Bus node

CPX-FB36

Festo SE & Co. KG

Postfach

73726 Esslingen

Germany

+49 711 347-0

www.festo.com

Brief description 8067482

1611a

[8067484]

Original: de

Bus node CPX-FB36 English............................................

1 Use for intended purpose

The module described in this document is intended for use as a participant in net

works with the protocols EtherNet/IP or Modbus TCP in an industrial environment.

The module is intended exclusively for use in CPX terminals from Festo for installa

tion in machines or automated systems and may be used only in the following

ways:

– in an excellent technical status

– in original status without unauthorised modifications, except for the adapta

tions described in this documentation

– within the limits of the product defined through the technical data.

Outside of industrial environments, e.g. in commercial and mixed-residential

areas, actions to suppress interference may have to be taken.

You will find detailed information in the following documentation:

– Description on the module (èCPX-FB36-…)

– CPX system description (èP.BE-CPX-SYS-…).

EtherNet/IP®, MODBUS®, SPEEDCON®are registered trademarks of the

respective trademark holder in certain countries.

2 Safety

Before assembly or installation work, switch off the power supply, switch off the

compressed air supply, exhaust any pneumatic components.

For the electrical power supply, use only PELV circuits in accordance with

IEC 60204-1/EN 60204-1.

Observe the handling specifications for electrostatically sensitive devices.

Seal unused connections with cover caps to achieve the required degree of

protection.

Use connection hardware with the required degree of protection.

Observe specifications in the description for the module and the CPX system

description.

Place only a completely mounted and wired CPX terminal into operation.

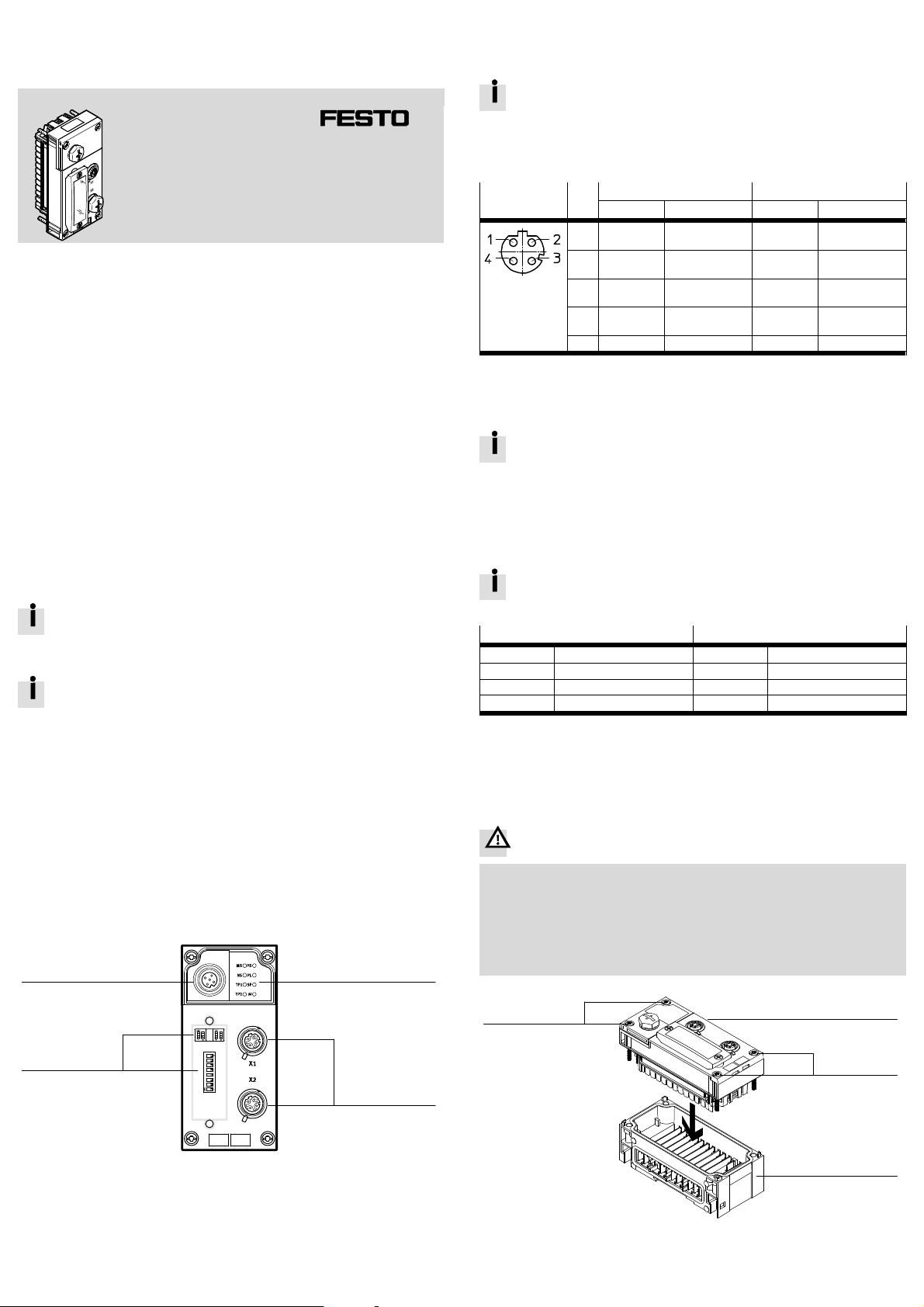

3 Connection and display components

1

2

3

4

1LED indicators

2Network connections [X1], [X2]1)

3DIL switches

4Service interface2)

1) 2× socket, M12, D-coded, 4-pin

2) Socket, M12, A-coded, 5-pin; for the operator unit CPX-MMI or Festo Maintenance Tool CPX-FMT

Fig. 1

3.1 Network connections

There are two 4-pin, D-coded M12 sockets on the bus node for the network con

nection. The sockets are compatible with SPEEDCON plugs. Both connections have

Auto-Negotiation and Crossover Detection (factory setting).

When crossover detection is activated, the bus node automatically

exchanges the transmitted and received data.

If Crossover detection is deactivated, assignment of the pins for transmit

ted and received data at the XP2 connection is crossed. As a result, several

bus nodes in a row can each be connected with a patch cable.

Connection1) Pin X12) X22)

Signal Explanation Signal Explanation

1 TD+ Transmitted

data +

RD+ Received data +

2 RD+ Received data + TD+ Transmitted

data +

3 TD– Transmitted

data –

RD– Received data –

4 RD– Received data – TD– Transmitted

data –

3) Shield Functional earth Shield Functional earth

1) Socket, M12, D-coded, 4-pin

2) Pin activation with deactivated crossover detection

3) Housing; equipotential bonding èCPX system description P.BE-CPX-SYS-…

Fig. 2

If the QuickConnect function has been activated, the crossover detection

function is not available.

3.2 LED indicators – normal operating status

Behaviour of the LED indicators in normal operating status:

– The green LEDs [PS], [PL], [MS] and [NS] are illuminated.

– The green LEDs [TP1] and/or [TP2] light up or flash.

– The red LED [SF] is off.

The yellow LED [M] lights up only when “System start with saved paramet

erisation and CPX extension” is set.

Network-specific LED indicators1) CPX-specific LED indicators2)

MS (red, green) Module status PS (green) Power system

NS (red, green) Network status PL (green) Power load

TP1 (green) “Link/traffic” X1 SF (red) System Failure3)

TP2 (green) “Link/traffic” X2 M (yellow) Modify4)

1) Detailed information (èDescription on the module CPX-FB36-…)

2) Detailed information (èCPX system description P.BE-CPX-SYS-…)

3) Flashes in case of error, error diagnostics (èCPX system description P.BE-CPX-SYS-…)

4) Parameterisation revised or “Force” active.

Fig. 3

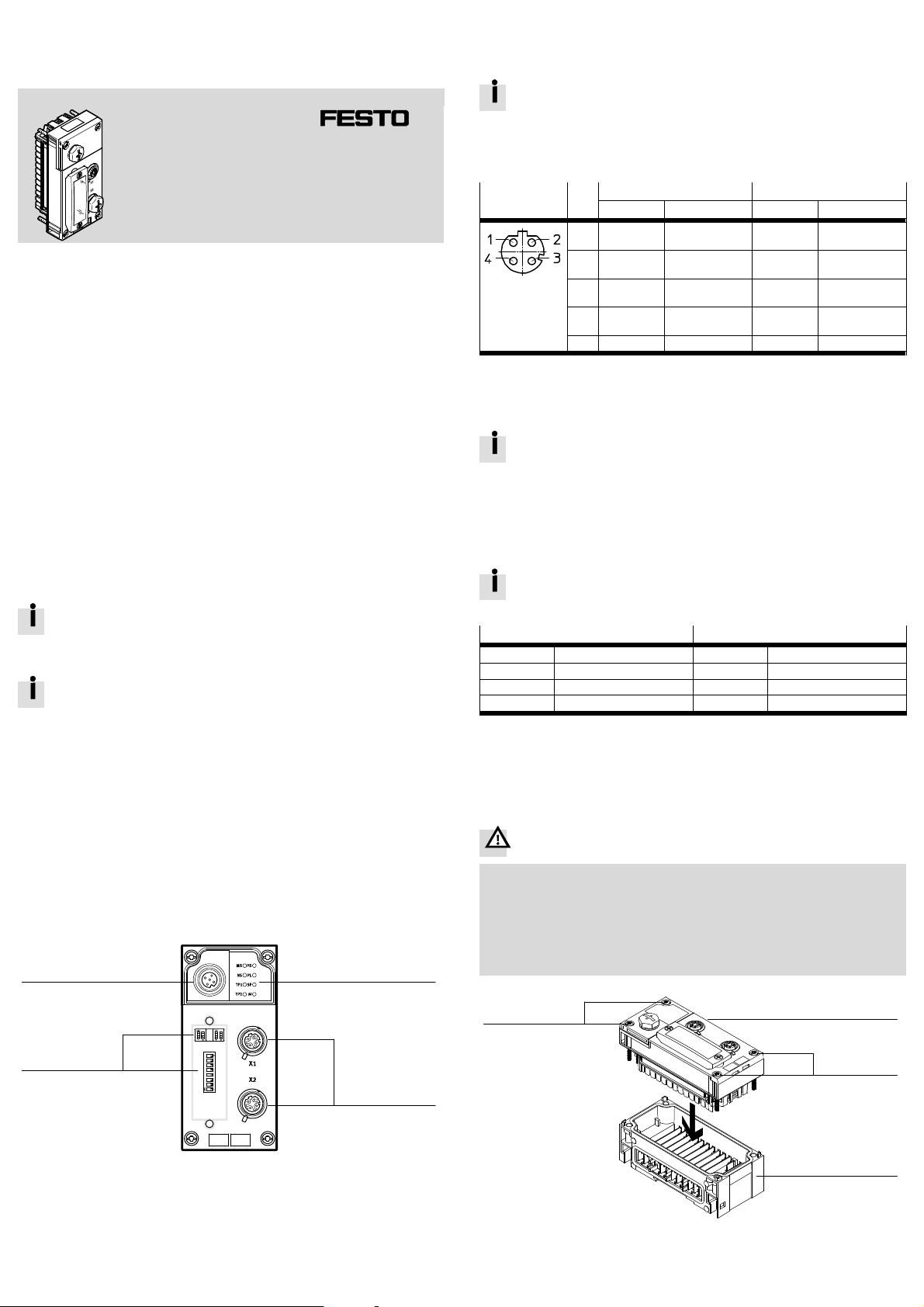

4 Mounting and removal

Warning

Uncontrolled movements of the actuators and loose tubing, undefined switching

states of the electronic components

Injury caused by moving parts, damage to machine and to system

Before mounting and installation work:

Switch off the power supply.

Switch off the compressed air supply.

Exhaust any pneumatic components.

2

1

3

2

1Bus node CPX-FB36

2Screw

3Interlinking block

Fig. 4