fine bubble MK3 User manual

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 1

MK3 FILTRATION SYSTEM

Operation and Maintenance Manual

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 2

TABLE OF CONTENTS

Introduction…….…………………………………………………………………………….3

Receiving your MK3……………………………………………………………………….3

Water Production Flow Chart………..……………………………………………… 4

Positioning and Installation of MK3 ………………….……………………….... 4

Start Up and Media Flush……………………………………………………………… 7

Cleaning and Maintenance…………….…………………………………………..… 9

Filter Media………………………………………………………………………………..…10

Specifications………………………………………….……………………………………. 12

Trouble Shooting………………………………………………………………………….. 14

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 3

INTRODUCTION

The purpose of this manual is to provide necessary information for

Installation

Operation

Maintenance

Please read all the instructions in this manual before

operating this unit

RECEIVING YOUR MK3

On receiving your MK3 Nano bubbler filter system, please insure that all the

parts are in the shipping container.

See attached figure A for all stock descriptions.

Stock

Quantity

Stock Received

MK3 Pump and venturie serial no:

1

Frame

1

Booster pump with pressure manager

1

Ozone generator 20g or 10mg

1

Filter media vessels 14x65

2

Auto flush heads serial no:

1

Auto flush heads serial no:

1

Transformers for auto flush heads

2

FBT filter media 40kg

5

Float valve ball type

1

S/S bag filter holder

1

Filter bag 50micron

1

Bag filter flush valve

1

Non-return valve white

1

Ozone pipe (meter)

2m

Stainless clamp 65mm

2

Non-return valve 32mm

2

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 4

WATER PRODUCTION FLOW CHART

POSITIONING AND INSTALLATION OF MK3

Positioning

To ensure that your pump and MK3 pump do not strain, the system must

not be higher than 500mm from the opening of your feeding tanks.

System should be out of direct sunlight and rain.

Well ventilated.

Not further than 10 meters from feeding tanks.

Your feeding and return lines should not be smaller than 40mm. But 50mm

preferably.

Ensure that it has a stable, level ground to stand on.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 5

Please see attach photo below for reference

Please read the manual before connecting your pumps

Installation of Electrical Component

Cam 100 HL blue pump 1100W 5 AMP

Spec Mk3 Pump Black 1100w 2.2AMP

Pumps come pre- fitted with 3 prong plugs. Please ensure that it is plugged

into a 10-amp circuit breaker. This will prevent the pump motors from

burning out.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 6

If you are running on an extension cord, please ensure that it is a 2.5mm

16amp extension cord. No longer than 20 meters.

Always ensure that a qualified electrician is used to do the electrical

installation.

Installation Piping on Filters System

See attached diagram for pipe assembly

Match piping using color-coded stickers.

Do not over tighten the union fittings.

Ensure that the system is on flat level service before you assemble.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 7

START UP AND MEDIA FLUSH

Open all valves that connect the system to water tanks.

Bleed the pumps by opening the copper bleed valve on the blue pump until

all the air is out.

Switch the system on by turning the pump switch on. A green light will

come on and the pump will start up.

Switch the system off again.

Now the Auto flush heads needs to be set.

Please follow the following steps.

Switch Auto flush heads on.

Press and hold the up/down arrow until you hear a beeping sound.

Use the to get the auto flush head to rotate to back wash.

Switch the pump on and run for 10 minutes.

The auto flush head will auto rotate to the rinse cycle.

Repeat until the water from rinse and back wash is clean.

Once this cycle is complete on the 1st vessel, switch the pumps off and

repeat the steps to flush the second head.

Now that the media is flushed your system is ready to operate.

On the bag filter there is a tap. Open the tap and start the pump.

Air will escape from the valve, close once the water comes out.

Ensure that the ball valve supplied with system is secure in the clean water

tank. If you are using directly into piping please ensure that there are no

leaks on taps and valves.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 8

Startup off MK3 pump

If you have tanks that your bore-hole water flows into first, ensure that the

outlet of the tank is connected to the MK3. Make sure that the outlet has a

separate intake on the top of your tank.

To prime the pump open the tank valve.

Open top lid of pump to drain any air from the inlet.

Ensure that the basket inside the pump has no obstruction in it.

Once the pump is primed you can start up by switching ON.

Allow 1 minute to start pumping before you switch the Ozone generator on.

If the air pump is causing severe cavitation in the MK3 pump, switch off and

only use the ozone generator.

Start-up of Ozone generator

WARNING: Improper use of the generator may create dangerous

conditions and cause personal injury and damage to property.

DANGER: Do not use this generator to handle flammable and/or

explosive liquids.

This unit will be plugged into a normal power socket 220 volt, 50Hz.

Ensure that the unit is switched off on the unit’s control panel.

Switch plug on and switch Ozone generator on. A green light will come on.

Do not switch the air pump on.

Allow for the unit to run after the MK3 pump is pumping.

Set the timer on the face of the Ozone generator to 3 hours ON and 1 hour

OFF.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 9

CLEANING AND MAINTENANCE

The MK3 filter system has media that will have to be replaced from time to

time. Most of the media has a minimum 3-year span understanding that it

is at normal use.

There is a 50ppu bag filter for the finer sediment that might get past the

first 2 filters. This needs to be replaced periodically.

Procedure for changing bag filter

Switch system off.

Open the tap on top of the bag filter to release the pressure.

Open the bag filter by loosening the bolt on the collar of the filter.

Open and unscrew the inner clamp.

Take bag filter out and replace.

Replace filter and tighten the inner clamp.

Place collar over ridge and tighten.

Start pump and bleed air out of bag filter on bleed valve on top off bag

filter. Close once water comes out.

Check that the pressure manager is functioning correctly by closing the

feeding tank once a month. The pressure manager should shut down after a

while. This is to protect the pump from running dry.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 10

FILTER MEDIA

Structure and properties

Mineralogically, there are about 40 known types of natural zeolites (hydrated

silicates) of which clinoptilolite is the most common.

Clinoptilolite is classified as a crystalline aluminum, silicon, oxide mineral

(Berkhout 2002; Rempel, 1996). This report describes a high purity 14 x 40

mesh, approximately 55 lb/cu. ft. bulk weight, clinoptilolite (zeolite) from the

western US that has a high porosity, high surface area, a micro-crystal

structure, and is abrasion resistant.

Performance and advantages

Since the mid-1970s, lab and field test data reports in the US have indicated

that zeolite filtration media has consistently outperformed sand,

sand/anthracite and multimedia in both pressure vessels and gravity filtration

tests (e.g., Foreman:1985: Johnson & Petersen, 2001 Hansen, 1997:, Johnson

et al, 1997; Fuger, 2003).

Generally, the filter beds have 1.7 to 1.9 times the solids loading capacity/ft3

and superior filtration performance versus multimedia.

Based on more than 100 lab and field tests (2/3 using pressure vessels and 1/3

using gravity beds) since the mid-1990s representing commercial, residential

and industrial water filtration projects, it has been concluded that high purity

zeolite media is superior to conventional granular media.

Our test results using pressure vessels indicate:

For solids loading capacity, high purity surpassed multimedia, sand/anthracite

and sand; FBT media more effectively removes fine particles in the 0.5µ to 10µ

range that escape conventional media (see Table I below).

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 11

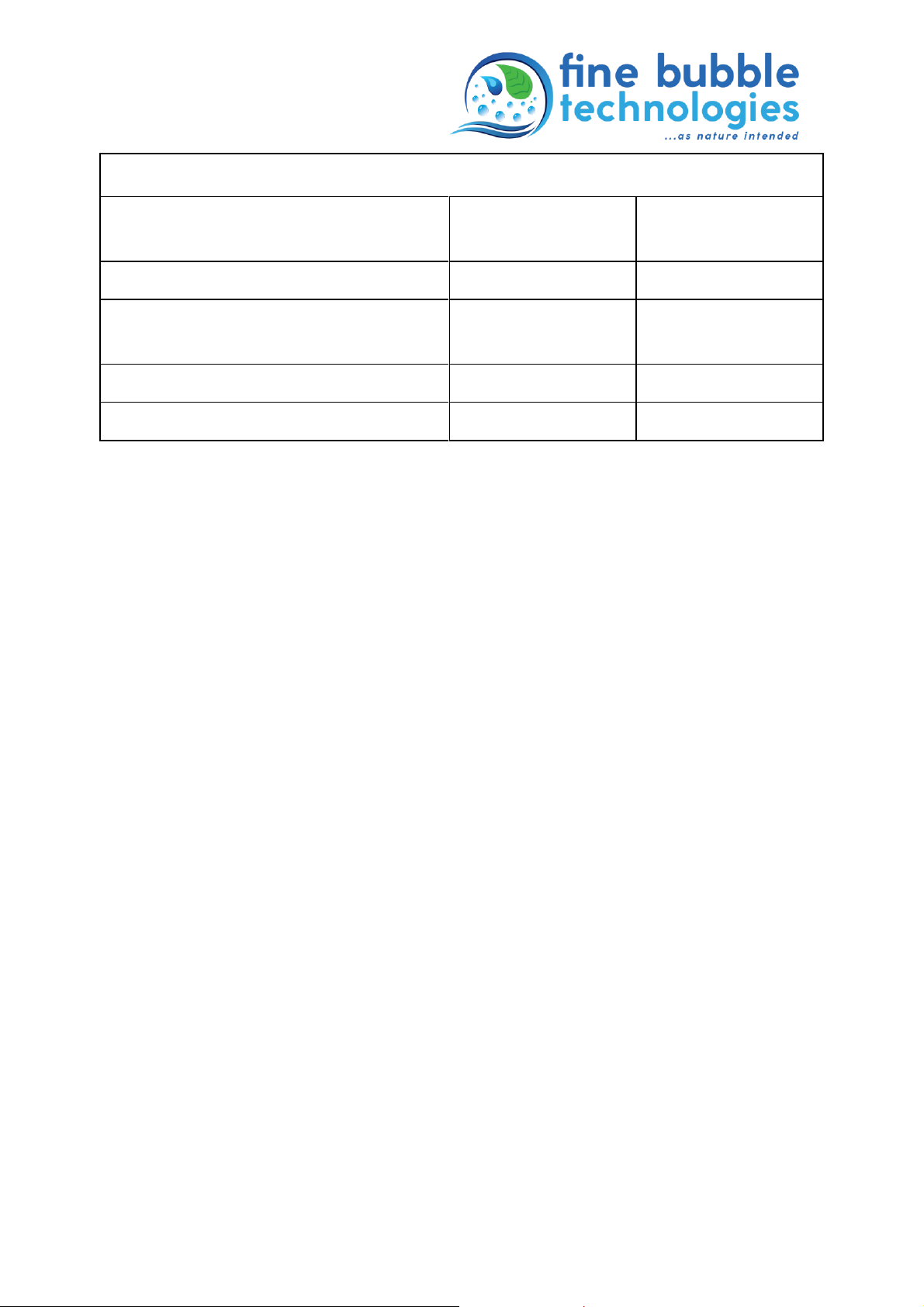

Table I Summary of performance test data for pressure vessels

Filter media

Filter rating

(nominal)

Solids loading

capacity

Sand (20 x 40 mesh)

µ

1X

Sand/Anthracite (20 x 40 mesh &

Anthracite)

µ

~1.4X

Multimedia

µ

~1.6X

FBT (14 x 40 mesh)

<5µ

~2.6X

Similar results were observed for gravity beds. Some representative examples

of high purity Fine Bubble Technology (FBT) filter performance are provided

below.

River water turbidity

FBT versus multimedia media filtration tests were conducted for fine particle

(turbidity) removal from river water. Pressure vessels (18″ diameter) were

operated with a service flow rate of 15 gpm/ft2 of bed area for six consecutive

days and turbidity (NTU) was measured in the feed and filtrate water.

The zeolite filtrate (product water) average NTU was approximately 1/3 of the

multimedia filtrate (see Figure 1), indicating superior fine particle removal by

the FBT.

Pre-filter for GAC

Municipal water supplied to a restaurant contained elevated iron and other

fine particles. Cartridge (5µ) filters rapidly loaded and caused reduced water

flow to the GAC beds and chiller.

A backwashing zeolite filter (10″ diameter vessel with a 24″ bed depth) was

installed and tested by an independent engineer and technical consultant.

The feedwater had 0.1µ to 10µ particles (average SDI or silt density index =

4.3). The FBT media bed effectively removed the iron particles. The product

water particles were in the 0.1µ to 2.3µ range, with an average SDI = 0.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 12

RO Pre-filter

An electric utility installed a 1,500 gpm water treatment facility with two

multimedia filters and RO equipment to produce boiler make-up water. The RO

units could not be operated due to filter vessel pressure loss problems and an

elevated SDI in the filtrate.

The two multimedia beds were replaced with equivalent bed volumes of 14 x

40 mesh high purity FBT media and the strict design specifications for the RO

feed water have been consistently met for over two years.

Bottled water plant

A bottled water plant pumped groundwater to four 48″ diameter pressure

vessels that feed two RO units.

The multimedia reduced the well water SDI by an average 5 percent compared

to 45 - 50 percent SDI reduction for the zeolite media.

Since virgin zeolite has “fines” from mine production, it is important to

backwash it prior to placing in service. The backwash rule-of-thumb is to

achieve 35 percent bed expansion using a backwash rate of 20 gpm/ft2 until

the water is clear for new zeolite, and for six minutes for routine operational

backwash cycles.

Alternatively, air scour can be used with water to reduce backwash water

usage.

SPECIFICATIONS

Cam 100 Booster Pump Blue

Capacity:

m3/h = 3.6 - l/m = 60

Total head:

H(m) = 45

Power:

kW = 0,75

Voltage:

230V-50Hz

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 13

Features

Operating Conditions

Maximum working pressure 8 bar

Liquid temperature up to 35°C

Ambient temperature up to 40°C

Total suction lift up to 8 mt

Continuous duty

Motor

Two–pole induction motor (n=2850 min-1)

Insulation Class F

Protection IP 44

Materials

Pump Body: Cast Iron

Motor Support: Aluminum

Impeller: Nylon

Diffuser: Nylon

Pump Flange: Stainless Steel AISI 304

Shaft with Rotor: Stainless Steel AISI 304

Mechanical Seal: Ceramic/Graphite/NBR

MK 3 Pump and Motor Black

Pump casing and internal parts made from Polypropylene.

German engineering and design combined for ultimate efficiency.

Plastic components are 100% recyclable.

Temperature stability up to 60°C.

Total electric separation.

German design mechanical seal using carbon to ceramic sealing surfaces.

Simple servicing.

Fully factory tested.

New 2-part easy screw on/off lid.

Stainless steel shaft.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd.

©Copyright 2018. All rights reserved. Page 14

Technical data

Inlet/outlet connection (Rp)2* 50/40 50/40 50/40

Inlet/outlet pipe, PVC-pipe, (d4)* 50/50 50/50 63/50

Power input P1 (kW) 1~230V 0.67 1.10 1.50

Power output P2 (kW) 1~230V 0.451) 0.751) 1.101)

Rated current (A) 1~230V 3.10 4.80 6.30

TROUBLE SHOOTING

Please refer to the booklets given with instruction manual

Table of contents

Popular Water Filtration System manuals by other brands

SpectraPure

SpectraPure PROPLUS RO System Installation and operating manual

Steinbach

Steinbach Speed Clean Classic 250N ORIGINAL OWNER'S MANUAL

ACO

ACO Oleopator P Installation guidelines

EHEIM classic

EHEIM classic 2215 manual

A.J.Antunes

A.J.Antunes UF-216C Series owner's manual

Water Well

Water Well MB18 user manual

ITT

ITT WEDECO Aquada Installation and maintenance instructions

Miele

Miele DFKS-A-1 Operating and installation instructions

Wilkerson

Wilkerson M31 Installation & service instructions

Pentair

Pentair INTELLICHLOR COMSYS-12 installation guide

Frizzlife

Frizzlife MK99 installation guide

Crystal Quest

Crystal Quest CQE-SP-00809 Installation and operation guide