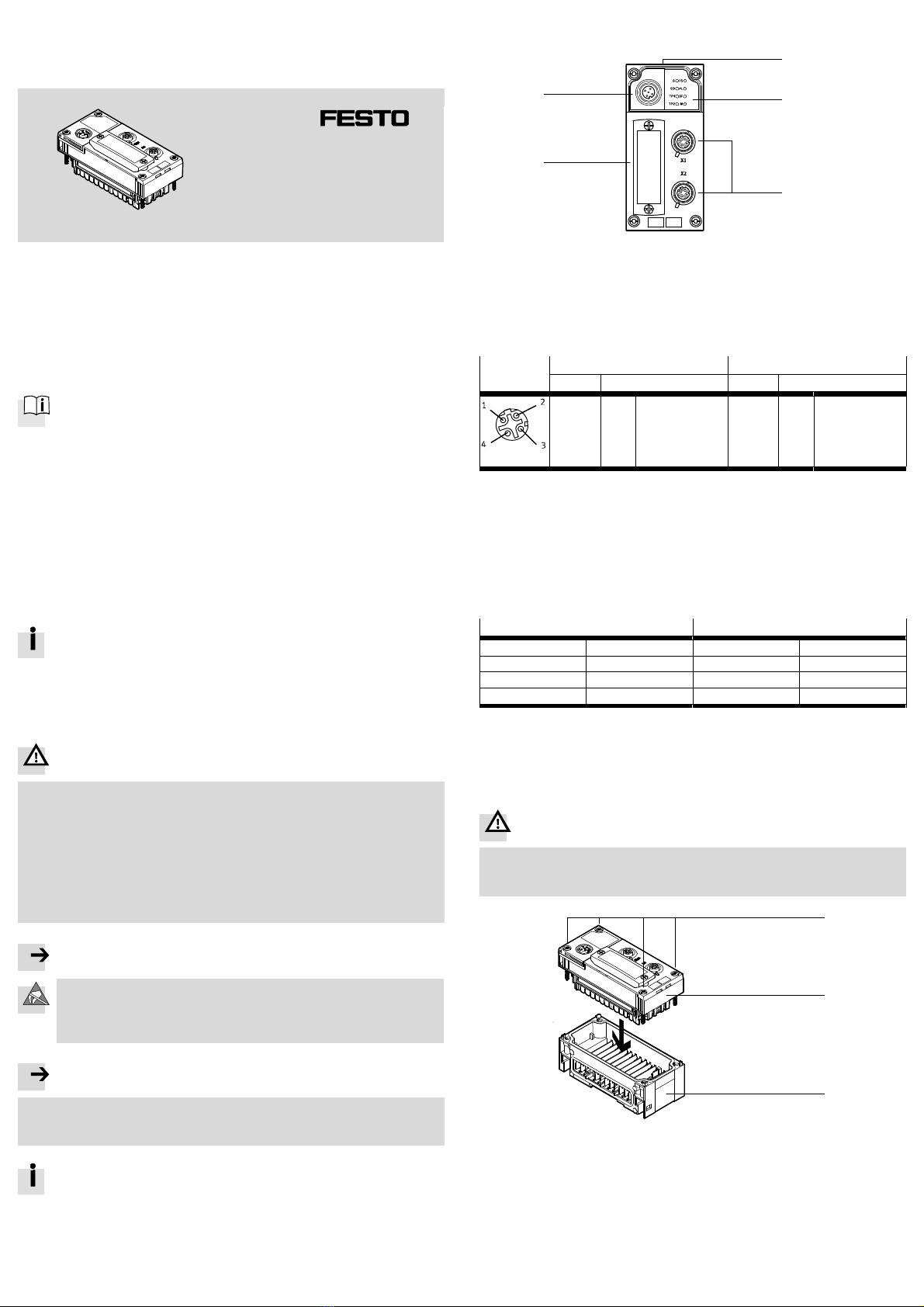

4.1 Mounting

Note

Material damage due to incorrect mounting

Select screws that are suitable for the material of the interlinking block:

– Plastic: Thread-cutting tapping screws

– Metal: Screws with metric thread.

When ordering a single module, all required screws are supplied.

1. Check seal and seal surfaces. Replace damaged parts.

2. Push the module carefully and without tilting into the interlinking block up to the

stop.

3. Turn the screws into the existing thread.

4. Tighten the screws in diagonally opposite sequence. Tightening torque: 0.9 …

1.1 Nm.

4.2 Dismantling

5. Unscrew screws.

6. Pull the module without tilting out of the interlinking block.

5 Power supply

The operating and load voltage supply is fed in via the interlinking block

(èCPX system description P.BE-CPX-SYS-…).

6 DIL switch elements

12

3

1DIL switch 1: Operating mode

2DIL switch 2:1)

– Diagnostics mode (remote I/O)

– I/O mode (remote controller)

3DIL switch 3: Sercos address

1) Dependent on the operating mode (èDIL switch 1)

Fig. 5

6.1 DIL switch 1: (Operating mode)

Setting DIL switch 1 Operating mode

DIL 1.1: OFF

(Factory setting)

Remote I/O

All functions of the CPX terminal are controlled directly by the

Sercos controller or a higher-order controller.

DIL 1.1: ON Remote controller

An FEC or CEC integrated into the CPX terminal controls all

functions of the CPX terminal.

Fig. 6

– The setting of the operating mode via DIL switch 1.1 has priority over all

other settings.

– The switch element 1.2 is reserved and without function.

6.2 DIL switch 2 (diagnostics or I/O mode)

Setting DIL switch 2 Diagnostics mode1) I/O mode2)

DIL 2.1: OFF

DIL 2.2: OFF

(Factory setting)

I/O diagnostics interface

and status bits switched

off

8 byte I/8 byte O for communication

of the bus node with the CPX-FEC

or CPX-CEC.

DIL 2.1: ON

DIL 2.2: OFF

I/O diagnostics interface

is switched on

Reserved

DIL 2.1: OFF

DIL 2.2: ON

Status bits switched on 16 byte I/16 byte O for

communication of the bus node with

the CPX-FEC or CPX-CEC.

DIL 2.1: ON

DIL 2.2: ON

Reserved Reserved

1) Only in the remote I/O operating mode

2) Only in the remote controller operating mode

Fig. 7

The diagnostics mode reduces the available address space.

Take account of this fact when planning the CPX terminal.

– Additional information can be found in the description for the module

(èP.BE-CPX-FB39-…).

6.3 DIL switch 3 (Sercos address)

Setting DIL switch 3 Sercos address

1234 5678

3.8:

3.7:

3.6:

3.5:

3.4:

3.3:

3.2:

3.1:

27=

26=

25=

24=

23=

22=

21=

20=

128

64

32

16

8

4

2

1

Example:

21+ 22+ 25= 2 + 4 + 32 = 38 (Sercos address)

Set Sercos address: 038

Permitted addresses: 1 … 255

Factory setting: 254 (dynamic)

Fig. 8

7 Parameterisation

Note

The CPX terminal and the module described here can be parameterised with the

operator unit (CPX-MMI), the Festo Maintenance Tool (CPX-FMT) software or the

higher-level system.

8 Note on module replacement

Caution

For CPX terminals with a continuously illuminated or flashing Modify LED (M),

parameterisation is not automatically created by the higher-level system when

the CPX terminal is replaced during servicing.

Before replacement, note required settings and make them again after re

placement.

9 Start-up behaviour of the CPX terminal

If the Modify LED (M) lights up or flashes permanently after the system start, “Sys

tem start with saved parameterisation and saved CPX expansion” is set or “Force”

is active.

Additional information on parameterisation, module replacement and

start behaviour of the CPX terminal can be found in the module descrip

tion (èP.BE-CPX-FB39-…).

10 Technical data

Feature Specification/value

General technical data èCPX system description(P.BE-CPX-SYS-…)

Degree of protection through housing1)

in accordance with IEC 60529, completely

mounted, plug connector in plugged-in status

or equipped with cover caps2).

IP65/IP67

Protection against electric shock

Protection against direct and indirect contact

in accordance with IEC 60204-1

through the usage of PELV circuits (protective

extra-low voltage)

Intrinsic current consumption at 24 V

from operating voltage supply for electronics/

sensors (UEL/SEN)

typ. 100 mA (internal electronics)

Separation of network interfaces to UEL/SEN Galvanically separated

Mains buffering time at least 25 ms

Module code (CPX-specific)

Remote I/O 224 (sub-module code 3)

Remote controller 171 (sub-module code 3)

Module identifiers (CPX-MMI, CPX-FMT)

Remote I/O FB39-RIO

Remote controller FB39-RC

Network-specific characteristics

Protocol Sercos III

Specification IEEE 802.3

Transmission rate 100 Mbit/s

Connection length Maximum 100 m

Cable specification

Cable type Industrial Ethernet cable, screened

Transmission class Category Cat 5

Cable diameter 6 … 8 mm

Wire cross section 0.14 … 0.75 mm2, AWG 223)

1) Note that connected devices may only satisfy a lower degree of protection or a smaller temperature

range, etc.

2) Cover caps ISK-M12 included in scope of delivery.

3) Required for maximum connection length between the network participants.

Fig. 9

11 Quoted guidelines and standards

Issue status

IEC 60204-1:2009-02 IEEE 802.3:2012

IEC 60529:2001-02

Fig. 10