FGD FlameSpec IR3-H2 User manual

FlameSpec IR3-H2 User Manual Doc. No. F150V0020.09

4222 E. La Palma Ave, Anaheim, CA 92807 USA T: (+1) 714-671-8500

www.fg-detection.com · [email protected]

FlameSpec IR3-H2

Information

FlameSpec-IR3-H2 Triple IR H2 Flame Detector User Guide, January 2023

Copyright © Fire & Gas Detection Technologies Inc. All rights reserved.

The owner or authorized user of a valid copy of this manual may reproduce this publication for the

purpose of learning to use the specified equipment. No part of this publication may be reproduced or

transmitted for commercial purposes, such as selling copies of this publication or for providing paid for

support services.

The Fire & Gas Detection Technologies logo is a trademark of Fire & Gas Detection Technologies Inc.,

registered in the U.S. and other countries.

Every effort has been made to ensure that the information in this manual is accurate. However, Fire &

Gas Detection Technologies Inc. is not responsible for any inaccuracy or omission in this document. The

information in this document is subject to change without notice.

Legal Notice

Hardware, software or documentation is forbidden to reproduced, transmitted, transcribed, stored in a

retrieval system or translated into any language or computer language, in any form or by any means.

While great efforts have been made to assure the accuracy and clarity of this document, FIRE & GAS

DETECTION TECHNOLOGIES INC. assumes no liability resulting from any omissions in this document, or

from misuse of the information obtained herein. The information in this document has been carefully

checked and is believed to be entirely reliable with all of the necessary information included.

FIRE & GAS DETECTION TECHNOLOGIES INC. reserves the right to make changes to any products

described herein to improve reliability, function, or design, and reserves the right to revise this

document and make changes from time to time in content hereof with no obligation to notify any

persons of revisions or changes. FIRE & GAS DETECTION TECHNOLOGIES INC does not assume any

liability arising out of the application or any use of any product or circuit described herein; neither does

it convey license under its patent rights or the rights of others.

FlameSpec IR3 H2 User Manual Doc. No. F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com iii

Table of Contents

1. Introduction .................................................................................................................... 1

Features ..............................................................................................................................1

Model Number Description ..................................................................................................2

Internal tests .......................................................................................................................2

Product Overview ................................................................................................................3

Accessories ..........................................................................................................................4

2. Installation ..................................................................................................................... 8

General Considerations ........................................................................................................8

Preparations for Installation ............................................................................................... 11

Required Tools ................................................................................................................... 11

Certification Instructions .................................................................................................... 11

Mounting the Tilt Mount .................................................................................................... 12

Mounting the detector ....................................................................................................... 14

Electrical Wiring ................................................................................................................. 15

Current Output (0-20mA) Wiring ........................................................................................ 17

4 Wire Relay Connection .................................................................................................... 19

RS-485 Communication Network ........................................................................................ 20

Cabling Recommendations ................................................................................................. 20

Earth/Ground Regime ........................................................................................................ 21

3. Configuration options ................................................................................................... 22

Sensitivity .......................................................................................................................... 23

Ultra-Fast Detection ........................................................................................................... 23

Alarm Delay ....................................................................................................................... 23

Alarm Latch ....................................................................................................................... 23

Enable Pre-Alarm 0-20mA .................................................................................................. 24

Enable dirty window warning 0-20mA ................................................................................ 24

Auxiliary Relay ................................................................................................................... 24

FlameSpec IR3 H2 User Manual Doc. No. F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com iv

Window Heater ................................................................................................................. 24

Modbus Address ................................................................................................................ 24

Manual BIT – Alarm Output Test (Full Loop test) ................................................................. 24

4. Operation ..................................................................................................................... 25

Output Signals ................................................................................................................... 25

Testing............................................................................................................................... 26

Flame Simulator ................................................................................................................. 26

5 Maintenance ................................................................................................................ 27

Cleaning Procedure ............................................................................................................ 27

6 Troubleshooting ............................................................................................................ 28

7 Servicing ....................................................................................................................... 29

8 FGD Communicator Software ........................................................................................ 29

9 Specifications ................................................................................................................ 30

Fire Detection .................................................................................................................... 30

Electrical Specifications ...................................................................................................... 30

Outputs ............................................................................................................................. 31

Mechanical Specifications .................................................................................................. 31

Environmental Specifications ............................................................................................. 31

Product Labeling ................................................................................................................ 32

Approvals .......................................................................................................................... 34

Electromagnetic Compatibility ........................................................................................... 34

10 Performance .............................................................................................................. 35

FLS-IR3-H2-ASX1 (Standard Model) ..................................................................................... 35

False Alarm Immunity ........................................................................................................ 36

11 Ordering Information ................................................................................................. 37

12 Warranty ................................................................................................................... 38

Appendix A .......................................................................................................................... 39

FlameSpec IR3 H2 User Manual Doc. No. F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com v

List of Figures

Figure 1 - Front view of the FLS-IR3-H2 ........................................................................................................ 3

Figure 2 - Rear view of the FLS-IR3-H2 .......................................................................................................... 3

Figure 3 - Tilt mount ..................................................................................................................................... 4

Figure 4 - Weather COVER ............................................................................................................................ 4

Figure 5 - Pole Mount ................................................................................................................................... 5

Figure 6 - Air Shield ....................................................................................................................................... 5

Figure 7 - Flame Simulator Kit ....................................................................................................................... 6

Figure 8 - FLS-FSIM-IR3-H2 Flame Simulator Front View .............................................................................. 6

Figure 9 - Duct Mount DMX-S01 ................................................................................................................... 7

Figure 10 - Duct Mount DMW-S01 ............................................................................................................... 7

Figure 11 - Horizontal Field of View .............................................................................................................. 9

Figure 12 - Vertical Field of View .................................................................................................................. 9

Figure 13: Tilt Mount Base - Front View ..................................................................................................... 13

Figure 14: Tilt mount base – Side View ....................................................................................................... 13

Figure 15 - Detector on Tilt Mount – Side View.......................................................................................... 14

Figure 16 – Terminal View .......................................................................................................................... 15

Figure 17 – Source 4-Wire Scheme ............................................................................................................. 17

Figure 18 – Sink 4-Wire Scheme ................................................................................................................. 17

Figure 19 – Source 3-Wire Scheme ............................................................................................................. 18

Figure 20 – Sink 3-Wire Scheme ................................................................................................................. 18

Figure 21 - 4 Wire Relay Connection .......................................................................................................... 19

Figure 22: RS-485 Networking .................................................................................................................... 20

FlameSpec IR3 H2 User Manual Doc. No. F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com vi

List of Tables

Table 1: Terminal connections .................................................................................................................... 16

Table 2: Detector Configuration Options .................................................................................................... 22

Table 3: Sensitivity levels ............................................................................................................................ 23

Table 4: Output Signals ............................................................................................................................... 25

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 1

1. Introduction

The FlameSpec-IR3-H2 flame detector will detect hydrogen and other “energy transition” fires quickly

allowing actions to be initiated to minimize the extend of the fire. The detector addresses slow growing

fires as well as fast eruptions of fire using improved IR3 technology. The detector operates in all weather

and light conditions.

These features, along with a built-in event logger, provide additional means to study the cause and

development of fire events.

The detector is certified for use in hazardous area locations; it may also be used in other areas not

classified as hazardous. The two cable/conduit entries either side of the lower part of the detector

housing are for connecting power and outputs to associated signaling equipment.

During normal operation, the flame detector performs self-tests of its optics, electronics, and software.

These include a periodic BIT (Built-In-Test) in which the sensors and window cleanliness are tested.

Features

High sensitivity - up to 100ft (30m)

Ultra-fast detection mode - detection within 40 milliseconds for fireballs or explosions.

Detection of “energy transition” flames, like hydrogen, methane, syngas, and methanol

Extreme sensitivity: Up to 100 ft. (30m) for a 32” plume, 1.5secs response

Option: Improved speed of response for standard fires - (0.5s) for enclosed space protection, like spray

paint booths or printing presses

Built-in-Test (BIT) - Automatic and manual self-test of window cleanliness and detector operation.

Window heater to avoid condensation and icing.

Tilt mounting bracket for accurate detector positioning.

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 2

Model Number Description

Model No are defined as follows:

FLS-IR3-H2 - A S X X

0 Standard, no Hart and not SIL certified.

1 Standard

5 Design for, but not limited to, automotive spray paint applications

where compliance with 0.5 s response (per NFPA 33) is needed.

Generally used for enclosed spare protection.

1 M25

2 ¾” NPT

1.2.1 Enhanced performance options

Option 5: Design for, but not limited to, enclosed space protection like automotive spray paint applications

where compliance with 0.5 s response (per NFPA 33) is needed

Internal tests

During normal operation, the flame detector performs self-tests of its optics, electronics and software. These

include a periodic BIT (Built-In-Test) in which the sensors and window cleanliness are tested. Any detected

fault is indicated as shown in Table 4 (in section 4). During “Dirty Window” fault the detection sensitivity is

significantly reduced, while “Fault” refers to critical faults which totally prevent flame detection.

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 3

Product Overview

FIGURE 1 - FRONT VIEW OF THE FLS-IR3-H2

FIGURE 2 - REAR VIEW OF THE FLS-IR3-H2

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 4

Accessories

1.5.1 Mounting Bracket

The detector should be mounted using the

stainless-steel tilt mount part number FLS-

TMO-S01. This allows the detector to be

securely attached to a wall, pole or other

solid surface using appropriate fixings. See

section2.5 and 2.6 for further details.

F

IGURE

3

-

T

ILT MOUNT

1.5.2 Weather Cover

The weather

cover

P/N

FLS-WCO-S01

protect the detector from extreme

weather conditions such heat, rain and

snow

FIGURE 4 - WEATHER COVER

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 5

1.5.3 Pole mount

The pole mount enables the detectors

to be

installed with its tilt mount brackets. The pole

mount kit we supply are suitable for 2-inch or 3-

inch poles. Part number FLS-PMA-S23.

F

IGURE

5

-

P

OLE

M

OUNT

1.5.4 Air shield

The air shield P/N FLS-ASD-S01 allows installation of

flame detectors in harsh weather conditions where

they may be exposed to dust, sand, and other

particulate matter. The connection point can be

mounted in the 3, 9 or 12 o’clock locations.

Air pressure source: Clean, dry, and oil-free air

Pressure: 2-3 bar /30-45 psi

Fitting: 7/16”—20UNF-2A

Operation temperature: -55°C to +85°C / -67°F to

+185°F

F

IGURE

6

-

A

IR

S

HIELD

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 6

1.5.5 Flame Simulator

The FLS-IR3-H2 may be tested using the FLS-FSIM-

IR3-H2-KIT. The FlameSpec flame simulator family

provides a fast and convenient means of

periodically testing the detector and control system

end-to-end. Maintenance costs can be reduced as

the detectors can be tested in situ without needing

a hot work permit.

FlameSpec Flame Simulators emit IR radiation in a

special electromagnetic radiation pattern which

simulates a hydrogen fire to the detectors. The

simulators are lightweight, easy to use, with testing

distances of up to 23 ft. (7m) and capable of more

than 1000 activations between battery charging.

FlameSpec Flame Simulators are ATEX approved for

use in hazardous Zone 1, Zone 2, Zone 11, Zone 22

areas.

Each simulator kit contains a carrying case,

simulator, carrying strap, battery charger, user

manual, Allen key and a tool for removing the

simulator rear cover.

FIGURE 7 - FLAME SIMULATOR KIT

FIGURE 8 - FLS-FSIM-IR3-H2 FLAME SIMULATOR FRONT

V

IEW

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 7

1.5.6 Duct Mounts

Duct Mount DMX-S01

The FLS-DMX-S01 allows a standard (non-HD)

detector to be mounted remotely from a potential

fire source by allowing the device to look through

cut hole in the side of a duct. This duct mount must

be use with air shield FLS-ADS-S01

Duct Mount DMW-S01

The FLS-DMW-S01 allows a standard detector to be

mounted remotely from a potential fire source by

allowing the device to look through a special

sapphire window. It must be acknowledged that

the detector cannot tell if this window becomes

dirty and so a maintenance routine must be

established to check the optical contamination of

this window. Please note, the frequency of cleaning

needed will vary from installation to installation. It

is highly recommended therefore that a means of

access be designed into the installation, as close as

practicable to the assembly, for inspection and

cleaning purposes.

F

IGURE

9

-

D

UCT

M

OUNT

DMX

-

S01

F

IGURE

10

-

D

UCT

M

OUNT

DMW

-

S01

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 8

2. Installation

This chapter does not attempt to cover all of the standard practices and codes of installation.

Rather, it emphasizes specific points of consideration and provides some general rules for

qualified personnel. You must always observe special safety precautions.

General Considerations

This section includes important information.

To help obtain optimal performance, the detector should be aimed toward the center of

the hazard or area to be monitored and protected ("detection zone") and have, to the

extent that is required, an unobstructed view of the protected area. Whenever possible,

the detector face should be tilted (aimed) down at an angle to prevent the accumulation

of dust and dirt.

Do not start an installation until the performance target, system configuration,

installation location and coverage considerations have been defined by the responsible

person.

To ensure optimal performance the following guidelines should be addressed:

Sensitivity

To determine the sensitivity level, the following points should be considered:

The size of the fire to be detected at the determined distance.

The type of flammable fuel.

Potential sources of false alarms that may be present (e.g., naked flames, hot process).

Spacing and Location

Consider the following factors when determining the number of detectors and their locations in

the protected area:

The size and shape of the protected area

The nature of the hazards, including materials stored or used and the protected objects

The sensitivity of the detectors

If there are any obstructed lines of sight

The field of view of the detectors (See Figure 11 and Figure 12)

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 9

FIGURE 11 - HORIZONTAL FIELD OF VIEW

FIGURE 12 - VERTICAL FIELD OF VIEW

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 10

Environment

Environmental conditions including but not limited to dust, snow or rain can reduce the

detectors sensitivity and require additional consideration.

Hot Work

Arc welding should not be performed within 15 ft. (5m) of the detector. It is

recommended that the system be inhibited during welding operations in situations

where the possibility of a false alarm cannot be tolerated.

Gas welding requires a system inhibit, since the gas torch is an actual fire.

Arc welding rods can contain organic binder materials in the flux that burn during the

welding operation and are detectable by the device.

Welding rods with clay binders do not burn and should not be detected. However, a

system inhibit is always recommended, since the material being welded may be

contaminated with organic substances (paint, oil, etc.) that will burn and may be of the

size that should be detected.

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 11

Preparations for Installation

The installation must comply with national and local regulations and standards applicable to

flame detectors (e.g., NFPA 72) and all local and common engineering practices. It is

recommended to consult with the authority having jurisdiction.

Prior to installation:

Make sure that you have all the components and tools required to complete the

detector installation readily available before beginning installation. In cases where you

cannot complete the installation in a single session, secure and seal the detectors and

conduits before leaving the site.

Use color-coded conductors or suitable wire markings or labels for the wiring. You may

use 14 to 17 AWG (2.5 to 1mm2) multi-strand wires for the site wiring. The selection of

wire gauge should be based on the number of detectors used on the same line and the

distance from the control unit, in compliance with specifications.

Individually screen twisted pair cable is recommended for RS485 terminals.

Use suitably rating wire for the application certification and temperatures.

Required Tools

The detector can be installed using the following tools:

Tool Function

Hex. KEY 6 mm Vertical alignment

Hex. KEY 10 mm Horizontal alignment

Wrench 13 mm Mounting the detector

Flat Screwdriver 6 mm Ground screw connection

Flat screwdriver 3.5mm Terminal connection

Certification Instructions

Warnings

Do not open the detector, even when isolated, when flammable atmosphere present.

The equipment may be used in hazardous areas with flammable gasses and vapors with

apparatus groups IIC, IIB and IIA and with temperature classes T1, T2, T3, T4 and T5. See

details of the explosion proof approvals in section 9.7.

The equipment is certified for use in ambient temperatures in the range of -67°F to

+167°F (-55°C to +75°C) or -67°F to +185°F (-55°C to +85°C) and should not be used in

temperatures outside this range.

Installation shall be carried out in accordance with the applicable code of practice by

suitably trained personnel.

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 12

Inspection and maintenance of this equipment shall be carried out by suitably trained

personnel in accordance with the applicable code of practice.

If the equipment is likely to come into contact with corrosive and other harsh

substances, consult with the relevant technical persons to take suitable precautions to

prevent the detector from being adversely affected, thus ensuring that the type of

protection is not compromised.

Harsh substances: For example, acidic liquids, gases, or solvents that may attack the

windows, metals, seals or polymeric materials.

Suitable precautions: For example, regular checks as part of routine inspections or

establishing from the material’s data sheet that it is resistant to specific chemicals.

Specific conditions for use

The equipment is not intended to be repaired by the user. Repair of this equipment shall

be carried out by the manufacturer in accordance with the applicable code of practice.

The flame paths are not intended for repair. Contact the manufacturer if the flame

paths are damaged.

Consult the manufacturer for genuine replacement cover and housing to connection box

fasteners. M6x1x18 Hexagonal Socket head fasteners with a minimum of ISO 4762

Grade A4 Class 80 are acceptable alternatives.

One suitably certified stopping plug is supplied with the detector.

The external earthing connection consists of cable lug with M5x10 stainless steel screw,

the terminals is suitable for connection of a wire of maximum 2.5mm2 / 14AWG.

The internal terminals are suitable for connection of a wire equal to or greater than the

power input wiring and at a minimum of 1mm2 / 17AWG conductor.

Mounting the Tilt Mount

The tilt mount enables the detector to be rotated up to 45 degrees (horizontal/vertical) in all

directions. The following installation instructions show how to use it to support the detector

from below (the preferred method). However, with a designated adapter the tilt mount can hold

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 13

the detector from above. Contact FGD for more details on mounts suitable for retro fit of

existing installations.

To install the tilt mount:

a) Mount the tilt mount base (Figure 13: Tilt Mount Base - Front View) to a solid structure using

four suitable fixings through the four 7mm (0.28") diameter holes. Four captive screws with

spring washers are provided in the tilt mount.

Figure 13: Tilt Mount Base - Front View

Figure 14: Tilt mount base – Side View

FlameSpec IR3-H2 User Manual F150V0020.09

For more information & technical support: (+1) 714-671-8500 · support@fg-detection.com 14

Mounting the detector

Referring to Figure 13 use the following steps to connect the detector to the tilt mount:

a) Place the detector, with its cable/conduit entries pointing down, on the holding plate of the

tilt mount (item 2).

b) Secure the detector to the plate using the two hex screws and spring lock washers (items 3

and 4).

c) Loosen the locking screws (Items 5 and 6) in such a way that enables you to rotate the

detector.

d) Point the detector towards the detection area and make certain that the view of the area is

unobstructed.

e) Secure the detector in that position by tightening the locking screws (Items 5 and 6) on the

tilt mount. (Make sure the detector is pointing in the correct direction).

The detector is now correctly mounted, aligned and ready for electrical connection. Please refer

to section 2.7 for wiring instructions, and section 3 for a description of the detector’s

configuration settings.

FIGURE 15 - DETECTOR ON TILT MOUNT – SIDE VIEW

3, 4

1

6

2

5

Other manuals for FlameSpec IR3-H2

1

Table of contents

Popular Gas Detector manuals by other brands

Medem

Medem AGDS-2 installation instructions

Polon-Alfa

Polon-Alfa ASG-2001 Installation and maintenance manual

Samon

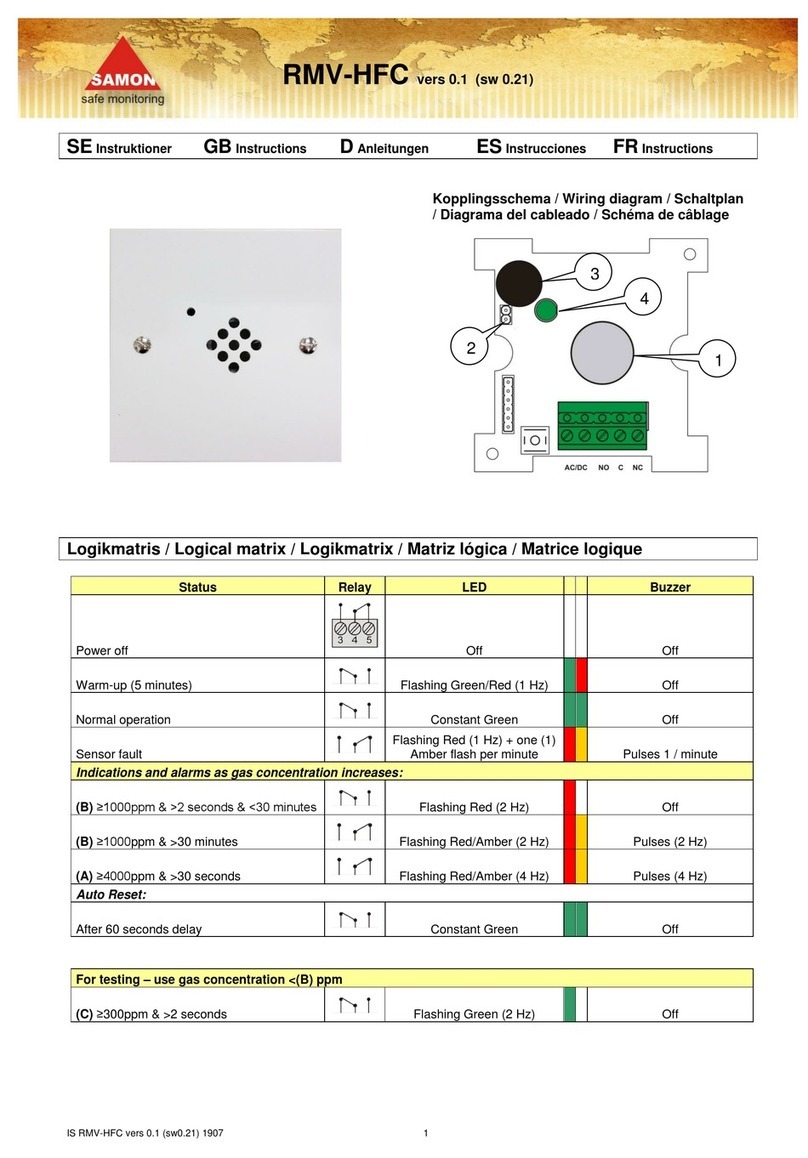

Samon RMV-HFC instructions

Macurco

Macurco CM-E1 manual

EsiWelma

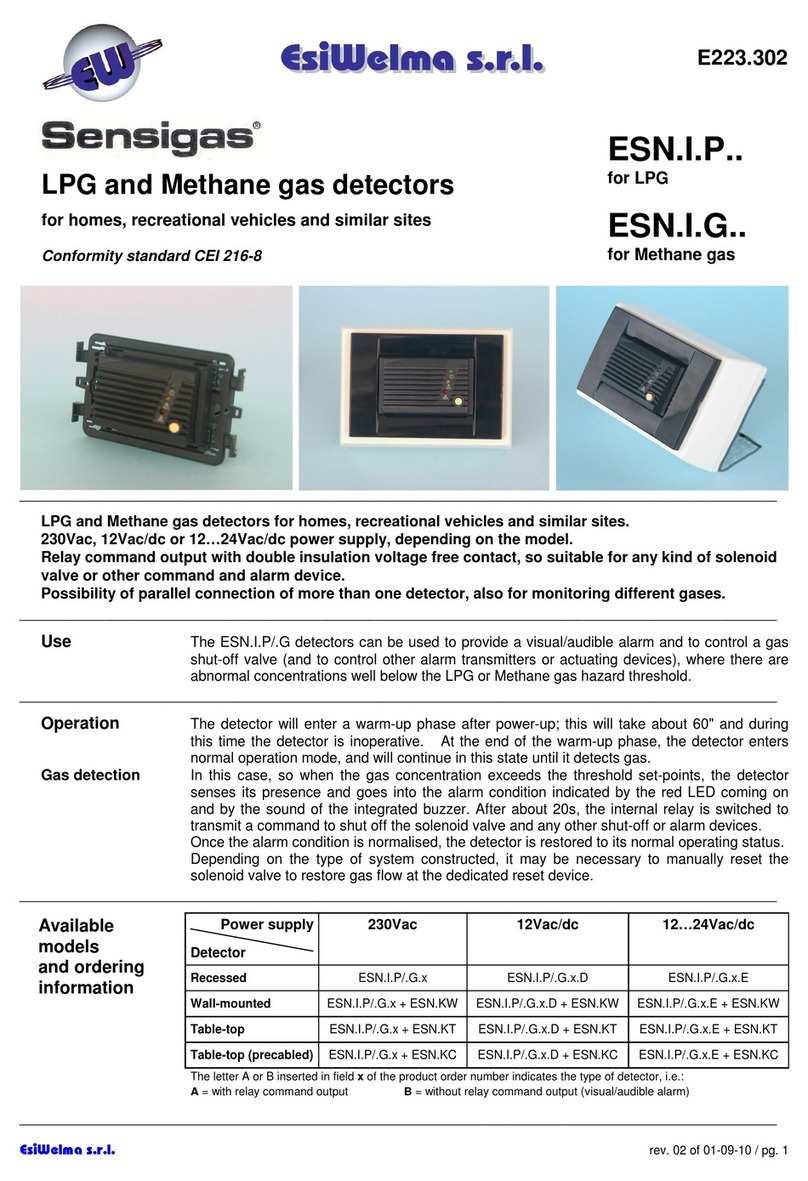

EsiWelma Sensigas ESN I Series quick start guide

S+S Regeltechnik

S+S Regeltechnik AERASGARD AC02-SD-TYR2 Operating Instructions, Mounting & Installation

Crowcon

Crowcon TETRA 4 user guide

BW Technologies

BW Technologies GasAlert MicroClip XT Quick reference guide

Hydro Instruments

Hydro Instruments GA-170 Operation and maintenance manual

Sensitron

Sensitron PATROL manual

Edaphic Scientific

Edaphic Scientific CM-500 Series operating instructions

EsiWelma

EsiWelma Sensigas ESN26.C General instructions