www.fiberoptions.com

5

1. Wipe the inside of the port’s sleeve with a lint-free

pipe cleaner moistened with reagent-grade isopropyl

alcohol. Blow dry with dry air.

2. Clean the connector using a lint-free cloth dampened

with alcohol to thoroughly wipe the side and end of

the ferrule. Blow the ferrule dry with dry air. Visually

inspect the ferrule for lint.

3. Fasten the fiber optic cable to the port.

Connecting Channels 12 - 20

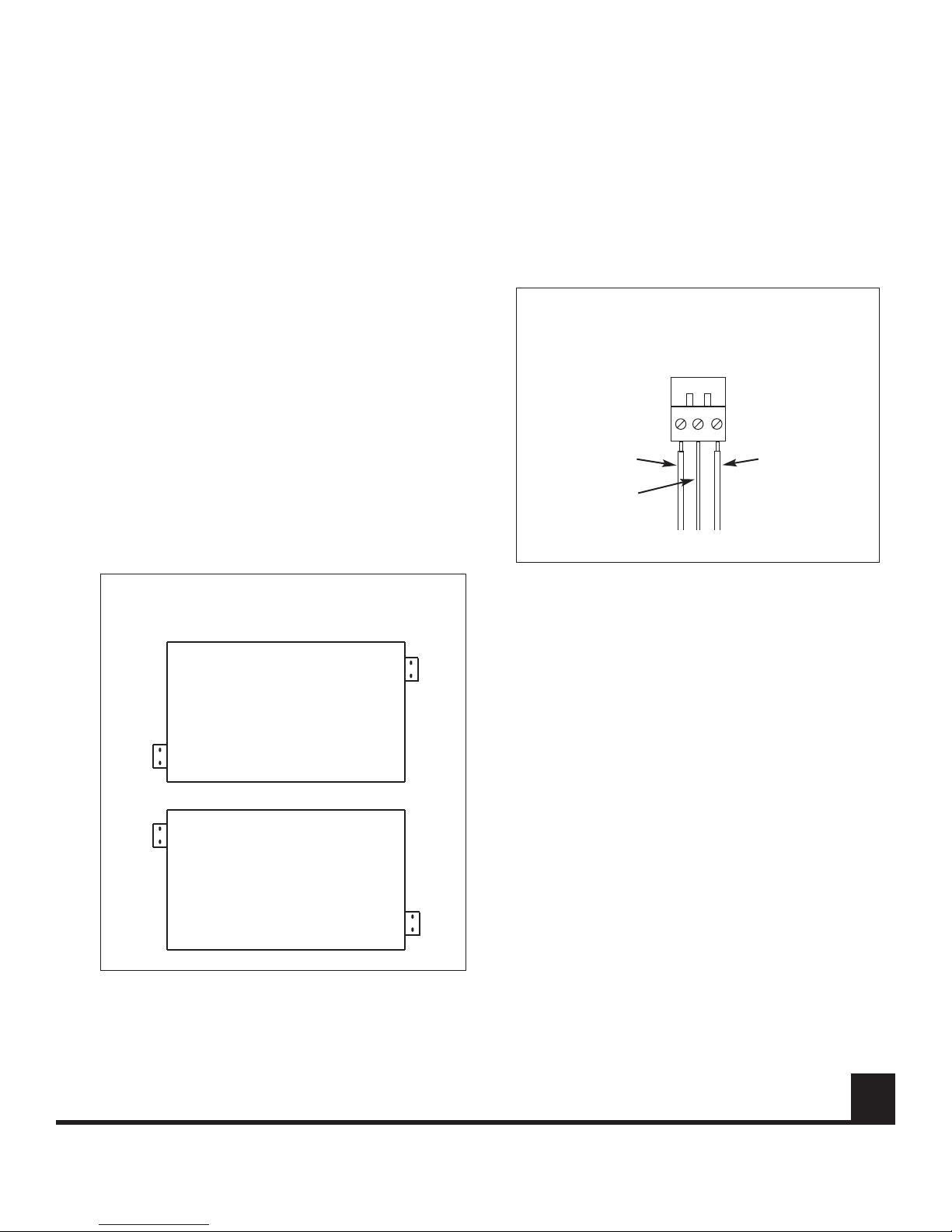

Units designed for transmission of more than 10 channels

(9912V - 9920V) consist of two 1-RU units and a fiber

jumper at each end of the link.

One of the two 9900V units will have BNC connections for

channels 1 - 10 . These units are the primary units in the

link and can complete the link with or without the second-

ary units. Secondary units

have BNC connections for

channels 11 and 12 and may

have connections for addition-

al channels, always in pairs,

up to channels 19 and 20.

Primary units have two optical

ports each, one labeled IN

and one labeled OUT.

Secondary units each have

only one optical port, labeled

OUT on the transmitter and IN

on the receiver. At each end of

the link, use the provided fiber

jumper to connect the second-

ary unit’s optical port to the

opposite port on the primary

9900V unit. In other words,

connect OUT to IN, and IN to

OUT (see Figure 8). Both

units at each end of the link

should now be joined with a

fiber jumper. The appropriate

fiber port should be free to

complete the link - OUT on the

transmitter side and IN on the

receiver side.

Video Cables

Video signals are sent over a

75 ohm coaxial cable termi-

nated in a BNC connector

(e.g., RG 59/U with a BNC

connector).

1. At the transmitter end, connect the video source to

one of the numbered VIDEO connectors.

2. At the receiver , connect the corresponding VIDEO

BNC to monitoring equipment.

Data Connection

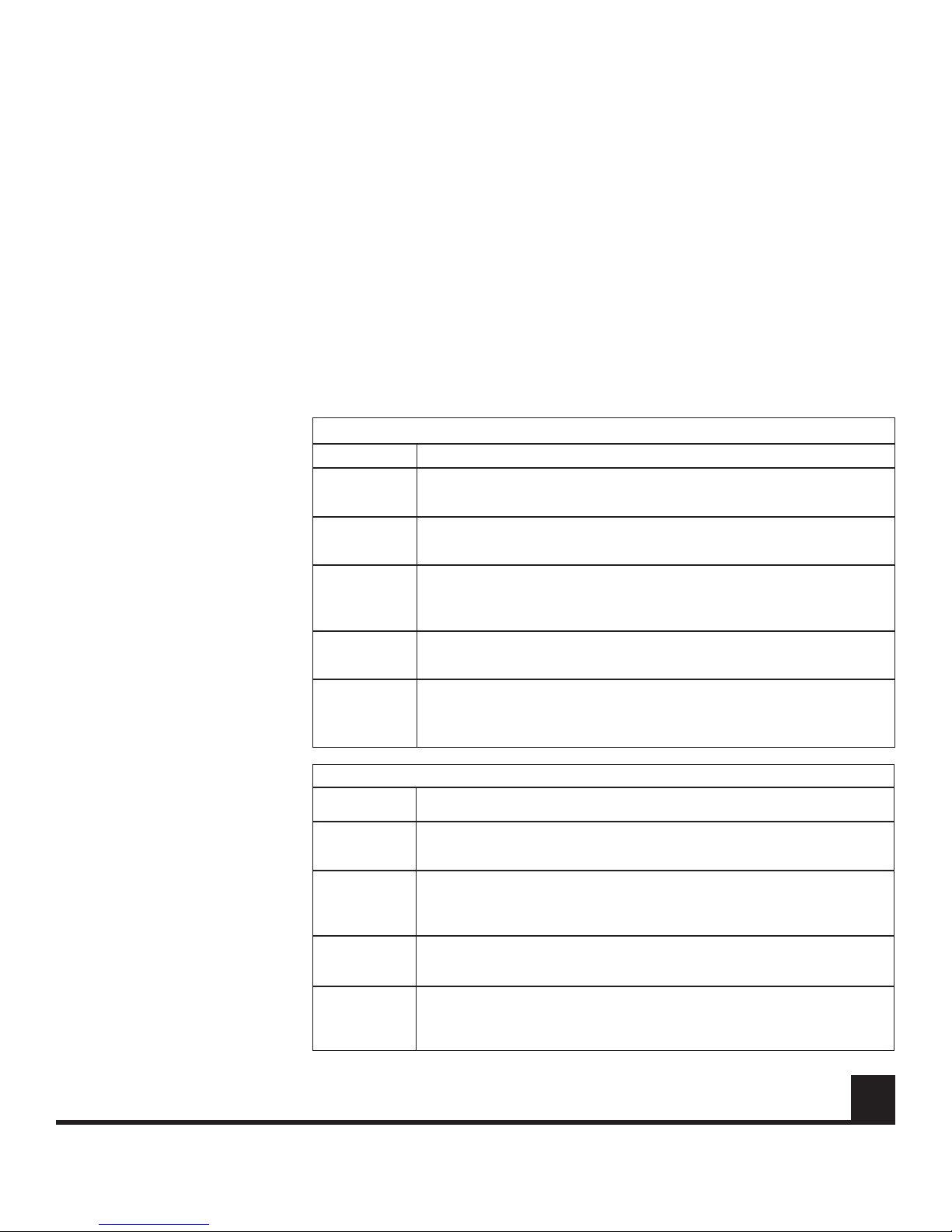

The 9900VD series units support RS232, RS442,

Manchester, and Biphase data formats. All are connected

a male RJ-45 plug which is then inserted into the corre-

sponding RJ-45 socket on the rear of the 9900VD unit.

Data connection must be made according to the tables on

page 4 depending upon the data format being used. Refer

to Figure 6.

Connection to the RJ-45 plug may also be made using a

cable adapter which is provided with the 9900VD unit.

Refer to Figure 7.

Table 2: Receiver LED Indicators

Green or flashing green - data is being transmitted. No action needed.

Unlit -no data transmitted (not used in 9900V series without data capabili-

ties). Verify that the data input is properly connected and that the data

source is operating properly.

DATA

TX

Green - communication is established with the transmitter. No action.

Unlit - no communication established. Verify that the transmitter is on and

operating and that the fiber is connected to both units.

LINK READY

Green - adequate optical signal received. No action needed.

Red - inadequate optical signal. Check Fiber connection and optical

cable. Verify optical budget is not exceeded. Verify that the transmitting

unit is connected and operating.

LEVEL/

LOSS

Green - AC power is present. No action needed.

Unlit - no power present. Check connection to AC outlet, check outlet for

AC if connection is good.

POWER

Indication - Suggested ActionLED Name

Green - Laser functioning properly. No action needed.

Unlit - laser has failed. Contact Fiber Options technical support for assis-

tance.

LASER

TX

Green - camera (video) signal normal on this channel. No action needed.

Unlit - video is not being received on this channel. Check coaxial cable

input for this channel. Verify that the video source (camera) is operating

and is properly connected.

Table 1: Transmitter LED Indicators

VIDEO

STATUS

Green - Received optical signal is adequate. No action needed.

Unlit - Inadequate optical signal. Check Fiber connection and optical

cable. Verify optical budget is not exceeded. Verify that the transmitting

unit is connected and operating.

DATA

RX

Unused in current models.

Reserved for future use.

COMMAND

TX

Green - AC power is present. No action needed.

Unlit - no power present. Check connection to AC outlet, check outlet for

AC if connection is good.

POWER

Indication - Suggested ActionLED Name