Filsa LIT-2 User manual

Page

Index

LIT-2, LIT-VL, LIT-VP, LIT-VT & LIT-VTM

Talleres Filsa, S.A.U. www.filsa.es• • • • •E-08100 Mollet del Vallès (Barcelona) Tel. +34 93 570 46 01 Fax +34 93 570 24 71 [email protected] 01

10/15 © by FILSA MI-LIT2LITV-EN-01

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

Operating instructions

1. Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

1.1 Intended use

1.2 Function

1.3 Technical data

1.4 Materials

1.5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

2.1 Preparing for use

2.2 Mechanical connection

2.3 Electrical connection

3. Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05

3.1 Commissioning

3.2 Normal operation

3.3 Inexpert handling

4. Maintenance, servicing and spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05

4.1 Maintenance

4.2 Servicing

4.3 Spare parts

5. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05

6. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05

Flow switch

for liquids

Operating

Instructions

Read these Safety Instructions before using the switch for the first time and follow the Operating instructions.

Safety instructions

1. The installation, initial operation and maintenance should only be carried out by a qualified expert with electrical know-how.

2. Comply with the local and statutory rules and/or the VDE0100.

3. Before electrical connection, check the specifications on the data plate and the technical data of this manual.

4. A fuse must be connected in series to the supply voltage, according to the Standard and Normative documents.

5. Protect the signal contacts of the limit switch against voltage peaks when inductive or capacitive loads are connected.

6. The device may be put into operation only if the electrical connection is correct. To secure the type of protection, the sealing cap and the gasket

must be placed correctly.

7. The earth connection of the device has to be installed in such a way that mechanical damage will be excluded.

8. For a proper function, the paddle must not touch the pipe

9. For a proper function, the device must be installed in straigh pipes with a mininum length at least of five times the diameter and far from valves or

filters to avoid turbulence.

10. Switch off the power supply, before disconnecting the device.

and it is necessary to ensure the free movement of the paddle.

LIT-2, LIT-VL, LIT-VP, LIT-VT and LIT-VTM

02 Talleres Filsa, S.A.U. www.filsa.es• • • • •E-08100 Mollet del Vallès (Barcelona) Tel. +34 93 570 46 01 Fax +34 93 570 24 71 [email protected]

10/15 © by FILSA MI-LIT2LITV-EN-02

Operating instructions

1. Specification

1.1 Intended use

The flow switches are used to control the flow of waters, oil,

chemical products, etc. through the device.

Depending on the model, it can be controlled a range flow from 0.5

l/min up to 24 l/min.

1.2 Function

Depending on the model, there is a paddle or a free movement

system inside the device.

1.3 Technical data

Manufacturer Talleres Filsa, S.A.U.

Address Bernat Metge, 33

08100 Mollet del Vallès

(Barcelona)

Name Flow switch

Type LIT-2 3/8" ref: 2606

LIT-2 1/2" ref: 2606-1

LIT-2 3/4" ref: 2606-2

LIT-2 1" ref: 2606-3

LIT-VL ref: 2606-4

LIT-VP ref: 2606-5

LIT-VT ref: 2606-6

LIT-VTM ref: 2606-7

Maximum pressure

Cable output

2 wires x 2 meters

2 wires x 0.5 meters

When the liquid flow of the pipe pulls the

paddle actuates a microswitch or a REED switch depending on the

model.

There are models with different proccess connections and made of

differents materials to can control the flow in a wide range of

applications.

LIT-2 +25 bar

LIT-V... +10 bar (+20 ºC)

LIT-2 DIN 43650 connector

LIT-VL and LIT-VP

LIT-VT and LIT-VTM

Maximum voltage 250 V AC

LIT-2 250 V AC

LIT-VL 250 V AC and 200 V DC

LIT-VP 250 V AC

LIT-VT and LIT-VTM 250 V AC and 200 V DC

Contact function 1 NO + 1 NC

LIT-2 contact

LIT-VL contact

LIT-VP contact

LIT-VT and VT-M contact

Protection IP65 according DIN EN60529

For capacitive or inductive loads reduce at

For capacitive or inductive loads reduce at

For capacitive or inductive loads reduce at

For capacitive or inductive loads reduce at

Weight

0.30 kg

0.30 kg

0.35 kg

0.39 kg

0.36 kg

0.14 kg

0.07 kg

1.4 Materials

ABS

Body

Brass

Noryl

Cupper

Paddle or contact material

Stainless Steel

Noryl

LIT-V... cable Double insulation

Double insulation

Capacity of the contact 5 A / 250 V AC

(resistive load)

50%

Max. power consumption 40 VA in AC; 40 W in DC

Contact current 1 A (resistive load)

50%

Contact current 1 A (resistive load)

50%

Max. power consumption 40 VA in AC; 40 W in DC

Contact current 1 A (resistive load)

50%

Temperature range

LIT-2 -20 °C ... +110 °C

LIT-VL -30 °C ... +100 °C

LIT-VP, LIT-VT and LIT-VTM -30 °C ... +85 °C

LIT-2 3/8"

LIT-2 1/2"

LIT-2 3/4"

LIT-2 1"

LIT-VL

LIT-VP

LIT-VT and LIT-VTM

LIT-2 housing

LIT-2 and LIT-VL

LIT-VP

LIT-VT and LIT-VTM

LIT-2

LIT-V...

PVC

LIT-VL and LIT-VP Single inulation PVC

LIT-VT and LIT-VTM PVC

LIT-2, LIT-VL, LIT-VP, LIT-VT and LIT-VTM

Talleres Filsa, S.A.U. www.filsa.es• • • • •E-08100 Mollet del Vallès (Barcelona) Tel. +34 93 570 46 01 Fax +34 93 570 24 71 [email protected] 03

10/15 © by FILSA MI-LIT2LITV-EN-03

2. Installation

-

-

The switch has to be insterted between a pipe welding the device

or using proccess accesories depending on the model.

The models LIT-2 and LIT-VT can be side or vertically mounted due

to a return spring meanwhile the others has to be inserted vertically.

The indication arrow in the body has to be faced to the flow.

- Fasten the DIN connector after making the electrical connection.

- Fix and fasten the screw of the DIN connector to ensure the

water-tightness.

2.1 Preparing for use

For a proper function, the device must be installed in straigh pipes

with a mininum length at least of five times the diameter and far

from valves or filters to avoid turbulence.

Read the Safety Instructions and the Operation Instructions before

using the controller.

2.2 Mechanical connection

2.3 Electrical connection

Connection diagram

LIT-2

LIT-V...

Output 2 wires, NC with flow.

DIN connector

Cable connections

Connections must be safe and water-tight. The connections should

be out of the tank.

1.5 Dimensions

Approximate measures are given in mm.

LIT-2

LIT-VL

LIT-VP

LIT-VT y LIT-VTM

LIT-2, LIT-VL, LIT-VP, LIT-VT and LIT-VTM

04 Talleres Filsa, S.A.U. www.filsa.es• • • • •E-08100 Mollet del Vallès (Barcelona) Tel. +34 93 570 46 01 Fax +34 93 570 24 71 [email protected]

10/15 © by FILSA MI-LIT2LITV-EN-04

Thread

H

3/8 "

83

1/2 "

83

3/4 "

88

1 "

90

H

50

109

45.5

40

32

Biconical

22 mm

Biconical

22 mm

37

16

35

Ø 22

Ø 30

Ø 12

Ø 42

17.5 16 10

43.5

18

Male thread

G 3/4 "x15

Ø 23

35

Ø 15

25

23

44 73 35

26 14

30

Female

thread

G 3/4 "x15

36

LIT2LITV-001

LIT2LITV-002

LIT2LITV-003

LIT2LITV-004

1

32

4

[

Terminal

1

2

3

4

Contact

NO

Common C

NC

LIT2LITV-005

LIT2LITV-006

32

Sensitivity adjustment

- The flow switches LIT-VL/VP/VT switch with a fix flow of 1 l/min.

- The flow switche LIT-VTM switchs with a fix flow of 0.5 l/min.

- The flow switch LIT-2 has a regulation system that allows the

adjustment of the sensitivity. Open the cap in the back of the

device body and turn the screw to reduce the sensitivity and

increase the strain of the flow to activate the microswitch.

Unterclockwise insensitive. The device is adjusted at the

maximum sensitivity.

- The range of flow can be consulted in the following table

(LIT2LITV-008)

* Tolerance ± 15% scale range.

Minimum hysteresy 0.7 l/min.

3. Use

3.1 Commissioning

- Put the controller into operation only if the installation and the

electrical connection have been done correctly.

3.2 Normal operation

- Use the device in its intended application only.

- Comply with the specifications

- If the controller is damaged, disconnect it immediately.

- It is forbidden to make changes to the device. This violates the

Normative.

on the data plate and the technical

data of this manual.

3.3 Inexpert handling

- Ignoring the Safety instructions and the Operating instructions.

- Not intended use.

- Making changes or handling the flow switch.

- Violation against applicable Law and Standards.

- Using of non original parts.

4. Maintenance, servicing and spare parts

4.1 Maintenance

- If used correctly, no specific maintenance is required.

4.2 Servicing

- Check and review the state of the housing and the correct

commutation of the electrical contact, as well.

4.3 Spare parts

- There are no spare parts for these controllers.

5. Storage

- Store the controller in a dry and dust-free environment.

6. Disposal

-

- The controller can be recycled.

- The disposal applies to the valid environmental Guidelines

according to the location of the carrier and the local

manufacturing conditions.

Switch off the power supply, before disconnecting the device.

LIT-2, LIT-VL, LIT-VP, LIT-VT and LIT-VTM

Talleres Filsa, S.A.U. www.filsa.es• • • • •E-08100 Mollet del Vallès (Barcelona) Tel. +34 93 570 46 01 Fax +34 93 570 24 71 [email protected] 05

10/15 MI-LIT2LITV-EN-05© by FILSA

Diameter of pipe

Flow range

G ”

l/min

3/8

5 ... 6

1/2

6 ... 7

3/4

7.5 ... 11

1

19 ... 24

LIT2LITV-008

More flow needed to activate the

signal.

Less flow needed to activate the

signal.

LIT2LITV-007

FILSA constantly strives to improve its products and reserves the right to modify designs, materials and data without prior notice.

Keep this manual for further questions!

This manual suits for next models

4

Table of contents

Other Filsa Switch manuals

Popular Switch manuals by other brands

3Com

3Com 3800 user guide

TRENDnet

TRENDnet TE100-DX8 - Specifications

SEIAOTEK

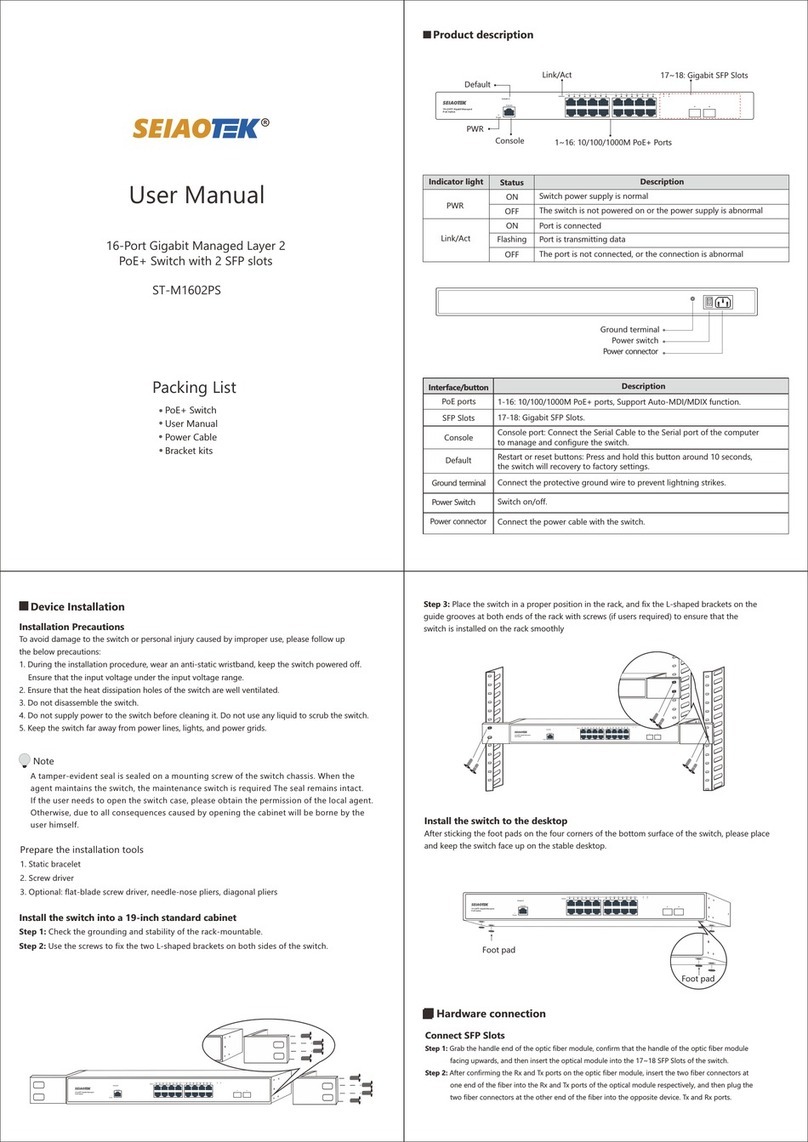

SEIAOTEK ST-M1602PS user manual

H3C

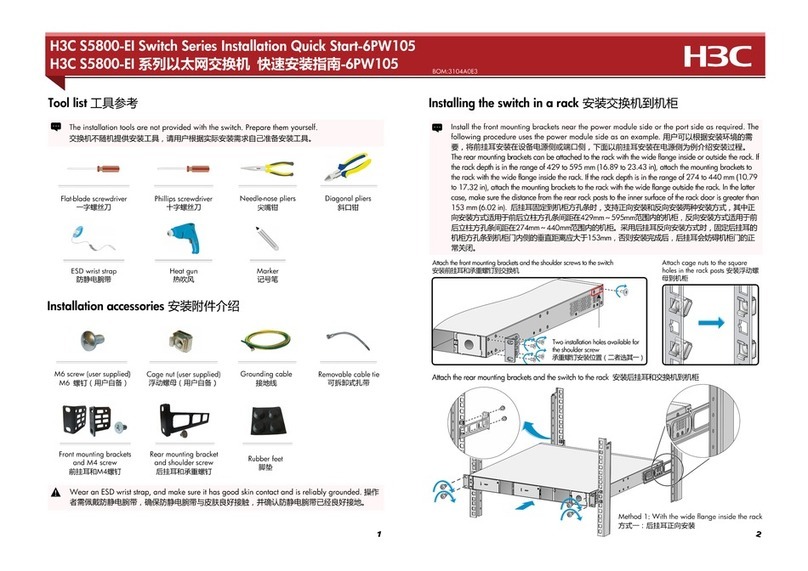

H3C S5800-EI Series Installation, quick start

Extron electronics

Extron electronics System 5 IP Series Specification sheet

TRENDnet

TRENDnet TEG-S2600I - 10/100Mbps Switch With Mini-GBIC... Quick installation guide