Fiamm Premium HF flex User manual

Fiamm Motive Power®

Premium HF flex

Technical manual GB

Contents

Warning..................................................................... 2

Aim of this manual....................................................2

Guarantee...................................................................2

Recommendations.................................................... 2

Electrical safety..........................................................2

Limitations on use.....................................................3

Destruction of the equipment.................................. 3

Improvements and modifications............................3

Receipt - Storage.......................................................3

Replacement parts.................................................... 3

Information plate.......................................................3

Glossary..................................................................... 3

EEC declaration of conformity................................. 3

Introduction............................................................... 4

Introduction............................................................... 4

External components................................................4

Control panel............................................................. 4

Menus.........................................................................5

Menu access.............................................................. 5

Memory...................................................................... 5

Status......................................................................... 6

Configuration.............................................................6

Contrast......................................................................6

Backlight.....................................................................6

Language................................................................... 6

Use............................................................................. 7

Unpacking.................................................................. 7

Mechanical Installation.............................................7

Electrical Connection................................................ 7

Factory configuration................................................7

Charging the battery................................................. 7

Display of the history per charging operation........9

Display of the charger’s history............................... 9

Fault messages..........................................................9

Technical characteristics.........................................10

Warning

Aim of this manual

This manual is designed for use by any skilled worker

wishing to use Fiamm Motive Power®Premium HF flex

3-phase battery chargers for rechar

ging lead/acid unsealed or

gel batteries.

This manual provides details of:

• The chargers’ functions.

• Any adjustments required and how to use the chargers.

• The chargers’ technical characteristics.

When producing this manual, Fiamm Motive Power has

aimed to provide its information in as simple and precise a

manner as possible but cannot assume any responsibility

for any misinterpretation.

The owner of the equipment is required to retain this

manual throughout the equipment’s life and to pass it on to

any purchaser in the event of its resale.

Guarantee

The manufacturer covers the guarantee in accordance with

the local regulations. Please contact your dealer for more

detailed information.

Recommendations

This manual contains information and advice that should be

followed by the operator to ensure his safety and maintain

the equipment’s safe condition.

Recommended use

This manual should be read through carefully before using

the equipment and also read by anyone likely to use the

equipment. The equipment:

• Presents no obstacles to the free circulation of air

through the air inlet and outlet but, nevertheless, should

be cleaned of dust every six months by a qualified

person.

• Must be used in conformance with its indicated level of

protection and never come into contact with water.

• Must be used within the temperature limits stated in the

technical characteristics.

• Must not be installed on surfaces subject to vibration

(near to compressors, engines, motors, etc.).

Operator safety

Take all necessary precautions when the equipment will be

used in areas where there is the possible risk of an accident

occurring. Ensure appropriate ventilation when charging

unsealed lead/acid batteries to allow any gases released to

escape. Never disconnect the battery while it is being

charged.

General checks

Before putting the charger into service, we recommend that

you check:

• That it is correctly earthed.

• That the local power supply conforms to the charger’s

operating voltage.

• That the battery voltage conforms to that of the charger.

• That the charger’s output is suitable for the battery’s

capacity.

Electrical safety

The prevailing safety regulations must be observed.

The system protection installed on the power supply to the

charger must conform to the charger’s electrical

characteristics. The installation of a suitable circuit breaker

is recommended. It is imperative to ensure that when fuses

are being replaced only fuses of the specified type and of

the correct calibre are used. It is strictly forbidden to use

inappropriate fuses or to short-circuit the fuse holders.

This equipment conforms to Class 1 safety standards, which

means that the appliance must be earthed and requires to

be powered from an earthed supply. Earthing is provided by

means of a braid or cable of cross-section in excess of or

ENGLISH

3

equal to 6mm2; this cable must be as short as possible.

Before opening the equipment for the purposes of

adjustment, replacement of components, maintenance or

repairs, it must be disconnected from all sources of electri-

cal power (including mains and battery power). The battery

must only be disconnected after the Start/Stop button has

been set to “0”. Any adjustment, maintenance or repairs to

the equipment while it is open must only be carried out by

an appropriately skilled person who is aware of the risks

involved.

Contact one of the company’s trained technicians if any

problem is encountered when putting the charger into

operation.

Limitations on use

This equipment has been designed for use in a covered

environment. It is only designed to recharge lead/acid

batteries on industrial premises.

Destruction of the equipment

When the equipment becomes obsolete, the casings and the

other internal components can be disposed of by specialist

companies. Local legislation takes precedence over any

instructions in this document and must be scrupulously

observed.

Improvements and modifications

Fiamm Motive Power®reserves the right to make any impro-

vements and/or modifications to the product described in

this manual at any time and without prior notice and is not

obliged under any circumstances whatsoever to update the

contents of this manual nor the equipment concerned.

Receipt – Storage

Upon receipt of the package, check for any external or

internal damage and, if necessary, notify the haulier at his

usual premises, by recorded delivery letter, fax or e-mail,

within 24 hours of delivery.

If the charger is to be stored before its use, it must be kept

carefully sealed in its original packaging. It must be stored

in a clean and dry location at a moderate temperature (0°C

to +40°C). Equipment stored at a temperature of less than

15°C must be brought progressively to operating

temperature (over a period of 24 hours) to avoid any risk of

condensation causing electrical faults (particularly

short-circuits).

Replacement parts

The equipment’s production number must be supplied when

ordering any replacement parts. This number can be found

on the information plate.

Information plate

This is located on one side of the charger.

Glossary

The chargers‘ advantages

Fiamm Motive Power chargers are microprocessor-

controlled. The processor calculates the battery’s capacity so

that the charging profile can be automatically adapted to the

battery’s actual state over a wide range of capacities. The

charging coefficient is maintained absolutely on all types of

batteries. Fiamm Motive Power chargers adapt to the

battery’s capacity and its discharge level.

Charging coefficient

The ratio of the number of amp hours restored during

charging to the number of amp hours consumed during

discharge.

Compensation charging

Compensation charging enables the battery to be

maintained at maximum charge all the time that it is

connected to the charger.

Desulphation charging

Desulphation charging, effected before normal charging,

enables the density of batteries that have been heavily

discharged or left a long time without use to be restored.

Equalisation charging

Equalisation charging, effected after normal charging,

balances the densities in the battery’s cells.

Fiamm Motive Power energycom

This unit, permanently mounted on the battery, ensures that

certain battery parameters can be sent to the charger, with

no additional cable required, for the purposes of optimising

the charge and monitoring the charging and discharging

characteristics.

Gel

A sealed battery with gellified electrolyte.

Charging profile

The charging profile defines the rate of current charge over

time. Different charging profiles can be selected, depending

on the type of charger. The charger adapts to the battery’s

age and level of discharge and prolongs its effective life.

Controlling the overcharge coefficient, whatever the

battery’s discharge level, reduces the amount of water

(except for sealed batteries) and electricity consumed.

“Ionic” profile

Also called “ionic mixing”. This type of charging profile

consists of sending short pulses of current to stimulate gas

formation in the active material, causing sulphuric acid to be

distributed outside the plates.

This system of mixing the electrolyte enables more rapid

charging of unsealed batteries subject to very high demands

and balances out differences in density, homogenising the

electrolyte across the surface of the plates.

Gel battery profile

The procedure for charging sealed, maintenance-free

batteries has been optimised to ensure that the particular

conditions required for recharging them are observed. The

main advantages of these batteries are that there is no

necessity to add water, thus reducing maintenance costs,

and no necessity for special charging rooms with ventilation

and water demineralisation units.

Rest function

The Rest function prevents the battery from being dis-

connected for a pre-defined period to ensure a period of

inactivity after charging.

EC declaration of conformity

EnerSys®hereby declares that the chargers in the

Premium HF flex range covered by this declaration

conform to the descriptions laid down in European

Directives

Directive 2006/95/EC (Low Voltage Directive):

EN60950-1

Directive 2004/108/EC (ElectroMagnetic Compatibility):

EN61000-6-2, EN61000-6-4:Immunity and emissions limits

for industrial electronics (Class A –Industrial Environments)

Directive 2002/95/EC (RoHS).

4

Introduction

The Premium HF flex range of chargers enable batteries to

be recharged from the 3-phase mains supply. The Premium

HF flex chargers can recharge automatically batteries in the

following ranges 24-36-48V or 48-72-80V.

The microprocessor control automatically recognises the

battery’s voltage, capacity, state of charge, etc., providing

optimum battery control from highly efficient analyses of its

condition. Several charging profiles are available (for free

electrolyte “unsealed lead/acid”, sealed, gellified or “gel”

battery types), depending on the user’s

configuration. Desulphation, equalisation and compensation

charging cycles are available.

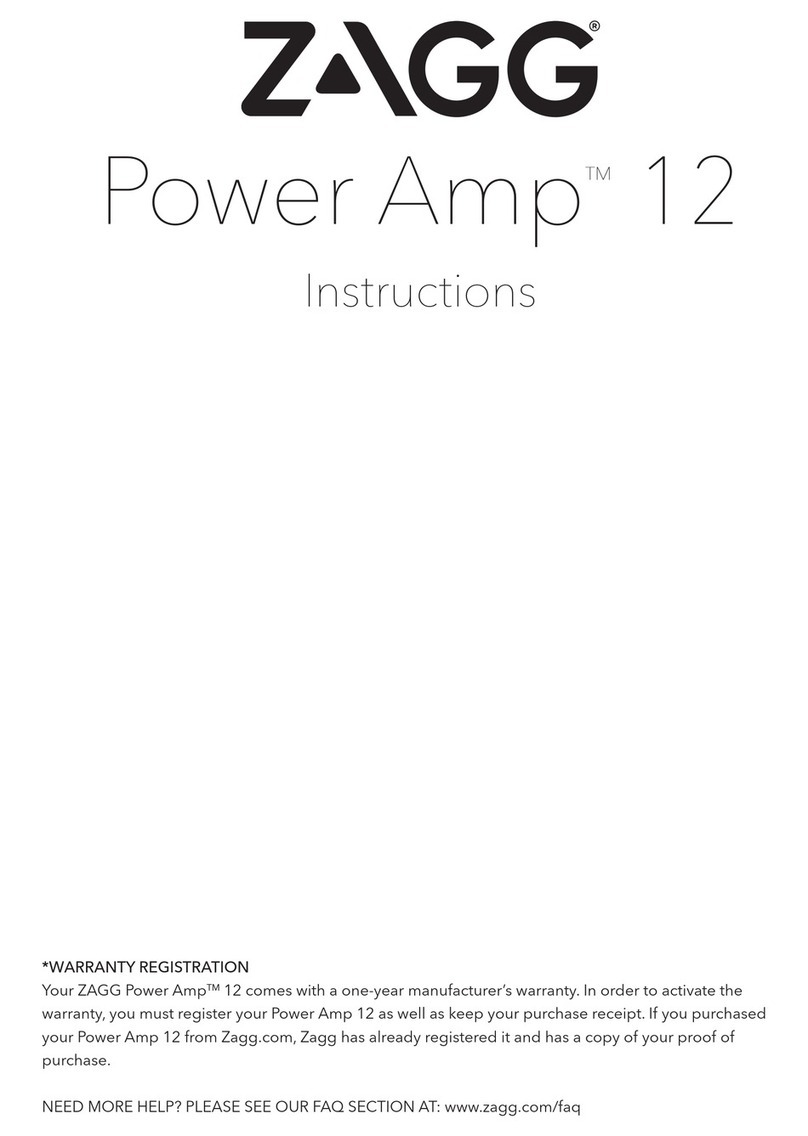

External components

The general components are shown below:

No. Function

1. Ventilation holes.

2. Controls and monitoring devices (please

see the next diagram).

3. Mains power cable.

4. Protective cover retaining screw.

5. Wall mounting bracket.

6. Battery cable.

Figure 1: The charger’s general components.

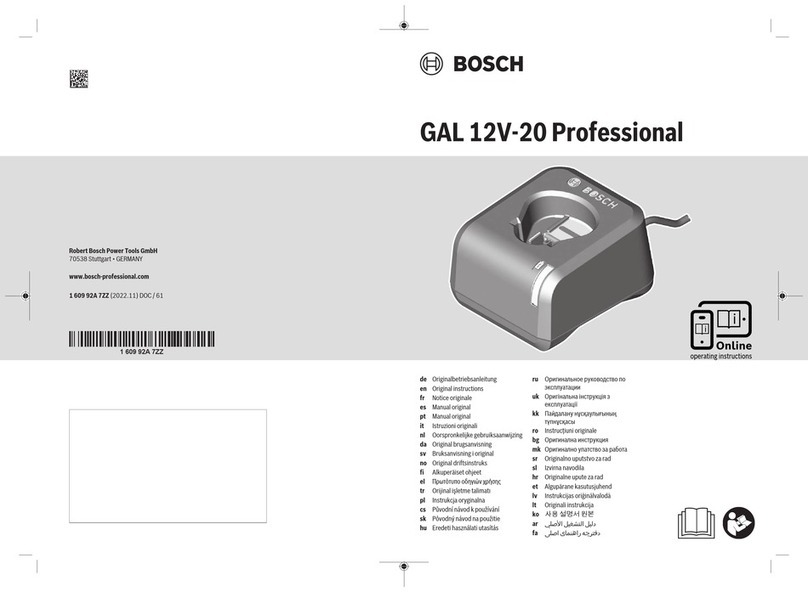

Control Panel

This contains the display and the control buttons. Please

refer to the Chapters on Menus and Use for details of the

information shown.

No. Function

1. LCD graphic display.

2. Menu navigation button (Up).

3. OK button.

4. Menu navigation button (Down).

5. Red ‘Fault’ light.

Unlit: no fault.

Flashing: fault detection in progress.

Permanently lit: fault.

6. Yellow ‘Charging in progress’ light.

Unlit: charger stopped.

Lit: charging in progress.

7. Green ‘Charging completed’ light

(battery charged).

Unlit: charger stopped or battery not

available

Flashing: relaxation phase.

Permanently lit: battery available.

8. Start-Stop switch.

9. Button for exiting the menu, initiating

equalisation and initiating desulphation.

Figure 2: The charger’s controls.

Introduction

5

1

2

3

4

5

6

7

9

8

4

5

4

1

2

3

7

3

2

6

6

The menus provide access to the following functions:

• View of the last 100 measurements (Memory Menu).

• View of the fault and alarm statuses, etc. (Status Menu).

• Charger configuration (Configuration Menu).

• Parametering the contrast (Contrast Menu), the display’s

back-lighting (Backlight Menu) and the display language

(Language Menu).

Menu access

The buttons’ functions

The buttons have the following general functions:

Button Function

▼▲ Menu navigation.

OK Selects the active menu or confirms the

entered value.

Closes the window.

Entering the password

When the charger is in the ‘Waiting’ position (Start-Stop

switch on “0”), press OK. Enter the password using the

▼/▲buttons until the valid number is displayed. The Main

Menu is then displayed.

Each of the six menus available is detailed below. The

current menu is automatically exited after one minute of

inactivity or can be exited voluntarily by pressing the

button.

Memory

This presents the history of each of the last 100 charging

operations.

Access

On the Main Menu, select MEMORY and press OK.

Call-up screen

The display shows here that 17 charges have been stored in

memory (title line). MEMO 1 is the latest charge

memorised. After memorising the one-hundredth charge,

the oldest record is deleted and replaced by the next oldest.

Displaying a history

Proceed as follows:

1. Select a record (MEMO x) using the ▼/▲buttons.

2. Display the first History screen by pressing OK.

3. Display the second History screen by pressing ▼.

4. Return to the Main Menu by pressing .

The information displayed

The history is presented on two screens.

Screen No. 1 (Battery information)

No. Without With

FMP energycom FMP energycom

1. Empty line. Battery’s serial number.

2. Voltage and Voltage, capacity

programmed and temperature

operating memorised before

temperature. charging.

3. Programmed type. Detected type.

4. Empty line. Alarm symbol (Table A).

Symbol Types of alarms

Alarms present.

Low electrolyte level alarm.

Voltage balance alarm.

Battery temperature alarm.

Equalisation charges missing.

Excessive over-discharges.

Average number of daily cycles too high.

FMP energycom disconnected.

Table A: Symbols for the types of alarms.

Screen No. 2 (Charger information)

No. Without With

FMP energycom FMP energycom

1. Type, percentage of Type, percentage

charge and of charge and

parametered temperature

temperature. memorised before

charging.

2. Voltage on starting and completing

charging and current on completing charging.

3. Capacity restored and charging time (hh:mm).

4. Symbol for condition when charging complete

(Table B) and type of fault, if present (see ‘Fault

messages’ section).

5. Coded indication of the charge.

Menus

!

C

7

The information on these screens can be reset to zero via

the Reset line on the Configuration Menu.

Symbol Condition when charging complete

Normal.

Abnormal (voluntary interruption or

interruption following a fault).

Table B: Symbols for condition when charging complete.

Status

This menu displays the status of the charger’s internal

counters (number of normal and equalisation charges, faults

by type, etc.).

Access

On the Main Menu, select STATUS and then press OK.

Call-up screen

An example is presented below.

The information displayed

The information on the screen can be reset to zero via the

Reset line on the Configuration Menu.

Message Information

Charge No. of charging operations performed.

This corresponds to the sum of lines 2 and 3.

No. of charging operations terminated

abnormally.

No. of charging operations terminated

normally.

Equal No. of automatic equalisation operations

performed by the charger.

TH No. of thermal faults*.

DF1, etc. No. of fault of types 1, 2, 3, 4, 5 or 7*.

(*) : See ‘Fault Messages’.

Configuration

This menus provides access to the charger’s 12

configuration menus.

Access

On the Main Menu, select Configuration and then press OK.

Profile

This defines the type of battery connected to the charger

from among different types (for example Ionic, Gel or PNEU).

To change the profile, press OK, select a profile from the list

using the ▼/▲buttons and confirm by pressing OK.

Temperature

This value is adjustable according to the battery technology.

•Without Fiamm Motive Power®energycom: it defines the

battery’s average operating temperature before charging.

•With Fiamm Motive Power energycom: the battery’s

operating temperature is defined automatically. It is

advisable to enter the average temperature recorded,

particularly in cold areas.

Equal time

Only valid for unsealed lead/acid batteries. This defines the

length of the equalisation operation (1 to 8 hours).

Delayed equal

Only valid for unsealed lead/acid batteries. This defines the

delay before equalisation (1 to 8 hours).

Auto equal

Only valid for unsealed lead/acid batteries. This defines the

initiation method: manual or automatic. Select:

•ON for equalisation to start automatically on completion

of charging.

•OFF to prevent automatic equalisation on completion of

charging.

Delayed charge

This defines the delay (1 to 8 hours) between the time

charging is initiated and the time that charging effectively

starts. This time delay enables you to take advantage of ‘

Off-Peak’ tariff times.

Battery rest

This defines the waiting time (1 to 8 hours) after charging

has finished to allow the battery to stabilise.

Electrovalve

This defines the opening time (15 to 120 seconds – Ionic and

Pneumatic profiles only) of the electro-valve for filling the

batteries automatically. When the OK button is pressed, a

function test is immediately initiated for ten seconds. The

operator can therefore check that the electro-valve is

opening correctly.

Range

Only accessible for chargers of the Premium HF flex

48-72-80V type. This defines the battery charging voltage

(48/72V or 48/80V).

Cable length

This defines the length of the cable battery-charger

(1.0 to 10.0m).

Cable section

This defines the cross-section of the cable (battery-charger).

Select a cross-section from the values offered (10, 16, 25, 35,

50 or 70mm2).

Reset

This reinitialises the Status and Memory counters after entry

of the password.

Config version

This shows the charger’s configuration version.

Contrast

This modifies the display’s contrast. A zero value shows a

white screen; a value of 100 shows a black screen. The

optimum value depends on the ambient lighting conditions.

If the messages on the display are unreadable (black or

white screen):

1. Hold down and ▲simultaneously.

2. When the LEDs flash (Fig. 2), adjust the contrast via the

▼/▲buttons.

3. Confirm by pressing OK.

Backlight

This activates (ON) or deactivates (OFF) the display’s

backlighting.

Language

This selects the language displayed in the menus.

8

Unpacking

The charger is supplied with the following components:

• A 2m-long mains cable.

• A 3m-long battery cable.

• The present instruction manual.

Mechanical Installation

The charger must be mounted on the wall in a vertical

position. The lower part of the charger must be at least

0.60m from the floor and/or the charger below and the

upper part 1.0m from the ceiling. The minimum distance

between two chargers must be 0.30m. You must avoid areas

where the chargers may be splashed with water.

The charger is held by 4 M8 screws suitable for the type of

support. The drilling pattern varies according to the model

of charger. Follow the illustration below.

Electrical Connection

To the three-phase supply

You may only connect to the 3-phase 400V AC mains supply

via a standard socket and an appropriate circuit breaker (not

supplied). The current consumption is shown on the

charger’s information plate.

To the battery

Polarity must be observed. Any reversal of polarity will blow

the output fuse, prevent charging and cause DF2 to be

displayed. Please refer to the Fault Messages section.

The charger must be connected to the battery by the cables

supplied:

• The RED cable: to the battery’s POSITIVE terminal.

• The BLACK cable: to the battery’s NEGATIVE terminal.

Factory Configuration

The charger is supplied with the following factory

configuration:

Profile: As per the order

Output cable length: 4 m

Configuration: As per the order

Automatic equalisation No

selected:

Deferred charging activated: No

• If no modification to the above is desired, please proceed

directly to the section on ‘Charging the battery’.

• If modification is required, go to the Configuration

section.

Charging the battery

When the charger has been configured in accordance with

the Configuration section, it can only be started when a

technically compliant battery is connected to it (type,

capacity, voltage).

Display when not charging

When the charger is in the waiting position (Start/Stop

switch on “0”) and the OK has not been pressed, the display

shows the information regarding the charger (top and

bottom lines):

1. Type of charger.

2. Charger’s characteristics.

3. ‘Waiting’ status message.

4. Previously selected charging profile.

5. Software version.

6. Selected operating temperature.

Initiating delayed charging

If the charger has been programmed in this way

(Configuration Menu / Delayed Start), charging starts after

the time delay set. The display shows the time remaining

before charging starts.

Use

394

H

H (mm)

Type 1 540

Type 2 540

9

Initiating desulphation before charging

Desulphation of an unsealed lead/acid battery:

• Either starts automatically when the battery is heavily

discharged; the length of the desulphating operation is

defined by the charger’s electronics. The charging

process is initiated automatically at the end of the

desulphation period.

• Or is initiated manually, as shown below.

To initiate desulphation manually:

1. Set the Start/Stop switch to “0”.

2. Hold down the button.

3. Set the Start/Stop switch to “1”. Release .

Desulphation is initiated for the programmed period

(“Equal time“ menu). The charging initiation process

must be started manually on completion of the

desulphation period.

Initiating charging

1. Set the Start/Stop switch to “ I “.

The display shows the information on the battery

connected and counts down the time remaining before

effective charging starts.

No. Without With

FMP energycom FMP energycom

1. Type of charger, software version.

2. Countdown for Countdown for 2

2 minutes before minutes maximum

charging effectively before charging

starts. effectively starts.

3. Programmed charging Detected charging

profile – flashing profile – flashing

during this phase. during this phase (*).

4. Empty line. Alternating display of

the voltage, capacity

and the serial number

detected, as the

information is received

and alarms if present (*).

5. Programmed Detected operating

operating T°. temperature (*).

6. Equalisation symbol requested on completion

of charging (see § Completion of charging with

equalisation).

(*) As the information is received.

Once the two-minute countdown is complete, the display

shows the information regarding the charging operation.

Proceed to the section on Effective Charging.

Faults DF1, DF2 and DF3 prevent charging. Please refer

to the section on Fault Messages.

Effective charging

A few moments after charging starts, the display shows the

various charging details in alternation.

No. Without With

FMP energycom FMP energycom

1. Type of charger, software version.

2. Charging symbol. Priority alarm if present.

3. Equalisation requested on completion of charging.

4. Programmed Detected operating

operating T°. temperature.

5. Programmed charging Detected charging profile.

profile.

6. Empty line. Alternation between

the voltage, capacity, the

serial number detected

and alarms if present.

7. Charging indicator.

8. Information updated and displayed cyclically.

Please refer to Table C.

9. Percentage of charge.

Information displayed

Sign Type of measurement Example

UBattery voltage (V). 26.1

uVoltage per cell (V). 2.18

IInstantaneous charging current (A). 55

CCapacity restored (Ah). 71

tCharging time spent (hh:mm). 03:36

HEstimated remaining charging time 05

(hours).

DF No. of any fault occurring. See § Fault DF5

Messages.

Table C: Symbols for the information displayed during charging.

Completion of charging without equalisation

1. The green light (Fig. 2, No. 7) illuminates when charging

has been completed correctly.

The green ‘charging complete’ light (Fig.2, No. 7) is

illuminated and the message AVAIL is displayed (1). The

display shows, in alternation (2):

• The charging time taken.

• The number of amp hours restored.

Please refer to the sections on Memory or Status for details

of the information on completion of charging.

Any other visual indication from any of the three lights

indicates a problem during charging. Please refer to the

Control Panel section.

10

If the battery remains connected, in order to keep it charged,

compensation and subsequent equalisation charging

operations will be initiated automatically, depending on the

type of battery.

2. If an equalisation charging operation has been

programmed (unsealed lead/acid battery), this is

initiated automatically.

If this is not the case, equalisation charging can be

initiated manually: please refer to the section on

Completion of charging with equalisation.

3. If the green light is flashing, the battery is in its resting

phase.

Wait until the light stops flashing.

4. Set the Start/Stop switch to “0”.

5. Disconnect the battery, which is now ready for use.

Completion of charging with equalisation

Equalisation only concerns unsealed lead/acid batteries. It

can be initiated either manually or automatically.

Manual initiation

1. As soon as charging is complete (the green light is

permanently lit or is flashing - Fig.2, No. 7), press

the button.

The messages EQUAL I = (equalisation current) and

EQUAL H = (remaining equalisation time) (Nos. 1 and 2

below) indicate that equalisation has been initiated.

2. The battery is ready for use as soon as the green light

(Fig. 2, No. 7) illuminates.

Automatic initiation

If equalisation has been programmed (Configuration Menu /

Equal time, Delayed equal and Auto equal set to ON),

equalisation charging is initiated automatically.

Furthermore, if the battery remains connected, in order to

keep it charged, maintenance charges (compensation and

subsequent equalisation charging operations) will be initia-

ted automatically, depending on the type of battery. The

same information as for manual initiation is displayed (see

above).

Display of the history per charging operation

To display the memorised information and to reset it to

zero, please refer to the Memory section.

Display of the charger’s history

To display the history and to reset it to zero, please refer to

the Status section.

Fault messages

Fault Cause Remedial action

DC Appears before a DF1

fault is displayed.

DF1* Charger fault. Check the power supply

voltage.

DF2* Output fault. Check that the battery is

correctly connected (that

the cables are not

reversed) and the output

fuse.

DF3* Unsuitable battery. Battery voltage too high

or too low. Connect the

correct charger for the

battery

DF4 The battery has been Charging continues.

discharged more than

80% of its capacity.

DF5 Battery requires Check the charging

inspection. cables (cross-section too

small), the terminals

(oxidisation, not tight)

and the battery

(defective elements).

DF7 Pneumatic mixing air Check the air

circuit fault (the red circuit (pump, tubing).

light flashes).

TH* Thermal fault Check that the fan(s)

resulting in is (are) working

interruption of correctly and/or

charging. that the ambient

temperature is not too

high or whether there is

poor natural ventilation

to the charger.

STOP* Critical electrolyte level in the battery.

Fill the battery.

(*): A blocking fault preventing charging from continuing.

Technical characteristics of Premium HF flex

Units 2004 2006 2008 2010

Power supply voltage V 400 ±10% tri 400 ±10% tri 400 ±10% tri 400 ±10% tri

Frequency Hz 50/60 50/60 50/60 50/60

Current absorbed A 7 10 13 17

Power supply cable mm24 x 2.5 4 x 2.5 4 x 4 4 x 4

Power supply fuse A Protistor 20A Protistor 20A Protistor 30A Protistor 30A

Battery cable (1) mm225 25 50 50

Battery cable length m 1 to 10 1 to 10 1 to 10 1 to 10

IP protection level IP20 IP20 IP20 IP20

Operating temp. °C 0 to +40 0 to +40 0 to +40 0 to +40

Display LCD LCD LCD LCD

Weight kg 30 30 30 55

Dimensions (Hx W xD) mm 750x410x317 750x410x317 750x410x317 940x410x317

(1) Take the electrical installation into account when determining the actual cable cross-section.

12.2011 / Subject to revisions without prior notice

European Headquarters:

EnerSys EMEA

EH Europe GmbH

Löwenstrasse 32

8001 Zürich

Switzerland

Phone: +41 44 215 74 10

Fax: +41 44 215 74 11

EnerSys Ltd

Oak Court

Clifton Business Park

Wynne Avenue

Swinton

Manchester M27 8FF

Phone: 0161 794 4611

Fax: 0161 727 3809

Please refer to the website address for details

of your nearest EnerSys office:

www.enersys-emea.com

© 2011. All rights reserved.

All trademarks and logos are the property of

or licensed to EnerSys and its affiliates unless

otherwise noted.

Table of contents

Other Fiamm Batteries Charger manuals