UF-216 WATER FILTRATION SYSTEM

8P/N 1010885 07/04

UF-216 WATER FILTRATION SYSTEM

9

P/N 1010885 07/04

INSTALLATION (continued)

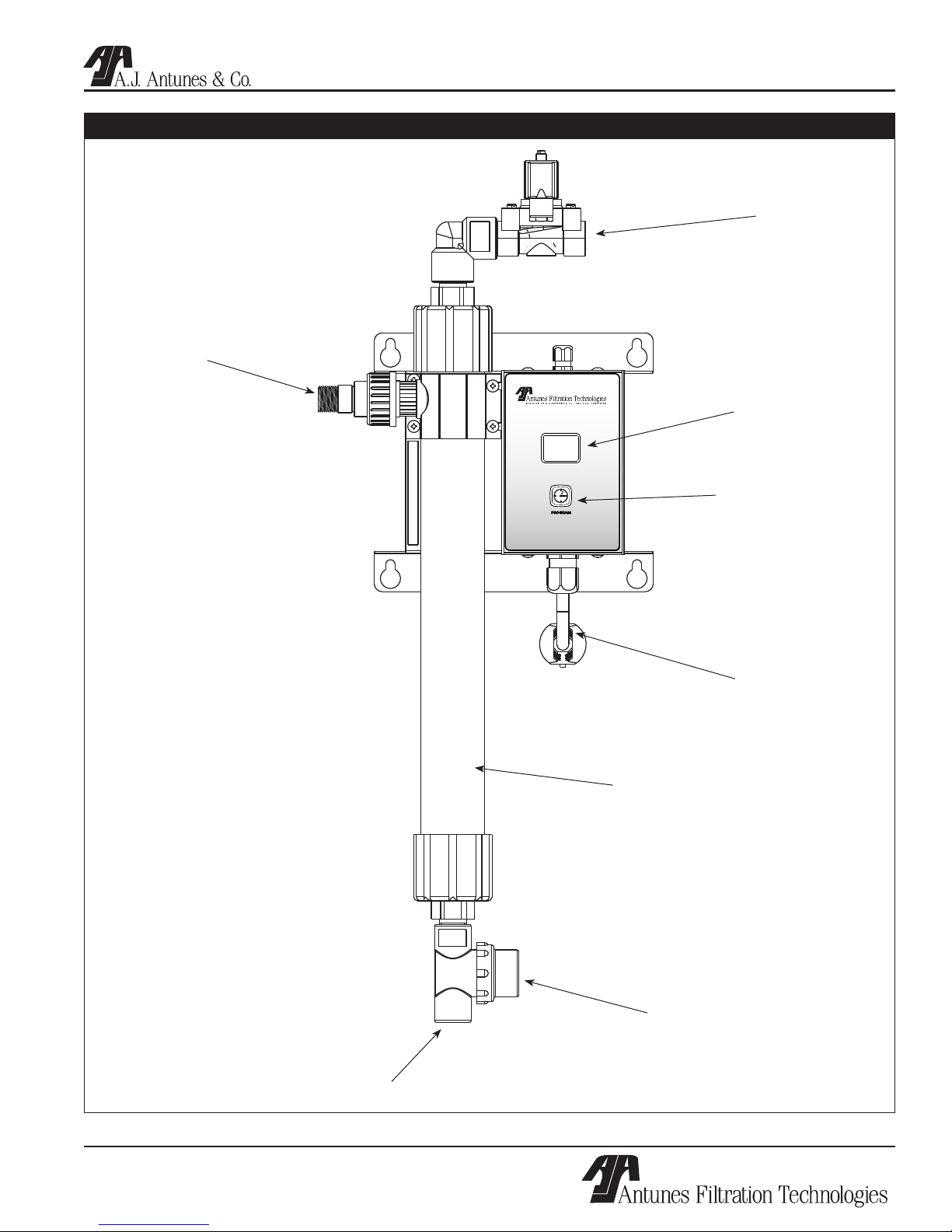

Locating and Mounting the system

Consider these points before mounting the system:

• Note the location of the water supply, drain, and

an appropriate electrical outlet when choosing a

mounting location.

• Remember to allow for access to the timer/

programmer controls.

• Do not mount the system above any electrical

equipment, or items that may be damaged if they

get wet.

• Install the system in a location that will allow for

future service access.

• Mount the system on a wall using appropriate

mounting hardware.

• Remember to consider the operating weight of

the system when choosing mounting hardware.

Depending on the type of wall the system is being

mounted to, wall reinforcement may be necessary.

INLET WATER PLUMBING

It is recommended that the inlet water plumbing line

be 1/2”” NPT or larger. A shutoff valve (not supplied)

should be installed in the line leading to the system.

The valve should be mounted close to the system inlet,

and sized properly for the inlet plumbing line. This

valve will allow for easier servicing and future cartridge

change-out.

NOTE: The system should only be connected to the

cold water line.

To ensure that the highest quality water is produced

from the system, the plumbing leading to the filter sys-

tem must be flushed clear of all debris before the sys-

tem is hooked up. Before making the connection to the

inlet of the filter system, hold a bucket or other contain-

er at the inlet water line and slowly open the inlet water

valve. Allow the pipe to flush until all debris is removed.

PERMEATE LINE PLUMBING

To ensure the highest quality and safest water, it is rec-

ommended that a check valve (to prevent back flow) be

installed in the water line after the permeate connec-

tion. This will help prevent possible contamination of

the filter system due to other equipment downstream.

The check valve (not supplied) should be mounted

close to the system outlet, and sized properly for the

plumbing line. Check with local codes for the proper

specification.

DRAIN LINE PLUMBING

The drain line is used to flush away the particle buildup

when cleaning the filter. The drain line must be able

to support the flow rate when the system flushes. The

flow rate from the flush depends on the inlet water pres-

sure, inlet pipe size, and system selected. It is recom-

mended that the drain line be as large as, or larger

than, the inlet plumbing line. The drain line should be

as short as possible, sloping downward without kinks

or loops. Be sure that the drain used is not blocked or

restricted.

The filter system must be protected from possible back

contamination by the installation of an air gap between

the drain connection of the system and the drain

(Figure 3). This gap in the line, with no physical contact

between the system and sewer, prevents contamination

of the system in the event of a backed-up sewer.

NOTE: Make sure that the end of the drain line is

positioned and secured at least 2 inches above

the drain so that the water flow is directed into the

drain, without splashing.

Flushing and Starting the System

FLUSH THE PIPES

To ensure that the highest quality water is produced

from the system, the plumbing leading from the filter

system must be flushed clear of all debris after the

system is hooked up. After making the connection to

the outlet of the filter system, open a faucet or tap clos-

est to the filter system, then slowly open the inlet water

valve. Allow the pipe to flush until all debris is removed.

FLUSH THE MEMBRANE CARTRIDGE

The ultrafiltration membrane cartridge must be flushed

to remove air and the shipping/storage solution. For

maximum quality, the permeate water produced during

the flushing procedure must be discarded. Direct this

permeate water to the drain.

1. Plug the power cord into the appropriate electri-

IMPORTANT

It is recommended that you flush the membrane

cartridge first, without the carbon cartridge

installed in the Carbon Filter Housing, followed

by flushing the carbon cartridge. This prevents

the shipping/storage solution in the membrane

cartridge from entering the carbon cartridge and

ensures that the system produces the highest

quality water.