FiDUS RHM250P Series Installation and operating instructions

1www.fiduspower.com

Model Number Output Power Output 1 Output 2(1,2) Efficiency(4)

Voltage Current Max Voltage Current Max

RHM25012P 250W 12V 20A 5V 2A 90%

RHM25015P 250W 15V 16A 5V 2A 90%

RHM25019P 250W 19V 12.63A 5V 2A 90%

RHM25024P 250W 24V 10A 5V 2A 91%

RHM25030P 250W 30V 8A 5V 2A 91%

RHM25036P 250W 36V 6.66A 5V 2A 92%

RHM25048P 250W 48V 5A 5V 2A 92%

Models & Ratings

Parameter Minimum Typical Maximum Units Notes & Conditions

AC Input range 90 264 VAC

Operating temperature -40 70 °C Derate linearly from 100% power at 50°C to 50%

power at 70°C

Efficiency 90 92 %

Dimensions 3 x 5 x 1.46” (76.2 x 127 x 37mm)

EMC EN55011 Level B conducted and radiated. EN61000-3 and EN61000-4, harmonics, flicker, Surge, EFT, ESD, conducted and

radiated. IEC 60601-1-2 4th Ed

Safety IEC60601-1 2006/A1:2013, ES60601-1:2005 (R2012), CSA-C22.2 No. 60601-1:14, EN60601-1:2006/A1:2013

Key specifications

RHM250P Series

Notes

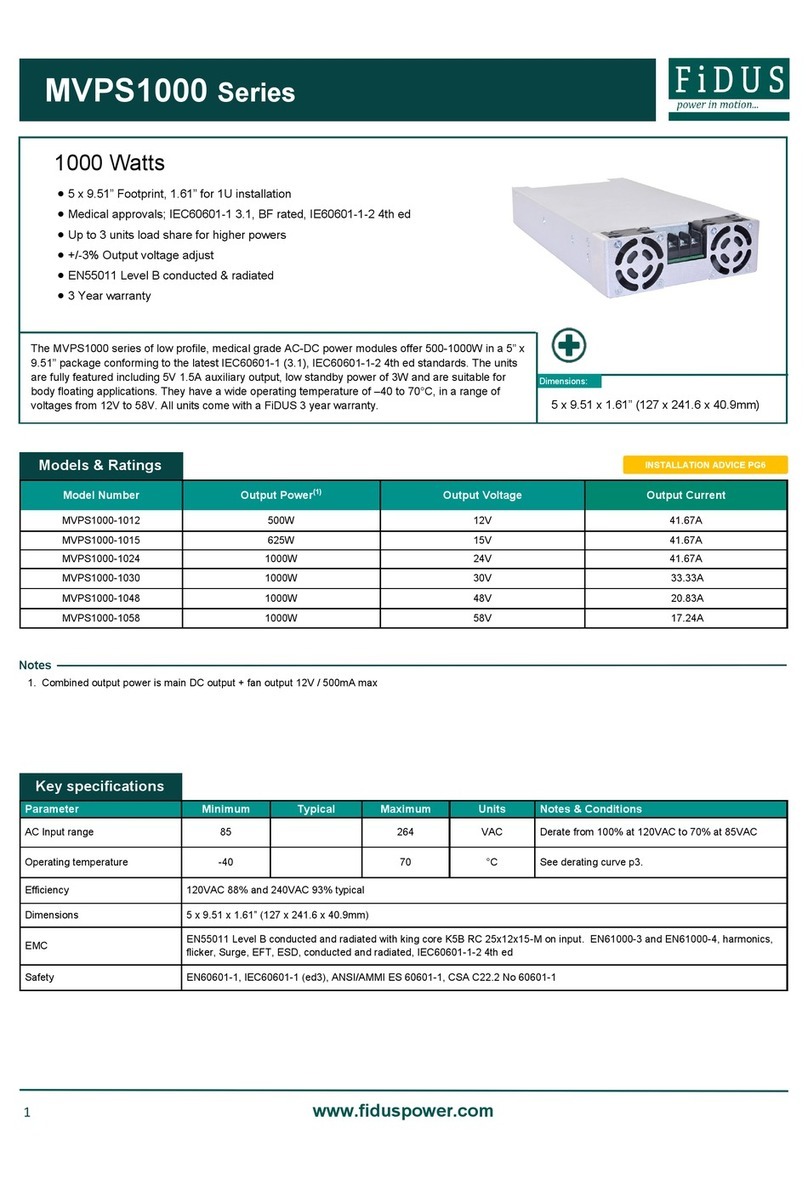

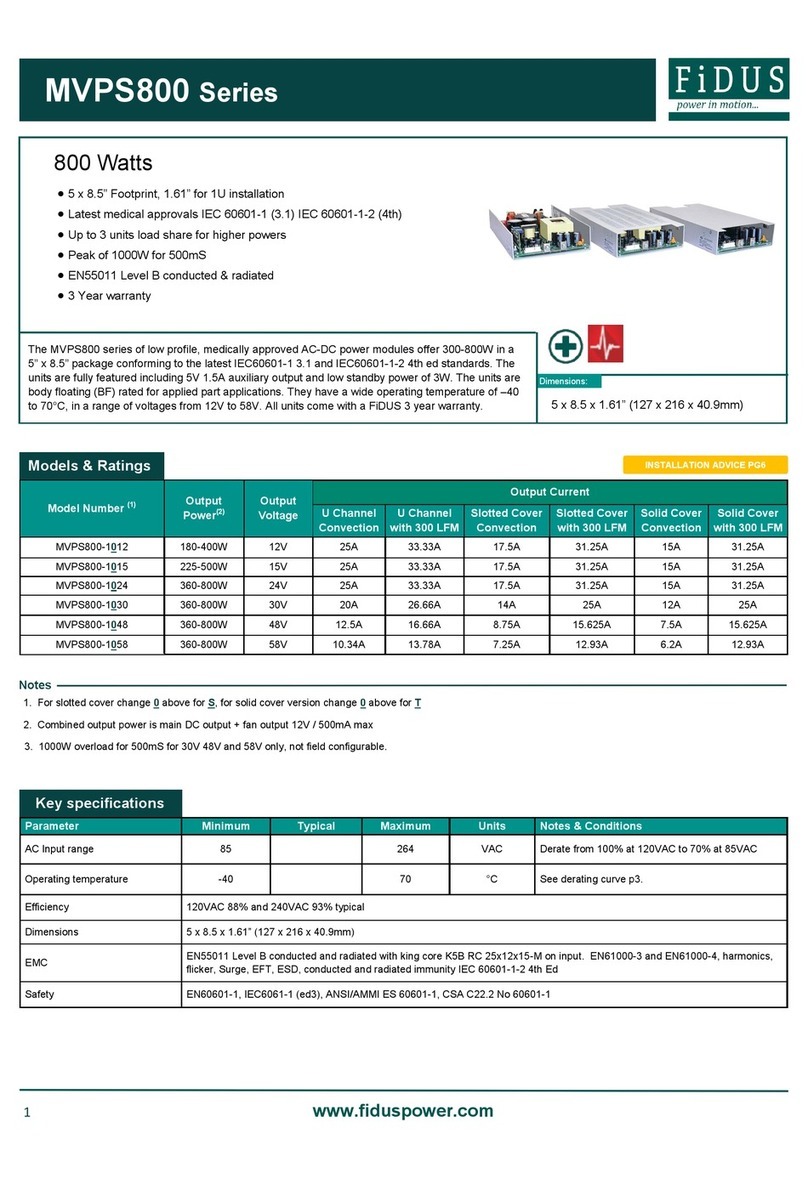

• Power dense 250W in 3 x 5”

• Remote on/off and 5V stand by

• Latest medical approvals IEC 60601-1 (3.1) and IEC 60601-1-2 4th Ed

• Earth leakage <300uA (BF rated)

• EN55011 Level B conducted & radiated

• -40 to +70°C Operation

• 5 Year warranty

Dimensions:

3 x 5 x 1.46” (76.2 x 127 x 37mm)

250 Watts

The RHM250P series offers 250W in a dense, 3 x 5” open frame package. The units are designed for

use in medical applications, are very efficient and have low emissions, meeting EN55011 Level B.

They have a wide temperature range from -40 to +70°C and offer low no load power consumption of

<0.3W. Outputs are available from 12 to 48V and all models come with a FiDUS 5 year warranty.

INSTALLATION ADVICE PG5

1. Output 2: Standby Power 5V@2A

2. Output 2: Minimum load 0.3A

3. Looms kits available, see ‘Installation Advice’ pg5

4. Efficiency at full load and nominal line voltage

2www.fiduspower.com

RHM250P Series

Parameter Minimum Typical Maximum Units Notes & Conditions

Output voltage 12 48 VDC See Model & Ratings table

Total regulation % ±10% AC line change at nominal load and ±40%

load change at 60% load nominal line.

Output 1: ±5% 12-19V models. ±3% 24V model.

±2% 30-48V models.

Output 2: ±5% all models

Minimum load 0%

Ripple & Noise

Output 1: 12V model 120mVp-p. 15V model 150mVp-p.

19V model 190mVp-p. 24V model 240mVp-p.

30-48V models 300mVp-p.

Output 2: all models 50mVp-p

mV(Vp-p) All models measured with 0.1uF and 0.47uF

capacitor and 20 MHz bandwidth.

Hold up time 16 ms

Overload protection 105 130 %Trip and restart. Automatic recovery

Short circuit protection Trip and restart. Automatic recovery

Overvoltage protection 112 132 %Trip and restart. Automatic recovery

Output

Parameter Minimum Typical Maximum Units Notes & Conditions

Efficiency 90 92 %

Isolation: Input to Output 4000 VAC 2 x MOPP (BF rated)

Input to Ground 1500 VAC

Isolation resistance 50 MΩ

Power density 11.4 W/In3

MTBF 200 KHrs As per MIL-HDBK-217F, 25°C GB

Weight 350 g

General

Parameter Minimum Typical Maximum Units Notes & Conditions

Operating temperature -40 70 °C Derate linearly from 100% power at 50°C to 50%

power at 70°C

Storage temperature -40 85 °C

Cooling Convection cooled

Temperature coefficient ±0.04 %/ᵒC

Humidity 095 % RH Non condensing

Operating altitude 3000 m

Vibration 5g10-500hz, 10min/cycle in each axis x,y and z

Environmental

Parameter Minimum Typical Maximum Units Notes & Conditions

Input voltage 90 264 VAC

Input frequency 47 63 Hz

Power factor 0.9 EN61000-3-2 class A compliant

Input current (rms) 3A Low line. At 100VAC

1.5 High line. At 240VAC

Inrush current 75 A 100VAC cold start at 25°C

150 240VAC cold start at 25°C

No load input power 0.3 W

Earth leakage current 0.3 mA 240VAC 60Hz

Input

3www.fiduspower.com

RHM250P Series

Standard Test level Criteria Notes & Conditions

Conducted EN55011 B

Radiated EN55011 B

Harmonic current EN61000-3-2Class A

Voltage flicker EN61000-3-3

EMC: Emissions

Derating curve

Load %

0

80

100

-40 020 40 60 80

20

60

40

50

70

Temperature (ᵒC)

20 50

Standard Test level Criteria Notes & Conditions

ESD EN61000-4-24A±15kV air, ±8kV contact,

Radiated EN61000-4-33A10V/m 80% AM (1KHz) 80-2700MHz (6V for ISM &

amateur radio frequencies)

EFT EN61000-4-43A±2KV (100V and 240V 50Hz)

Surges EN61000-4-5Installation Class 3 A±2KV (100V and 240V 50Hz) ±1KV L-N

Conducted EN61000-4-63/6Vrms A80% AM (1KHz)

Magnetic Fields EN61000-4-830A/m A50/60Hz 1 min

Voltage Dips EN61000-4-11 100% for 0.5 cycles, 60% 5 cycles, 30% for 25/30 cycles, interrupt 250/300 cycles and 1 sec -

performance criteria A, A, B

EMC: Immunity

Safety standard Notes & Conditions

UL ES 60601-1:2005 (R2012),

CSA-C22.2 No 60601-1:14

CB IEC 60601-1 2005 + A1 (Ed 3.1)

TUV EN 60601-1:2006 + A1: 2013

CE 2011/65/EU RoHS Directive and 2014/35/EU Low voltage directive

Means of patient protection

Input to Output: 2 x MOPP

Input to Ground: 1 x MOPP

Output to Ground: 1 x MOPP

Equipment protection class Class I

Safety Approvals

4www.fiduspower.com

RHM250P Series

Notes

Mechanical Details

*Note: Enable output 1 by shorting PIN 2 and

PIN 3. Output 3 floating or shorted to 1 unit is off

2. AC input header mates with JST VHR-5N

P4 - Pin Connections

Pin Function

1COM

2Output 2

3ON/OFF

1. All dimensions shown in millimetres (inches)

4. Standby power output connector mates with JST housing XHP-3 and JST SXH series crimp terminals

Input Pin Connections P1

Pin Function

1Ground

2Neutral

3Line

Output Pin Connections

Pin Function

P2 Vout

P3 Return

3. DC output M3 screws torque to 3 lb-in (30 CNm) max.

5www.fiduspower.com

Thermal

Thermal management is an important consideration when thinking about equipment service life. Electrolytic

capacitors within the PSU wear with time and are typically the first end-of-life failure. Keeping the operation

temperature of key components within the PSU, such as the electrolytic capacitors, as low as possible is para-

mount. As a general rule, for every 10°C drop in the operating temperature of the electrolytic capacitators you

double their lifetime, and thus the lifetime of the power supply. When looking at thermal performance it is helpful

to test under a worst-case set of conditions, to ensure component temperatures are in an acceptable range for

the required service life. Then consider the impact of operational time, load and temperature profile to estimate

a more realistic lifetime for your PSU.

Also, many FiDUS power supplies offer a Peak Power rating to provide for customers with pulsing loads. When

using a peak power capability customers must consider:

1) Peak duration rating: the maximum length of time the peak can be drawn for

2) Duty cycle: the frequency with which the peak can be drawn. (e.g. 10% duty cycle, 1 second on:9 seconds

off)

3) Average power value: datasheets will state the maximum average power acceptable with peak power PSUs.

If any of these elements are exceeded the supply may overheat, with performance and lifetime suffering as a

result.

Installation Advice

Conducted and radiated emissions compliance is a common application consideration. It is important to remem-

ber that even when using a properly filtered PSU, an application may still not achieve compliance if it is not de-

signed to minimise emissions. That being said, there are a number of things that can be done to optimise EMC

performance either as best practice, or if you are struggling for compliance:

1) Connect all marked EMI ground points to earth. Often these are combined with the safety earth point (in class

I installations), but on some power supplies there may be additional earth tags or mounting points.

2) Minimise the length of input/output wiring where possible and try to maintain max distance of the conductors

from the PSU, to prevent noise pick up. Avoid bundling input and output cables together. A common component

to avoid placing wiring near is the PFC inductor in power factor corrected power supplies.

3) Apply additional filtering before the PSU input (ensure consideration of which frequencies there are issues

with before selecting a filter).

4) When using an open frame PSU, mount the supply on a metal plate and connect EMI mounting points.

5) In multi circuit systems, decouple the circuits locally.

6) Ferrites added between the PSU and system input connector and/or the DC output cables can help in reduc-

ing radiated noise issues in systems. If seen, issues are commonly in the 30-150MHz area.

For more detailed assistance, if you still have any concerns with compliance, please get in contact with our Engi-

neering department who are on hand to assist with any queries.

EMC

On installation customers must consider the required creepage and clearance distances between the PSU and

the end-equipment enclosure. These distances vary depending on the installation class and safety standard

requirements.

For Class I installations there should be 3-4mm between any part of the PSU and any earthed metal part of the

enclosure. 3mm is acceptable for IT applications, 4mm required for medical applications. In Class I installations

the PSU earth point must be connected to system safety ground.

For Class II installations distances may need to be increased if being installed into a surrounding metal enclo-

sure.

Ensure consideration of components on the underside of the PCB or low lying spills when measuring clearance

distances between the PSU and the end-equipment. Also top surface especially in tight enclosures such as 1U

boxes. An insulation material can be used between PSU and metal if smaller gap required.

FiDUS recommends installing the PSU on 6mm stand offs typically, but check the distances.

Safety

All FiDUS Power engineering samples requested will arrive with a free of charge loom kit for ease of testing.

The loom kit connects to the input/output terminals of the PSU and provides the customer with bare wire ends to

connect with.

The loom kits can also prove advantageous

for ease of installation in production. Please

contact sales if you are interested in includ-

ing the loom kit in your quotation.

Alternatively the input/output connector and

mating part details can be found in the

attached table.

Part Number Mating Part Number

Input B5P-VH VHR5N

Output M3 screw terminal N/A

Loom Kit RHM250 LK

Connectivity

RHM250P Series

20/05/20

This manual suits for next models

7

Table of contents

Other FiDUS Power Distribution Unit manuals

Popular Power Distribution Unit manuals by other brands

EuroLite

EuroLite SB-66 user manual

Rockwell Automation

Rockwell Automation Allen-Bradley B Series user manual

LDR

LDR PDU6M operating instructions

GÜDE

GÜDE Expert Power Control 8031 Series manual

Middle Atlantic Products

Middle Atlantic Products HDR Series instruction sheet

Powerware

Powerware 9125 user guide