8

FIG. 13

Ground

Clamp

Inlet & Outlet

Pipes

Installation (continued)

b. Place bypass valve(s) into “bypass” position. On a

single valve, slide the stem inward to BYPASS

(See ig. 8 on page 6). On a 3 valve system,

close the inlet and outlet valves, and open the

bypass valve (See ig. 7 on page 6).

c. ully open the house main water pipe shutoff valve.

Observe a steady flow from both opened faucets.

d. Close both faucets.

e. Check your plumbing work for leaks and, if any are

found, fix right away. Be sure to observe previous

caution notes.

f. Turn on the gas or electric supply to the water

heater. Light the pilot, if applicable.

7. CO ECT TO ELECTRICAL POWER:

The filter controller works on 28V DC electrical power.

The included power supply converts 120V AC house-

hold power to 28V DC. Plug the power supply into a

120V, 60 Hz electrical outlet. Be sure the outlet is

always “live” so it can not be switched off by mistake.

8. PROGRAM THE CO TROLLER

See pages 10-11 for instructions to program the elec-

tronic controller.

9. START UP PROCEDURE

a. Confirm that the filter’s main valve is in the “service”

position (“S” on the cam).

b. Place bypass valve(s) into “service”, EXACTLY as

follows:

=Single Bypass Valve: SLOWLY, pull the valve

stem outward to ”service” position, pausing sev-

eral times to allow the filter to pressurize slowly.

=3 Valve Bypass: ully close the bypass valve

and open the outlet valve. SLOWLY, open the

inlet valve, pausing several times to allow the

filter to pressurize slowly.

c. Check all connections for leaks.

d. Push and hold the RECHARGE button until the fil-

ter starts a RECHARGE NOW cycle. Verify that

the valve advances to “backwash” (BW) position.

e. Allow the unit to remain in “backwash” (BW) while

air is purged and water exits the drain line. Ensure

that the drain line is secure and will withstand the

mix of air and water exiting.

f. Allow the unit to complete the 15 minute “backwash”

cycle and automatically advance to the “aspirate” (A)

position. Allow it to remain there as it aspirates air

into the mineral tank. After 75 minutes, the filter will

then automatically return to “service”. Start up is

complete.

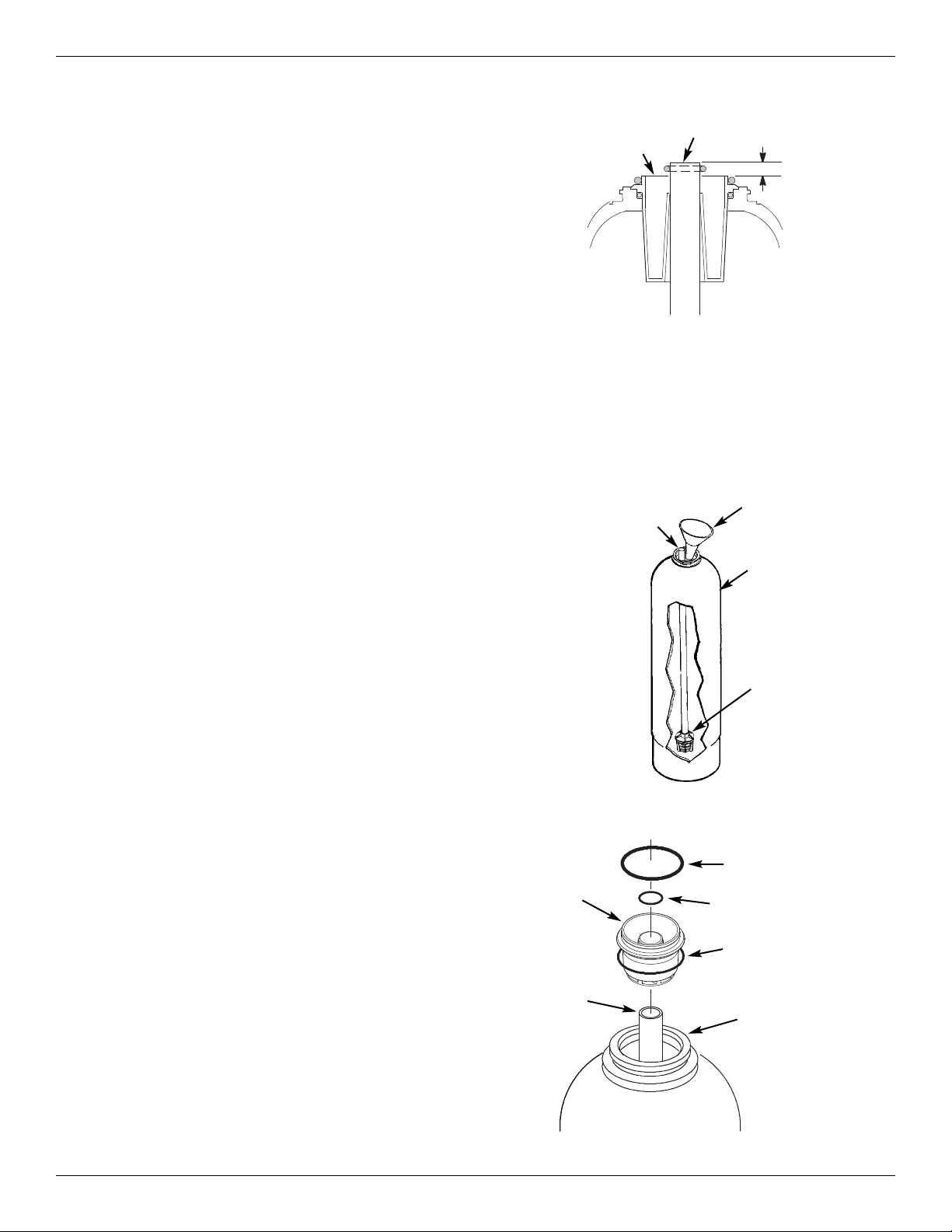

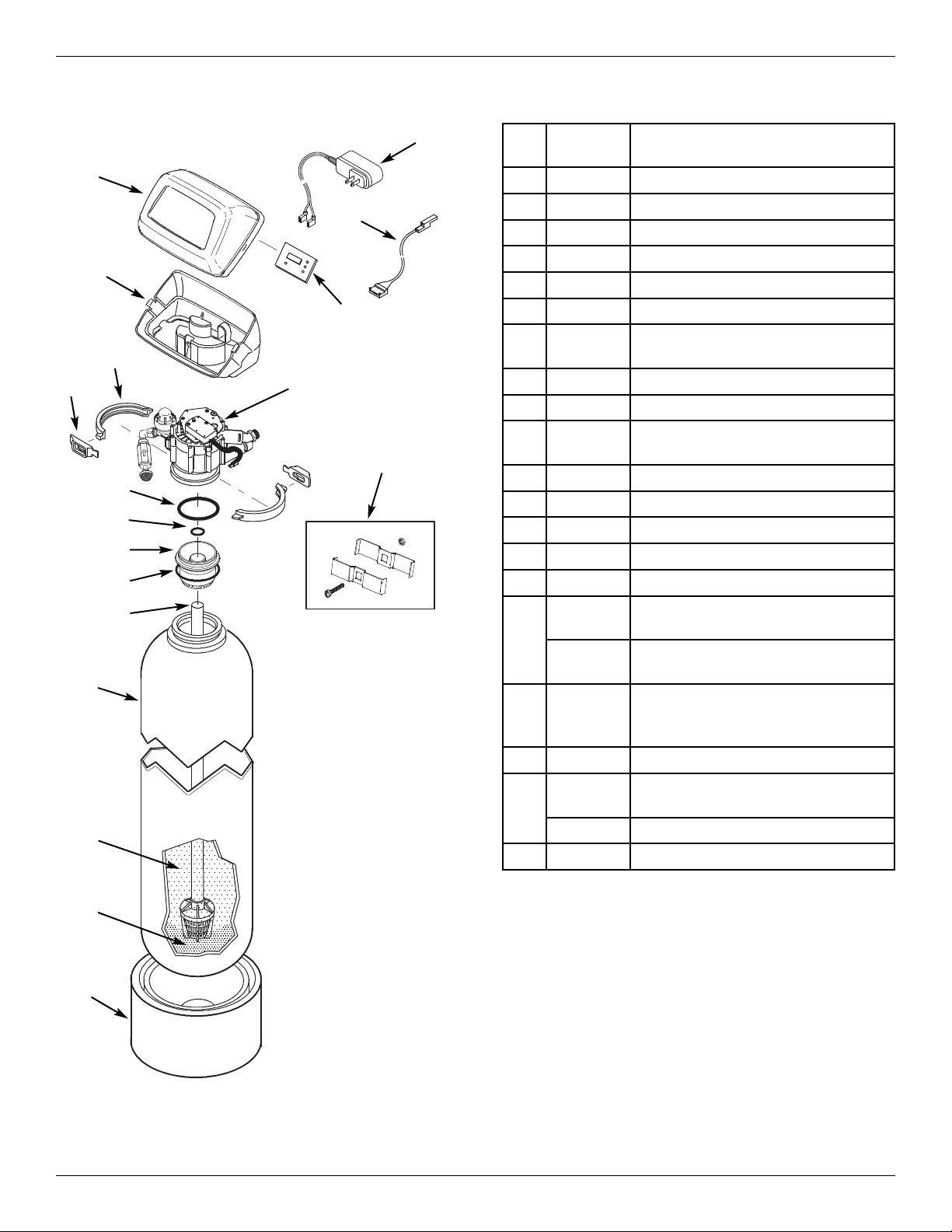

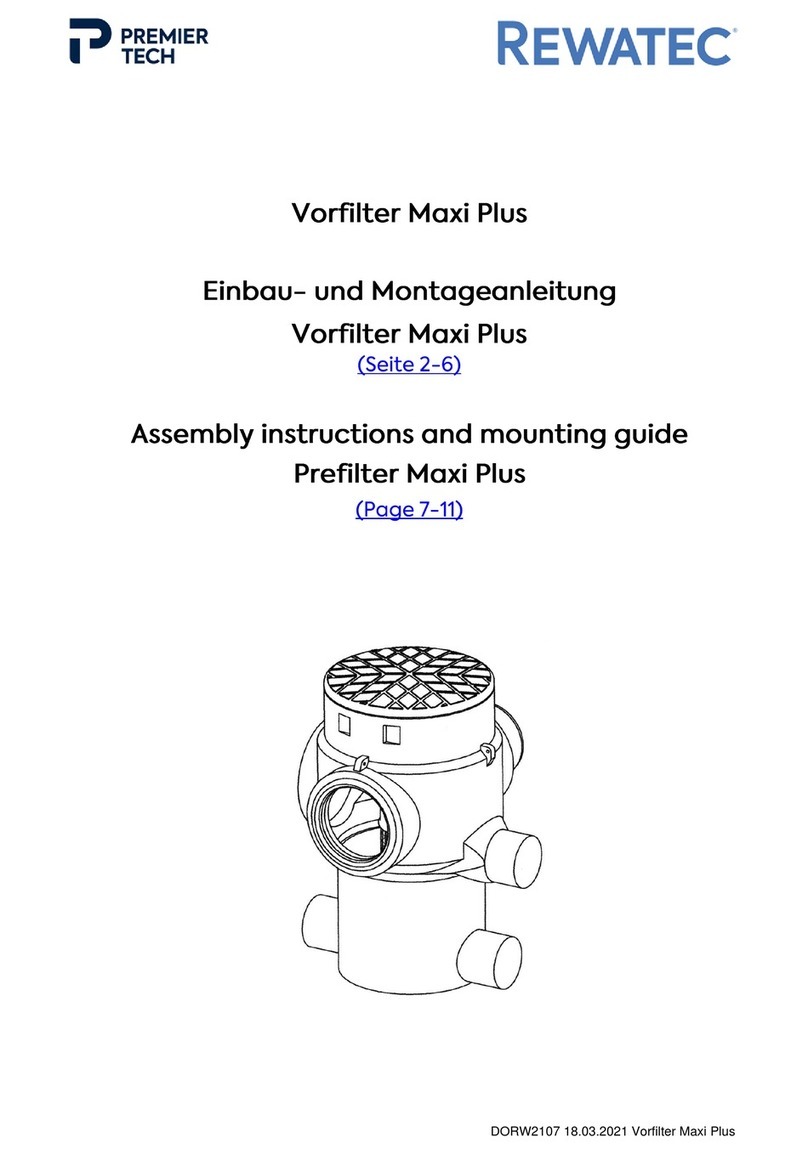

4. I STALL GROU D CLAMP (IF EEDED):

If the home’s cold water piping is being used for elec-

trical grounding, a 3 valve bypass system maintains

ground continuity. If you are using a single plastic

bypass valve, install the included ground clamp, as

shown In igure 13, to maintain electrical ground conti-

nuity in the house cold water piping. Be sure the pipes

are clean, under the clamps, to assure good contact.

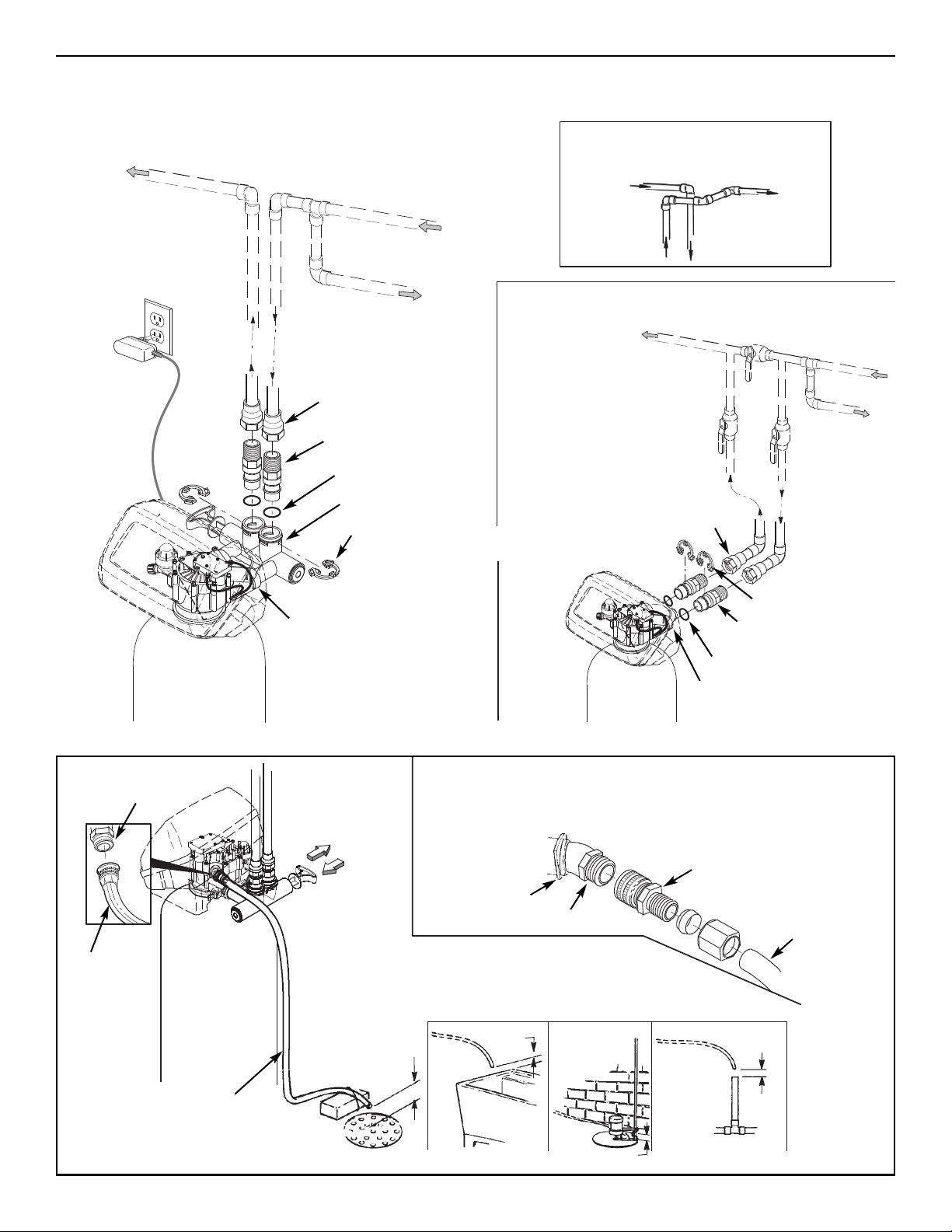

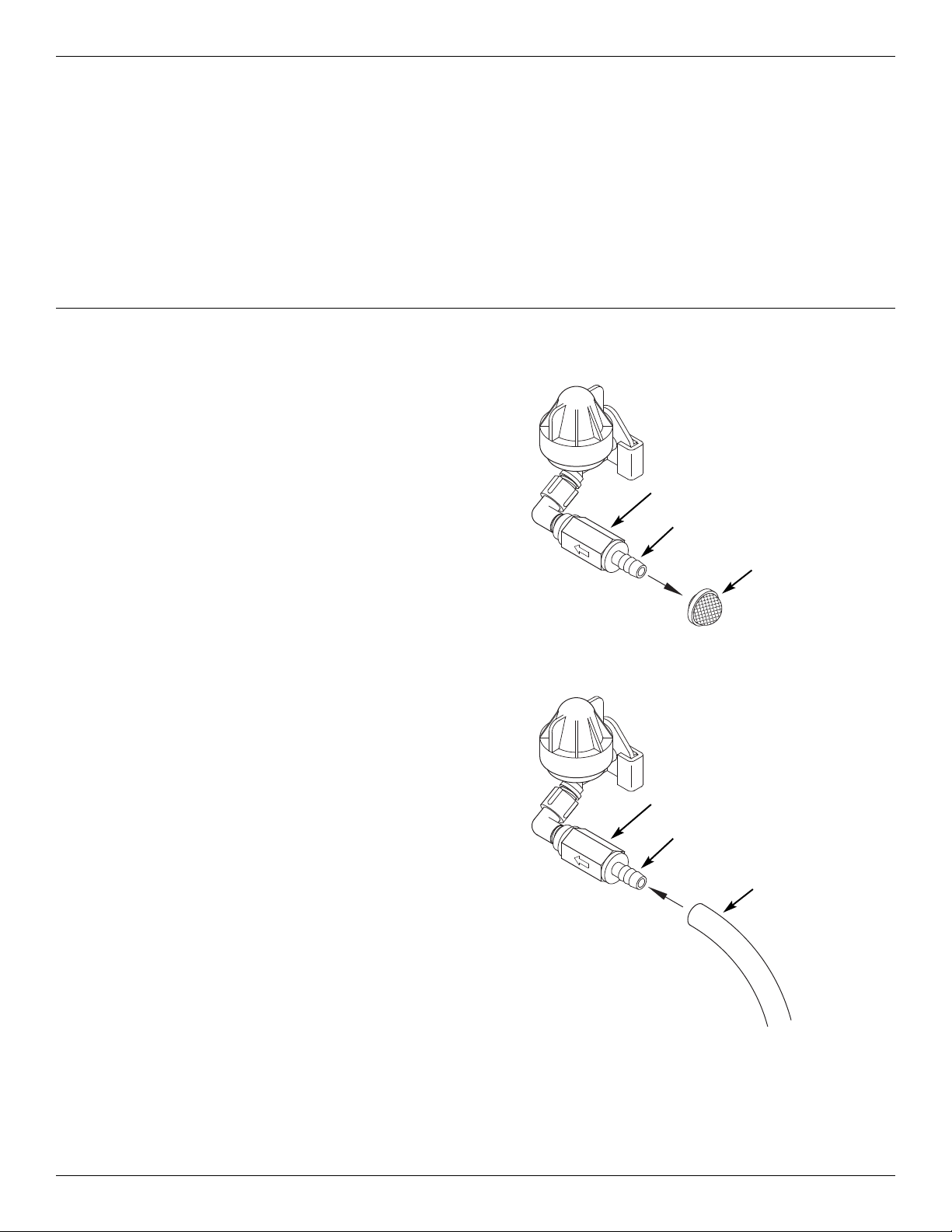

5. I STALL VALVE DRAI HOSE

a. Take a length of 5/8” inside diameter garden hose

and attach to the valve drain fitting (See igure 8

on page 6).

b. Locate the other end of the hose at a suitable drain

point (floor drain, sump, laundry tub, etc.). Check

and comply with local codes. Refer to igure 8 on

page 6 if codes require a rigid pipe drain run.

IMPORTA T: Use high quality, thick wall hose that

will not easily kink or collapse. The fil-

ter will not backwash properly if water

cannot exit this hose during recharges.

c. Tie or wire the hose in place at the drain point.

Water pressure will cause it to whip during the

backwash portion of the recharge cycle. Also pro-

vide an air gap of at least 1-1/2” between the end

of the hose and the drain point. An air gap pre-

vents possible siphoning of sewer water, into the

filter, if the sewer should back up.

d. If raising the drain hose overhead is required to get

to the drain point, do not raise higher than 8 feet

above the floor. Elevating the hose may cause a

back pressure that could reduce backwash flow

and proper mineral bed cleaning.

6. FLUSH PIPES A D TEST FOR LEAKS

CAUTIO : To avoid water or air pressure damage to

filter inner parts, be sure to do the follow-

ing steps exactly as listed:

a. ully open two filtered water faucets, one cold and

one hot, nearby the filter.