FilterSense DynaCHARGE PM 1 Series User manual

INSTALLATION & OPERATING MANUAL

Particulate Monitor

Model DynaCHARGE™ PM 1

T: (978) 927-4304 | 800 Cummings Center, 355W Beverly, MA 01915 USA | www.ltersense.com

PM 1 Installation and Operating Manual v1.2 3FilterSense © 2016

Table of Contents

1Notifications..................................................................................................................................4

1.1 Technical Support Contact......................................................................................................................................................4

1.2 Disclaimer......................................................................................................................................................................................5

1.3 Symbols and Conventions ......................................................................................................................................................5

1.4Safety...............................................................................................................................................................................................6

1.5 Associated Documentation....................................................................................................................................................7

2Introduction..................................................................................................................................8

2.1 PM 1 Overview.............................................................................................................................................................................8

2.2 Components.................................................................................................................................................................................9

2.3 Technical Data............................................................................................................................................................................10

2.4 Model Configuration...............................................................................................................................................................12

3Installation ..................................................................................................................................13

3.1 Location........................................................................................................................................................................................13

3.2 Process Mounts..........................................................................................................................................................................15

3.3 Mounting.....................................................................................................................................................................................16

3.4 Test Port........................................................................................................................................................................................18

4Wiring ..........................................................................................................................................19

4.1 Terminal Connections.............................................................................................................................................................21

5Operation ....................................................................................................................................23

5.1 User Interface .............................................................................................................................................................................23

5.2 Settings.........................................................................................................................................................................................24

6Commissioning ...........................................................................................................................27

6.1 Signal Smoothing.....................................................................................................................................................................27

6.2 Alarms (PM 1-A).........................................................................................................................................................................28

6.3 Analog Output (PM 1-T).........................................................................................................................................................29

7AlarmSetpointGuidance...........................................................................................................30

8FunctionalVerification...............................................................................................................32

8.1 Power-Up Check........................................................................................................................................................................32

8.2 System-Zero Check..................................................................................................................................................................32

8.3 Response Testing......................................................................................................................................................................33

8.4 Factory Testing ..........................................................................................................................................................................33

9Troubleshooting.........................................................................................................................34

10 Maintenance................................................................................................................................35

11 Spare Parts ..................................................................................................................................36

11.1 Electronics Module Replacement.......................................................................................................................................36

PM 1 Installation and Operating Manual v1.2 4FilterSense © 2016

1 Notifications

1.1 Technical Support Contact

FilterSense provides industry leading Engineering and Technical Support for all product lines. The Technical

Support department is staffed with a team of engineering professionals. Areas of assistance provided by the

Technical Support department include:

Pre-Installation Site Analysis

Product Installation

General Operation

Application-Specific Review

Routine Calibration

EPA Compliance

Performance Upgrades and Add-On Features

To assure the best and most efficient technical support, please be prepared with the following information prior

to contacting FilterSense. If it is determined that the component must be returned for evaluation/repair, a

Return Material Authorization (RMA) number will be issued. You must include the RMA number on the packing

slip and mark the outside of the shipping container.

Company Name

Product Model Number

Product Serial Number

Date of Installation

Reason for Return

FilterSense Technical Support may be reached by:

Phone: (978) 927-4304

Fax: (978) 927-4329

E-Mail: [email protected]

Hours of Operation: 8:00AM 5:00PM U.S. Eastern Time

Any control unit or particulate sensor that was exposed to hazardous materials in a process must be

properly cleaned in accordance with OSHA standards and a Material Safety Data Sheet (MSDS) must be

completed before it is returned to the factory.

All shipments returned to the factory must be sent by prepaid transportation.

All shipments will be returned F.O.B. factory.

Returns will not be accepted without an RMA number.

PM 1 Installation and Operating Manual v1.2 5FilterSense © 2016

1.2 Disclaimer

This document contains important information necessary for proper operation of the product. It is

strongly urged that all users of the product read this manual in its entirety. All instructions should be

followed properly and any questions that arise should be discussed with FilterSense (A Division of Impolit

Environmental Control Corp.).

Any use or distribution of this document without the express consent of FilterSense is strictly prohibited.

Any reproduction is prohibitedwithout written permission.

In no event will FilterSense be liable for any mistake, including lost profits, lost savings, environmental

compliance costs, or other incidental or consequential damages or injury arising out of the use or

inability to use this manual, even if advised of the possibility of such damages, or any claim by any other

party. Terms and conditions supplied with each order contain additional liability limitations related to

this product.

1.3 Symbols and Conventions

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss.

Warning statements help you to:

Identify a hazard

Avoid a hazard

Recognize the consequences

Identifies information that is critical for successful application and understanding of

the product.

Identifies information, sections or statements in this manual that apply to approved

hazardous area systems, regulations, or installation.

PM 1 Installation and Operating Manual v1.2 6FilterSense © 2016

1.4 Safety

AREA CLASSIFICATION

Before installing any device, confirm area classification requirements as specified on

the product label. Do not install any device that is not tagged as suitable for the

required area classification.

ENVIRONMENT

Before installing any device, confirm ambient temperature, process temperature, and

process pressure requirements. Do not install any device that is not tagged as suitable

for the required temperatures and pressures.

NOT A SAFETY RATED DEVICE

This model must not be used independently for safety or as a critical input signal to a

safety system. This model is designated for general process control, diagnostics, and

environmental monitoring. Safety must be addressed with the detailed engineering,

redundancy, and safety certified components where applicable. Consult factory for

critical safety applications.

GROUNDING

Before turning on the instrument, you must connect the protective earth terminal of

the instrument to a proper earth ground. Grounding to the neutral conductor of a

single-phase circuit is not sufficient protection.

INSTALLATION AND SERVICE PERSONNEL

Only appropriately licensed professionals should install this product. Always

disconnect power before servicing.

Personnel must be familiar with operational hazards, such as those caused by hot,

pressurized, or toxic gases, liquids, or particulates.

Service of individual electronics is limited to replacement of the electronics module. Do

not attempt to disassemble electronics. Any components that are not operating

properly should be returned to FilterSense for service.

PM 1 Installation and Operating Manual v1.2 7FilterSense © 2016

1.5 Associated Documentation

This manual is to be referenced in conjunction with the following FilterSense documentation:

Product Information

Publication Number

Title

228-1077

FilterSense Particulate Monitoring Application and Alarm Guide

EXXXX

Project Specific Drawings if Applicable

PM 1 Installation and Operating Manual v1.2 8FilterSense © 2016

2 Introduction

2.1 PM 1 Overview

a single-point/basic functionality particulate monitor employing charge induction

sensing for reliable continuous monitoring of particulate in stacks, ducts, and pipes. Applications include filter

leak detection, cyclone overflow, and powder flow/no flow. The PM 1 is available in two versions.

PM 1

PM 1-A

oBasic Particulate Monitor with Alarm

Relay Outputs

oIntegral Electronics Only

PM 1-T

oBasic Particulate 4-20mA Transmitter

oIntegral Electronics Only

The PM 1 is also available in a PRO version for demanding process control and EPA compliance applications.

Refer to separate manual for the PM 1 PRO.

PM 1 PRO

PM 1 PRO-A

oAdvanced, High-Performance Parti-

culate Monitor with Alarm Relay

Output

oIntegral or Remote Electronics

oGraphical Display/Keypad

PM 1 PRO-AT

oAdvanced, High-Performance Parti-

culate Monitor with Alarm Relay

Outputs and Analog Output

oIntegral or Remote Electronics

oGraphical Display/Keypad

PM 1 PRO-T

oAdvanced, High-Performance Parti-

culate 4-20mA Transmitter

oIntegral or Remote Electronics

oGraphical Display/Keypad

PM 1 Installation and Operating Manual v1.2 9FilterSense © 2016

Principle of Operation

As particles flow near or around the electrically

isolated sensing probe, minute charge is continuously

induced into the probe. The charge flows through a

measurement circuit to ground.

The induced charge signal is digitally analyzed and

processed to provide an output that is reasonably

linear to mass. The unit of measure is picoamperes

(pA). For highest accuracy and linearity to mass, refer

to model PM 100 PRO.

For best understanding of particulate levels, 4-20 mA

analog outputs should be converted to pA at remote

recording devices or remote displays.

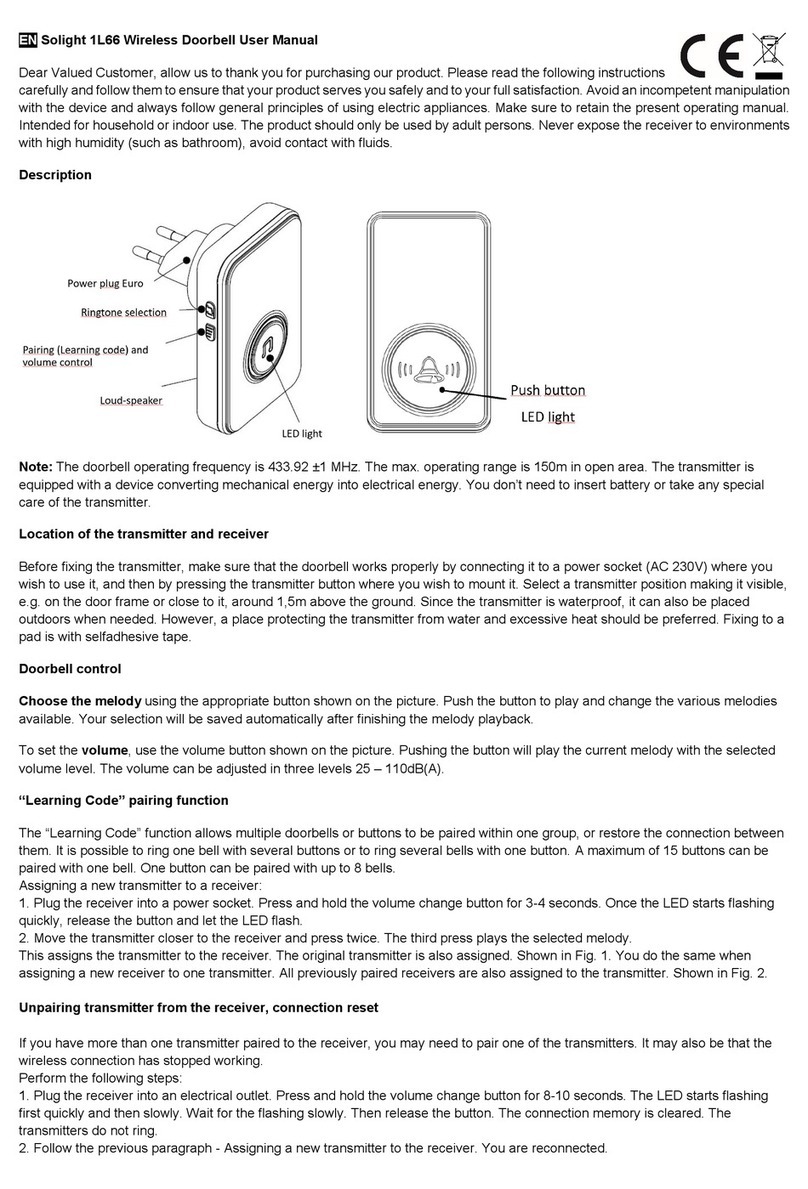

2.2 Components

The PM 1 consists of the following main elements:

① Electronics Module

② Electronics Enclosure

③ Process Mount

④Sensing Probe

PM 1 Installation and Operating Manual v1.2 10 FilterSense © 2016

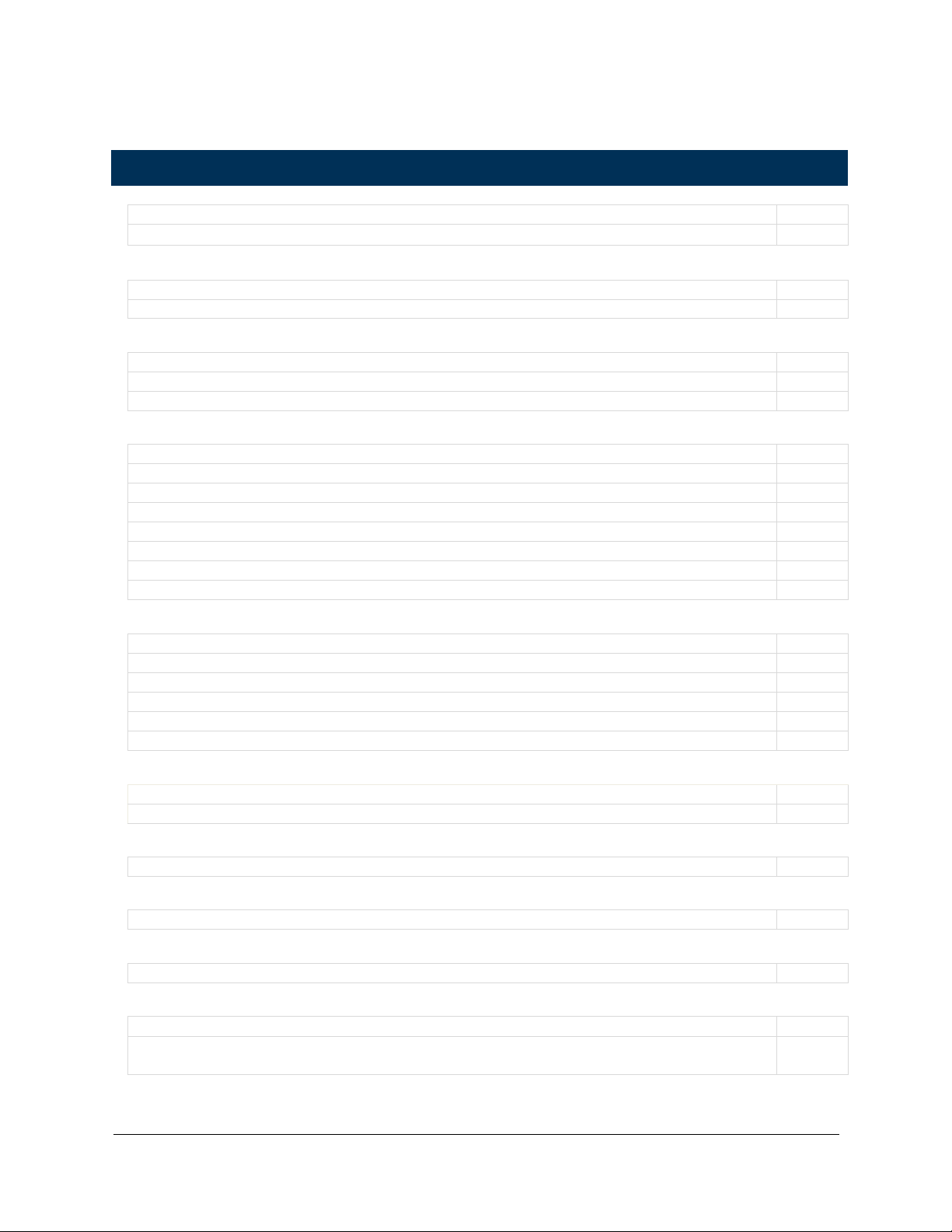

2.3 Technical Data

Electronics Module

Parameter

Model Code

Specifications

Notes

Measurement

Technology

Charge Induction

Measurement Units

Picoamperes (pA)

1 x 10-12 A

Input Voltage

-A-U

-A-D

-T

Universal 20-250 VAC/VDC, 47-63 Hz

18-60VDC

Fuse: 1.0A, Slo-

12-32 VDC Loop Power

Input Power

-A

3 Watts Max.

Electronic Resolution,

Range

-R1

-R2

-R9

0.5pA, Range 0 to 5,000pA

5.0pA, Range 0 to 5,000pA

10.0pA, Range 0 to 100,000pA

Powder Flow Only

Minimum Detection

Level

-R1

-R2

-R9

~1-5 mg/m3

~5-10 mg/m3

~10 mg/m3

Minimum Particle Size

0.3 Micron

Temperature Ambient

-13F to +160F (-25C to +71C)

-40F to +185F (-40C to +85C)

Operating

Storage

Relay Outputs

-A

Form A (SPST)

250 VAC / 5A (Resistive), 2A (Inductive)

30 VDC / 5A (Resistive), 2A (Inductive)

Type

Max Rating

4-20mA Output

-T

@ 24 VDC

Loop Power

Adjustable via Keypad

Rating

Span

Enclosure

-N4

NEMA 4/IP 66 Aluminum, Powder

Coated

Area Classification

-G

-H2

Ordinary/General Purpose Only, CE

Approved (CSA/UL Approval Pending)

Optional Hazardous Location, CSA

Approved, Class II, Division II, Groups E-

G, ATEX, IECEx (Approval Pending)

PM 1 Installation and Operating Manual v1.2 11 FilterSense © 2016

Sensor Probe

Parameter

Detail/Code

Specifications

Notes

Mounting

-N05

-B10

-Q15

NPT Male 0.5 in

BSPT Male 1.0 in

Quick Clamp, 1.5 in

Wetted Materials

-C

316L Stainless Steel

Optional Fully Insulated Probe (Teflon

Coating)

316L Stainless Steel, Teflon

Probe

Nipple/Mount

Process Temperature

Operating Range

-T12

-T14

-13F to +250F (-25C to +121C) Max.

-13F to +450F (-25C to +232C) Max.

Process Pressure

Operating Range

Full Vacuum to 10PSI (0.69 Bar) Max.

PM 1 Installation and Operating Manual v1.2 12 FilterSense © 2016

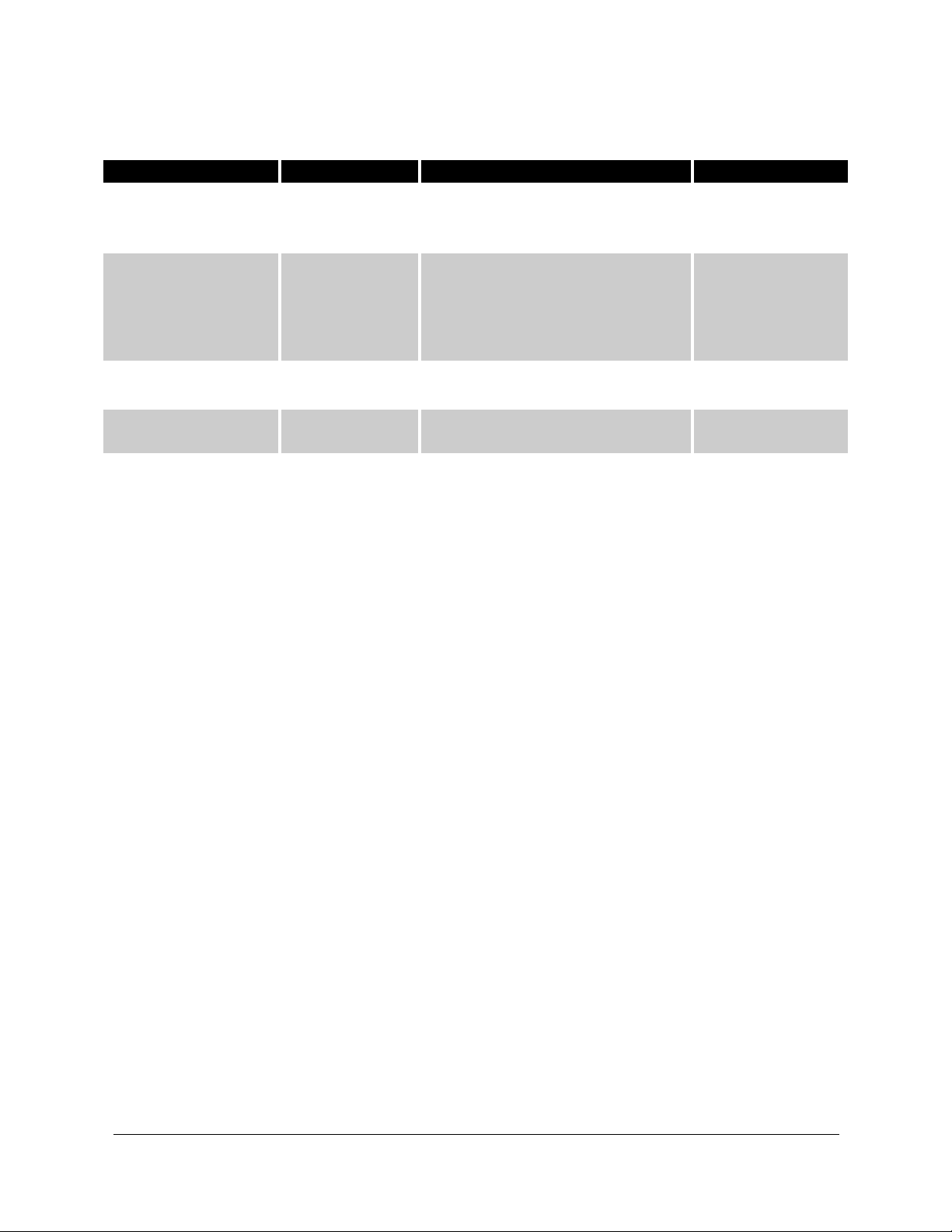

2.4 Model Configuration

DynaCHARGE™ PM 1 Particulate Monitor

Order

Code

Base Unit

Transmitter (4-20 mA), 2-Wire Loop Power

PM 1-T

Alarm (2 Relays)

PM 1-A

Power Supply (PM 1-A Only)

Universal AC/DC Power (20 to 250 VAC/VDC)

U

DC Power Only (18-60 VDC)

D

Resolution and Range

Resolution: 0.5 pA, Range: 0 to 5,000 pA

R1

Resolution: 5.0 pA, Range: 0 to 5,000 pA

R2

Resolution: 10.0 pA, Range: 0 to 100,000 pA

R9

Probe Length

Length - 1.5 in (3.8 cm)

L1.5

Length - 3.0 in (7.6 cm)

L3

Length - 6.0 in (15.2 cm)

L6

Length - 12 in (30.5 cm)

L12

Length - 18 in (45.7 cm)

L18

Length - 24 in (60.9 cm)

L24

Length - 30 in (76.2 cm)

L30

Length - 36 in (91.4 cm)

L36

Process Mount

NPT Male 0.5 in (1.3 cm) with Mounting Coupling

N05

Optional - Remove NPT Mounting Coupling

R

BSPT Male 1.0 in (2.5 cm) with Mounting Coupling

B10

Optional - Remove BSPT Mounting Coupling

R

Quick Clamp, 1.5 in (3.8 cm) with Mounting Kit (Z= Mount Extension Size in Inches)

Q15(Z)

Optional - Remove Quick Clamp Mount Kit

R

Process Temperature

-13 °F to 250 °F (-25 °C to 121 °C) Max.

T12

-13 °F to 450 °F (-25 °C to 232 °C) Max.

T14

Process Pressure

Full Vacuum to 10 PSI (0.69 Bar) Max.

P0

Additional

Fully Insulated Probe (Teflon Coating)

C

Enclosure

NEMA 4/IP 66 Aluminum, Powder Coated

N4

Area Classification

Ordinary/General Purpose Only, (Approval Pending), CE Mark

G

Hazardous Location, Class II, Division II, Groups E-G, CSA/FM, ATEX, IECEx (Approval

Pending)

H2

PM 1 Installation and Operating Manual v1.2 13 FilterSense © 2016

3 Installation

Only trained professionals should install/maintain this product.

Shutdown processes that include high temperatures, high pressures, toxic

gases, hazardous particulate, or explosion risks prior to installing or removing

equipment.

3.1 Location

Temperature, Pressure, and Area Classification

Do not install any device that is not tagged as

suitable for the required area classification.

Confirm compatibility of sensor ratings with

process and installation area.

Check label for the following:

oProcess temperature rating

oProcess pressure rating

oWetted materials

oEnclosure rating

oArea classification

Installation must be in grounded metal

duct/pipe. Consult factory for non-metallic

duct/pipe solutions.

Enclosure Label Example

Filter Outlet Locations

①Ensure good access.

②Avoid locating too close to stack exit.

③Straight runs and laminar flow best for

measurement.

④ Short straight runs are acceptable for basic

leak detection.

⑤Accessible negative pressure locations may be

preferred to prevent exposure to toxic gases

and particulate.

④

③

⑤

①

⑤

③

②

PM 1 Installation and Operating Manual v1.2 14 FilterSense © 2016

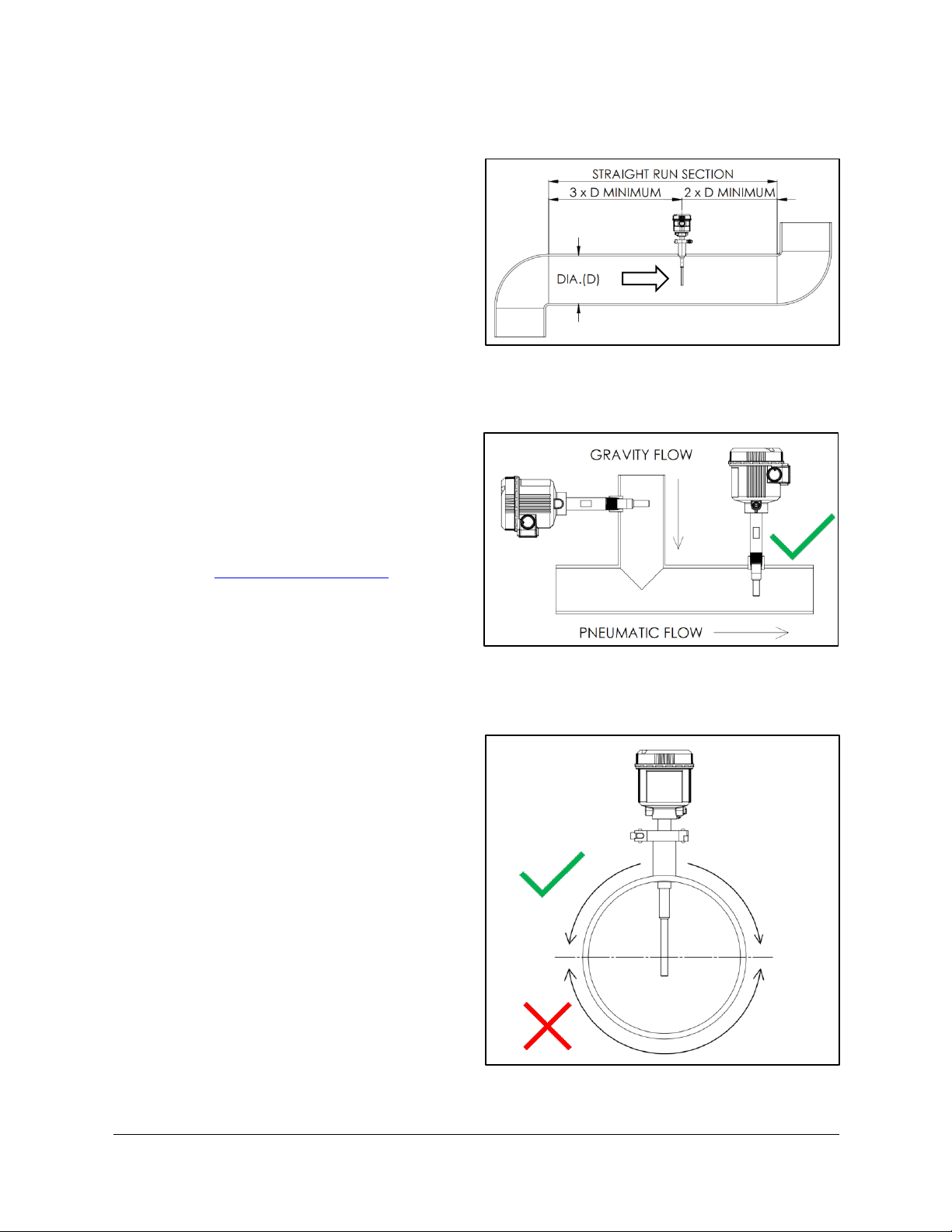

Straight Run Considerations

Install in straight run if possible (not required).

Three (3) duct diameters upstream.

Two (2) duct diameters downstream.

Straight run can be horizontal or vertical.

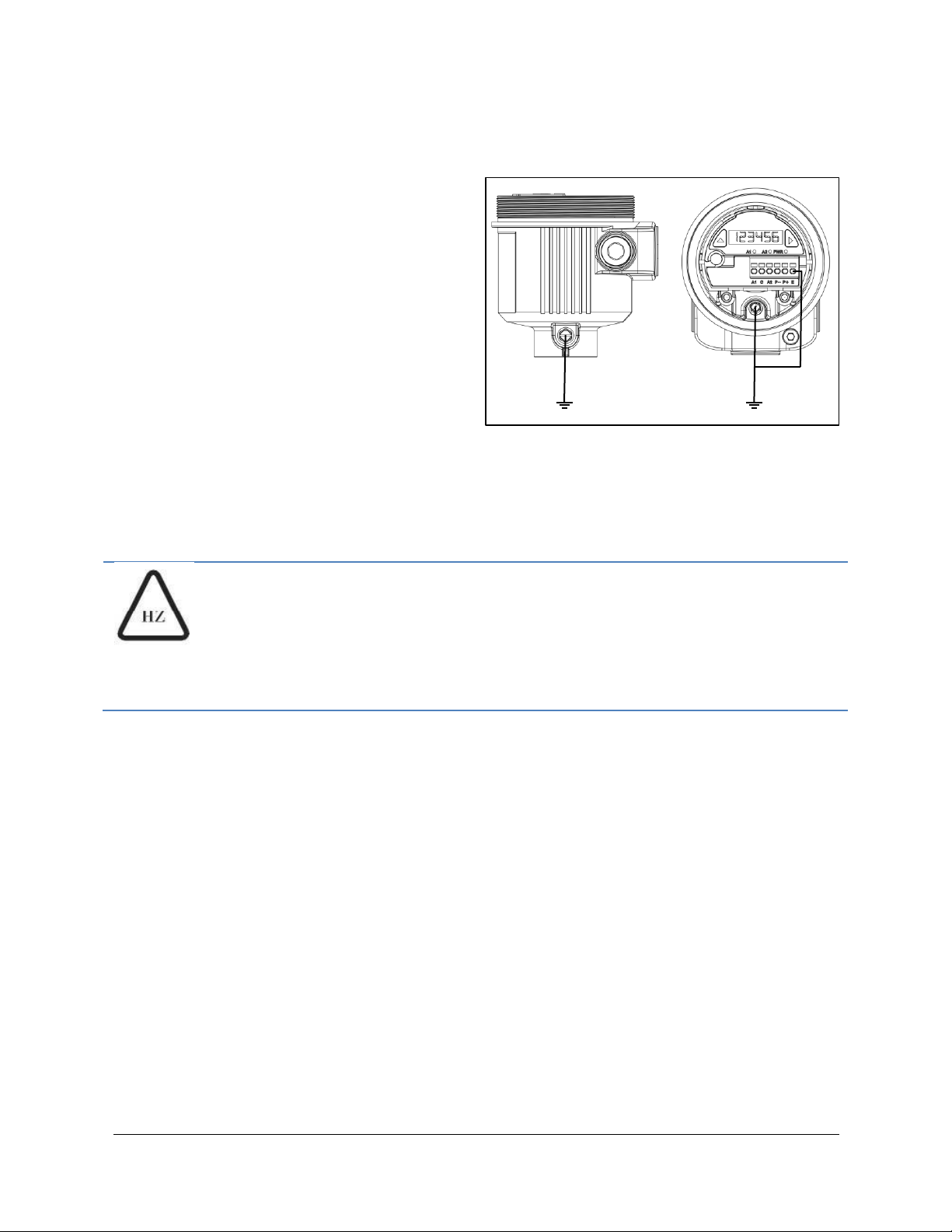

Powder Flow Locations

①Best installed in pneumatic section (positive

or negative pressure).

②For gravity feed, consult factory.

Grounded metal duct required.

oConsult factory for nonmetallic duct/

pipe solutions.

Follow straight run considerations.

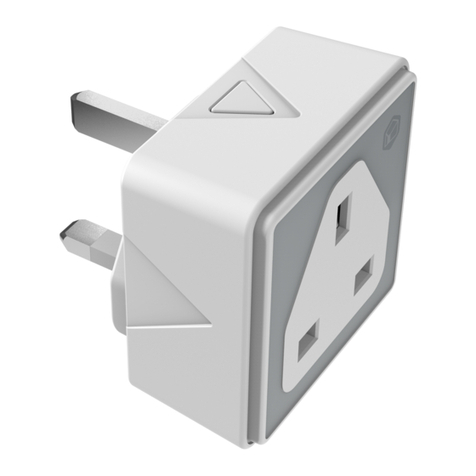

Horizontal Pipes/Ducts

Side or top mount recommended.

Bottom mount notrecommended.

Proper mount and installation location will

prevent buildup.

①

②

PM 1 Installation and Operating Manual v1.2 15 FilterSense © 2016

3.2 Process Mounts

The following types of process mounts are available:

Threaded

NPT Standard

G/BSPT Optional

① Threaded Nipple

② Threaded Half-Coupling Process Mount

Quick-Clamp

-Clamp

Allows quick and easy removal from process

Allows rotation to easily align

① Quick-Clamp Nipple

② Quick-Clamp Process Mount

①

②

①

②

PM 1 Installation and Operating Manual v1.2 16 FilterSense © 2016

3.3 Mounting

Mounting Considerations

①Process mount should protrude into process

0.125 in (3.175 mm) to 0.5 in (12.7 mm).

②Sensor probe should extend approximately

1/2 of the duct diameter for filter outlet

applications and 1/4 to 1/2 of the pipe

diameter for powder flow applications.

In smaller pipes, the probe should be 1 in

(25.4 mm) minimum from the opposing side.

Welding and Clearance

①-clamp

mount to ensure proper clearance and to

prevent particulate buildup in mount. Process

mount should protrude into process 0.125 in

(3.175 mm) to 0.5 in (12.7 mm).

②Do not face weld.

Weld in center of the duct/pipe,

perpendicular to the flow.

Air and water tight seal.

Quick-Clamp

Threaded

①

①

②

②

②

②

①

①

PM 1 Installation and Operating Manual v1.2 17 FilterSense © 2016

Improper Extensions

①Do not use an extended or improper mount.

②Longer mounts can cause the nipple not to

protrude into the process.

③Extended mounts can cause particulate

buildup on the insulator and sensing probe.

Contact the factory for custom sensor nipple

extensions for proper installation in an

existing port.

Do not use non-stainless steel mounts that

may corrode and cause corrosive residue to

drip on the sensor.

①

②

③

PM 1 Installation and Operating Manual v1.2 18 FilterSense © 2016

3.4 Test Port

Installation of a sensor test port is for introducing particulate upstream of the sensor as a method for checking

the response to an increase in particulate. Some applications are required by EPA regulations to include a sensor

test port for Response Testing.

Location and Mounting

Non-hazardous areas only.

Negative pressure location.

Install at least 3 ft upstream of the particulate

sensor.

In line with sensor on the same side of the

duct.

If possible, locate the test port at ground level

and/or a location with easy access.

If the test port must be located at an

inaccessible location, a length of tubing can

be used to improve access.

Typical test port is a

with a cap or shutoff valve.

PM 1 Installation and Operating Manual v1.2 19 FilterSense © 2016

4 Wiring

Conduit Entries

One (1) and two (2) NPT entries

provided.

Conduit fittings should be tight.

Conduit should be routed downward to

prevent moisture from entering enclosure.

Recommended Service Loop

Flex conduit and ground cable should be

sufficient length to allow removal of the

sensor.

Recommended service loop is 1 to 2 times the

sensor probe length.

Service loop should extend downward to

prevent moisture from entering enclosure.

PM 1 Installation and Operating Manual v1.2 20 FilterSense © 2016

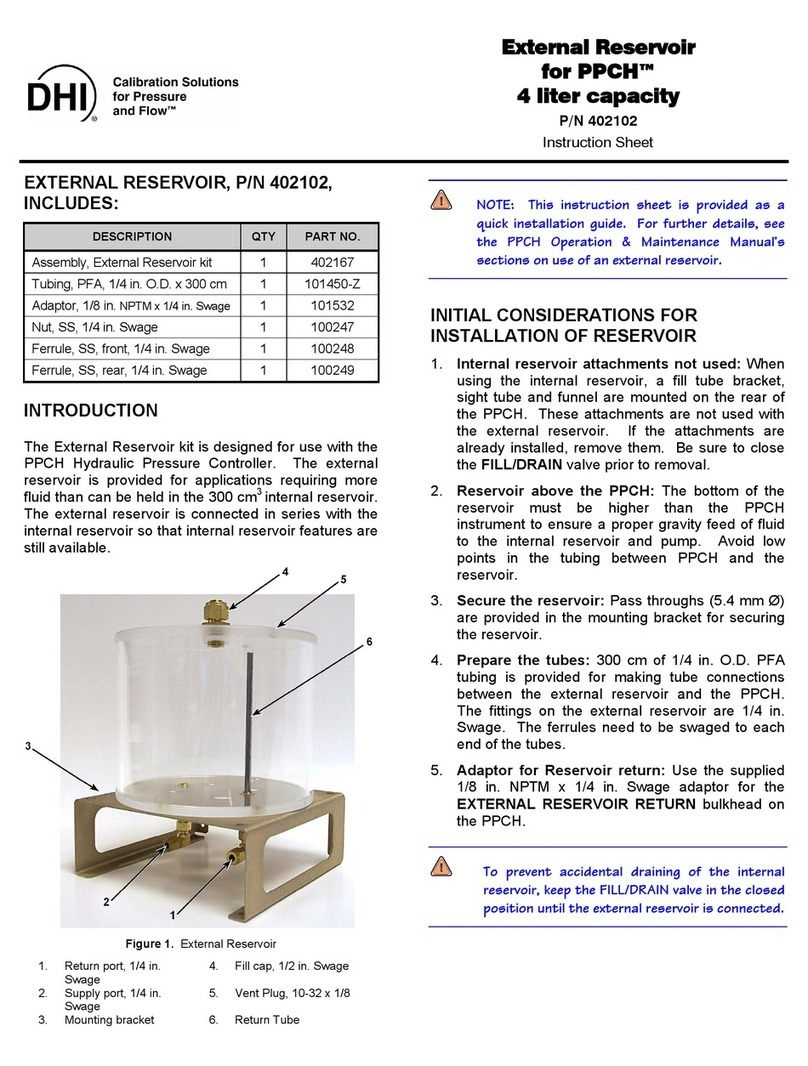

Grounding

Required for reliable operation and safety.

PM1-T: Earth ground connection is made

through the process mount. Grounding to the

enclosure ground studs is not required.

PM1-A: Earth ground connection should be

made to one of the three ground locations:

oExternal enclosure ground screw.

oInternal enclosure ground screw.

oElectronics module earth ground

terminal.

Analog wiring cable shield should be

terminated to earth ground in PLC/DCS

cabinet or at panel meter (terminate at one

end only).

Ground wire should not impede service loop.

GROUNDING IN HAZARDOUS AREAS

For hazardous area applications, an external sensor earth ground cable is

required to maintain sensor grounding during installation and maintenance.

The ground cable must remain attached when the sensor is temporarily

removed from the process. Do not disconnect the ground cable.

This manual suits for next models

5

Table of contents

Popular Accessories manuals by other brands

Aztech

Aztech KylaS WiFi Plug UK Easy start guide

Johnson Controls

Johnson Controls NS Series installation instructions

ALLDOCK

ALLDOCK To Go Assembly instructions

Milesight

Milesight VS121 user guide

DH Instruments

DH Instruments EXTERNAL RESERVOIR FOR PPCH instruction sheet

MKS

MKS HPS 903 Series Operation and maintenance manual