rom the previous engine

ground test.

♦ Connect the test lead to the point in the wheel arch or wherever the

vehicle’s ground is connected.

♦ Connect the negative (-) lead o the F-1860 to the negative (-) battery

terminal.

11

♦ Press the MAX/MIN button on the F-1860.

♦ Turn on all the accessories such as headlights, ventilator an, heated rear

window, windscreen wipers....

♦ Disable the ignition so the engine doesn’t start; crank the engine or 2-3

seconds.

A voltage drop in excess o 0.5 V indicates de ective ground.

Clean and inspect the battery cable connections and the ground, and test again.

(3) Battery Power to Starter Solenoid (+)

This test checks battery source e iciency to the starter solenoid.

.Set the rotary switch to Voltage.

.Establish the base voltage that you will compare test voltage against (see base

voltage, Volt Drop Test [1]).

.Connect the positive (+) lead to the positive (+) battery terminal.

.Connect the negative (-) lead to the positive (+) terminal on the starter

solenoid.

.Set the Min/Max eature on the meter.

.Disable the ignition so the engine doesn't start; crank the engine or 2-3

seconds.

A voltage drop o more than 0.3 volts would indicate a poor ground circuit.

Clean and inspect the battery cables and cable connections; test again.

(4) Battery Power to Complete Starter Circuit (+)

This test checks battery power e iciency to the starter through the starter

solenoid.

.Set the rotary switch to Voltage.

.Establish the base voltage that you will compare test voltage against (see base

voltage, Volt Drop Test [1]).

.Connect the positive (+) lead to the positive (+) battery terminal.

.Connect the negative (-) lead to the positive (+) terminal on the starter motor.

.Set the Min/Max on the meter.

12

.Disable the ignition so the engine doesn't start; crank the engine or 2-3

seconds.

A voltage drop o more than 0.8 volts would indicate a poor ground circuit.

Clean and inspect the battery and starter cables, solenoid and cable

connections; test again.

Note: A de ective starter solenoid may cause an excessive voltage drop; check

the cables and connections be ore replacing the solenoid.

Important: Repeat this test when the engine is thoroughly warmed up. Heat

expansion o metal may cause resistance to increase.

Charging System Tests

[1]Battery (+)

This test checks tor alternator output voltage at the battery.

.Set the rotary switch to voltage.

.Connect the positive (+) lead to the positive (+) battery terminal.

.Connect the negative (-) lead to the positive (+) battery terminal.

.Set the MiniMax teature on the meter.

.Mark sure all vehicle accessories are turned OFF.

.Start the engine and hold at 1500 RPM.

A reading ot 13.1 -15.5 volts is an acceptable charging rate. It the voltage is low

check tor:

.Loose, cracked, or glazed drive belt.

.Loose or tau!ty wires or connectors.

.De ective alternator or regulator. See [2] Alternator Voltage Output (+),

Loaded.

[2]Alternator Voltage Output (+), loaded

This test checks or alternator output voltage. This test is necessary only i

the vehicle ailed [1] Battery (+) test.

.Set the rotary switch to the Voltage setting.

.Connect the positive ( + ) lead to the battery (B+ ) output post on the back ot

the alternator.

13

.Connect the negative (-) lead to the negative (-) battery terminal.

.Set the MinIMax eature on the meter.

.Start the engine and hold a 1500 RPM.

A reading o 13.1-15.5 volts is an acceptable charging rate.

Ignition System Tests

[1] Ignition Coil, Primary Resistance Test (Ω)

This test checks primary winding resistance.

IMPORTANT: Test the ignition coil cold and hot.

.Set the rotary switch to the Resistance (Ω) setting.

INSERT:

.Black lead in COM terminal.

.Red lead in V/Ω/RPM terminal.

.Disconnect the coil rom the vehicle wiring harness.

.NOTE: The resistance in the meter leads must be subtracted to get an

accurate measurement at the 0.50-2.0 range. Short the leads together

and press the ZERO ∆ Button. The meter will automatically subtract the

resistance in the leads.

.Connect the negative (-) lead to the negative (-) terminal on the coil.

.Connect the positive (+) lead to the positive (B+) terminal on the coil.

Typical measurements are between 0.50-2.0 Ω's consult the manu acturer's

speci ications or required resistance measurements.

[2] Ignition Coil, Secondary Resistance Test (Ω

ΩΩ

Ω)

This test checks secondary winding resistance.

IMPORTANT: Test the ignition coil cold And hot.

.Set the rotary switch to the Resistance (Ω) setting.

INSERT:

.Black lead in COM terminal.

.Red lead in V/Ω/RPM terminal.

14

.Disconnect the coil rom the vehicle wiring harness.

.Connect the negative (-) lead to the high tension terminal on the coil.

.Connect the positive (+) lead to the positive (B+) terminal on the coil.

Typical measurements are between 6,000-30,000 'S Consult the manu acturer's

speci ications or required resistance measurements.

[3] Secondary Ignition Wire Resistance Test (Ω

ΩΩ

Ω)

This test checks or open circuits or high resistance in the secondary

(sparkplug) wires.

IMPORTANT: Twist and bend the sparkplug wire while measuring the

resistance or this test.

.Set the rotary switch to the Resistance (Ω) setting.

INSERT:

Black lead in COM terminal.

Red lead in V/Ω/RPM terminal.

.Connect the test probes to opposite ends o the sparkplug wire.

.Set the MinIMax eature o the meter.

Typical measurements are approximately 1,000 Ω 's per inch o wire. For

example, 10 inch cable = 10.000 Ω.

[4] Distributor Cap/Rotor Resistance Test (Ω

ΩΩ

Ω)

This test checks or open circuits or high resistance in the distributor cap and

rotor.

Set the rotary switch to the Resistance (Ω).

INSERT:

Black lead in COM terminal.

Red lead in V/Ω/RPM terminal.

Dist. Cap Center connector Test:

Connect the test probes to opposite ends o the distributor cap terminal in

general, resistance (Ω) should be 0.1 (Ω) or less. Re er to the manu acturer's

speci ications.

Rotor Test:

Connect the test probes to opposite ends o the rotor contacts.

15

In general, resistance should be 0.1 (Ω) or less. Re er to the Manu acture's

speci ications.

[5] Pick-up Coil Resistance (Ω

ΩΩ

Ω)/ Voltage Test (Ω

ΩΩ

Ω)

The resistance test checks or open circuits or high resistance.

The Voltage test compares voltage output to resistance.

Test procedure

Set the rotary switch to the Resistance (Ω).

INSERT:

Black lead in COM terminal.

Red lead in V/Ω/RPM terminal.

Connect the test probes to the pick-up coil lead

Resistance Specifications

The majority o the pick-up coils will test between 500-1500 Ω 's resistance. See

manu acture's speci ication or required range.

Set rotary switch to volts. Press the Blue, Alternate Function button to select

AC.

Crank engine 10-15 seconds at normal speed; measure voltage.

Resistance Test/Voltage output

Resistance (Ω) on a "good" pickup coil will match AC output voltage (Ex., 950

Ω's = 950mV output). Resistance can be good but voltage low i the magnet has

lost magnetism or i the reluctor is too ar rom the stator (Airgap).

Basic Diagnostic Testing

This chapter describes a computer controlled sensor and actuator system

typically Found on today's automobile.

Test procedures are also provided or the basic ground o electrical input and

output components commonly ound in a computer controlled automotive

system. The test procedures are, due to the complexity o components, general

theory tests. Be sure to consult the vehicle service manual or component

schematics and test speci ications.

Computer Controlled Systems

16

A need or better uel economy and lower emissions resulted in today’s

automobiles Utilizing computer controlled unctions that were previously

activated by mechanical, Electrical and vacuum devices.

Computerized vehicle control systems are made up o three basic component

groups. These groups are:

Sensors: they are input devices that supply in ormation about engine operating

conditions and the surrounding environement to the vehicle computer.

Engine Control Module: a vehicle computer that processes the in ormation

supplied by the sensors, then sends an electronic command to the appropriate

components actuators.

Actuators: these are output devices that may be electrical, mechanical or

vacuum components controlled by the vehicle computer.

Typical Sensors

Coolant sensor

Vacuum sensor

Throttle position sensor

RPM

Barometric sensor

Oxigen sensor

Actuators

Fuel injection

Ignition spark advance

Air pump

Exhaust gas recirculeting valve

Canister purge

Converter clutch

Basic Diagnostics for the Computer Controlled Engine

There are two important steps that must always be ollowed when diagnosing

and repairing vehicles with computer controls.

Do basic engine diagnostics irst. Many problems can be traced to lack o

routine maintenance on components such as plug wires, ilters and spark plugs.

Also check or vacuum leaks on any vehicle, new or old, A completes engine

diagnosis should precede any electrical system diagnostics.

Follow the published diagnostic Charts EXACTLY through every step to mark a

repair on computer component.

Self-Diagnostic Computer Systems

One o the unctions o the vehicle computer is to record ault codes produced

when a sensor or actuator ails. These ailures are usually displayed as a

"Current Code" or as an "History Code". Current codes are urther grouped into

17

"Hard Failures" and "Intermittent Failures". Be aware, however, that some

vehicle manu acturers use di erent terminology and older vehicles do not have

all o the ground o codes described.

Current Codes are aults that are active.

Hard Failure causes the dash "Check / Engine" light to remain ON.

Intermittent Failure causes the dash "Check Engine" light to licker and then go

OFF a ter a short period o time. Generally the trouble code stays in the

computer memory.

History Codes are stored codes or aults that have occurred in the past.

Failure Codes

When a ailure is detected b the computer, it stores the in ormation in the orm

o "Fault Codes" (also known as Trouble Codes or Service Codes). These Fault

Codes are usually a two or three digit number that identi ies the electrical circuit

e ected. Once these codes have been read the vehicle repair can be stared. Be

sure to closely ollow the vehicle service manual diagnostic precedures, repairs

and speci ications.

Component Testing

Component testing with a meter generally requires detailed schematics and

speci ications that are provided by the manu acture. The ollowing section

provides general in ormation or the main groups o sensors (input) devices and

actuators (output) devices.

The primary input devices (sensors) are:

Temperature sensors

2-wire devices

3-wire devices

Oxygen sensor

Pressure sensors

Primary output devices (actuators) are a orm o an electromagnet that is either

ON or OFF.The ON/OFF signal, in general, will be in one o three

con igurations:

ON o OFF only (switch)

Pulse width in a speci ied length o time ( uel injector)

Duty cycle measured in percent o high or low time or dwell degrees

(mixture control solenoid)

Duty Cycle, What is it?

Duty Cycle is the percentage (%) o time

a voltage is positive campared to negative: ON compared to OFF. For example;

duty cycle measurements are used or Mixture control solenoids. The amount o

ON time is measured as a percent o the total ON/OFF cycle. The meter can

18

read the negative (-) or positive (+) slope and display it as a percent (%) o the

total cycle.

Frequency (Hz), What is it?

Frequency is the number o times a voltage pattern repeats positive compared

to negative: ON compared to OFF, during one (1) second o time. For example;

requency (Hz) measurements are speci ied or digitally controlled mani old

Absolute Pressure sensors. The requency o the ON/OFF signals per second

are measured and displayed.

Frequency (Hz) is shown as Analog: A continuous positive to negative cycle; or

Digital: A positive to negative/ON Dig to OFF cycle.

Pulse Width. What is it?

Pulse width is the length o time an actuator is energized. Foe example; uel

injectors are activated by an electronic pulse rom the engine control module.

This pulse generates a magnetic ield that pulls the injector nozzle valve open.

The pulse ends and the injector nozzle is closed. This "open to close" time is

the pulse width and is measured in milliseconds (mS).

Typical Port uel injectors (PFI) operate with

a single ON to OFF electrical pulse.

Typical Port Throttle Body injectors (TBI) operate with an ON to HOLD to OFF

electrical pulse. This method creates a double electrical "spike". An oscilloscope

is required to measure this type o pulse.

Maintenance

Fuse and Battery Replacement

WARNING:

Avoid electrical shock; remove test leads be ore opening case.

Do not operate the meter or rotate the meter switch when the case is open.

1. To replace a battery or use, loose the three screws in the case back and

remove the case by li ting up and orward.

Replace the battery with an 9 volt alkaline battery.

2. To replace use, irmly grasp the printed circuit board (PC boards by the

edges and li t up and out o the case.

IMPORTANT:

To prevent contamination o the circuits, your hands must be clean and the

printed circuit board must be help by the edges.

Replace the use with the same type o use.

20A is a F20A, 500V high energy, ast acting use.

mA is a F500mA ,250V high energy, ast acting use.

Make sure the replacement use is centered in the use holder.

Care ully re-insert the PC boards into the case. Re-assemble the case, then

asten the three screws.

Trouble Shooting

Meter will not turn ON.

19

Check the battery contacts or a tight it.

Check or a minimum battery voltage o 8.0 volts.

Mark sure the battery wire, are not pinched in the ca e.

Ampere reading is erratic or there is no reading at all.

Disassemble the me~er back cover and test the uses or continuity.

Meter reading is erratic.

Printed circuit board contaminated rom handling with hands.

Low battery.

Open circuit in a test lead ( rayed or broken wire).

Wrong range selected.

For requencies below 1 Hz, the display will show 00.00 Hz.

"Blown" use.

Meter reading do not change.

"Hold" eature is still toggled ON.

Table of contents