Filtertechnik SFC-3000-316-AIR User manual

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

SFC-3000-316-AIR

User Manual

September 2019

V1.01

© Copyright 2019 Filtertechnik

Table of Contents

Specifications........................................................................................................................................... 1

Typical Applications................................................................................................................................. 2

Health, Safety & Environmental Considerations..................................................................................... 2

Basic Description ..................................................................................................................................... 3

Best Efficiency ......................................................................................................................................... 3

Precautionary Measures ......................................................................................................................... 3

Component Identification ....................................................................................................................... 4

Flow Direction ......................................................................................................................................... 5

Starting & Stopping ................................................................................................................................. 5

Filtration.................................................................................................................................................. 6

Differential Pressure Gauge ................................................................................................................ 6

Pump Information ................................................................................................................................... 7

Performance Curve.................................................................................................................................. 7

Hoses & Lances........................................................................................................................................ 8

Suction Strainer....................................................................................................................................... 8

Troubleshooting ...................................................................................................................................... 9

Spare Parts List...................................................................................................................................... 10

Warranty Statement.............................................................................................................................. 10

EC Declaration of Conformity................................................................................................................ 11

Appendix A –Achieving ISO Cleanliness Codes...................................................................................... 12

NAS Codes (NAS 1638) ...................................................................................................................... 13

SAE Codes (SAE AS4059) ................................................................................................................... 13

Conversion between Standards ........................................................................................................ 14

Appendix B - Required Cleanliness Codes for Fluid Power Components.............................................. 15

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 1 of 15

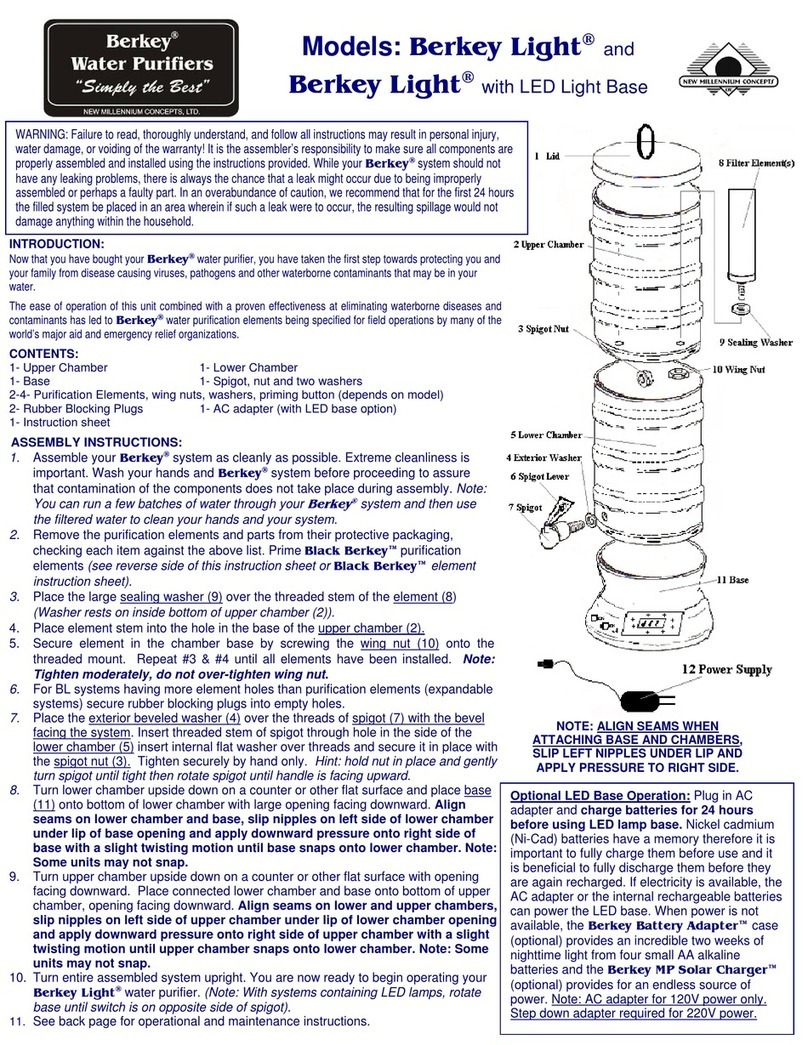

Specifications

Specification

Detail

Dimensions

(w)580 mm x (d)478 mm x (h)1044 mm (with lances (h)1150mm)

Weight

42.5 kg

Frame

316 stainless steel

Finish

N/A

Voltage

N/A

Frequency

N/A

Current

N/A

Power

N/A

Pump type

Air operated diaphragm pump

Flow rate (max)

50 L/min

Viscosity range

5 to 100 cSt

Duty Cycle

Continuous

Filtration

2 x 9” filter housings

Filter blocked indicator

Visual indicator gauge

Filter bypass

N/A

Connections

1" BSP male hydraulic

Suction hose

5m x 1" BSP female swivel hydraulic (with strainer)

Discharge hose

5m x 1" BSP female swivel hydraulic

Ambient temperature

-10°C to +60°C

Maximum humidity

90% relative humidity, non-condensing

Environment

N/A

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 2 of 15

Typical Applications

Typical applications for the filtration unit include:

•Filtering the fluid in a hydraulic reservoir periodically as a supplement to continuous filtration

by system filters.

•Cleaning up your hydraulic system before restarting the system following component failure.

•Providing clean fluid when re-filling and adding fluid to the system reservoir.

•Reclaiming contaminated fluid.

•Pre-filling and cleaning up hydraulic systems on new or re-built machinery and equipment.

•Off-line contamination of hydraulic systems.

•Emptying waste fluid quickly.

Health, Safety & Environmental Considerations

•This equipment should only be used for its intended purpose by competent and authorised

persons, inappropriate use could cause serious injury or death.

•Prolonged contact with oil can cause damage to the skin. Appropriate PPE (personal

protective equipment) should be worn when operating the unit e.g. protective gloves, safety

glasses, safety shoes etc. Always observe local health and safety requirements.

•The unit should only be used on a flat, even surface and be attended at all times.

•Do not operate switches with wet hands.

•The unit must always be disconnected from the air supply before carrying out any routine

maintenance or repairs.

•Air and fluid hoses should be checked for any signs of damage before starting the unit.

•Ensure a spill kit is available in case of any accidental spills.

•Used filters must be disposed of in accordance with local environmental requirements.

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 3 of 15

Basic Description

The SFC-3000 portable filtration unit is a compact, self-contained filtration system, equipped with

high efficiency, high capacity filter elements capable of removing particulate contaminants and/or

water quickly, conveniently and economically. It is designed for on-site preventative maintenance

and is fitted with two standpipes and hoses for efficient fluid transfer. The suction standpipe is fitted

with a strainer to trap any large contaminants and protect the pump.

Best Efficiency

When used for recirculation filtration (as opposed to transfer filtration) position the ends of both the

inlet and outlet standpipe as far apart as possible inside the reservoir in order to ensure proper

recirculation and cleaning.

Cycle the hydraulic system thoroughly in order to flush the contaminated fluid from the lines and

system components so that all the system fluid will be filtered through the unit.

Operate the filtration cart until the total volume of the system fluid passes through the filtration cart.

For recirculation filtration, cycle the reservoir fluid through the filter cart six to eight times to ensure

the total system fluid is filtered completely.

Precautionary Measures

•The filtration unit is designed for hydraulic and lubrication oils only.

•It is not to be used for highly volatile fluids, such as gasoline, paint thinners etc.

CAUTION - DO NOT USE THE UNIT WITH THE FOLLOWING FLUIDS:

Fluids not to be used

Related dangers

Gasoline

Fire / Explosion

Inflammable liquids with PM <55°C

Fire / Explosion

Water

Oxidation

Corrosive chemicals

Oxidation / Injury to persons

Solvents

Fire / Explosion / Damage to gaskets

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 4 of 15

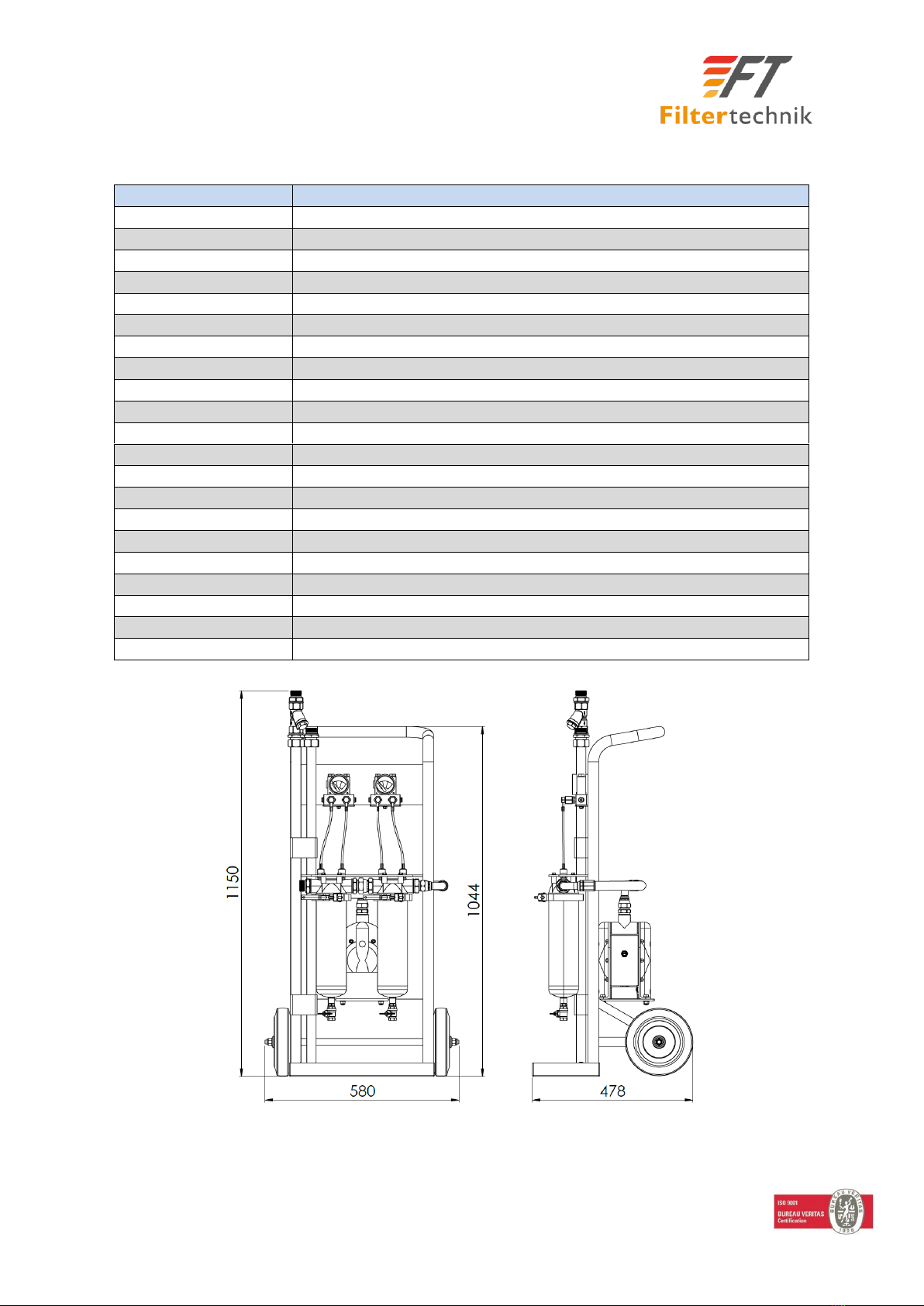

Component Identification

Key:

1.) 1” Suction Lance (With Strainer)

6.) 1/4" Drain Valve

2.) 1” Discharge Lance

7.) Inlet Port (1” BSP)

3.) Differential Pressure Indicator

8.) Air Connection 8mm

4.) Outlet Port (1” BSP)

9.) Needle Valve for Air Flow Control

5.) 9” Filter Housing

10.) T70 Diaphragm Pump

7

5

4

3

1

2

6

8

9

10

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 5 of 15

Flow Direction

Starting & Stopping

With the need valve fully closed connect the unit to a suitable air supply via the 8mm tube fitting.

Connect the suction and delivery hoses to the system/lances.

Gradually open the needle valve to regulate air flow, where the pump will start to operate.

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 6 of 15

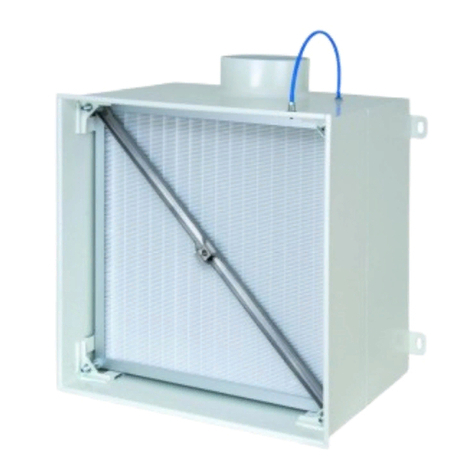

Filtration

The unit is equipped with two filter housings which can be fitted with a range of media for removing

particulate and water contamination. If using only particle filters, it’s best to stage the filtration, i.e. a

5µm first followed by a 3µm. If a water filter is being used alongside a particulate filter it’s best to fit

the particulate filter first to protect the water absorbing filter from blocking prematurely.

To change a filter element:

1) Make sure the air supply is disconnected from the unit.

2) Open the drain port and collect the oil/fuel into a suitable waste container.

3) Remove the v-band clamp and filter bowl, along with the old filter element.

4) Fit the new element to the filter head and replace the bowl and v-band clamp. The v-band

clamp should only need to be tightened by hand.

5) Close off the drain valve before running the system.

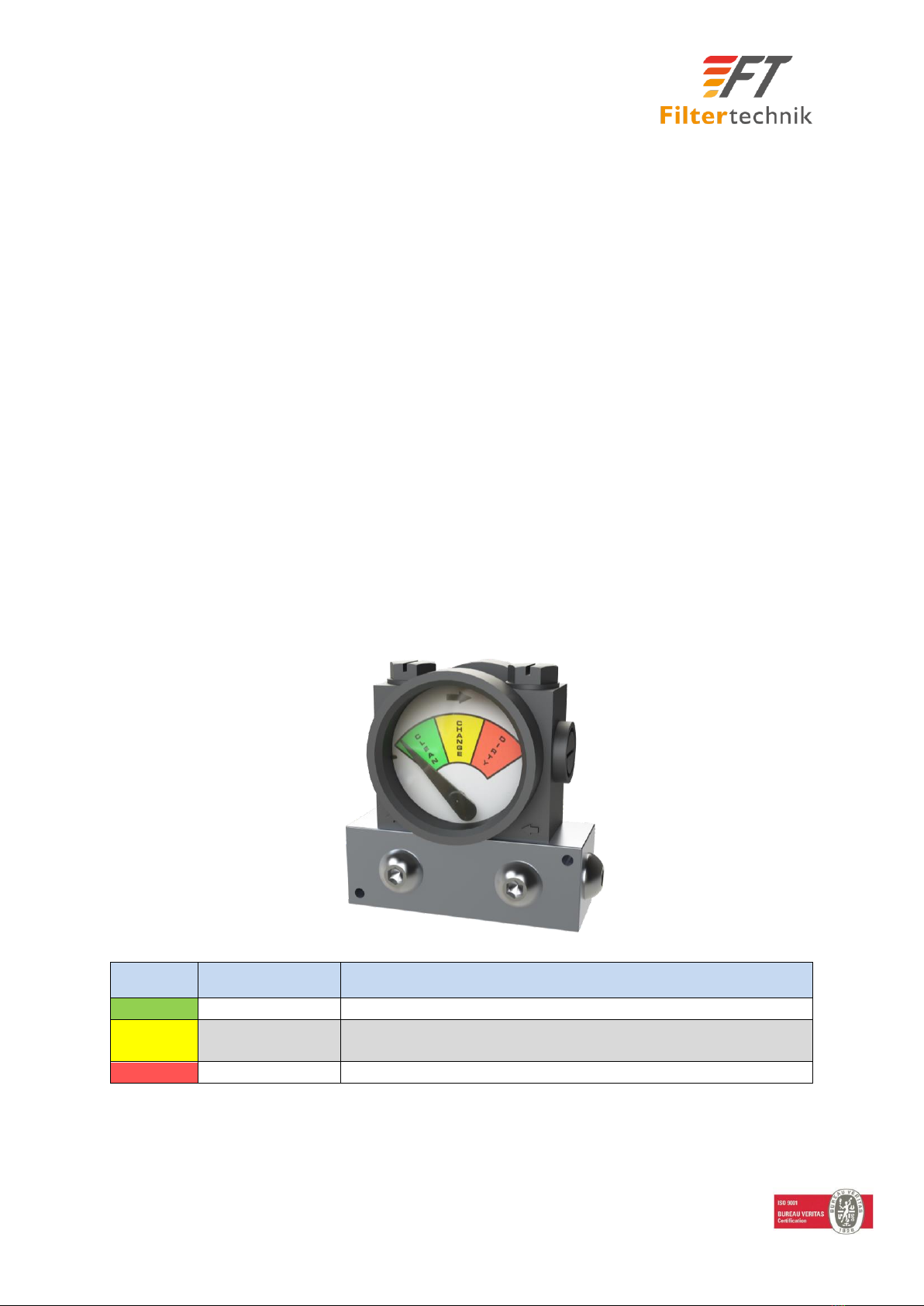

Differential Pressure Gauge

The unit comes with differential pressure gauges that gives an indication of the filter condition via a

green, yellow and red visual indication.

Colour

Pressure Range

Notes

Green

0-15 psid

Indicates a clean and healthy filter

Yellow

16-22 psid

Indicates the filter is starting to become blocked and requires

more frequent monitoring

Red

23-30psid

Indicates the filter is now fully blocked and requires changing

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 7 of 15

Pump Information

Specification

Detail

Max capacity

78 l/min

Volume per stroke

130 ml

Max discharge pressure

8 bar

Max air pressure

8 bar

Max suction lift (dry)

3m

Max suction lift (wet)

8m

Max size of solids

4mm

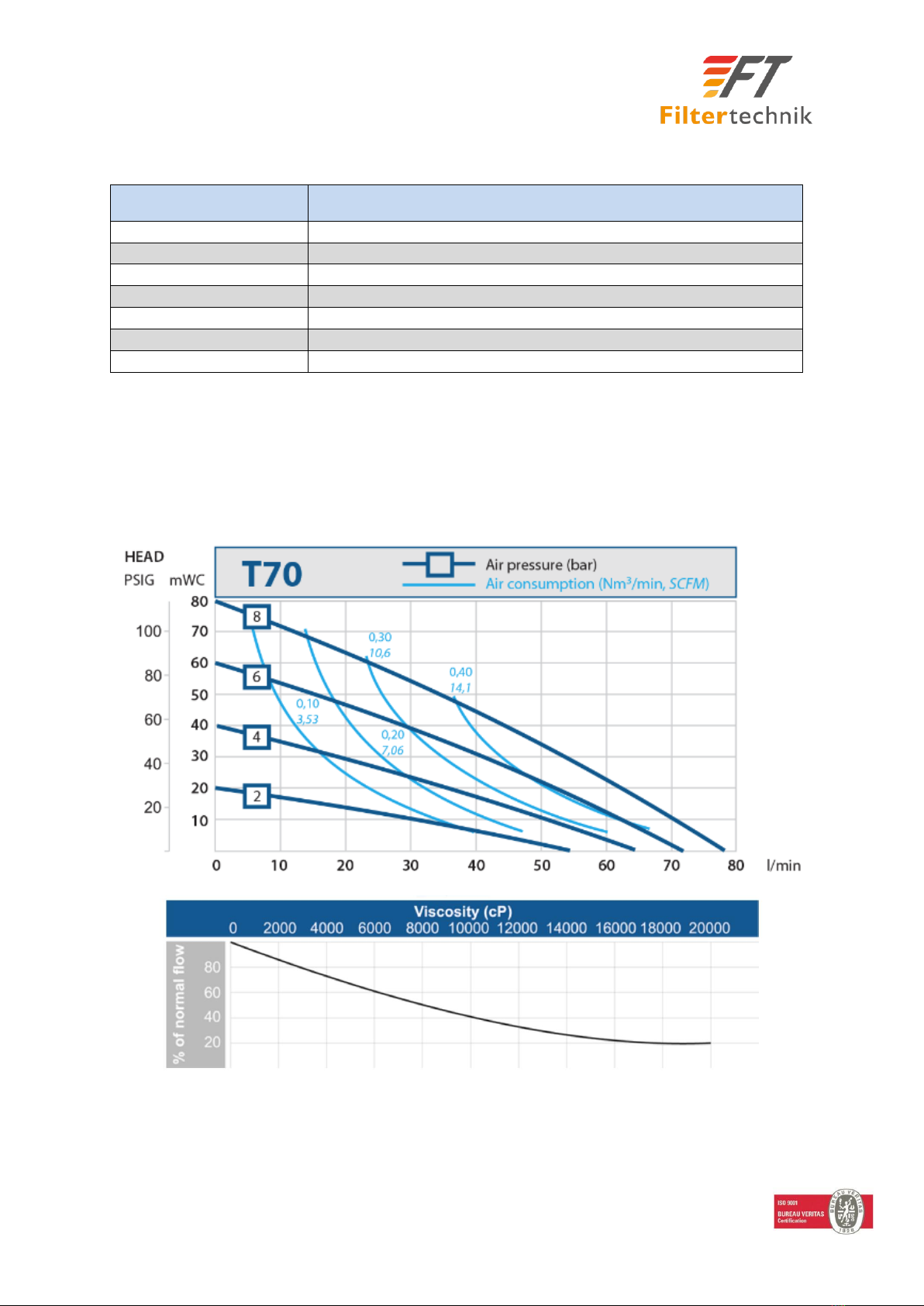

Performance Curve

The performance curves are based on water at 20°C. Other circumstances might change the

performance, such as a viscosity.

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 8 of 15

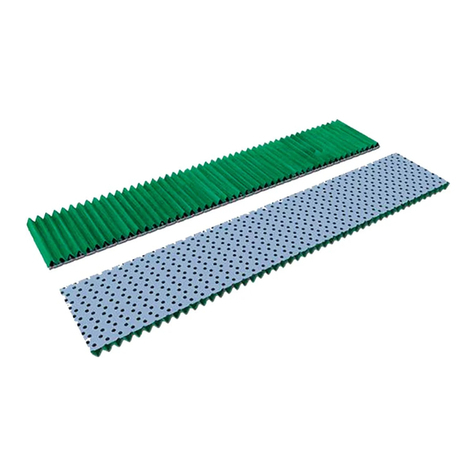

Hoses & Lances

The unit is supplied with two 1" lances,

a suction lance with strainer to protect

the pump and a discharge lance. Each

lance is 1000mm long.

When not in use it is advisable to plug

the hoses and cap off the lances to

prevent ingress of dust or other

contaminants.

Lances should be cleaned prior to

inserting in the tank/barrel being

cleaned.

Suction Strainer

The suction strainer will periodically need cleaning by unscrewing the cap, removing the mesh

strainer and cleaning this out with a fluid suited for the units intended purpose e.g. hydraulic oil.

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 9 of 15

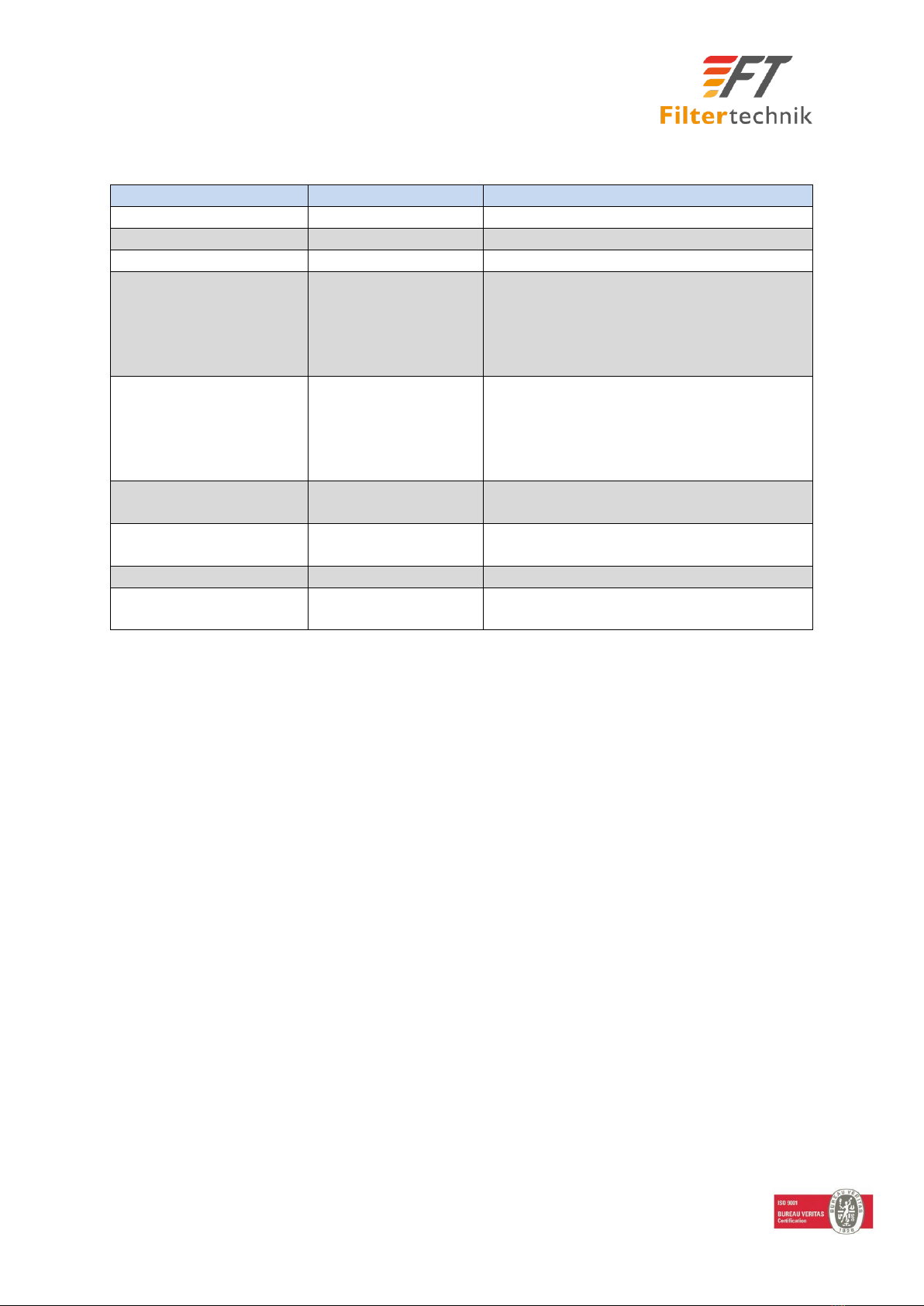

Troubleshooting

Symptom

Problem

Solution

No flow

No oil in filter housing

Run the unit for a few seconds

Erratic pump noise

Suction leak

Check inlet fittings and hoses

No suction

Blocked strainer

Clean or replace strainer

Reduced oil flow

High viscosity

Element dirty

Obstruction in hoses

Suction leak

Worn diaphragm

Normal for H.V fluids

Replace element(s)

Clean hoses

Check tightness of fittings

Replace gears

Element indicator shows

red

Element dirty

Oil extremely cold

Oil viscous

Obstructed outlet

Defective indicator

Replace or clean element

Allow system time to heat up

Increase element micron size

Clear outlet obstruction

Replace indicator

Indicator does not move

No element fitted

Defective indicator

Install element

Replace indicator

Hoses discolour

Fluid Compatibility

May occur over time, should not impair

performance

Hoses becoming rigid

Fluid Compatibility

Brittle hoses would require replacement

Oil spills under unit

Defective seal

Hose leaks

Replace seals where necessary

Tighten all joints

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 10 of 15

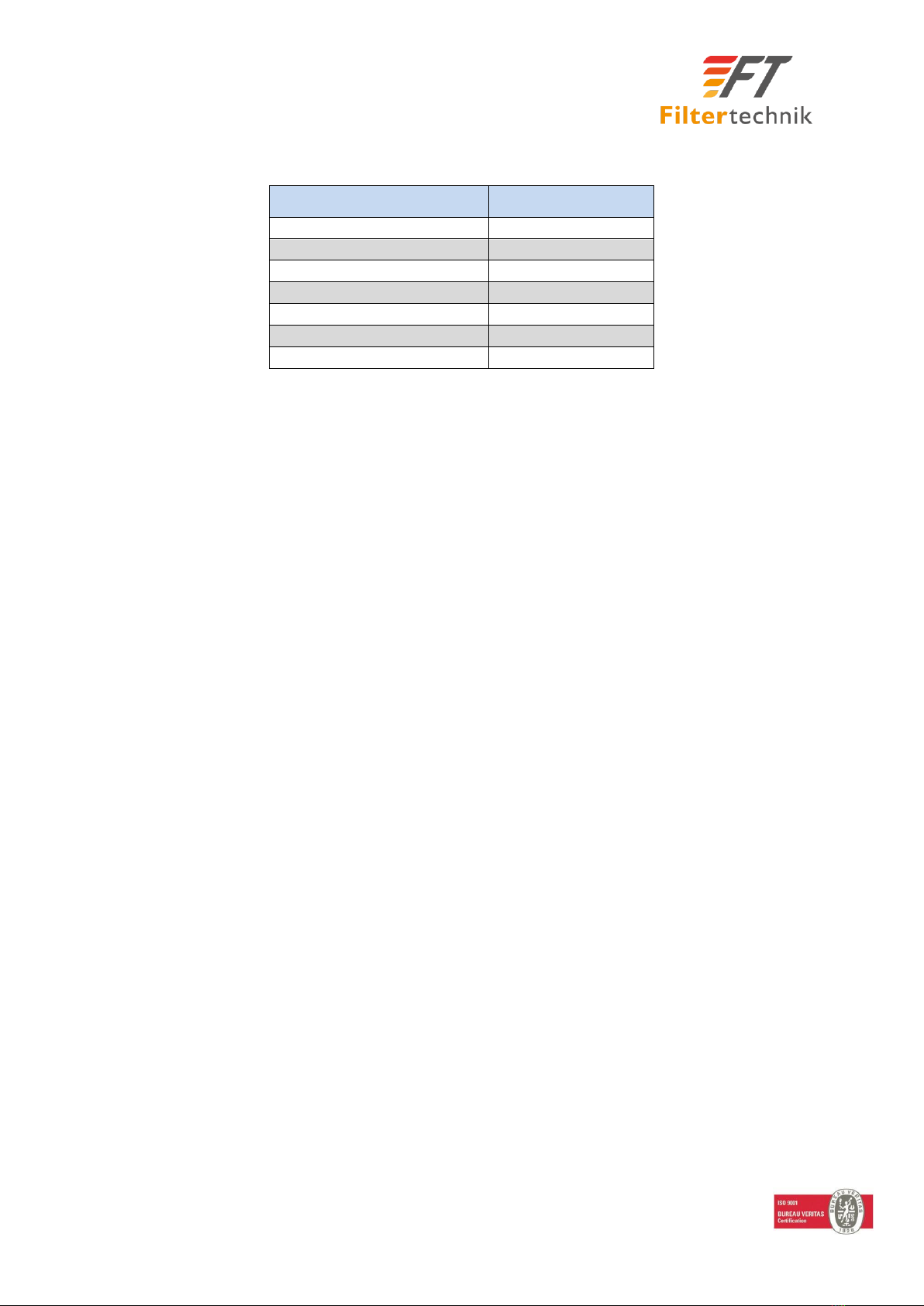

Spare Parts List

Warranty Statement

All products manufactured or distributed by Filtertechnik Ltd are subject to the following, and only

the following, Limited Express Warranties, and no others:

For a period of one (1) year from and after the date of delivery of a new Filtertechnik product,

Filtertechnik warrants and guarantees only to the original purchaser/user that such a product shall

be free from defects of materials and workmanship in the manufacturing process. The warranty

period for pumps and motors is specifically limited to ninety (90) days from the date of delivery. A

product claimed to be defective must be returned to the place of purchase. Filtertechnik, at its sole

option, shall replace the defective product with a comparable new product or repair the defective

product. This express warranty shall be inapplicable to any product damaged or impaired by external

forces or used for any purpose other than that for which it was originally sold.

THIS IS THE EXTENT OF WARRANTIES AVAILABLE ON THIS PRODUCT. FILTERTECHNIK SHALL HAVE NO

LIABILITY WHATSOEVER FOR CONSEQUENTIAL DAMAGES FOLLOWING THE USE OF ANY DEFECTIVE

PRODUCT OR BY REASON OF THE FAILURE OF ANY PRODUCT. FILTERTECHNIK SPECIFICALLY

DISAVOWS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED INCLUDING, WITHOUT LIMITATION, ALL

WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE (EXCEPT FOR THOSE WHICH APPLY TO

PRODUCT OR PART THEREOF THAT IS USED OR BOUGHT FOR USE PRIMARILY FOR PERSONAL, FAMILY

OR HOUSEHOLD PURPOSES), WARRANTIES OF DESCRIPTION, WARRANTIES OF MERCHANTABILITY,

TRADE USE OR WARRANTIES OF TRADE USAGE.

Description

Part Number

1 µm Absolute

9VZ1

3 µm Absolute

FTB-03

5 µm Absolute

FTB-05

10 µm Absolute

FTB-10

25 µm Absolute

FTB-25

150 µm Recleanable

9VM150

Water Removal

9VW

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 11 of 15

EC Declaration of Conformity

SFC-3000-316-AIR

T

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 12 of 15

Appendix A –Achieving ISO Cleanliness Codes

Filtertechnik has a wide range of elements available to effectively achieve the required cleanliness

level for the intended system. Maintaining the fluid at the required cleanliness level is a cost-

effective way of extending the service life of system components. The tables below can be used to

determine the required micron rating of the filter to achieve the desired cleanliness code,

understand the ISO 4406 contamination scale, conversion between the various cleanliness standards

and understanding how the ISO 4406 scale relates to the NAS contamination scale.

Number of Particles per 1ml

of Fluid

ISO

Scale

Number

More Than

Up to and

Including

1,300,000

2,500,000

28

640,000

1,300,000

27

320,000

640,000

26

160,000

320,000

25

80,000

160,000

24

40,000

80,000

23

20,000

40,000

22

10,000

20,000

21

5,000

10,000

20

2,500

5,000

19

1,300

2,500

18

640

1,300

17

320

640

16

160

320

15

80

160

14

40

80

13

20

40

12

10

20

11

5

10

10

2.5

5

9

1.3

2.5

8

0.64

1.3

7

0.32

0.64

6

0.16

0.32

5

0.08

0.16

4

0.04

0.08

3

0.02

0.04

2

0.01

0.02

1

0.00

0.01

0

ISO 4406 Contamination Scale

Desired Cleanliness

Level (ISO Code)

Recommended

Filtration Media

20/18/15 –19/17/14

25 µm

19/17/14 –18/16/13

10 µm

18/16/13 –15/13/10

5 µm

15/13/10 –14/12/9

3 µm

14/12/9 –13/11/8

1 µm

Filter Media Selection Guide

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 13 of 15

NAS Codes (NAS 1638)

Class

Particle Size Range (Particles/100 mL)

5 to 15 µm

15 to 25 µm

00

125

22

0

250

44

1

500

89

2

1,000

178

3

2,000

356

4

4,000

712

5

8,000

1,425

6

16,000

2,850

7

32,000

5,700

8

64,000

11,400

9

128,000

22,800

10

256,000

45,600

11

512,000

91,200

12

1,024,000

182,400

SAE Codes (SAE AS4059)

Maximum Contamination Limits (Particles/100 mL)

Size, ISO 4402

calibration, or optical

microscope count1

> 1 µm

> 5 µm

> 15 µm

> 25 µm

> 50 µm

> 100 µm

Size, ISO 11171

calibration, or electron

microscope2

> 4 µm(c)

> 6 µm(c)

> 14

µm(c)

> 21

µm(c)

> 38

µm(c)

> 70

µm(c)

Size Code

A

B

C

D

E

F

Class 000

195

76

14

3

1

0

Class 00

390

152

27

5

1

0

Class 0

780

304

54

10

2

0

Class 1

1560

609

109

20

4

1

Class 2

3120

1220

217

39

7

1

Class 3

6250

2430

432

76

13

2

Class 4

12,500

4860

864

152

26

4

Class 5

25,000

9730

1730

306

53

8

Class 6

50,000

19,500

3460

612

106

16

Class 7

100,000

38,900

6920

1220

212

32

Class 8

200,000

77,900

13,900

2450

424

64

Class 9

400,000

156,000

27,700

4900

848

128

Class 10

800,000

311,000

55,400

9800

1700

256

Class 11

1,600,000

623,000

111,000

19,600

3390

512

Class 12

3,200,000

1,250,000

222,000

39,200

6780

1020

1Particle size based on the longest dimension.

2Particle size based on the projected area equivalent diameter.

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 14 of 15

Conversion between Standards

ISO 4406 Code

4µm / 6µm / 14µm

Mil Std.

NAS 1638

Mil Std.

1246A

ACFTD Gravimetric

Level mg/L

SAE Level

21/19/16

10

20/18/15

9

6

19/17/14

8

300

5

18/16/13

7

1

4

17/15/12

6

3

16/14/12

200

16/14/11

5

2

15/13/10

4

0.1

1

14/12/9

3

0

13/11/8

2

12/10/8

100

10/10/7

1

12/10/6

0.01

11/9/6

Cleanliness Standards Conversion

Equivalent ISO

4406 Code

(approx.)

NAS

Code

Size Range in Microns (µm)

5-15

15-25

25-50

50-100

>100

-

00

125

22

4

1

0

-

0

250

44

8

2

0

10/12/7

1

500

89

16

3

1

13/11/8

2

1,000

178

32

6

1

14/12/9

3

2,000

356

63

11

2

15/13/10

4

4,000

712

126

22

4

16/14/11

5

8,000

1,425

253

45

8

17/15/12

6

16,000

2,850

506

90

16

18/16/13

7

32,000

5,700

1,012

190

32

19/17/14

8

64,000

11,400

2,025

360

64

20/18/15

9

128,000

22,800

4,050

720

128

21/19/16

10

256,000

45,600

8,100

1,440

256

22/20/17

11

512,000

91,200

16,200

2,880

512

23/21/18

12

1,024,000

182,400

32,400

5,760

1,020

ISO 4406 vs NAS 1638 Contamination

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Tel: +44 (0)115 9003 600

Email: [email protected]

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

Page 15 of 15

Appendix B - Required Cleanliness Codes for Fluid Power

Components

Component

Type

ISO 4406 Target Level

Low Pressure

<130 bar

Medium

Pressure

130 - 200 bar

High Pressure

200 - 1000

bar

Pump

Fixed Gear or Fixed Valve

20/18/15

19/17/14

18/16/13

Fixed Piston

19/17/14

18/16/13

17/15/12

Variable Vane

18/16/13

17/15/12

N/A

Variable Piston

18/16/13

17/15/12

16/14/11

Valve

Check Valve

20/18/15

20/18/15

19/17/14

Directional (Solenoid)

20/18/15

19/17/14

18/16/13

Standard Flow Control Valve

20/18/15

19/17/14

18/16/13

Cartridge Valve

19/17/14

18/16/13

17/15/12

Proportional Valve

17/15/12

17/15/12

16/14/11

Servo Valve

16/14/11

16/14/11

15/13/10

Actuator

Cylinder, Vane Motor, Gear Motor

20/18/15

19/17/14

18/16/13

Piston Motor, Swash Plate Motor

19/17/14

18/16/13

17/15/12

Hydrostatic Drive

16/14/11

16/14/11

15/13/10

Test Stand

15/13/10

15/13/10

15/13/10

Bearing

Journal Bearing

17/15/12

N/A

N/A

Industrial Gear Box

17/15/12

N/A

N/A

Ball Bearing

15/13/10

N/A

N/A

Roller Bearing

16/14/11

N/A

N/A

Station

Nozzle

Worldwide fuel charter cleanliness

standard for fuel delivered

18/16/13

N/A

N/A

Table of contents

Popular Water Filtration System manuals by other brands

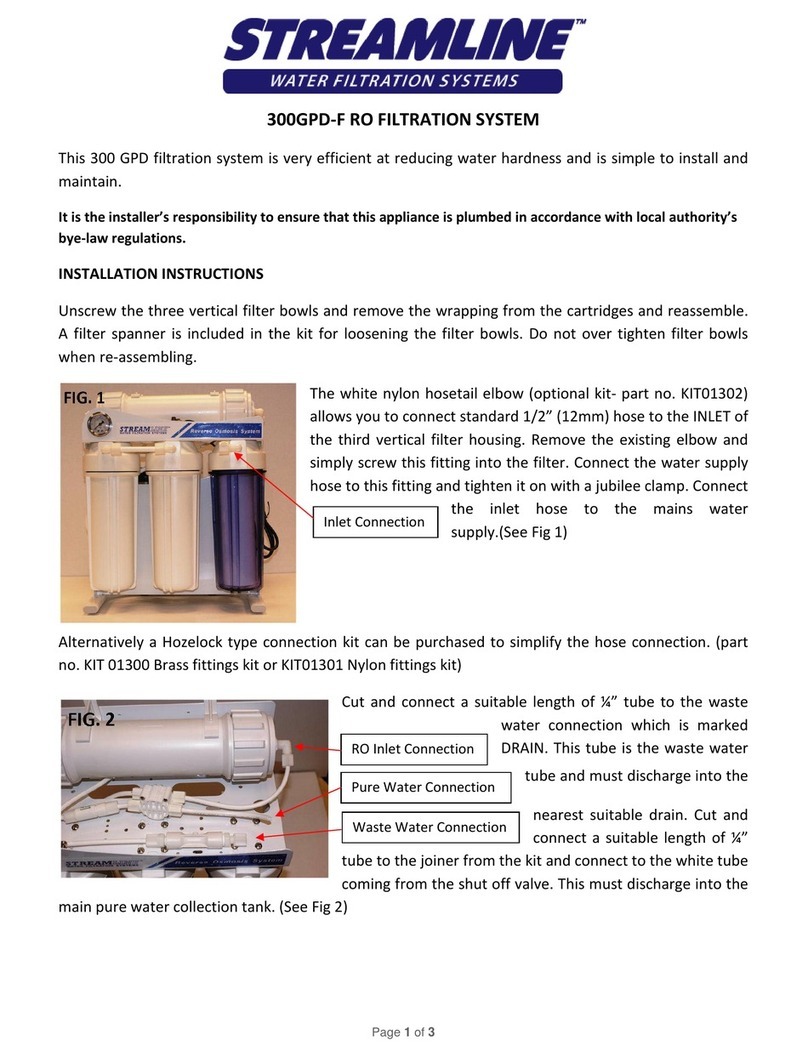

Streamline

Streamline 300GPD-F installation instructions

3M

3M Aqua-Pure AP800 Series Installation and operating instructions

Doheny's

Doheny's 5216 Installation, operation & parts

Pall

Pall UR219 Series Service instructions

Trane Technologies

Trane Technologies BAYFLTR101C Installer's guide

Glowforge

Glowforge Air Filter user manual

Purex

Purex iFume 200 operating manual

Ecodyne Water Systems

Ecodyne Water Systems OH2-Iron Installation, operation, maintenance & repair parts

SMC Networks

SMC Networks AM30 Series Operation manual

Ecosoft

Ecosoft RO 5-36 Installer and user guide

Aqua Free

Aqua Free Baclyser neo T user manual

Henden

Henden HHDMSC24 Installation & owner's manual