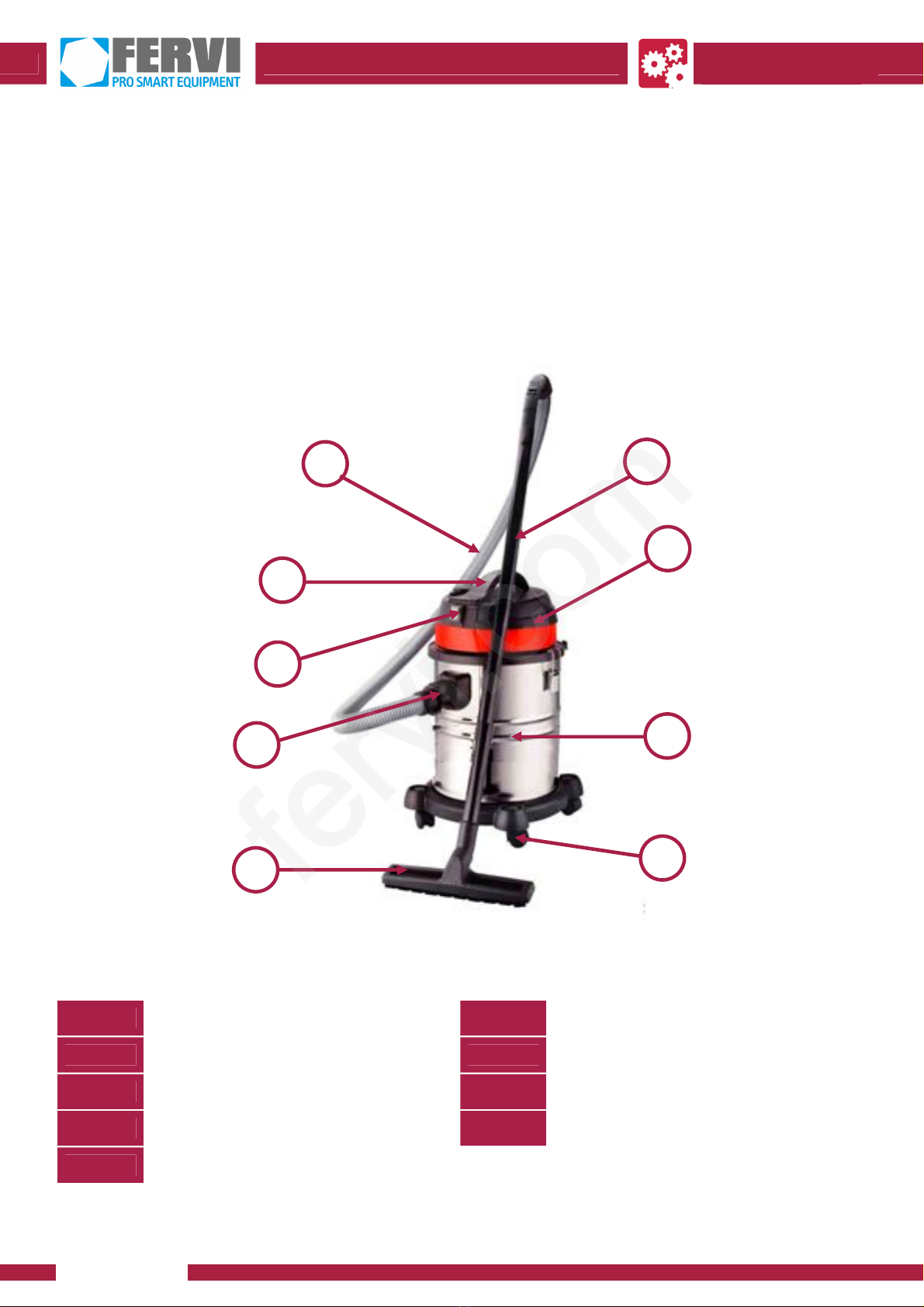

ACCESSORIES

Page 4 of 27

All rights are reserved of reproduction and dissemination of this Technical Manual and documentation cited and/or attached. It is expressly forbidden to reproduce, publish or distribute any information from this Manual. Copyright by FERVI

This manual is delivered with the machine, and it must be regarded as an inseparable part of

it.

The manufacturer holds all ownership to material and intellectual property of this manual;

any disclosure or copying, even partial, of this publication without prior written consent is

forbidden.

The purpose of this manual is to provide the knowledge necessary for the use and

maintenance of the Industrial wet and dry vacuum cleaner Art. A030/30A and create a

sense of responsibility and knowledge of the possibilities and limits of the device entrusted to

the operator.

As the machine is entrusted to experienced and skilled operators, the following machine must

be perfectly known by the operator if it is to be used safely and effectively.

Operators must be properly trained and prepared, so make sure that this manual is read and

consulted by the staff responsible for commissioning, operation and maintenance of the Wet

and dry vacuum cleaner. This is to make all operations the safest and most effective possible

for those who carry out these tasks.

Therefore, it is imperative to strictly comply with the requirements in this manual, a

necessary condition for safe and satisfactory operation of the machine.

Before starting operation, installation and usage of the Wet and dry vacuum cleaner,

authorised personnel must therefore:

carefully read this technical document;

know which protections and safety devices are available on the machine, their location

and how they work.

The buyer is responsible for ensuring that users are properly trained, that they are aware of

all the information and instructions in this document and that they are aware of the potential

risks of operating the Wet and dry vacuum cleanerIndustrial wet and dry vacuum cleaner

with accessories.

The manufacturer waives any and all responsibility for damage to people and/or

things caused by non-observance of the instructions in this manual.

The Wet and dry vacuum cleaner was designed and built with mechanical guards and safety

devices designed to protect the operator/user from possible injury. It is strictly forbidden to

modify or remove guards, safety devices and caution labels. If this must be done (for

example, for cleaning or repair), make sure that no one can use the machine.

Modifications to the machine carried out by the user must be considered their sole

responsibility, therefore the manufacturer waives any and all responsibility for any

damage caused to persons and/or property resulting from maintenance performed

by unqualified personnel and in a manner unlike the operating procedures shown

below.