Ados A100E User manual

492-MTU10006 Rev. 4 Page 1 of 49

INSTRUCTION

MANUAL

A100E

SW Version 1.06

5

4Changes to Rev 1.6 22/11/00 Golinelli G. Paulitti G.

3Changes to Rev 1.5 10/04/99 Golinelli G. Paulitti G.

2Changes to Rev 1.2 (password) 15/06/98 Golinelli G. Paulitti G.

1MODBUS protocol 02/03/98 Golinelli G. Paulitti G.

0Issue 27/11/97 Golinelli G. Paulitti G.

492_4 Rev. Subject of the revision Date Prepared Checked Approved

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 2 of 49

Contents

1. INTRODUCTION ....................................................................................................................... 4

1.1 General................................................................................................................................... 4

1.2 Versions/options ..................................................................................................................... 4

1.3 Documentation....................................................................................................................... 4

1.4 Equipment marking description............................................................................................. 5

2. OPERATING SPECIFICATIONS .............................................................................................. 6

2.1 Technical data ........................................................................................................................ 6

3. INSTRUMENT OPERATIONS ................................................................................................. 7

3.1 Turning on the instrument...................................................................................................... 7

3.2 Display indication................................................................................................................... 8

3.3 Tare ......................................................................................................................................... 8

3.4 Manual Zero........................................................................................................................... 8

3.5 Automatic Zero Tracking ....................................................................................................... 8

3.6 LED status indicators ............................................................................................................ 9

3.7 Key functions ......................................................................................................................... 9

3.8 Switch.....................................................................................................................................11

3.9 Self diagnostic .......................................................................................................................11

3.9.1 Configuration memory integrity check .................................................................................11

3.9.2 Configuration parameter integrity check ..............................................................................12

3.10 Output relay operation......................................................................................................... 13

3.11 SERIAL INTERFACE MANAGEMENT.......................................................................... 15

3.11.1 Primary serial interface ......................................................................................................15

3.11.2 RS485 interface.................................................................................................................15

3.11.3 Continuous modality ...........................................................................................................16

3.11.4 Bi-directional modality........................................................................................................16

3.11.5 Print On Request modality..................................................................................................18

3.11.6 Bi-directional modality with MODBUS protocol...................................................................19

3.11.7 Auxiliary serial interface.....................................................................................................24

4. INSTALLATION........................................................................................................................ 25

4.1 Material receiving ............................................................................................................... 25

4.2 Instrument mounting ............................................................................................................ 26

4.3 Connections .......................................................................................................................... 27

4.3.1 Wiring the instrument to the protective earthing system ........................................................28

4.3.2 Power supply connection....................................................................................................28

4.3.3 Load cell connection ..........................................................................................................29

4.3.4 Relay output connection .....................................................................................................30

4.3.5 Serial port connection.........................................................................................................31

5. MAINTENANCE....................................................................................................................... 32

5.1 Preventive maintenance ...................................................................................................... 32

5.2 Corrective maintenance....................................................................................................... 32

6. INSTRUMENT CONTROL ..................................................................................................... 33

6.1 Introduction.......................................................................................................................... 33

6.2 Control function selection.................................................................................................... 34

6.2.1 Password..........................................................................................................................35

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 3 of 49

6.2.2 Keyboard time out .............................................................................................................35

6.3 Operating parameter configuration..................................................................................... 36

6.3.1 Operating parameter selection ............................................................................................36

6.3.2 Modifying the value of the operating parameters ..................................................................37

6.3.3 Graduation.........................................................................................................................38

6.3.4 Resolution .........................................................................................................................38

6.3.5 Decimal point ....................................................................................................................38

6.3.6 Averages ..........................................................................................................................38

6.3.7 Zero limit...........................................................................................................................40

6.3.8 Motion band ......................................................................................................................40

6.3.9 Zero tracking limit ..............................................................................................................40

6.3.10 Primary serial port .............................................................................................................41

6.3.11 Auxiliary serial port............................................................................................................41

6.3.12 Transmission delay.............................................................................................................41

6.3.13 Receiver Time out .............................................................................................................41

6.3.14 Address on RS485 .............................................................................................................41

6.3.15 Baud rate ..........................................................................................................................41

6.3.16 Relay function ...................................................................................................................43

6.3.17 Relay threshold ..................................................................................................................43

6.3.18 Dead Band........................................................................................................................43

6.4 Calibration............................................................................................................................ 44

6.4.1 Zero calibration..................................................................................................................45

6.4.2 Span calibration .................................................................................................................46

6.5 Test....................................................................................................................................... 47

6.6 System Initialization............................................................................................................. 48

6.6.1 Switch controlled initialization..............................................................................................48

7. INSTRUMENT CONFIGURAZIONE TABLE....................................................................... 49

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 4 of 49

1. INTRODUCTION

1.1 General

The A100E instrument is a microprocessor based weight amplifier and indicator.

It was designed to connected to a maximum of 6 load cells (350 ?bridge), connected in parallel.

The keyboard can be used to carry out all the programming, configuration and calibration functions.

A series of display messages guides the operator through all the phases.

A series of options sets up the instrument for the main functions related to electronic weighing.

1.2 Versions/options

A

1

0

0

E

X

X

Type of power supply 1 = 115 Vac - 2 = 230 Vac

3 = 24 Vac - 4 = 24 Vcc

5 = 12 Vcc

Version set up for management: Transpallet (T)

SAMPLE ORDER

A100E wired for 230 Vac operation: A 1 0 0 E 2

1.3 Documentation

This technical manual is relevant to the base version of the instrument.

The technical manual is relevant to the transpallet management version is 538-MTU10007.

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 5 of 49

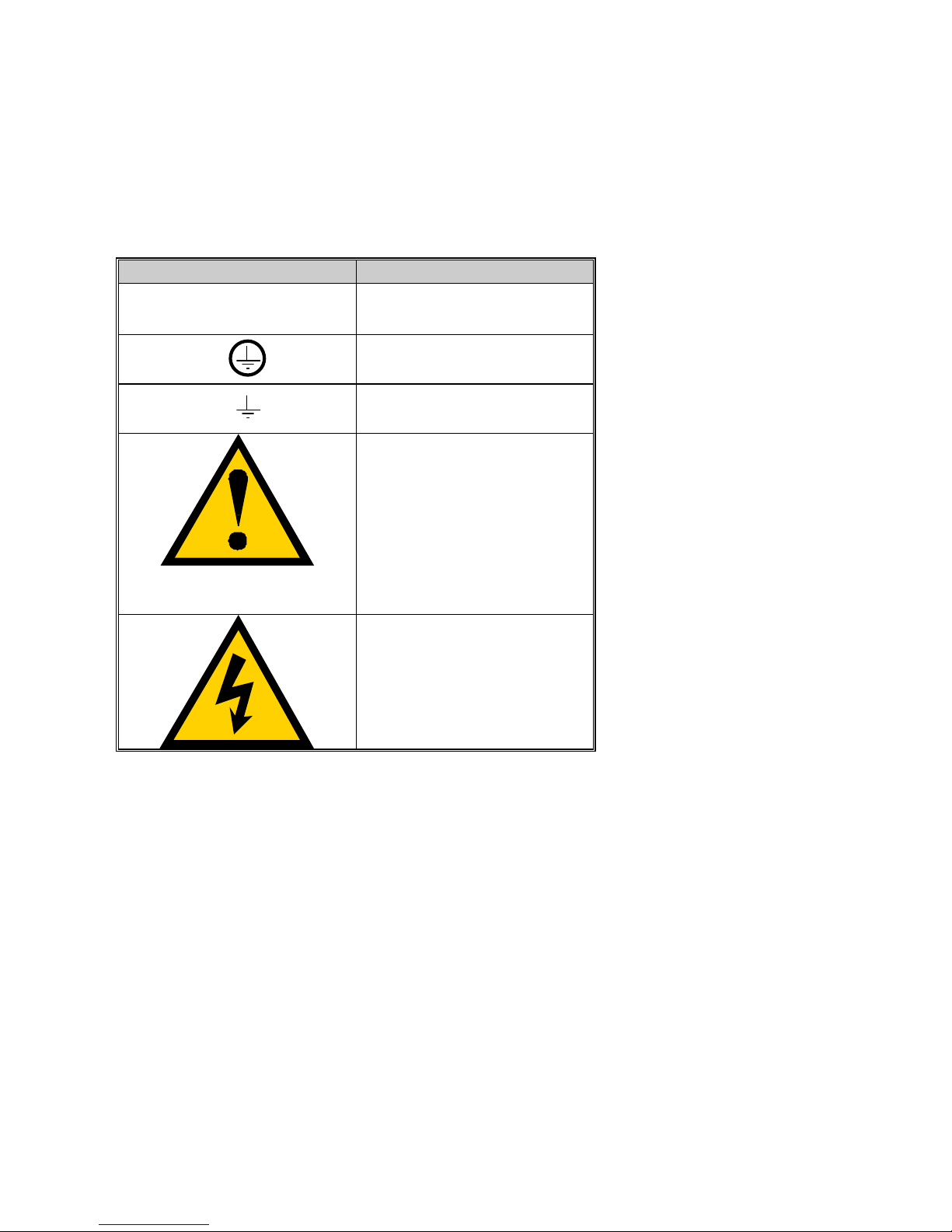

1.4 Equipment marking description

A100E is marked with symbols compliant with European Standard 61010-1 (April 1993).

SYMBOL DESCRIPION

?Alternating current

Protective conductor terminal

Earth (ground) terminal

Caution (refer to accompanying

documents)

Caution, risk of electric shock

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 6 of 49

2. OPERATING SPECIFICATIONS

2.1 Technical data

Power supply 230 Vac 50/60 Hz -15%...+10%

120 Vac 50/60 Hz (optional) -15%...+10%

Consumption 10VA (15 VA MAX.)

Fuse 230 Vac: 80 mA Time lag T

120 Vac: 160 mA Time lag T

+ 12 Vdc: 500 mA Fast

+ 24 Vdc 630 mA Fast

Operating temperature from - 10 ?C to + 40 ?C

Storage temperature from - 40 ?C to + 70 ?C

Relative humidity 95% non-condensing

Load cell power supply 8 Vdc (short-circuit proof)

Maximum current 90 mA (4 x 350 ?load cells in parallel)

Electric connection 4 wires

Analog signal 0.5 - 2.5mV/V

Resolution 0.8 ?V/Grad

Conversion speed 55 conversion/sec

Graduation 1000-2000-3000-4000-5000

Resolution 1-2-5-10-20-50

Off scale limit (UL/OL) 20% of full scale load

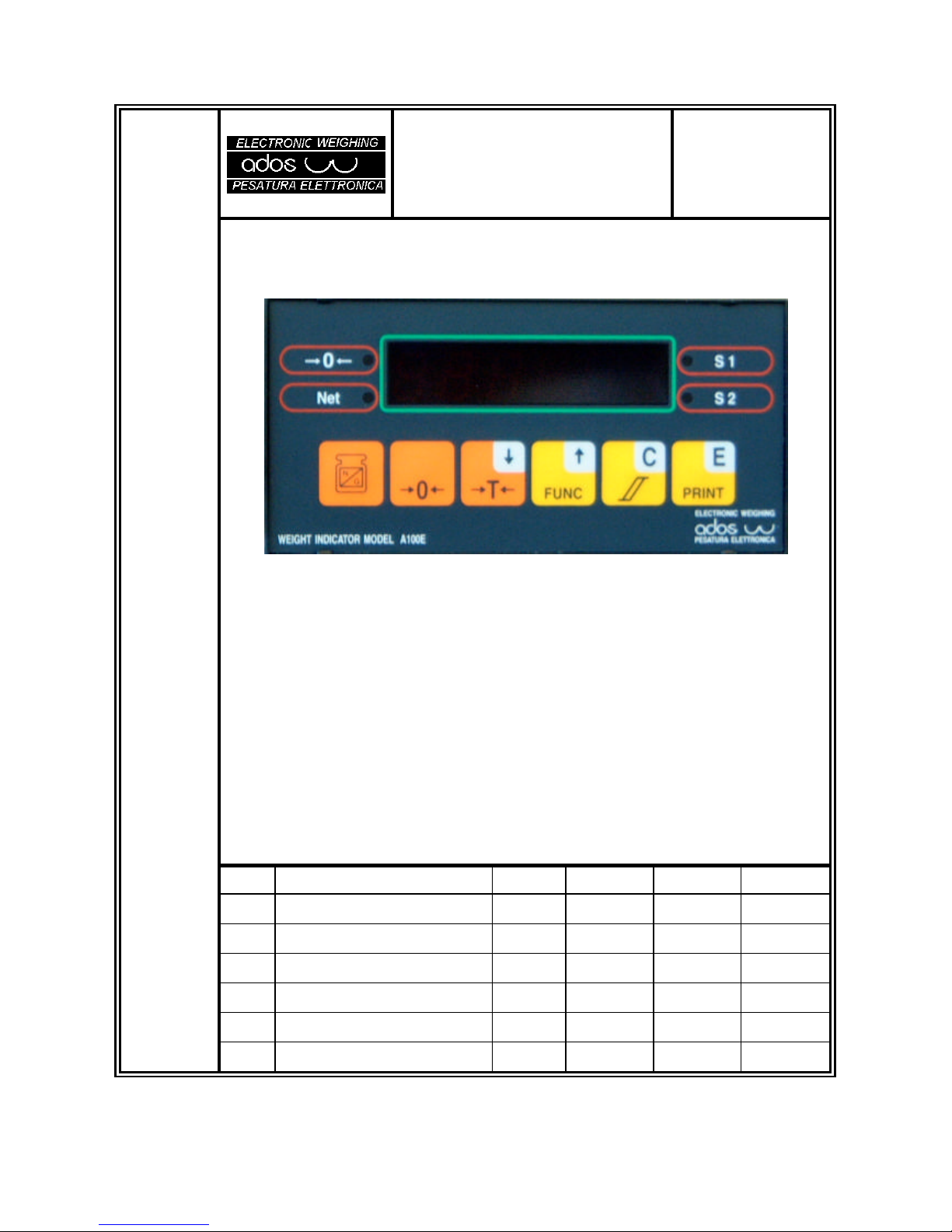

Display five (5) digits LED

Polarity sign -

Keyboard six (6) keys

Status indicators four (4) LED indicators

Decimal point user defined: 0 - 0.0 - 0.00 - 0.000 - 0.0000

Zero tracking user defined (0.5 - 1 - 2 - 5 - 10 div/s)

AZM aperture user defined (OFF - 1.9% - 100% of F.S.)

Motion band user defined (OFF - 0.5 - 1 - 2 - 5- 10- 20 div)

Serial outputs main output RS232 or RS485 Half-duplex, aux

output RS232, Tx only

Digital outputs two (2) base relay outputs and eight (8) extra

Contact rating 0.5 A @ 24 Vdc

Housing self extinguishing NORYL UL 94 V- (Black) for

front panel mounting according toDIN 43700

Dimensions 72 x 144 x 129 mm

Drilling 68 x 138 mm

Weight 0.7 Kg

Mounting Front panel mounting with two holding brackets

mounted on the sides of the enclosure

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 7 of 49

3. INSTRUMENT OPERATIONS

3.1 Turning on the instrument

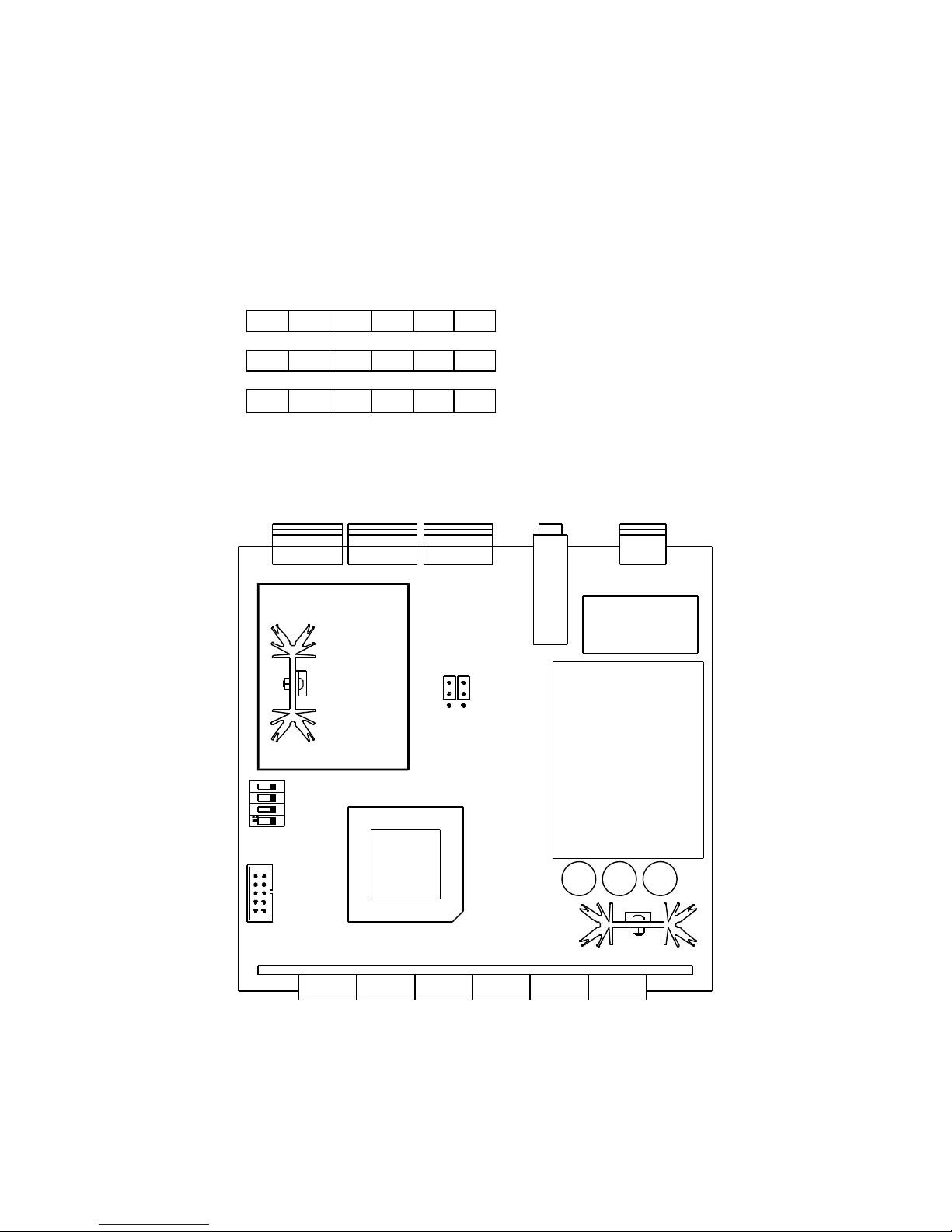

When the instrument is turned on, the primary display indicates the following, at intervals of about two

seconds:

A D O S

A100E

V E R 1. 0 6 (Revision of the installed software)

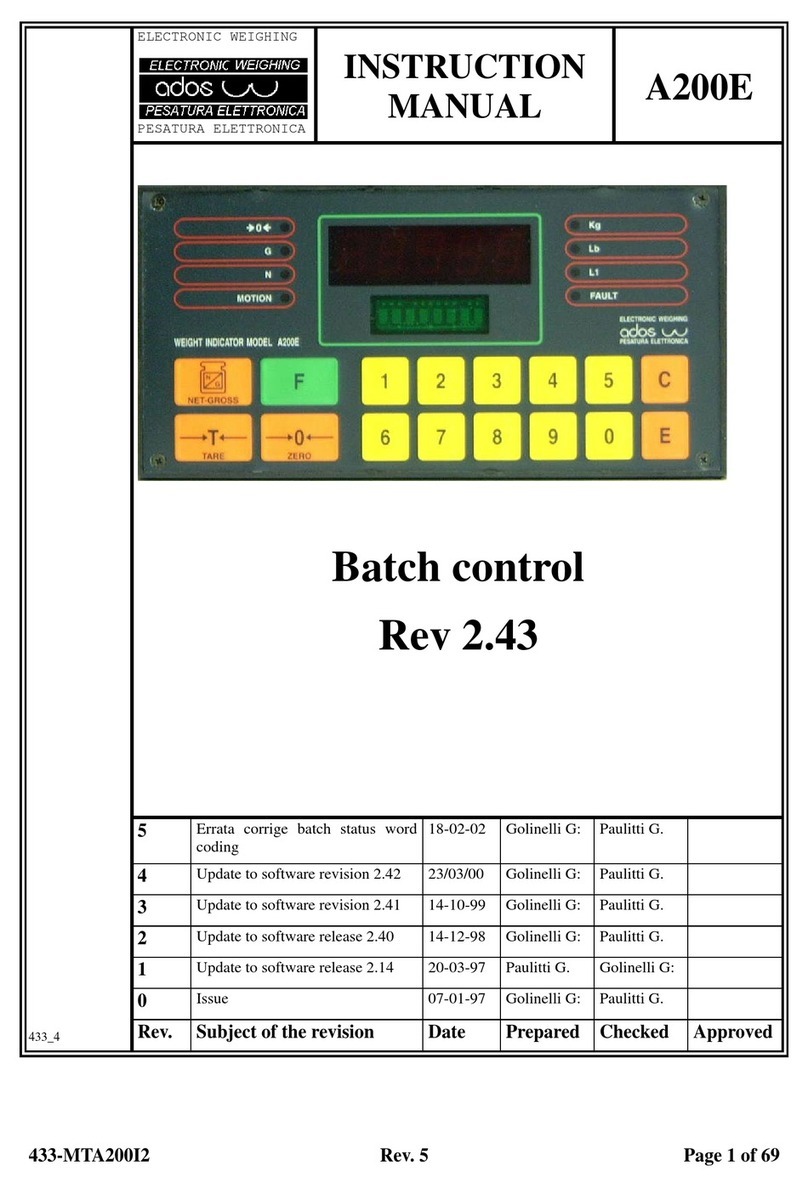

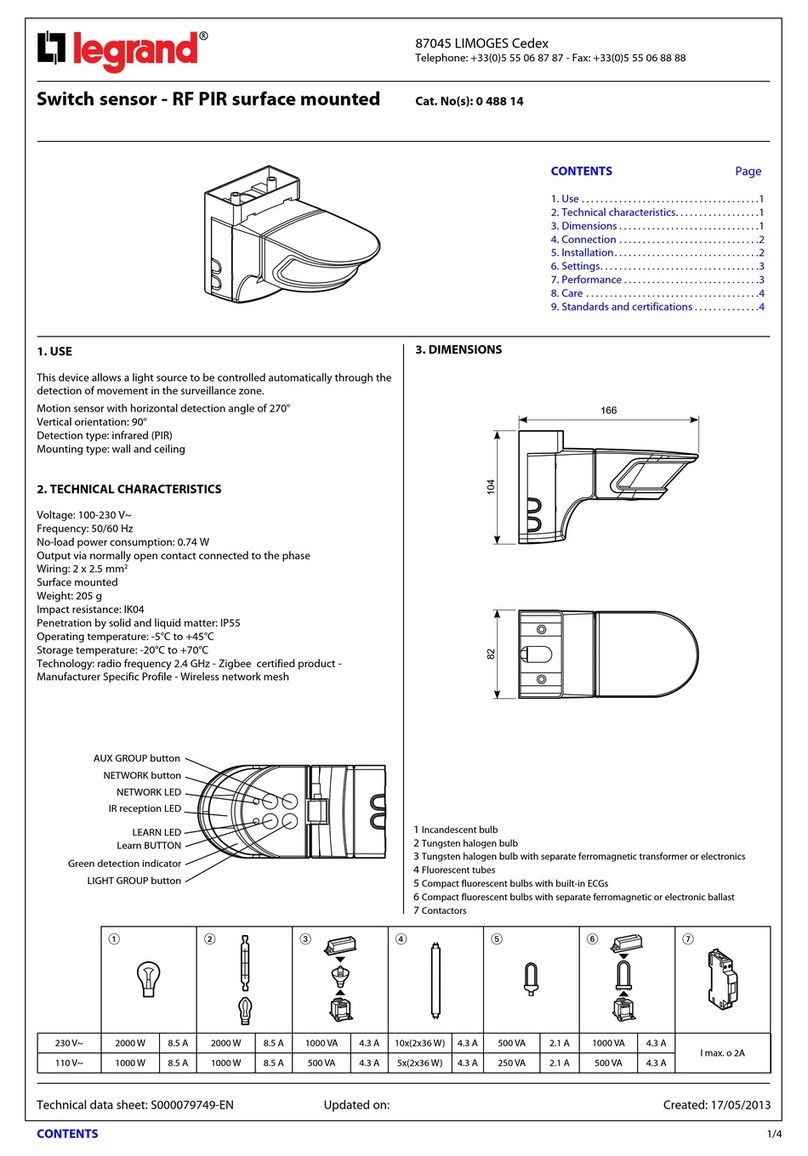

Figure 1

SW1

JP2-JP1

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 8 of 49

3.2 Display indication

Under normal operating condition (i.e. during weighing) the display shows the value of the weight, using the

following criteria:

?leading zeroes will presented as blank

?the polarity “minus” (in case of negative values) is indicated in the leftmost digit

?if the negative value is composed of six digits (for example -132400), the leftmost digit will show

alternatively the “minus” and the fifth digit value.

Indication limits are the following:

lower limit: - 20% of full scale

higher limit: 120% of full scale

if the weight is under the lower limit the following will be displayed:

? ? UL? ?

if the weight is over the upper limit (or if the load cell signal is higher than 20 mV the following will be

displayed:

? ? OL? ?

3.3 Tare

Pressing the Tkey (with the instrument setted in the Net mode and the weight stable) the instrument will

copy the current value of the gross weight into the tare value, thus clearing the net weight value.

The Tare command can also be issued from serial line.

3.4 Manual Zero

Value of gross weight can be manually zeroed out by pressing the >0< key if the instrument is setted in

GROSS, the weight is stable and the total zeroed value is lower than the limit defined by parameter “0

LIMIT”.

The Zero command can also be issued from serial line.

The effect of a ZERO command is a translation of the response curve of the instrument, without affecting its

slope: if 2000 Kg are zeroed out in a system having 5000Kgof full scale, the new full scale will become

3000 Kg.

3.5 Automatic Zero Tracking

Automatic Zero tracking can be achieved if the value of weight is stable, the total zeroed value is lower than

the limit defined by parameter “0 LIMIT” and the rate of change of weight is lower than value defined by

parameter “Zero Tracking”.

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 9 of 49

3.6 LED status indicators

The indications provided by the signal LED’s located on the front panel of the instrument are explained

below:

?0?

The LED is on when the value of the weight is 0 and is stable within 1/4 of a division.

The indication is available under gross weight and net weight conditions.

N

The LED is on when the instrument displays the net weight (gross weight minus the tare).

Pressing the Tkey in NET the instrument copies the current value of the gross weight into the tare value,

thus clearing the value of the net weight.

S1

The LED is on when relay 1 is energized.

S2

The LED is on when relay 2 is energized.

3.7 Key functions

ZERO

Press this key (with the instrument in the Gross mode and the weight stable) to clear the divisions indicated

on the display within the limits set by the configuration of the “AZM limit” parameter.

G/N

Press this key to toggle between the Gross and Net condition.

T

Press this key (with the instrument in the Net mode and the weight stable) the instrument to copy the

current value of the gross weight into the tare value, thus clearing the net weight value.

F

Press this key to enter the configuration modality.

C

Press this key to enter the threshold configuration modality.

E

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 10 of 49

Press this key to perform a print request on the primary serial port. The request takes effect only if the

serial port is configured for “print on request”.

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 11 of 49

3.8 Switch

The instrument is equipped with a DIP switch banck having the following functions:

Position Function Normal State

SW1-1 Not used OFF

SW1-2 Not used OFF

SW1-3 Not used OFF

SW1-4 Initialization of configuration parameter memory

Can be used as an alternative to the normal init procedure.

See “Initialization” paragraph for operation details.

OFF

3.9 Self diagnostic

A100E transmitter has a number of built-in self diagnostic features intended to improve the overall

operating safety.

Generally speaking, when a fault condition is detected, the instrument is driven to a safety condition

deenergizing alarm relays.

Display indications are provided to help in fault finding.

3.9.1 Configuration memory integrity check

Check is carried out at power on.

If the configuration memory is found defective, the power on sequence will not be completed , all relays

are driven to alarm condition (deenergized) and the serial line is deactivated.

A forced reconfiguration to default is then performed and the primary display shows the following message:

I N I T Blinking

The transmitter stays in this condition as long as a key is pressed by operator to acknowledge the situation.

The instrument must be reconfigured and recalibrated.

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 12 of 49

3.9.2 Configuration parameter integrity check

Check is carried out every operating cycle.

If a configuration parameter is found defective, the message “ER XX” will be reported on display for half a

second every two seconds, where XX is the code of the wrong parameter, according to the following table:

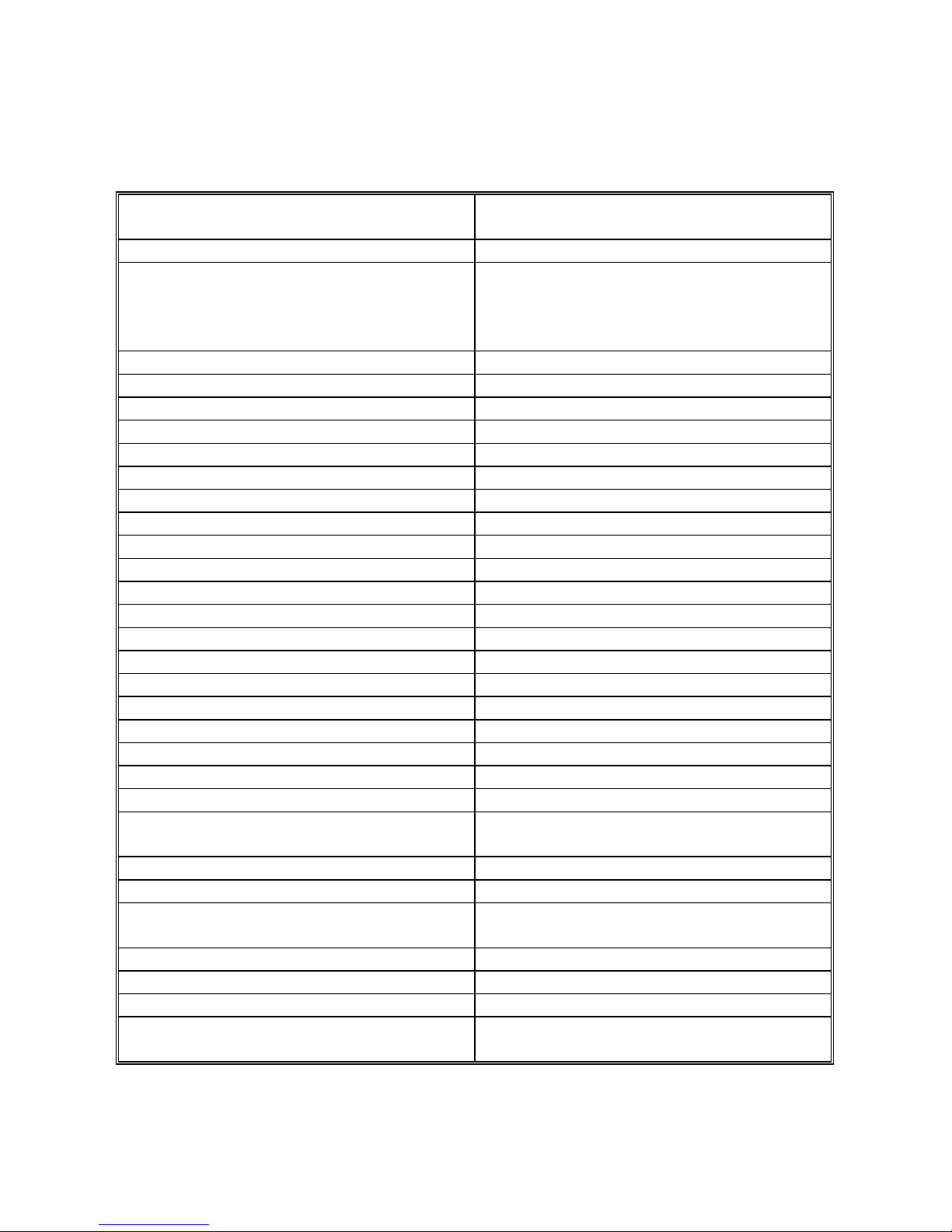

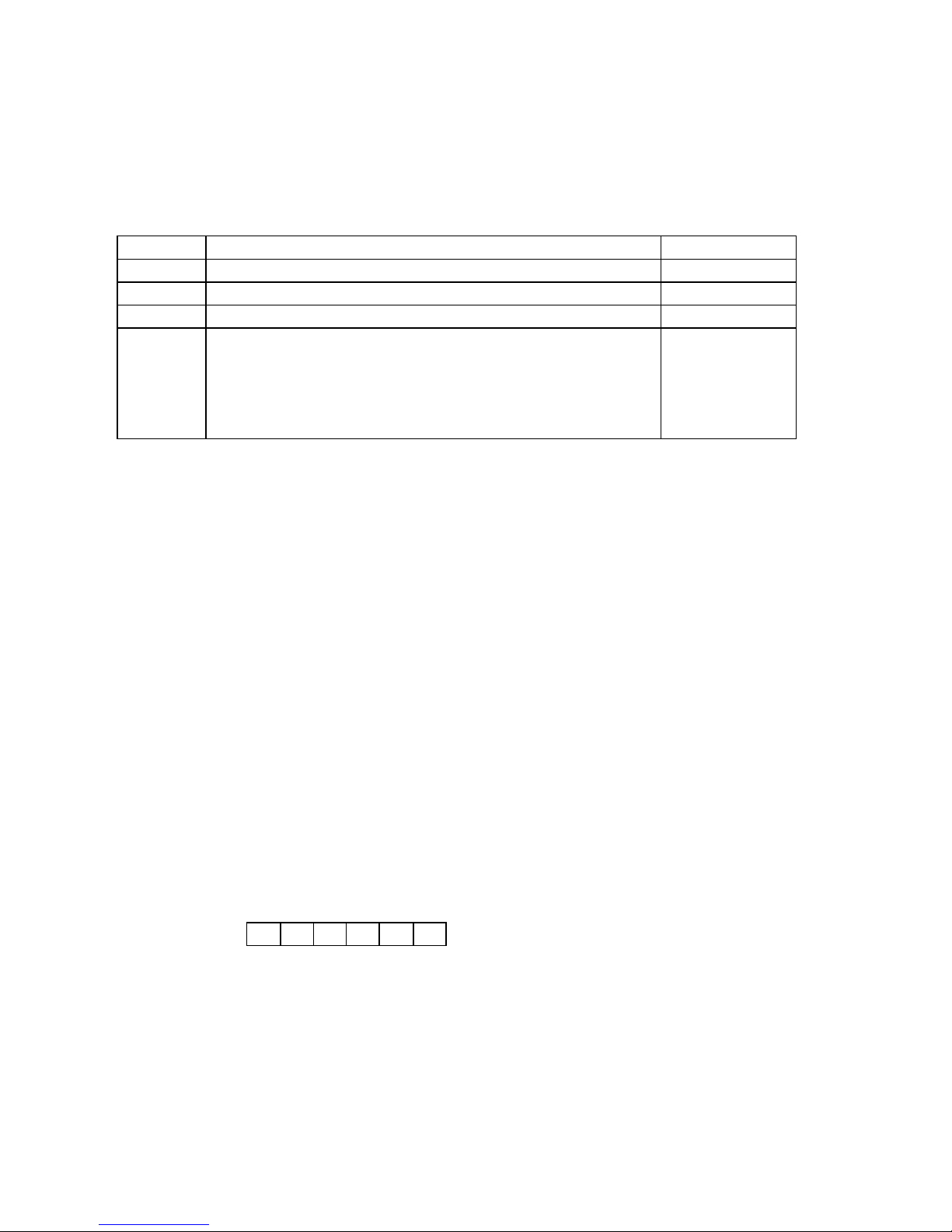

CODE Meaning Effect on indicator Resolution

ER 01 Error in the CALIBRATION

parameters

Relays are deenergized.

Error code is reported on serial line.

Instrument must be

recalibrated

ER 02 Error in the TARE

parameters

Relays are deenergized.

Error code is reported on serial line.

Redo tare

ER 03 Error in DIVIS e SENSIB

parameters

Relays are deenergized.

Error code is reported on serial line.

Reconfigure parameters

ER 04 Error in

AVER and DEC. PNT

No effect

Error code is reported on serial line.

Reconfigure parameters

ER 05 Error in LIM AZM -

MOTION - ZERO

TRACKING parameters

Relays are deenergized.

Error code is reported on serial line.

Reconfigure parameters

ER 06 Error in SER P - SER A-

BAUD - DLY SND - DLY

RCV - AD485 parameters

No effect Probably malfunctions on

serial line operation. The error code is

reported on the serial line

Reconfigure parameters

ER 07 Error in the RELAY 1

parameters

Relay 1 is deenergized.

Error code is reported on serial line.

Reconfigure parameters

ER 08 Error in the RELAY 2

parameters

Relays are deenergized.

Error code is reported on serial line.

Reconfigure parameters

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 13 of 49

3.10 Output relay operation

The action of the relay depends on the weight condition (gross or net) defined in the configuration phase

independently from what is indicated on the display. Therefore, the user can switch the display selection as

required without accidentally enabling the thresholds.

The relay returns to “normal” conditions when the weight value again drops below the value calculated as

the sum of the threshold value and the defined dead band value.

Each relay can be configured to operate in one of the following modes:

Off

The relay is permanently disabled.

Closing on Gross

The relay is de-energized (and the output contact opened) for all the gross weight values lower than the

threshold set in the configuration. The relay is energized (and the output contact closed) for all the gross

weight values greater than or equal to the threshold set in the configuration.

Closing on Net upon Loading

The relay is de-energized (and the output contact opened) for all the gross net values lower than the

threshold set in the configuration. The relay is energized (and the output contact closed) for all the net

weight values greater than or equal to the threshold set in the configuration.

Closing on Net upon Unloading

The relay is de-energized (and the output contact opened) for all the negative net weight values lower than

(in terms of absolute value) the threshold set in the configuration. The relay is energized (and the output

contact closed) for all the negative net weight values greater than or equal to (in terms of absolute value) the

threshold set in the configuration.

Example: if the threshold set is 1250, the relay is de-energized for positive values and for the negative

values from -1 to -1249. The relay is energized for values ranging between -1250 and -F.S.

Opening on Gross

The relay is energized (and the output contact closed) for all the gross weight values lower than the

threshold set in the configuration. The relay is de-energized (and the output contact opened) for all the

gross weight values greater than or equal to the threshold set in the configuration.

Opening on Net upon Loading

The relay is energized (and the output contact closed) for all the net weight values lower than the threshold

set in the configuration. The relay is de-energized (and the output contact opened) for all the net weight

values greater than or equal to the threshold set in the configuration.

Opening on Net upon Unloading

The relay is energized (and the output contact closed) for all the net negative weight values lower than (in

terms of absolute value) the threshold set in the configuration. The relay is de-energized (and the output

contact opened) for all the net negative weight values greater than or equal to less (in terms of absolute

value) the threshold set in the configuration.

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 14 of 49

Example: if the threshold set is 1250, the relay is energized for positive new values and for all the negative

values from -1 to -1249. The relay is de-energized for values ranging between -1250 and -F.S.

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 15 of 49

3.11 SERIAL INTERFACE MANAGEMENT

3.11.1 Primary serial interface

The primary serial line is available in both the RS232 and RS485 mode.

The factory configuration is RS232 (see Figure 1).

1RS485

2

3RS232

JP2 JP1

JP1 e JP2 closed in position 1-2 RS485 mode

JP1 e JP2 closed in position 2-3 RS232 mode

If the instrument is used in the RS485 modality, an integrated circuit MAX483E must be mounted in the

socket U4 (see Figure 1).

The primary serial line can be configured in one of the following operating modes:

?Off

?Continuous transmission

?Bi-directional (eventually with address for 485)

?Print On request from keyboard command or external button

The transmission parameters of the primary and auxiliary line are :

?8 bit - No Parity - 1 Stop

The primary line speed can be configured as follows:

?9600

?4800

?2400

?1200

3.11.2 RS485 interface

The instrument can control an RS485 line as an alternative to the main line RS232.

The physical interface is on two balanced wires.

The logic protocol is half duplex master/slave and the instrument responds as a slave.

?

?

?

?

?

?

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 16 of 49

For the RS485 line connection the instrument must be equipped with the driver in U8 and the jumper Z8

must be positioned in 1-2.

The RS232 or RS485 selection is determined by the value of the configuration parameter “address 485”: if

the parameter is 0 the instrument controls the protocol RS232, otherwise it controls the protocol RS485.

The modality is activated independently from the physical configuration of the board, therefore it is possible

to operate with messages addressed also on the physical line RS232.

The data structure is the same, with the only addition of the addressed field (two characters from “01” to

“32”) in reception and in transmission.

3.11.3 Continuous modality

The instrument continuously transmits a string with the following format:

<STX><POL><WEIGHT><K><L/N><STATUS><CR><LF>

where:

<STX> “Start Of Test” (Hex 02) character

<POL> “Blank” (Hex 20) or “-” (Hex 2D) character to indicate the polarity of the data

< WEIGHT > string of 7 numerical characters (Hex 30 .. 39) representing the weight shown on display

and possibly with “.” (Hex 2E)

<K> “K” (Hex 4B)

<G/N> “G” (Hex 47) or “N” (Hex 4E) character to indicate the Gross/Net state

<STATUS> one of the following characters:

“Blank” (Hex 20) System under normal operating conditions

“I” (Hex 43) Instrument to calibrate (invalid data)

“S” (Hex 43) Instrument being configured

“O” (Hex 4F) Instrument off scale

“M” (Hex 4D) Moving weight

<CR> “Carriage Return” character (Hex 0D)

<LF> “Line Feed” character (Hex 0A)

3.11.4 Bi-directional modality

In this modality the instrument transmits the data only when requested by an external system.

The protocol can be used with RS232 lines and with RS485 half-duplex lines. The selection depends on

the configuration value of the RS485 address: if other than zero, the instrument controls the value of the

address field in the received data and inserts the address field in the transmitted data.

The request string has the following format

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 17 of 49

<STX><ADDH><ADDL><CMD><DATA><CR><LF>

where:

<STX> “Start Of Text” (Hex 02) character

<ADDH> 485 address character - high (Hex 30 .. 32)

<ADDL> 485 address character - low (Hex 30 .. 39)

<CMD> Command identification character

<DATA> Any data related to the command

<CR> “Carriage Return” (Hex 0D) character

<LF> “Line Feed” (Hex 0A) character

Commands from host to A100E

P (hex 50) weight request command. A string is transmitted with the same format of what is

described for continuos mode. If 485 address is other than zero, the <ADDR>

field is inserted after STX

p (hex 70) weight request command. A string is transmitted with the following format:

<STX><G_P><GROS_W><T_P><TARE_W><K/L><L/N><STATO><CR><LF

where:

<G_P><GROSS_W> polarity and value of the gross weight (8 char)

<T_P><TARE_W> polarity and value of the tare weight (8 char)

If 485 address is other than zero, the <ADDR> field is inserted after STX

l (hex 5C) gross weight request command. A string is transmitted with the same format of what

is described for continuos mode, but always sending the value of the gross weight,

independently from display selection.

If 485 address is other than zero, the <ADDR> field is inserted after STX

ZZERO command. The command is always accepted, even if the instrument is in

Net mode or the Motion is ON. The command is effective only if the gross weight

is lower then the defined AZM limit, otherwise en error message is issued

GGROSS command. The command is always accepted.

NNET command. The command is always accepted.

TTare execution command. The command is always accepted, even if the instrument

is in Net mode or the Motion is ON.

SRn request for the value of the set point “n”, with “n” equal to 1 or 2

The answer message has the following format:

<STX><SRnt(0001234)

where:

n is the set point number

tis the code of the relay function

0 = OFF

1 = Closing on Gross

2 = Closing on Net upon Loading

3 = Closing on Net upon Unloading

4 = Opening on Gross

5 = Opening on Net upon Loading

6 = Opening on Net upon Unloading

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 18 of 49

0001234 is the value of the set point (7 char including decimal point, if any)

SEnt(ddddddd) set value of the set point “n” to type “t” and to value “dddd”

3.11.5 Print On Request modality

The weight string is transmitted like in the continuous transmission when operator pressing the “E” key

(when the instrument is not being configured).

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 19 of 49

3.11.6 Bi-directional modality with MODBUS protocol

The RTU version of MODBUS is used.

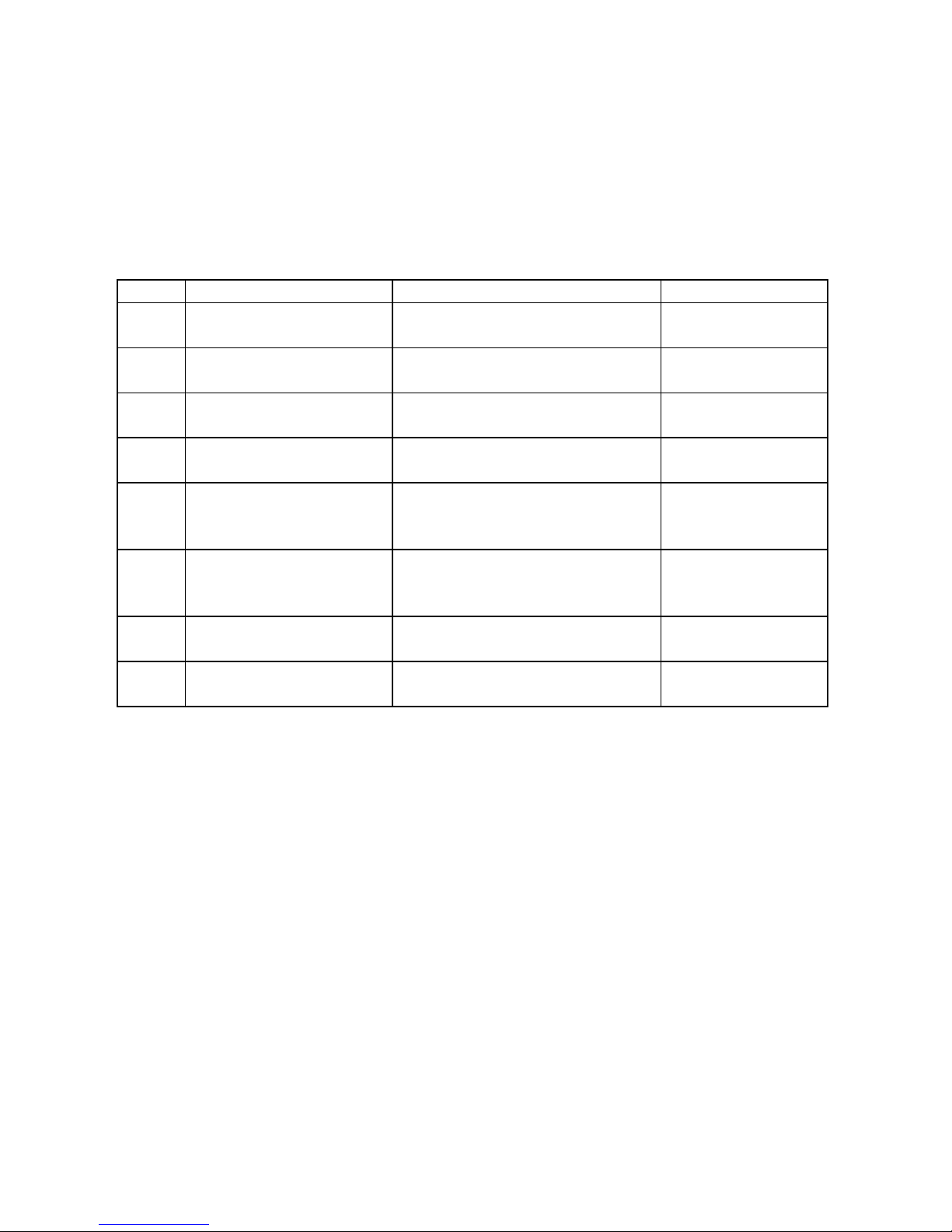

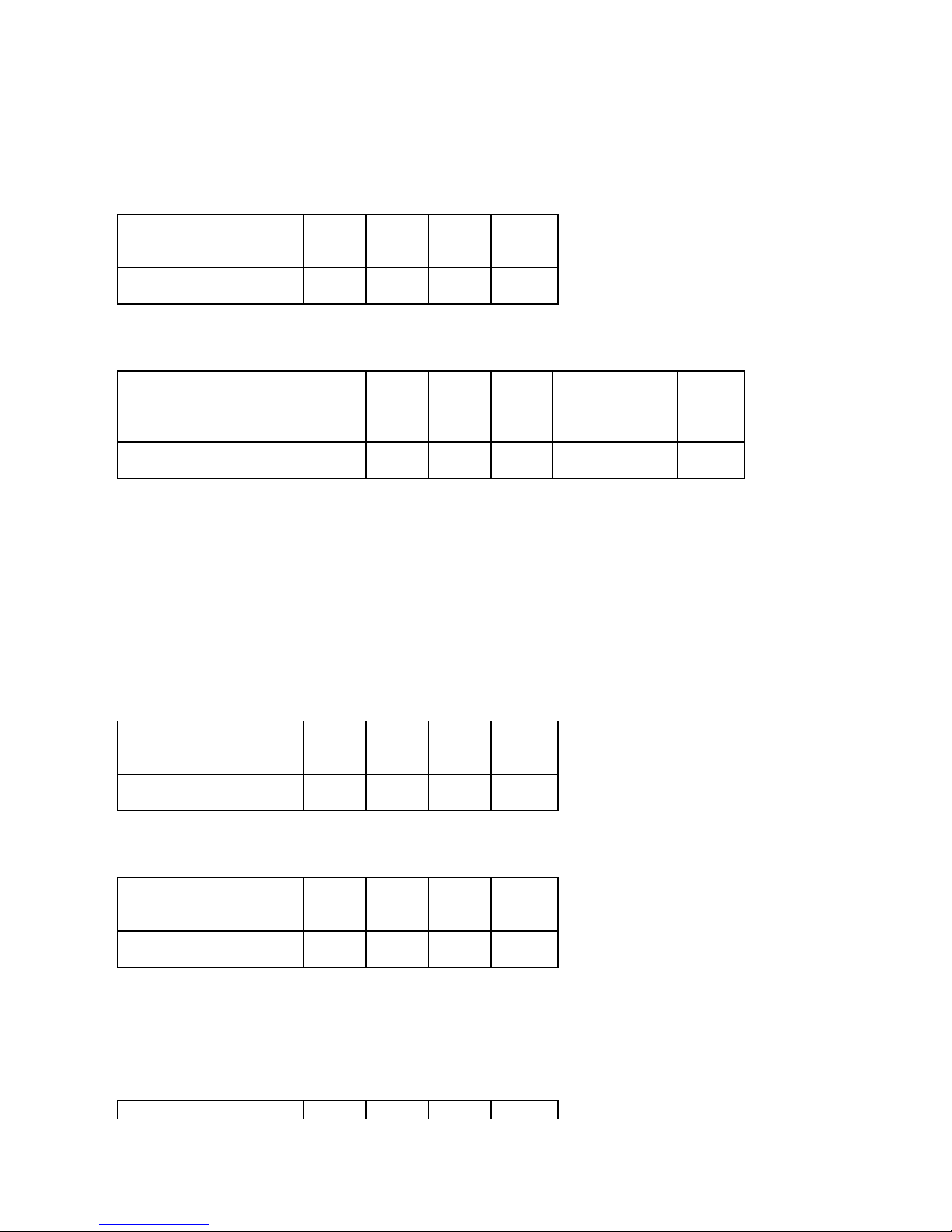

Received and transmitted frame structure

General frame structure is as follows:

ADDRESS FUNCTION DATA CHECK

8 bits 8 bits N x 8 bits 2 x 8 bits

ADDRESS 8 bit defining the slave address and ranging from 1 to 32

FUNCTION 8 bit defining the required function.

The functions supported by A100E are the following

Code 03 Read Holding Registers

Code 05 Force Single Coil

Code 06 Preset Single Register

Code 16 Preset Multiple Registers

DATA All data relevant to the specific function

CHECK CRC-16 (Cyclic Redundancy Check) frame validation

Exception responses

When A100E receives a request involving illegal functions or illegal data an exception response is generated

containing address, function code, error code and checksum.

To indicate that the response is a notification of an error, the high order bit of the function code is set to “1”.

Supported error code are:

01 Illegal function. The message function received is not an allowable action for the

addressed slave.

02 Illegal data address. The address referenced in the data field is not an allowable

address in the address slave location

03 Illegal data value. The value referenced in the data field is not allowable in the

addressed slave location

A100E supported functions

For a complete description of MODBUS available functions, please refer to detailed MODBUS

documentation.

Function 03 - Read Holding Registers

ADOS S.R.L. Buccinasco (MI)

492-MTU10006 Rev. 4 Page 20 of 49

Allows the host to obtain the binary value of the content of A100E registers

All registers can be transferred in a single read request.

The below example reads registers 0 through 2 from slave 01:

ADDR FUNC START

REG HI

START

ERG

LOW

# OF

ERG HI

# OF

ERG

LOW

CHECK

01 03 00 00 00 03 05 CB

Slave answer is as follows:

ADDR FUNC BYTE

COUNT

REG

0

HI

REG

0

LOW

REG

1

HI

REG

1

LOW

REG

2

HI

REG

2

LOW

CHECK

01 03 06 00 0F 00 00 01 C0 74 B4

Value of register 0 is 15, register 1 is 0 and register 2 is 448.

Function 05 - Force Single Coil

Allows the host to force a single coil. In A100E the command is used to issue a ZERO, G/N, TARE or

POF reset command.

If the ZERO cannot be done (not enabled or weigh higher than the allowable limit) an “Illegal Data Value”

exception response will be generated

The below is a valid example:

ADDR FUNC COIL

#

HI

COIL

#

LOW

DATA

VALUE

HI

DATA

VALUE

LOW

CHECK

01 05 00 00 FF 00 8C 3A

The normal response is to retransmit the query message:

ADDR FUNC COIL

#

HI

COIL

#

LOW

DATA

VALUE

HI

DATA

VALUE

LOW

CHECK

01 05 00 00 FF 00 8C 3A

Function 06 - Preset Single Register

Allows the host to modify the contents of an holding register

The below example preset register 12 of slave 01 with 54:

ADDR FUNC REG REG DATA DATA CHECK

Table of contents

Other Ados Accessories manuals

Popular Accessories manuals by other brands

ekwb

ekwb EK-FC1080 GTX Ti FTW3 installation manual

iNels

iNels RFTI-20 quick start guide

Alarm Controls Corporation

Alarm Controls Corporation SREX-100 operating instructions

Diamond Tech International

Diamond Tech International FIREWORKS Beginners Beadmaking Kit Instructional manual

Office Star Products

Office Star Products ProLine II PRDPOW1 operating instructions

Flowserve

Flowserve IPS Smart RTU User instructions