FICEP 1001 DFB User manual

Line Model: 1001 DFB

Serial number: 32292

Programming

and operating manual

Programming and operating manual Model 1001 DFB

2 FICEP S.p.A.

Blank page

Model 1001 DFB Programming and operating manual

FICEP S.p.A. 3

INTRODUCTION

This manual provides people involved with all information about operating use and programming of the

machine or of the production line which refers to. It has to be considered like an important part of the ma-

chine supply and must follow the machine until its demolition.

This manual has to be kept with care in a place near by the machine and within reach of all operating and

programming people concerned, who have to be aware of its contents, provided that it can’t substitute the

experience and common sense of a qualified and well trained staff.

Keep this manual for all future references; in the event of loss or damage, ask for a new copy to FICEP

After Sales Service.

The technical information included in this manual are property of FICEP S.p.A. and must be considered

reserved. Law forbids the reproduction, even if partial, of the graphic work, the text or the images.

Some details described in the texts and/or represented in the illustrations of this manual could be slightly

different from the machine which refers to, or in the figures some element could have been omitted to en-

sure the illustrations understanding.

This manual has been divided into chapters to make the consultation easier.

The subjects covered in this manual are exactly the ones required by “CE Machine Directive 98/37”.

The manual reflects the technological development at the moment the machine is manufactured and

could not be considered obsolete and incomplete only because it has been updated in a consequent date.

Ficep S.p.A., with the aim of a continuous technical and technologic improvement of its products, reserves

the right to modify the production and the manual without being bound to update previous editions.

READ CAREFULLY THIS MANUAL BEFORE OPERATING WITH THE MACHINE OR THE LINE.

STRUCTURAL STEEL WORK DIVISION

SALES DEPARTMENT – AFTER-SALES SERVICE

21045 - GAZZADA - SCHIANNO (VA) ITALY

Tel +39 (0332) 876111 - Fax +39 (0332) 462459

Programming and operating manual Model 1001 DFB

4 FICEP S.p.A.

Blank page

Model 1001 DFB Programming and operating manual

FICEP S.p.A. 5

Symbols used in this manual

Warnings included in the paragraphs

marked by this symbol, if disregarded

can be dangerous for things and/or per-

sons.

Subjects dealt with in the paragraphs

marked by this symbol are particularly im-

portant and related to programming.

Subjects dealt with in the paragraphs

marked by this symbol are particularly

important and related to machine setup.

Subjects dealt with in the paragraphs marked

by this symbol attain to procedures and rep-

resent the practical operative guide.

Subjects and concepts expressed in the

paragraphs marked by this symbol are par-

ticularly important.

Programming and operating manual Model 1001 DFB

6 FICEP S.p.A.

Blank page

Model 1001 DFB Programming and operating manual

FICEP S.p.A. 7

INDEX

INTRODUCTION ............................................................................................................. 3

Symbols used in this manual ................................................................................................................. 5

INDEX ............................................................................................................................. 7

CHAPTER 1: SYSTEM DESCRIPTION ........................................................................ 11

Introduction of the system ................................................................................................................... 11

Possible layout of a standard system .................................................................................................. 11

Identification of the machine plates position........................................................................................ 11

Electrical data plate ............................................................................................................................. 12

Machine identification data plate ......................................................................................................... 12

CNC controlled positioning .................................................................................................................. 13

Introduction .......................................................................................................................................... 13

Axes table ............................................................................................................................................ 13

Origins and sign conventions of the axes............................................................................................ 14

Controls and signalling ........................................................................................................................ 15

Main electric cabinet ............................................................................................................................ 15

Switching ON procedure ..................................................................................................................... 15

Operator’s position .............................................................................................................................. 16

CHAPTER 2: CNC DESCRIPTION ............................................................................... 19

Introduction of the CNC operating environment................................................................................ 19

Touch screen ......................................................................................................................................... 19

Fixed elements for all pages ................................................................................................................ 19

CHAPTER 3: THE CNC WORKING ENVIRONMENT .................................................. 21

CNC Software sections ......................................................................................................................... 21

Line start up ........................................................................................................................................... 21

The main push-button panel ................................................................................................................ 22

Control and protections zone .............................................................................................................. 23

Axes zero cycle ...................................................................................................................................... 24

Preliminary remarks ............................................................................................................................ 24

Procedure to execute the axes zero cycle .......................................................................................... 25

CHAPTER 4: MANUAL CONTROLS ............................................................................ 28

Procedure to activate the manual control of the axes ....................................................................... 28

Procedure to manual control the axes ................................................................................................ 29

Manual control of the auxiliary devices and adjustments ................................................................ 30

The auxiliary push-buttons panel ........................................................................................................ 30

Functions of the auxiliary push buttons panel ..................................................................................... 30

Soft-keys for adjustment and setup operations of the machine .......................................................... 31

Soft-keys window for drilling unit ......................................................................................................... 31

Function of the drilling unit soft-keys ................................................................................................... 32

Soft-keys window for sawing unit ........................................................................................................ 33

Function of the sawing unit soft-keys .................................................................................................. 34

CHAPTER 5: TOOLS SETUP ....................................................................................... 36

Machine setup ....................................................................................................................................... 36

Drilling tools ......................................................................................................................................... 36

Band of the cutting unit ........................................................................................................................ 37

Portable push buttons panel for service operations ............................................................................ 38

CNC preparation .................................................................................................................................... 39

Tables ..................................................................................................................................................... 40

Programming and operating manual Model 1001 DFB

8 FICEP S.p.A.

Drilling-milling operations table ........................................................................................................... 40

Cutting operations table ...................................................................................................................... 42

Setup ...................................................................................................................................................... 43

Drilling-Milling operations setup window ............................................................................................. 43

Cutting operation setup window .......................................................................................................... 47

Codes describing the tool and the operations types ........................................................................... 48

Setup general page ............................................................................................................................ 50

CHAPTER 6: PROGRAMMING .................................................................................... 52

Preliminary remarks ............................................................................................................................. 52

Terminology ........................................................................................................................................ 52

The programming window .................................................................................................................. 53

To input a new program ...................................................................................................................... 54

Editing a program: preliminary remark .............................................................................................. 57

Programming: single hole ................................................................................................................... 58

Programming: linear pattern of holes with same diameter ................................................................. 59

Programming: matrix pattern of holes with same diameter ................................................................ 60

Programming: pattern of holes with same diameter arranged on an arc of circle or a whole circle ... 61

Programming: marking operations ..................................................................................................... 62

Programming: special functions ......................................................................................................... 63

Use of the absolute and incremental coordinates .............................................................................. 63

Temporary repositioning of the part origin .......................................................................................... 64

Permanent repositioning of the piece origin ....................................................................................... 65

Programming of special functions ...................................................................................................... 65

Milling operations ................................................................................................................................ 67

Automatic execution of particular drilling and pointing operations ...................................................... 69

Edit of program remarks ..................................................................................................................... 70

Bar nesting ............................................................................................................................................ 70

Basic procedure for nesting execution ............................................................................................... 72

Variants for basic nesting procedure: how to use the push-button “Rotation” .................................... 74

Variants for basic nesting procedure: manual nesting ....................................................................... 75

Variants for basic nesting procedure: automatic nesting ................................................................... 76

Bars list ............................................................................................................................................... 76

Execution parameters ......................................................................................................................... 77

CHAPTER 7 : PROGRAM EXECUTION ...................................................................... 80

Execution of working operations: introduction................................................................................. 80

Procedure to execute a program of a single piece ............................................................................. 82

Procedure to execute a program of a nesting .................................................................................... 86

The execution window ........................................................................................................................ 89

Operator controls during automatic execution .................................................................................... 90

Procedure to restart the line after emergency .................................................................................... 91

Procedure to restart the line after unexpected power shut off ........................................................... 91

CHAPTER 8: SPECIAL AND ADDITIONAL OPERATIONS ........................................ 92

Alternatives using the pincher ............................................................................................................ 92

Working flat profiles ............................................................................................................................ 92

Working “U” profiles and square tubes ............................................................................................... 92

Working “D” profiles (different flanges)............................................................................................... 93

Change of pincher orientation ............................................................................................................. 93

Procedure for semi-automatic cut....................................................................................................... 94

Test working ....................................................................................................................................... 96

Operator parameters for basic operations ......................................................................................... 96

Verifying the correct axes displacement ............................................................................................ 97

CHAPTER 9: ARCHIVE OPERATIONS ....................................................................... 98

File management .................................................................................................................................. 98

Import operations ................................................................................................................................. 98

Import of DSTV files ........................................................................................................................... 98

Import of single piece or bar programs generated by third applications ............................................. 99

Final working data of the line ............................................................................................................ 101

Model 1001 DFB Programming and operating manual

FICEP S.p.A. 9

CHAPTER 10: MAINTENANCE AND TROUBLE SHOOTING ................................... 102

Signalling and messages ................................................................................................................... 102

Display of Input/Output (I/O) condition ............................................................................................. 103

Dynamic synoptic ................................................................................................................................ 105

Summary of all commands of menu “View” and “Setup”............................................................... 106

“Debug” window ................................................................................................................................. 106

Graphic push-button “Installation-Servicing”.................................................................................. 107

General rule ....................................................................................................................................... 107

Contents of each tab ......................................................................................................................... 107

CHAPTER 11: PROCEDURE TO SHUT OFF THE LINE ........................................... 110

APPENDIX A – DIAGNOSTICS .................................................................................. 112

List of more frequent signals ............................................................................................................. 112

Service messages class 200 – Operator Messages ......................................................................... 113

Programming and operating manual Model 1001 DFB

10 FICEP S.p.A.

Blank page

Model 1001 DFB Programming and operating manual

FICEP S.p.A. 11

CHAPTER 1: SYSTEM DESCRIPTION

Introduction of the system

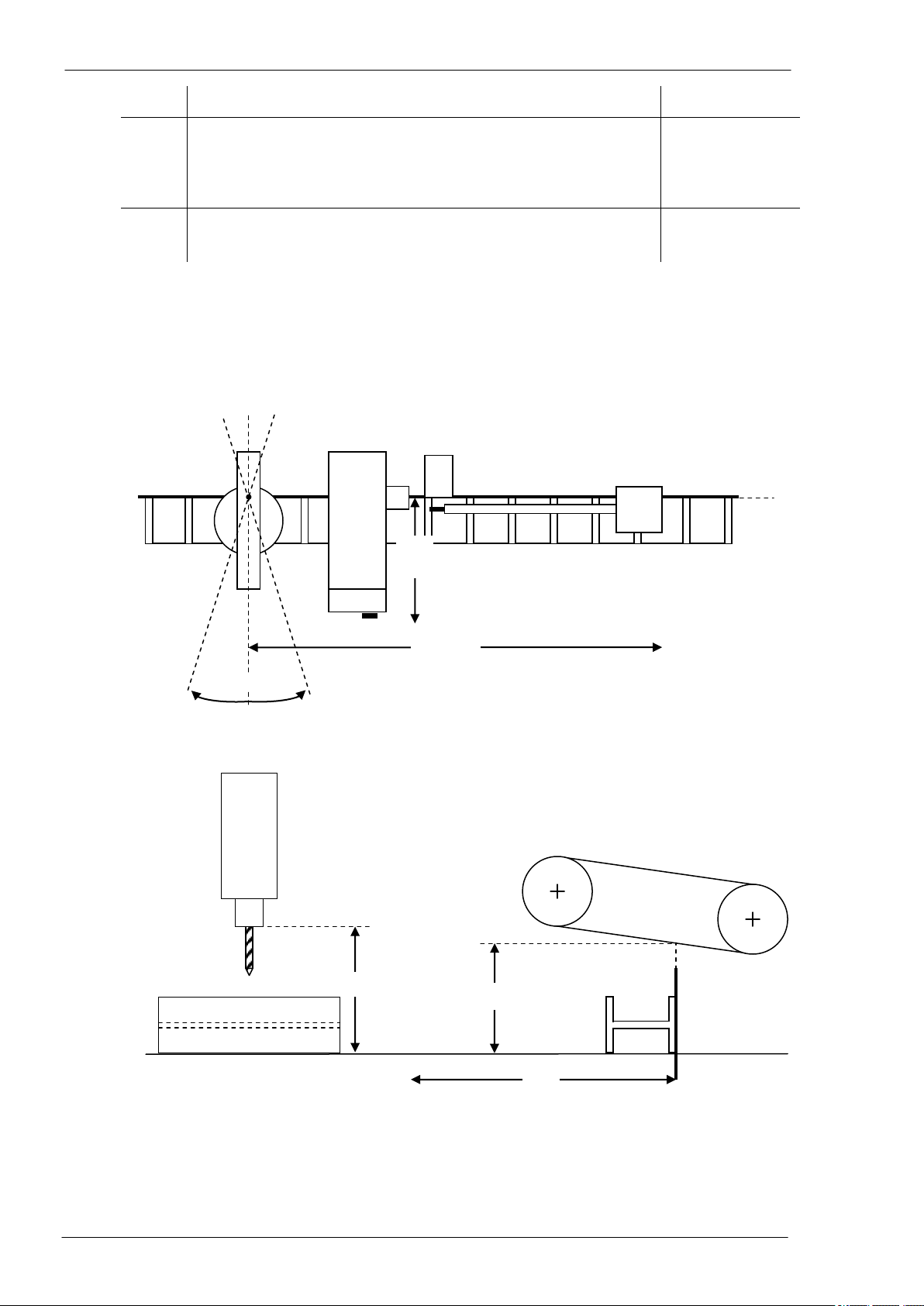

Possible layout of a standard system

The standard system is complete with:

1) rollers (loading side)

2) carriage

3) pincher

4) drilling unit

5) drilling head

6) cutting unit (saw)

7) marking unit (optional)

8) main switch

9) articulated arm

10) CNC and Operator’s position

11) rollers (unloading side)

Identification of the machine plates position

The plate with rating data is near the main electric switch while the plate with machine identification data is

fixed on the machine left lower corner, looking the machine from the loading (carriage) side.

1

2

3

4

6

7

8

5

9

10

11

Programming and operating manual Model 1001 DFB

12 FICEP S.p.A.

Electrical data plate

Machine identification data plate

The serial number identifies the system all over the world; for any spare-parts, assistance or technical

support requests use this number as reference.

GAZZADA SCHIANNO (VA) - ITALY

Type

XXXXX

Serial Number

XXXXX

Drawing number

DES XXXXX

Year

XXXX

XXX V

XX Hz

3 ~

XX A

Voltage

Frequency

Phases

Max load

XXX A

Max load current

● GAZZADA SCHIANNO ● VARESE ● ITALIA ●

SERIAL NUMBER

XXXXX

YEAR OF CONSTRUCTION

XXXXX

V/Hz

XXXXX

MACHINE MODEL

XXXXX

SECTIONS TO BE PROCESSED

mm

MAX Ø

mm

MAX THICKNESS

Kg

MAX WEIGHT

N/mm2

TENSILE STRENGHT

BAR

PNEUMATIC SYSTEM

BAR

CUTTING GAS

BAR

HYDRAULIC SYSTEM

WORKING PRESSURES

+39(0332)-876111

FAX +39(0332)-462459

Model 1001 DFB Programming and operating manual

FICEP S.p.A. 13

CNC controlled positioning

Introduction

1. In this manual the expressions “side A”, “side B”, “side C” and “side D” are often used; these expres-

sions refer to the profile sides as shown in the following pictures. Note that the “A” refers always to the

profile side on the datum line of the machine, “B” to the mobile vice reference, “C” to upper side and

“D” to lower side of the profile.

The pictures on the left are applicable for each type of profiles except angles; while those on the right

are valid only for angles.

2. In this manual, we call “axes” all the CNC automatic controlled movements.

Axes table

Name

Description

Function

AXX

Carriage axis for longitudinal positioning of material

Material handling

AXP

Pincher positioning axis to suit profiles height (optional)

APE

Magnet positioning axis for transferring of cut pieces (optional)

AMM

Mobile vice axis

Material holding

AXY

Traverse axis for the horizontal positioning of the drilling unit 1

Drilling

operations

(standard head)

AXZ

Traverse axis for the vertical positioning of the drilling unit 1

MDY

Spindle rotation axis (stationary vice side)

AXV

Traverse axis for the horizontal positioning of the drilling unit 2 (op-

tional)

Drilling opera-

tions (second op-

tional head)

AXW

Traverse axis for the vertical positioning of the drilling unit 2 (op-

tional)

MDZ

Spindle rotation axis (mobile vice side) (optional)

AP1

Probe axis on the stationary vice side (optional)

Probing

operations

AP2

Probe axis on the mobile vice side (optional)

A

B

C

D

A

B

B

A

C

D

B

A

Programming and operating manual Model 1001 DFB

14 FICEP S.p.A.

Name

Description

Function

ADM

Marking unit disc rotation axis (optional)

Marking

operations

APD

Counteracting axis of marking unit (optional)

AXU

Scribing axis for the lower side of the web (optional)

AXR

Saw mitering axis

Cutting

operations

AXS

Saw band feedrate axis

All axes tagged with a star are shown in the following pictures

Origins and sign conventions of the axes

NOTE The above pictures refer to a 1001 DFB machine with right datum line (represented by the thick

line); the system can be assembled with left datum line (in accordance with the selected layout).

AXX

0

-

+

AXY

AMM

-

+

AXR

+

-

AXY = 0

AMM = 0

AXZ = 0

+

-

AXZ

AXS = 0

+

-

AXS

AXY

AMM

AXY = 0

AMM = 0

-

+

Model 1001 DFB Programming and operating manual

FICEP S.p.A. 15

Controls and signalling

Main electric cabinet

On the electric cabinet, there are the main switch and the “RESET” push-button with blue warning light.

To power the line it is necessary to rotate the main switch in “ON” position; to start up the line it is neces-

sary to push the “RESET” push-button to switch the blue warning light OFF. Meaning of the blue warning

light: line powered but not ready.

Switching ON procedure

On the others electric cabinets, there are no controls or signalling for the operator.

ON

OFF

ON

OFF

1 ÷ 2 seconds

1)

2)

3)

RESET

Programming and operating manual Model 1001 DFB

16 FICEP S.p.A.

Operator’s position

The operator’s position, connected to the drilling machine, is build up from a colour video, some push-

button stations and a PC keyboard.

Through screen and keyboards, the operator can program and completely control the line.

1) Main push-button panel: push-button and selectors switches necessary for the manual or auto-

matic execution of the main operative functions.

2) Colour screen: with touch screen function

3) Auxiliary push-button panel: this includes special functions typical of each line (ex. vices,

pincher controls, etc…)

In this zone, there is an emergency push-button with mechanical reset. When activated, all

actuators on the machine and the auxiliary circuits are immediately switched OFF. To re-

store the normal functioning, it is necessary to unlock the push-button (depending on the

different model it is required to pull or to clockwise rotate the red head) and to push again

the “RESET” push-button with blue warning light sideways to the main electric switch.

Another emergency push-button is on the portable push buttons panel for maintenance

operations (see “Portable push buttons panel for service operations”, page 38).

4) Controls and protections zone: Key type selector switch to lock the machine in safety mode for

tool setup, STOP push-button for drilling cycle and protections alarm RESET push-button (acti-

vated by interruption of protection barriers round the machine, if provided).

5) Alphanumeric keyboard: standard PC keyboard having letters, numbers and others symbols; it

is used to input data and information, to edit programs, etc…

Main and auxiliary push-button panels - Push buttons with LED included may properly be considered true

two-position selector switches:

If the LED is not illuminated, the selector switch is in OFF position and the relevant command is

not activated. To move the selector switch to ON position, just press the push button and wait till

when the LED is illuminated.

If the LED is illuminated, the selector switch is in ON position and the relevant command is acti-

vated. To move the selector switch to OFF position, just press the push button and wait till when

the LED is no more illuminated.

If the LED is blinking, it signals the system availability to accept the command of the push-button.

1

3

4

5

2

Model 1001 DFB Programming and operating manual

FICEP S.p.A. 17

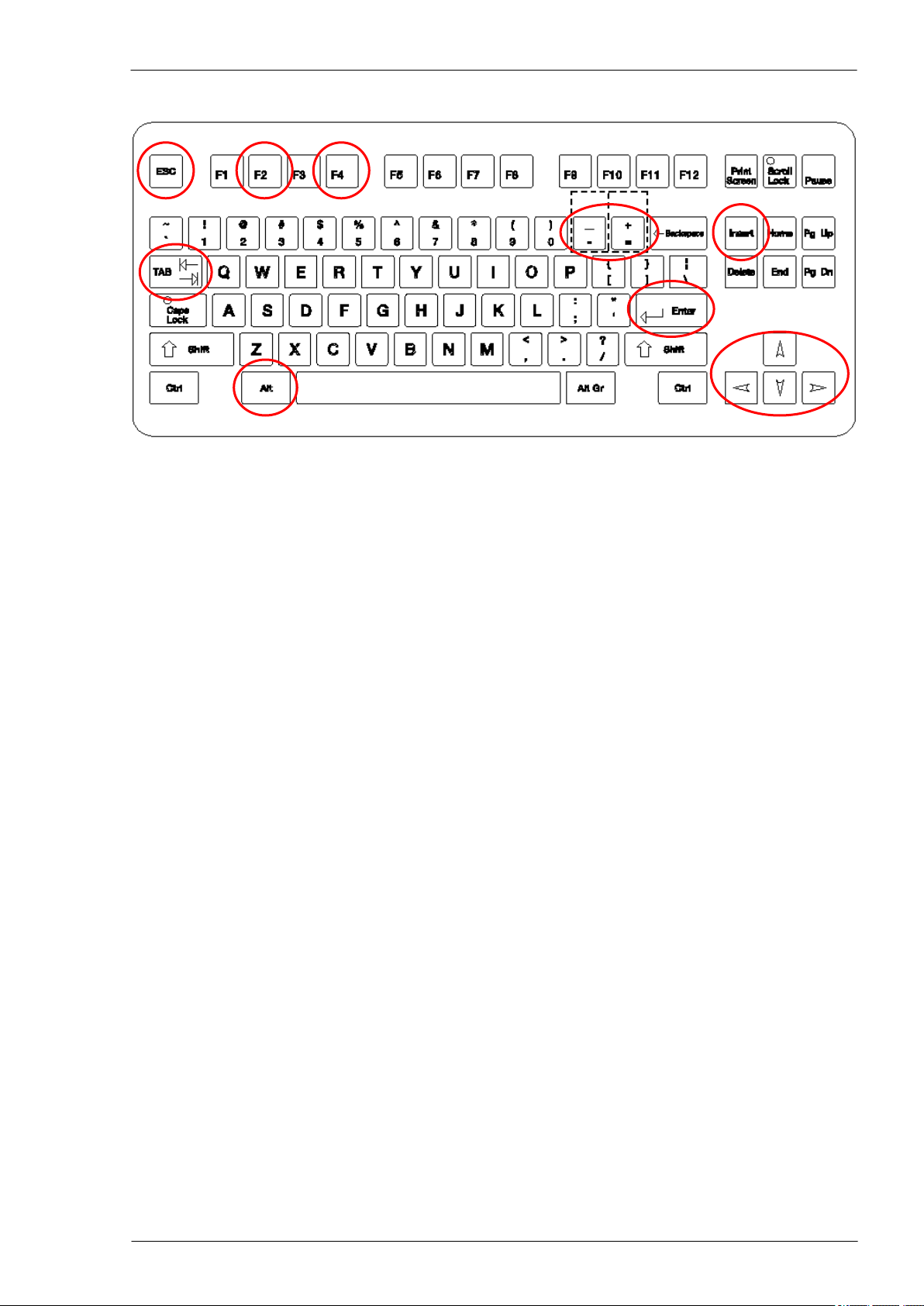

Alphanumeric PC keyboard

Some keys have particulars functions:

ESC:

To escape from an application, coming back to the previous level.

TAB:

To move the cursor on different boxes.

ENTER:

To open the selecting window evidenced by the cursor, or to confirm the execution

of a common request (OK).

ARROWS:

To move the cursor in the selected direction, on a field or on a list.

F2:

To modify data already input or to confirm modifications executed.

F4:

To open lists of options to be used when programming or in processing operations

(Aided programming).

INSERT:

To move the curser on a blank table, and input new working data (it is named INS

in the example).

+/- :

To increase (+) or decrease (-) the axes speed, or to program negative/positive

incremental or absolute coordinates.

DELETE

To delete characters on the right of the cursor position

BACKSPACE

To delete characters on the left of the cursor position

Keys combinations:

ALT+H:

Opens the windows describing messages.

ALT+TAB:

Enables to select one of the already opened applications or activates the actual

page on the video

CTRL+ESC:

Opens the Windows menu list (ESC to close)

CTRL+X:

Stores and removes the data evidenced by the cursor

CTRL+C:

Stores the data evidenced by the cursor to be copied

CTRL+V:

Paste the stored data in the actual position of the cursor

Programming and operating manual Model 1001 DFB

18 FICEP S.p.A.

Blank page

Model 1001 DFB Programming and operating manual

FICEP S.p.A. 19

CHAPTER 2: CNC DESCRIPTION

Introduction of the CNC operating environment

The CNC operating environment is called “Minosse” and the previous picture represents the introduction

screen page.

There are five graphic push-buttons which define four different working sections (Programming, Execu-

tion, Installation and Servicing, Communication CAM) and the system shut down (“OFF”).

To enter one of the four main pages or to shut down the system, it is necessary to press the key corre-

sponding to the underlined character of the word of each graphic push button or press the screen in the

graphic push-button corresponding area.

Press the ESC key on the PC keyboard to return to the first page.

Touch screen

To carry out a touch screen command, just gently touch the area on the screen where the relevant push-

button is displayed.

Clean the screen only when the system is shut down to avoid wrong commands.

Fixed elements for all pages

The background of all pages (1) is the one shown in the following picture.

Programming and operating manual Model 1001 DFB

20 FICEP S.p.A.

2, 3 Box signalling a current alarm, error or messages (numerical code and brief description). To open

the alarm window press the combination ALT+H on the PC keyboard.

4 shows the current time in the following format: hh:mm:ss = hours:minutes:seconds, of the clock

inside the PC.

5 per cent value of the AXX axis movement speed (from a min. of 10% up to a max. of 100%). The

value, which has been set, is displayed by a filling bar and by a value written as percent. The speed

variation is made by 10% steps.

6, 7 by “+” and “-“ graphic push buttons or the corresponding keys of the PC keyboard, the operator can

increase or decrease the speed.

This manual suits for next models

1

Table of contents

Popular Industrial Equipment manuals by other brands

transnorm

transnorm TS 2733 operating instructions

Atlanta Attachment Company

Atlanta Attachment Company 1390HCB Technical Manual & Parts Lists

BERRIDGE

BERRIDGE TZ-21 Operation manual

Can Industrial

Can Industrial W40H21P Series Assembly manual

Grundfos

Grundfos IO 113 Installation and operating instructions

Simplex

Simplex LT0290 User manual and reference guide