FiDUS MVPS600 Series User manual

1www.fiduspower.com

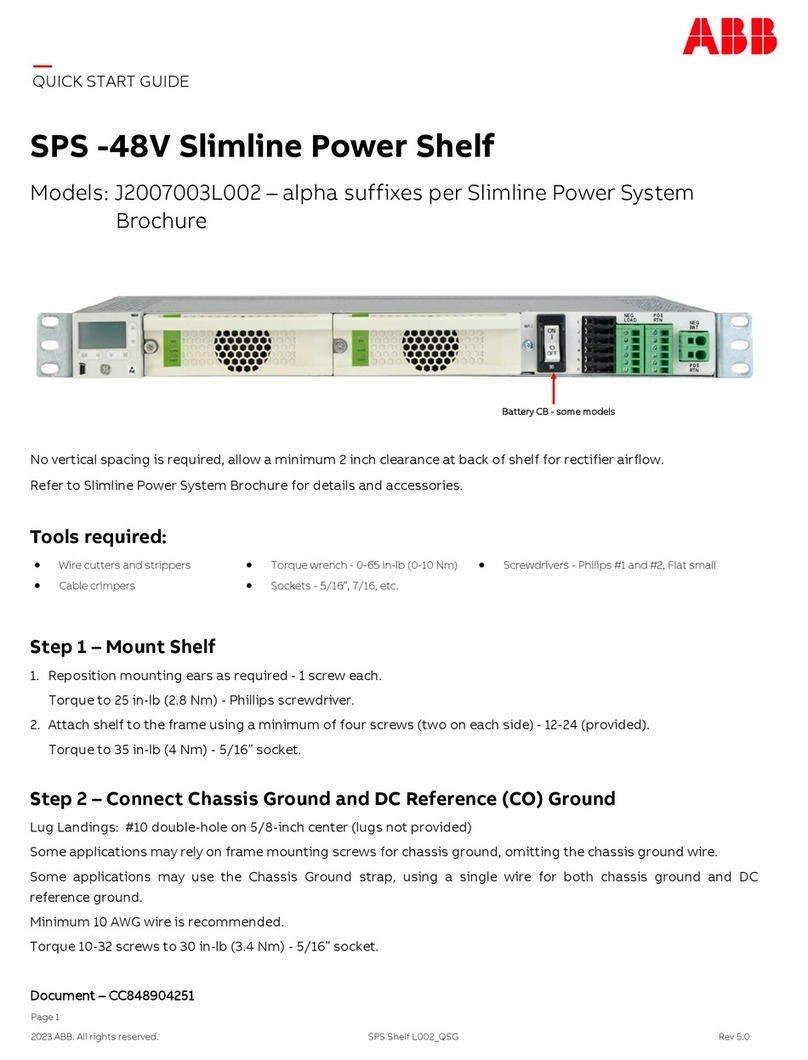

MVPS600 Series

Model Number (1) Output Power(2) Output Voltage Output Current (Natural Convection)

U Channel Slotted Cover Solid Cover

MVPS600-1012 180-300W 12V 25A 17.5A 15A

MVPS600-1015 225-375W 15V 25A 17.5A 15A

MVPS600-1024 360-600W 24V 25A 17.5A 15A

MVPS600-1030 360-600W 30V 20A 14A 12A

MVPS600-1048 360-600W 48V 12.5A 8.75A 7.5A

MVPS600-1058 360-600W 58V 10.34A 7.25A 6.2A

Models & Ratings

Dimensions:

5 x 8.5 x 1.61” (127 x 216 x 40.9mm)

Parameter Minimum Typical Maximum Units Notes & Conditions

AC Input range 85 264 VAC Derate from 100% at 120VAC to 70% at 85VAC

Operating temperature -40 70 °C See derating curve p3.

Efficiency 120VAC 88% and 240VAC 93% typical

Dimensions 5 x 8.5 x 1.61” (127 x 216 x 40.9mm)

EMC EN55011 Level B conducted and radiated with king core K5B RC 25x12x15-M on input. EN61000-3 and EN61000-4, harmonics,

flicker, Surge, EFT, ESD, conducted and radiated immunity to IEC 60601-1-2 4th ed

Safety EN60601-1, IEC60601-1 (ed3), ANSI/AMMI ES 60601-1, CSA C22.2 No 60601-1

Key specifications

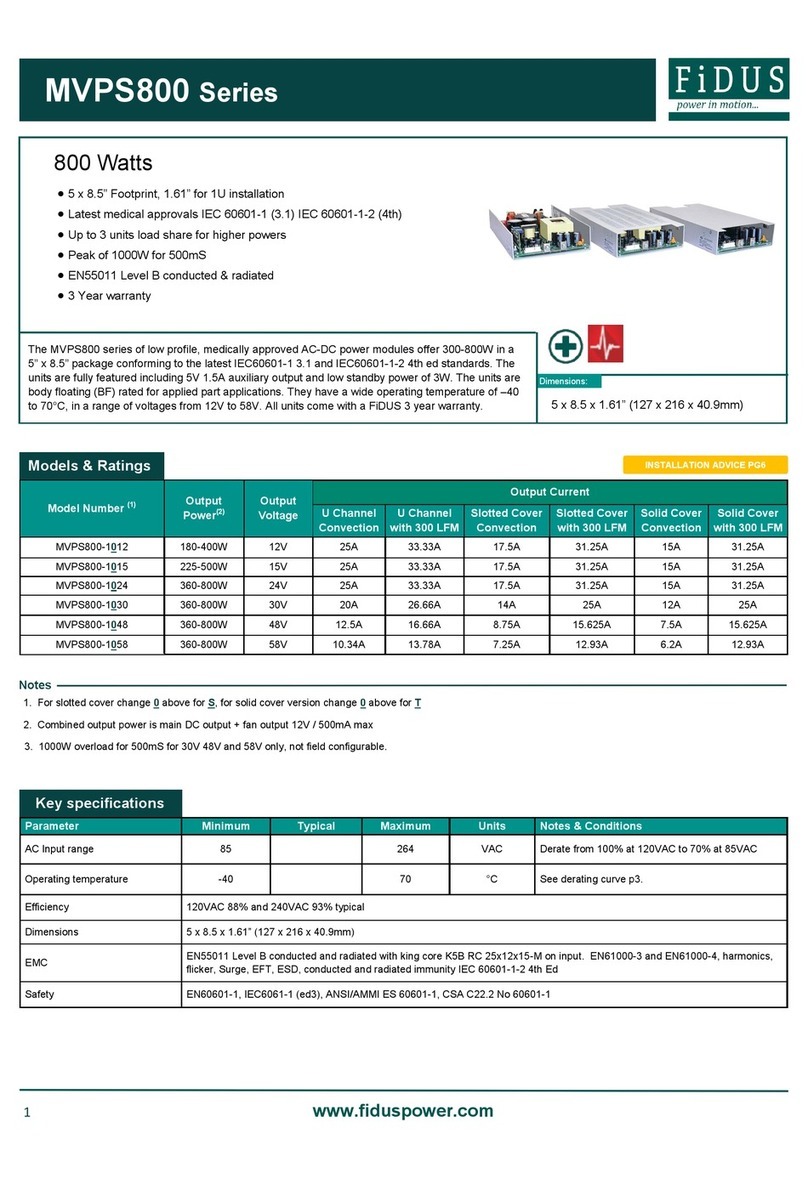

• 5 x 8.5” Footprint, 1.61” for 1U installation

• Latest medical approvals IEC60601-1 (3.1) IEC60601-1-2 (4th ed), BF rated

• Up to 3 units load share for higher powers

• Peak of 1000W for 500mS

• EN55011 Level B conducted & radiated

• 5 Year warranty

600 Watts

The MVPS600 series of low profile, medically approved AC-DC power modules offer 300-600W in a

5” x 8.5” package conforming to the latest IEC60601-1 3.1 and IEC60601-1-2 4th ed standards. The

units are fully featured including 5V 1.5A auxiliary output and low standby power of 3W. The units are

body floating (BF) rated for applied part applications. They have a wide operating temperature of –40

to 70°C, in a range of voltages from 12V to 58V. All units come with a FiDUS 5 year warranty.

Notes

INSTALLATION ADVICE PG6

2. Combined output power is main DC output + fan output 12V / 500mA max

1. For sotted cover change 0 above for S, for sold cover version change 0 above for T

3. 1000W overload for 500mS for 30V 48V and 58V only, not field configurable.

2www.fiduspower.com

ULP275 Series

Parameter Minimum Typical Maximum Units Notes & Conditions

Output voltage 12 58 VDC See Model & Ratings table

Output voltage Adjust ±3 %

Set point accuracy ±1 %

Line regulation ±0.5 %

Load regulation ±1 %

Minimum load 0%

Transient response 10 %50-100% step change 0.1A/uS slew 50% duty 50hz in <5ms

Ripple & Noise 2%

All models measured with 0.1uF ceramic and 10uF

electrolytic capacitor. 20 MHz bandwidth. At rated line and

25W min load.

Hold up time 8mS

Overload protection 110 %Hiccup mode, Auto recovery

Short circuit protection Latch reset

Overvoltage protection 114 %Latch reset

Over temperature protection 130 140 °CMeasured at primary heatsink. Auto recovery

Leakage current 400 uA 240VAC / 50Hz

Touch current 100 uA

Output

Parameter Minimum Typical Maximum Units Notes & Conditions

Efficiency 120VAC 88% and 240VAC 93% typical

Isolation: Input to Output 4245 VAC

Input to Ground 1625 VAC

Output to ground 1500 VAC

Switching frequency 85 100 kHz 100 kHz variable for power switching. Variable PFC

switching 85kHz

Power density 8.77 W/In3

MTBF >1.28 MHrs As per Telcordia-SR332– issue 3

Weight 1100 g

General

Parameter Minimum Typical Maximum Units Notes & Conditions

Operating temperature -40 70 °C Please see derating curve on page 3

Storage temperature -40 85 °C

Cooling Natural convection

Altitude 4876 12192 m4876m operating 12192m non operating

Humidity 595 % RH Non condensing

Environmental

Parameter Minimum Typical Maximum Units Notes & Conditions

Input voltage 85 264 VAC Derate from 100% at 120VAC to 70% at 85VAC

Input frequency 47 63 Hz

Power factor 0.95 0.98 EN61000-3-2 class D compliant, at full load. 0.98 at

120VAC and 0.95 at 240VAC

Input current (rms) 6.5 A At 120VAC

3.2 At 240VAC

Inrush current 25 A 230VAC cold start at 25°C

No load input power 3W 6W W3W output disabled 6W output enabled

Input

WLP350 Series VPS1000 Series VPS1000 Series MVPS600 Series

3www.fiduspower.com

ULP275 Series

Standard Test level Criteria Notes & Conditions

Conducted EN55011 BCISPR22-B, FCC PART15-B also

Radiated EN55011 BWith ferrite king core K5B RC 25x12x15-M on input

Harmonic current EN61000-3-2Class A

Voltage flicker EN61000-3-3

EMC: Emissions

Standard Test level Criteria Notes & Conditions

ESD EN61000-4-24A±8kV contact, ±15kV air.

Radiated EN61000-4-33A10V/m 80MHz-2.7GHz sine wave 80% AM 1kHz

EFT EN61000-4-43A2kV Power, 1kV I/O 5kHz

Surges EN61000-4-5Installation Class 3 A1kV Live-Neutral, 2kV Live/Neutral—Earth

Conducted EN61000-4-63A10V, 0.15 to 80MHz sine wave 80AM 1kHz

Magnetic Fields EN61000-4-8430A/M

Voltage Dips / Interruptions EN61000-4-11 100% for 0.5 & 1 cycle, 30% for 25 cycles: B,B,B

interrupt 250,300 cycles and 30% for 30 cycles: B,B,B

EMC: Immunity

Safety standard Notes & Conditions

UL/CSA ANSI/AMMI ES 60601-1, CSA C22-2 NO- 60601-1 UL Certificate No : 20190221-E173812

CB IEC60601-1 3rd ed CB Test Certificate No : NO105338

Nemko EN60601-1 3rd ed Nemko Certificate No : P19223365

CE 2015/863/EU RoHS Directive and 2014/35/EU Low voltage directive

Equipment protection class Class I

Safety Approvals

WLP350 Series VPS1000 Series MVPS600 Series

Power Derating Curve 12V

-40 -20 020 40 60

Temperature (ᵒC)

80

300

Load W

Power Derating Curve 15V Power Derating Curve Others

50

30

125

250

-40 -20 020 40 60

Temperature (ᵒC)

80

375

200

Load W

50

30

157

314

-40 -20 020 40 60

Temperature (ᵒC)

80

600

Load W

50

30

250

225

150

75

300

100

200

300

100

500

400

210

175

87

180

U Channel

Sloed cover

Solid cover

262

220

110

225

188

94

420

350

175

360

150

4www.fiduspower.com

ULP275 Series ULP275 Series WLP350 Series VPS1000 Series

AC Power Derating Curve

0

85 95 105 115

100

80

60

40

20

70

120 125 135 255 265

Application notes

Signals

Power Good: TTL output activated at 90% of Vout. Delay between 100 and 500mS

At least 1mS before Vout falls below 90% TTL signal switches low

Load share

The volt sense lines must all be connected to one point and the output voltage of each the

power supplies must be adjusted to be within 1% for the current share to operate. Should they

not be adjusted the current share will not function. When using the load share function derate

the cumulative power total by 10%. Please follow the below step by step process to ensure

smooth operation:

• Connect all output cables to Vout

• Connect all Vs cables and twist pairs together

• Terminate all the Vs lines to the same +/- points

• Connect the load share (LS pin 10 on J3) of all the units

• With other units tuned off, on each PSU use the output adjust to change

Vout within 1%

• The current share should be checked with a DC hall sensor showing that

the power supplies share the current within 10%

Remote Sense: Compensation for 200mV voltage drop on cable runs

Remote on/off: Unit comes pre-configured with pin 6 & 7 shorted to enable the unit

Current limit: Do not remove. This feature is not field configurable.

MVPS600 Series

5www.fiduspower.com

ULP275 Series

Notes

1. All dimensions shown in mm [inches]

2. J1: Input connector: TE Connectivity: NC6-P107-03

Mechanical Details

J2: Output Connector(3)

Pin Connections

Pin Function

J2A +Vout

J2B -Vout

3. J2: Output connector: 6-32 pan screw. Can accept AMP 8-31886-1

Tongue (11A max AWG16)

J3: I/O Connector(4)

Pin Connections

Pin Function

1GND

2+5V 1.5A

3PGPF

4VS-

5VS+

6GND

7Remote on/off

8Current limit p2

9Current limit p1

10 Load share

ULP275 Series WLP350 Series

4. J3: I/O header Molex: 22-23-2101 mating part Molex: 22-01-2107

MVPS600 Series

J1: Input Connector(2)

Pin Connections

Pin Function

1Line

2Neutral

3Earth

U Channel

Sloed cover

Solid cover

Side view

Boom view

MVPS600 Series

6www.fiduspower.com

Thermal

Thermal management is an important consideration when thinking about equipment service life. Electrolytic

capacitors within the PSU wear with time and are typically the first end-of-life failure. Keeping the operation

temperature of key components within the PSU, such as the electrolytic capacitors, as low as possible is para-

mount. As a general rule, for every 10°C drop in the operating temperature of the electrolytic capacitators you

double their lifetime, and thus the lifetime of the power supply. When looking at thermal performance it is helpful

to test under a worst-case set of conditions, to ensure component temperatures are in an acceptable range for

the required service life. Then consider the impact of operational time, load and temperature profile to estimate

a more realistic lifetime for your PSU.

Also, many FiDUS power supplies offer a Peak Power rating to provide for customers with pulsing loads. When

using a peak power capability customers must consider:

1) Peak duration rating: the maximum length of time the peak can be drawn for

2) Duty cycle: the frequency with which the peak can be drawn. (e.g. 10% duty cycle, 1 second on:9 seconds

off)

3) Average power value: datasheets will state the maximum average power acceptable with peak power PSUs.

If any of these elements are exceeded the supply may overheat, with performance and lifetime suffering as a

result.

Installation Advice

Conducted and radiated emissions compliance is a common application consideration. It is important to remem-

ber that even when using a properly filtered PSU, an application may still not achieve compliance if it is not de-

signed to minimise emissions. That being said, there are a number of things that can be done to optimise EMC

performance either as best practice, or if you are struggling for compliance:

1) Connect all marked EMI ground points to earth. Often these are combined with the safety earth point (in class

I installations), but on some power supplies there may be additional earth tags or mounting points.

2) Minimise the length of input/output wiring where possible and try to maintain max distance of the conductors

from the PSU, to prevent noise pick up. Avoid bundling input and output cables together. A common component

to avoid placing wiring near is the PFC inductor in power factor corrected power supplies.

3) Apply additional filtering before the PSU input (ensure consideration of which frequencies there are issues

with before selecting a filter).

4) When using an open frame PSU, mount the supply on a metal plate and connect EMI mounting points.

5) In multi circuit systems, decouple the circuits locally.

6) Ferrites added between the PSU and system input connector and/or the DC output cables can help in reduc-

ing radiated noise issues in systems. If seen, issues are commonly in the 30-150MHz area.

For more detailed assistance, if you still have any concerns with compliance, please get in contact with our Engi-

neering department who are on hand to assist with any queries.

EMC

On installation customers must consider the required creepage and clearance distances between the PSU and

the end-equipment enclosure. These distances vary depending on the installation class and safety standard

requirements.

For Class I installations there should be 3-4mm between any part of the PSU and any earthed metal part of the

enclosure. 3mm is acceptable for IT applications, 4mm required for medical applications. In Class I installations

the PSU earth point must be connected to system safety ground.

For Class II installations distances may need to be increased if being installed into a surrounding metal enclo-

sure.

Ensure consideration of components on the underside of the PCB or low lying spills when measuring clearance

distances between the PSU and the end-equipment. Also top surface especially in tight enclosures such as 1U

boxes. An insulation material can be used between PSU and metal if smaller gap required.

FiDUS recommends installing the PSU on 6mm stand offs typically, but check the distances.

Safety

ULP275 Series WLP350 Series VPS1000 Series MVPS600 Series

24/10/19

This manual suits for next models

6

Table of contents

Other FiDUS Power Distribution Unit manuals

Popular Power Distribution Unit manuals by other brands

Middle Atlantic Products

Middle Atlantic Products MPR Series instruction sheet

Omicron

Omicron CMC 850 user manual

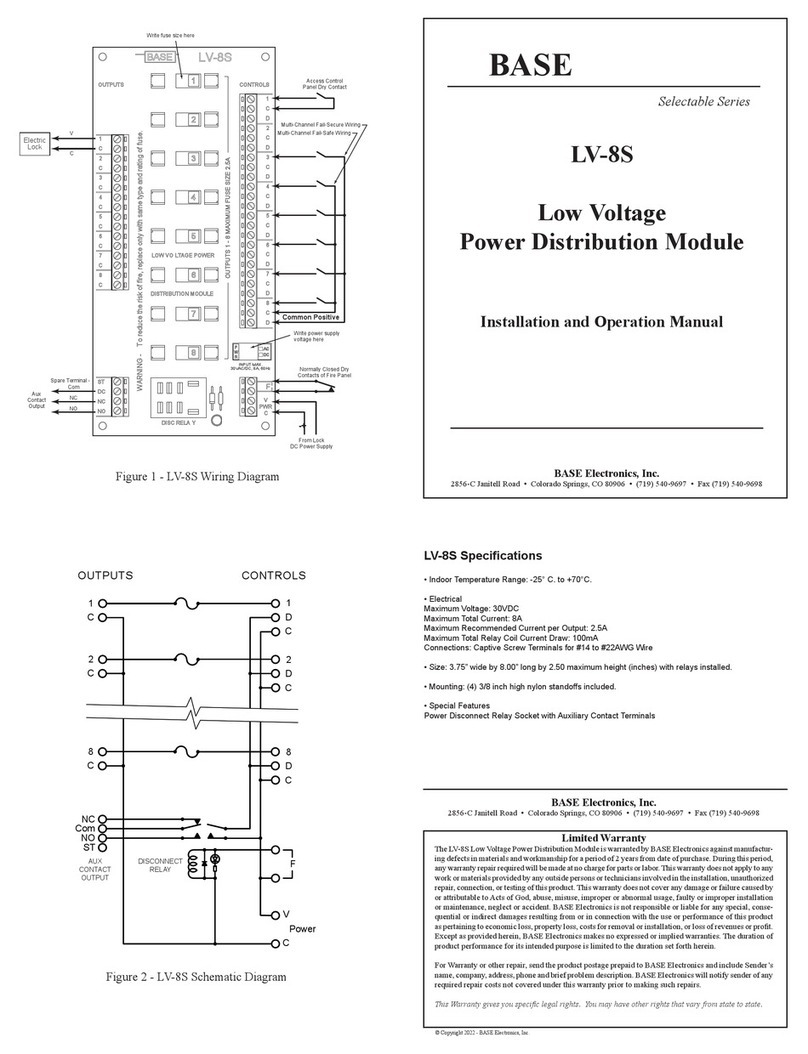

BASE Electronics

BASE Electronics LV-8S Installation and operation manual

Konig

Konig CMP-POWG21 manual

LIGHTNING PROTECTION INTERNATIONAL PTY LTD

LIGHTNING PROTECTION INTERNATIONAL PTY LTD Stormaster ESE installation manual

Vertiv

Vertiv Geist user manual