FES FES-LAK-M100 User manual

FES MOTOR MANUAL

Version 1.41

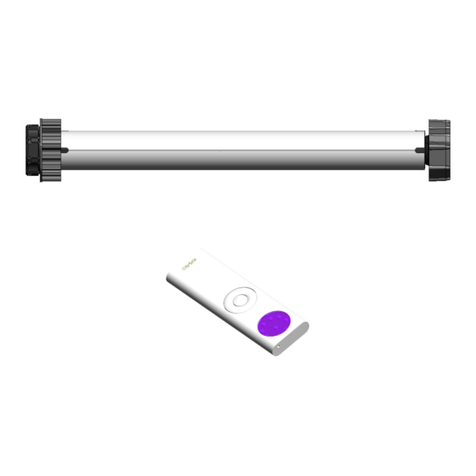

Type: FES-LAK-M100

LZ design d.o.o., Brod 3D, 1370 Logatec, Slovenia tel +386 59 948 898

UAB Sportinė Aviacija ir Ko, Debesu str.16, Pociunai LT-59327, Prienai, Lithuania

UAB „SPORTINE AVIACIJA ir KO“

Chief designer

_________________/K. Juočas/

2017-10-18

FES-LAK-M100 MOTOR manual Version 1.41 October 2013

Page 2 of 10

Table of Content

1. Important notices.....................................................................................................3

1.1 Limited Warranty.................................................................................................3

2. General....................................................................................................................4

2.1 Warnings, cautions and notes...............................................................................4

3. Model designation ....................................................................................................4

4. Technical data and limitations of motor......................................................................5

5. Drawing of motor.....................................................................................................7

6. Maintenance ............................................................................................................8

7. Removal of motor.....................................................................................................9

8. Installation of motor.................................................................................................9

9. Repair and service.................................................................................................. 10

10. Revision history.................................................................................................... 10

FES-LAK-M100 MOTOR manual Version 1.41 October 2013

Page 3 of 10

1. Important notices

Please read this manual thoroughly. It contains important information about your

system, having a vital importance to the flight safety.

1.1 Limited Warranty

This motor is warranted to be free from defects in materials or workmanship for two

years from the date of purchase. Within this period, LZ design will, at its sole option,

repair or replace any components that fail in normal use. Such repairs or replacement will

be made at no charge to the customer for parts and labour, the customer shall be

responsible for any transportation cost. This warranty does not cover failures due to

abuse, misuse, accident, or unauthorised alterations or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED OR STATUTORY, INCLUDING

ANY LIABILITY ARISING UNDER ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, STATUTORY OR OTHERWISE. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS, WHICH MAY VARY FROM STATE TO STATE.

IN NO EVENT SHALL LZ DESIGN BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT

OR CONSEQUENTIAL DAMAGES, WHETHER RESULTING FROM THE USE, MISUSE, OR

INABILITY TO USE THIS PRODUCT OR FROM DEFECTS IN THE PRODUCT. Some states do

not allow the exclusion of incidental or consequential damages, so the above limitations

may not apply to you. LZ design retains the exclusive right to repair or replace the unit or

software, or to offer a full refund of the purchase price, at its sole discretion. SUCH

REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF

WARRANTY.

To obtain warranty service, contact your local LZ design dealer or contact LZ design

directly.

February 2013 © 2013 LZ design. All rights reserved

FES-LAK-M100 MOTOR manual Version 1.41 October 2013

Page 4 of 10

2. General

Congratulations on your purchase. This is a high-end product of brushless

synchronous permanent magnet motor with electronically controlled commutation system

3 phase, which will keep its capability for a long time if treated the right way.

The drive was developed and very elaborately tested by Ing. Matija Žnidaršič and

Ing. Luka Žnidaršič.

The development objective was to build suitable motor for FES application which

must be light and small enough to fit into sailplane front part of fuselage, but very

powerful providing specific performance at highest efficiency.

This motor allows a gearless drive without the usually essential gear unit which cause

power losses, additional weight, complexity and maintenances.

Because of the little internal resistance of the motor, very good performances are achieved

in a wide range and at an excellent efficiency.

Though many intensive tests had already been made and though the parts were

produced by modern CNC machines, the drive is still not a real series product.

Some manufacturing processes like windings are made by hand, what makes every drive

of the first series unique.

2.1 Warnings, cautions and notes

The following definitions apply to warnings, cautions and notes used in this manual.

Warning: Means that the non-observation of the corresponding procedure

leads to an immediate or important degradation of the flight safety.

Caution: Means that the non-observation of the corresponding procedure

leads to a minor or to a more or less long term degradation of the flight

safety.

Note: Draws the attention to any special item not directly related to safety

but which is important or unusual.

3. Model designation

Motor model designation is the following:

FES-LAK-M100

(1)

(2)

(3)

where:- (1) motor application

- (2) designed for sailplane model; LAK17A, LAK17B

- (3) approximate motor length in mm

Motor serial-number is identified as number which follows model designation

sn: XXX

Motor identification numbers are engraved into rear Aluminum plate of motor.

FES-LAK-M100 MOTOR manual Version 1.41 October 2013

Page 5 of 10

4. Technical data and limitations of motor

Motor construction is outrunner BLDC brushless synchronous permanent magnet

motor with electronically controlled commutation system 3 phase. Rotor position is

determined by 3 hall sensors and additional 4th hall sensor for automatic propeller

positioning.

This motor can work only in combination with suitable electronic Controller which

transform DC current from Battery packs to 3 phase current which supply motor. We use

controller type which needs hall position sensors in motor, but this motor can work also

with some sensorless controllers.

Electrical motor type FES-LAK-M100 power ratings at 116V on motor controller and

loaded with FES-LAK-P10-100 propeller:

Maximum torque

75 Nm

Maximum current

200A

Maximum Voltage

180V

Rpm non loaded

45 rpm/V

Rpm non loaded (at 116V DC on Controller)

5300 rpm

Non loaded motor current (at 5300 rpm)

16-18 A

Rpm loaded with FES-LAK-P10-100 propeller (1m diameter)

4500 rpm

Battery current loaded (4500 rpm, 116V) with FES-LAK-P10-100

up to 200 A

Rotor rink diameter

177mm

Motor length

100mm

Motor weight cca.

7,3 kg

Motor efficiency

82-95 %

Maximum allowed temperature

90 °C

Minimum allowed starting temperature

-20 °C

Power load on motor P (kW) is dependable of propeller diameter, geometry, pitch

and its rotation speed n (RPM-rotation per minute). However rotation speed of motor is

than dependable on available Voltage on controller. Higer Voltage, higher rpm!

With small propeller (1m) and high Rpm (4500 Rpm) at 116V motor is loaded with

190A. This motor is mostly suitable for smaller, and faster rotating propellers!

Maximum continuous current is mostly dependable of how good cooling can be

provided to motor.

FES-LAK-M100 MOTOR manual Version 1.41 October 2013

Page 6 of 10

Power Consumption

0; 0

Horizontal flight

Max climb

0

5

10

15

20

25

0 1000 2000 3000 4000 5000

n (RPM)

P (kw)

Power consumption curve

Rpm versus Power at 116V

FES-LAK-M100 MOTOR manual Version 1.41 October 2013

Page 7 of 10

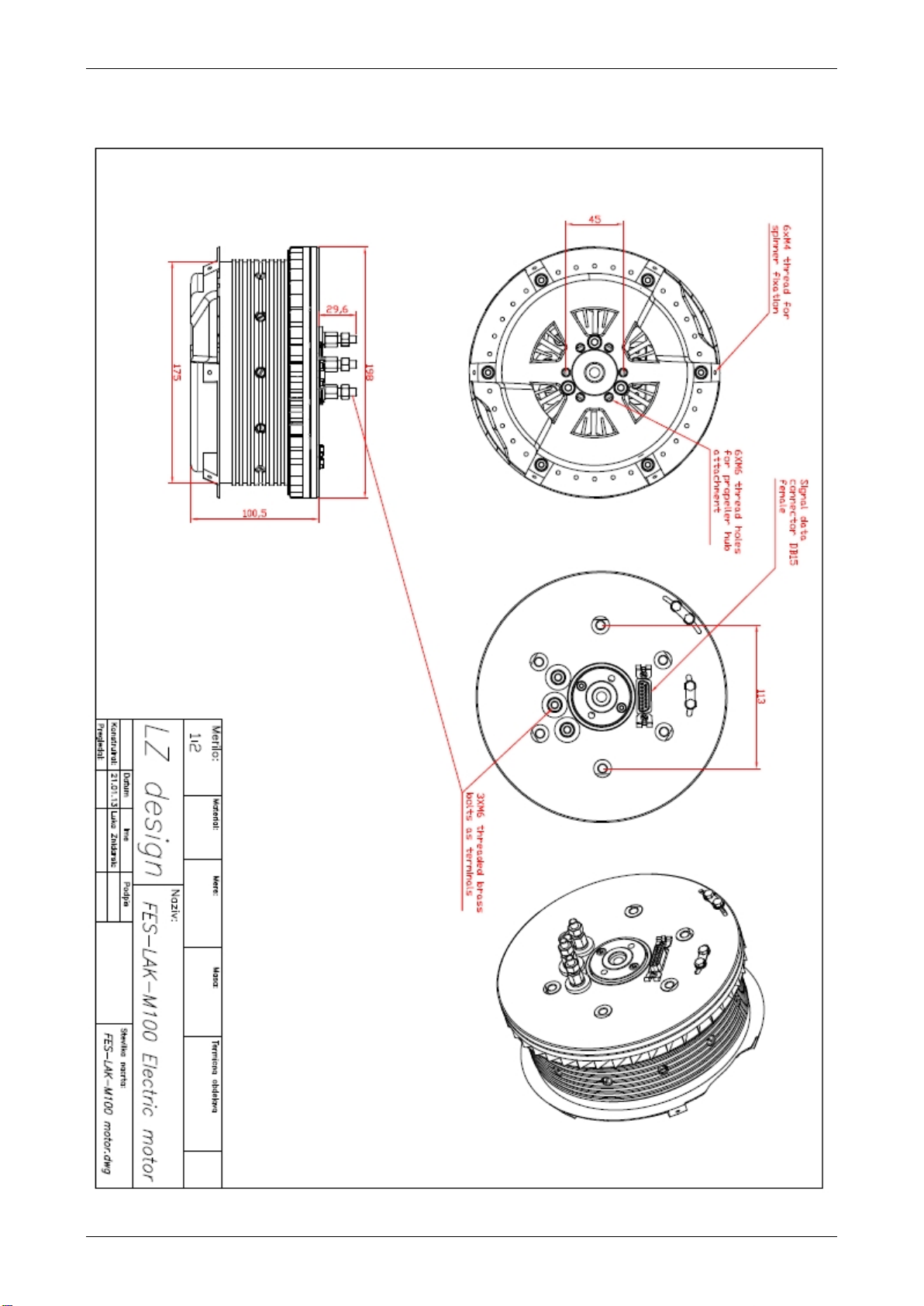

5. Drawing of motor

FES-LAK-M100 MOTOR manual Version 1.41 October 2013

Page 8 of 10

6. Maintenance

The motor do not need any maintenance. Opening or disassembling of the

motor would cause a forfeit of warranty claims! It could be also very

dangerous, due to very strong magnets on rotor!

Though, it has to be considered that no foreign objects at all can enter the interior of

the drive.

Further, it is necessary to protect the motor from humidity, dirt, paint, glues etc. If

this is ignored, a proper functionality of the motor can not be guaranteed and irreparable

damages are possible. In case of damage, ship the drive back to the manufacturer for

repairs. Unintended handling leads to secondary damages.

Keep magnetic memory cards or electronic devices out of the rotor’s close-up range,

because the alternating magnetic field can cause a delete of data. Be also careful with

medical devices (e.g. pacemakers) which are sensitive to alternating magnetic fields.

The small gap between the stator and the magnets of the rotor function-bound has a

thickness of only a few tenth millimeters. Here, the danger of foreign objects accumulating

in this gap exists but can be heard by scratching-sounds. In this case spinner should be

removed and the motor should be blown-out with compressed air. Do not at all simply

keep on using the drive. Be especially aware of cuttings which can almost irremovably

stick to the magnets. In this case, the only thing that helps is a disassembly of the drive

by the manufacturer.

FES-LAK-M100 MOTOR manual Version 1.41 October 2013

Page 9 of 10

7. Removal of motor

Note: Removal of motor from sailplane is only allowed in case of written

permission from manufacturer otherwise warranty is not valid any more!

Warning: It is not allowed to fly with removed motor from the sailplane, as

C.G. position change significantly!

To remove the motor from the glider (complete with spinner and propeller)

1. Open ventilation (fully forward position)

2. Remove round laminated cover from center of front motor mounting rib (from

cockpit side)

3. Unlock springs which hold DB15 cable connector and than carefully unplug

connector from motor rear wall.

4. Unscrew 3 self-locking nuts from rear motor wall and disconnect 3 power cables.

Before disconnection is recommended to mark them as A, B, C, and draw their position

against each other on list of paper.

5. Unsecure six M8 bolts and unscrew them out. One of M8 bolts which is below

powers wires have lower head. Hold motor assembly, and carefully take it out of fuselage.

8. Installation of motor

To install motor back to the glider, follow the reverse order.

Take care about additional steps:

1. Open ventilation fully-lever pushed forward.

2. It is recommended to use new bolt securing plates to secure M8 motor fixation

bolts.3. Make sure that power cables are connected in the same order A, B, C like before

and use only new M6 self-locking nuts. Make sure that there is no contact between cable

shoes aluminum mounting wall or M8 fixing bolts. Below cables must be M8 bolt with

shorter head.

4. Carefully plug in signal wires connector into motor rear wall connector. Lock

springs which hold connector in place.

After motor is reinstalled, check the following:

Spinner is in the center of fuselage.

Gap between spinner and fuselage is 0,5-1mm

All bolted connections assembled correctly and secured properly

Start the motor on a ground and run it for a few seconds to check:

Motor rotating direction, smooth run of motor

Braking of propeller works OK

FCU instrument is functioning properly;

FES-LAK-M100 MOTOR manual Version 1.41 October 2013

Page 10 of 10

9. Repair and service

In case of a fault or damage(s), contact manufacturer.

10. Revision history

February 2013

Initial release of manual v1.4

October 2013

Update to v 1.41

Table of contents

Other FES Engine manuals

Popular Engine manuals by other brands

Volvo Penta

Volvo Penta 3.0 GS Operator's manual

CAB

CAB PRESTIGE PS2.60FA User handbook

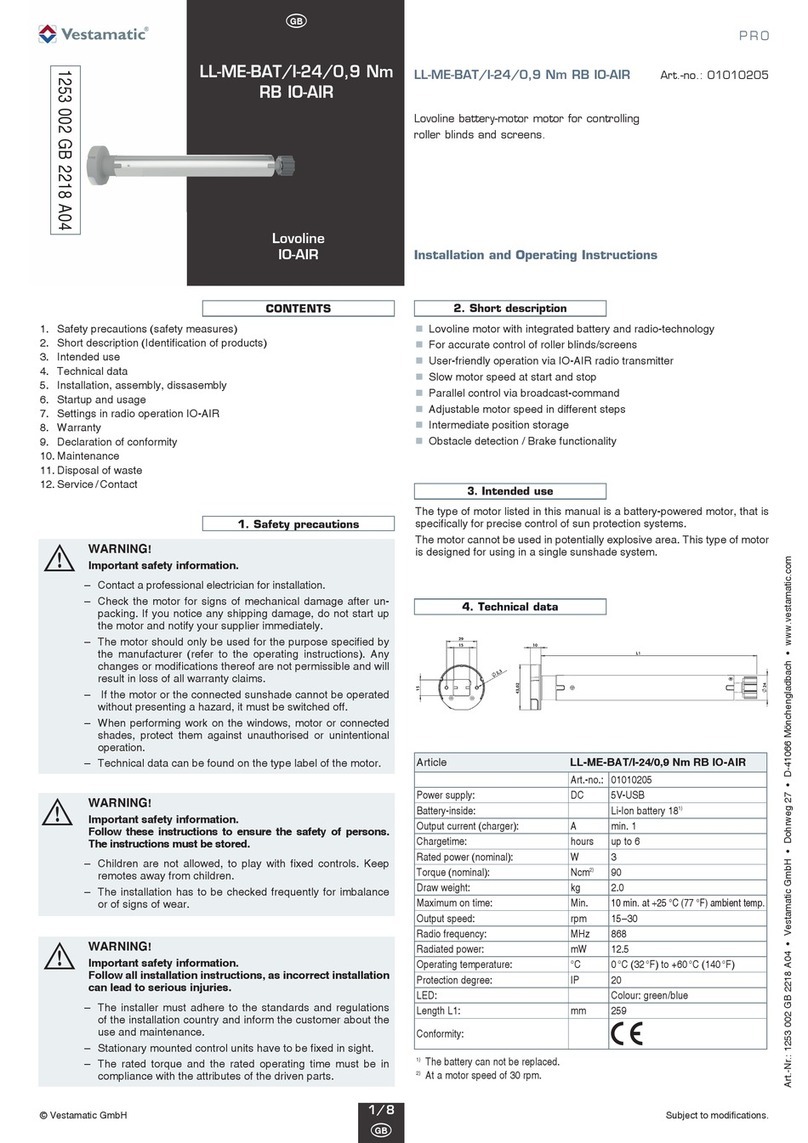

Vestamatic

Vestamatic LL-ME-BAT/I-24/0,9 Nm RB IO-AIR Installation and operating instructions

Kohler

Kohler K91 Service manual

Motive

Motive BOX025 Operation and maintenance manual

Hino Motors

Hino Motors W06D-TI Workshop manual