Finesse VCS -F-B-10S User manual

FINESSE Air Curtain

CONDITIONS FOR

SAFETY AND PROPER

FUNCTION OF THE

AIR CURTAIN

ENVIRONMENT

PROTECTION

ASSEMBLY INSTRUCTION

INSPECTION OF THE

DELIVERY

This instruction contains important hints and safety instruction. To ensure proper function and own safety read

thoroughly this manual before the use of the air curtain and follow the instruction. We reserve the right of changes in

accordance with the technical development in the production.The priority of electric wiring schemes placed on the

product is higher than these ones which are included in this user´s manual. Any changes or interventions to the inner

connexion are prohibited, and lead to cancellation of the warranty. We recommend to use the accessories supplied by

us. In the case other than original accessories or regulations are used the product may be damaged. The manufacturer is

not responsible for damage occurred as a result of using non-original accessories (regulations),or improper use of the

accessories (regulations). Frequency converter shall not be used to adjust the fans' rotation.

-

-

Our company is continuously improving the new technologies and technical solutions with the aim to reduce energy

consumption and to maintain natural sources and to contribute thus effectively to slow down the environment harm.

- Before you will put the air curtain to scrap, make it unusable. Even the old air curtain contain reusable raw materials. It is

recommended to scrap the air curtain by a specialised company which is capable to recycle the materials.

- Air curtain is protected by packing against damage during transport. All used packing materials are ecological and

recyclable. Will you contribute actively to the environment protection and dispose and recycle properly all packing

material.

- Will you follow this instruction manual for maximum gains from function, energy savings and long service life of the air

curtain.

Read this instruction manual before the installation and using of the air curtain and keep the instruction thereof. You will

find there the important information not only for installation and use, but also for safety and air curtain maintenance.

- Close to the air curtain and in distance up to 100 mm in all directions around just incombustible materials (do not burn, do

not glow, do not carbonate) or hard to burn materials (do not burn, mostly glow and carbonate e.g. gypsboard) can be

used. However, these materials may cover neither inlet nor outlet openings. National technical standards are applicable

for safe distance of combustible materials from electric appliances.

- As to the safety distance of the electric-heated air curtain from surfaces of structure constructions, floor covers and items

made from combustible materials, the following applies:

- safe distance of combustible materials in the direction of the main air stream (behind the outlet slot) is 500 mm

- safe distance of combustible materials above the air curtain is 500 mm

- safe distance of combustible materials in all other directions is 100 mm

- Never start damaged air curtain.

- Assembly and connection of the air curtain must be executed by an authorised person and according to the installation

hints and applicable regulations. When you will not comply with the hints and regulations, you risk the loose of warranty.

- We do recommend to keep this instruction manual for future reference or for possible use by another user.

- FINESSE air curtains have been designed for operation indoors in dry environment with ambient temperature between 0°

and 40°C for transportation of air free of fat, chemical vapours and other impurities.

- Relative humidity of the air should be up to 80%.

- Electric protection degree of the air curtain equipped with inlet cover is IP 20.

- Operator of this air curtain should be acquainted with this manual.

- When the air curtain has been transported under other temperatures that the operation one (lower than 0°C), it is

necessary to let it under operation environment for at least 1 hour switched off to balance the inner and outer

temperatures (recommendation).

- As to the appliances powered by 400 V AC it is necessary to place close to that an lockable switch with minimum

contactors distance 3mm when it is not connected by a power cord, pursuant to requirements of EN 292-2+A1:2000, EN

60335-1:1997.

- There must be the main switch connected to the main power supply of the air curtain for disconnection of all poles.

To minimize the possibility of damage in transport the air curtain is packed in a wooden framed structure. The air curtain

must be carefully handled to avoid damage if dropped. On delivery check that no damage has occurred in transport. The air

curtain must be stored indoors in dry environment with ambient temperature between 0° and +40°C.

- Check immediately after delivery if there is not any damage to the air curtain during the transport.

- Check the data on the machine index plate with those on the purchase order. When of any discrepancy, or of any damage

on the packing, will you not unpack the air curtain and report the problem to the supplier, when of damage of the packing

call the forwarder, too. When the claim is not applied immediately, none claim related to that can be laid in the future.

- Check the index plate, when of the discrepancy of the parameters, follow the instruction in the above sentence.

FINESSE air curtains are manufactured in accordance with the internationally valid standards and regulations and they

confirm with Electric, Mechanic and Noise Safety.

EN 60335-2-30 ed. 2:2004+A1:05+A2:08 / idt EN 60335-2-30:2003+A1:04+A2:07

EN 60335-1 ed. 2:2003+A11:04+A12:06+A2:07+Z1:07

/ idt EN 60335-1:2002+A11:04+A1:04+A12:06+A2:06+A1/Cor:07

EN 60204-1 ed. 2:2007 / idt EN 60204-1:2006

EN 55014-1 ed. 3:2007 / idt EN 55014-1:2006

EN 61000-6-3 ed. 2:2007 / idt EN 61000-6-3:2007

EN 61000-3-2 ed. 3:2006 / idt EN 61000-3-2:2006

EN 61000-3-3:1997+Z1:02+A2:06+Z2:07 / idt EN 61000-3-3:1995+A1:01+A2:05+IS1:05

EN 55014-2:1998+A1:02 / idt EN 55014-2:1997+A1:01

CERTIFICATION

12/09 page 01

A

80

R

EN

OPERATION

INSTRUCTIONS

The right for changes reserved ©2VV, spol. s r.o.

AIR CURTAIN

DESCRIPTION

TYPES OF AIR

CURTAINS

12/09 page 02

*) Values are measured at ambient air temperature 20°C and temperature drop 90/70°C / 80/60°C

**) Acoustic pressure level at distance of 3m on the inlet side according to the standard EN-ISO 3743-1 and EN-ISO 3744.

Stated values apply for maximum air flow.

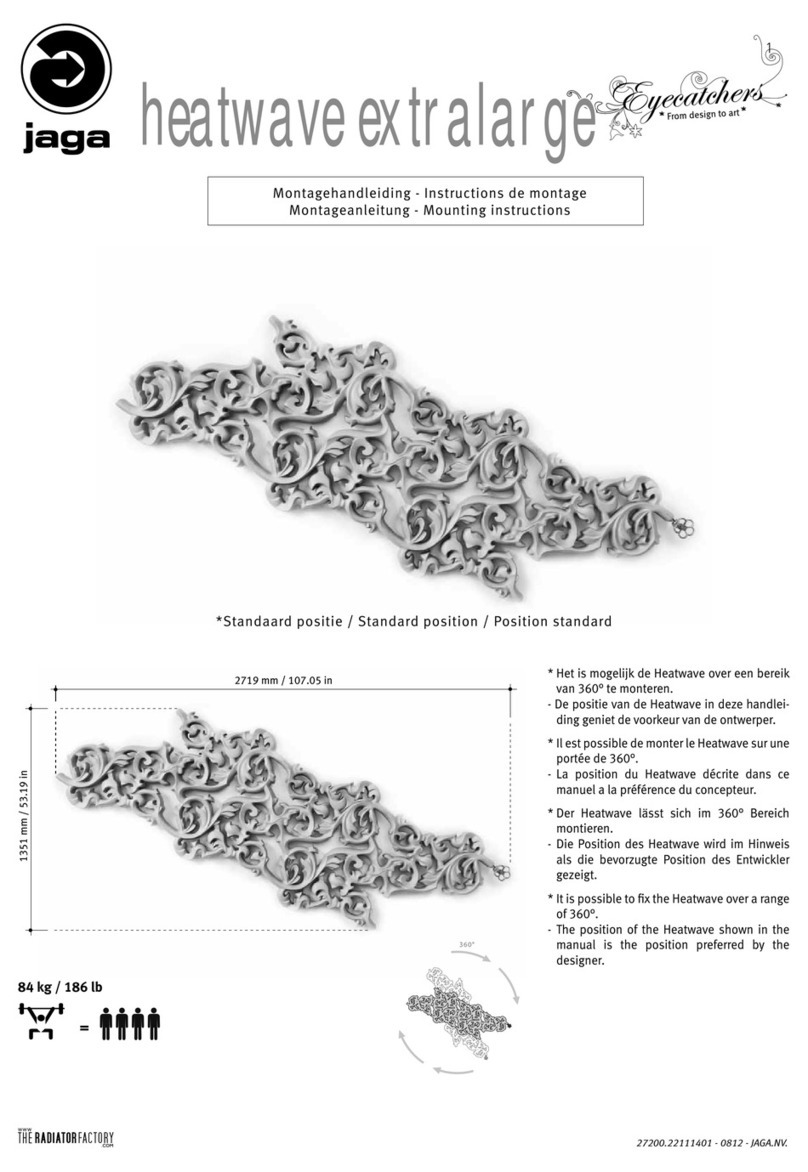

Gromments for

the mains cable

Openings for

threaded bars

Terminal board for

connection of the

mains and motherboard

Position of RESET button

for activation of safety

thermostat with manual

reset function.(electric version,

see chapter “Overheating

of electric heater”)

Grille can be removed

by aid of a screwdriver

Air curtain fans

Tiltable electric or

water heat exchanger

Side connection for

water heater G 1”

Transformer for fans,

and filter clogging signal

OPERATION

INSTRUCTIONS

[m] [m3/h] [kW] [dB(A)]** [V/Hz] [A] [kg]

VCS -F-B-10S 2240

- 54,8 230/50 2 21

VCS -F-B-15S 3360

- 58,9 230/50 3 34

VCS -F-B-20S 4480

- 60,5 230/50 4 48

VCS -F-B-10E 2220 9,0 54,8 400/50 15 25

VCS -F-B-15E 3330 13,5 58,9 400/50 22,5 37

VCS -F-B-20E 4440 18,0 60,5 400/50 30 51

VCS -F-B-10V 2180 18,5/15,1* 53,6 230/50 2 27

VCS -F-B-15V 3270 29,4/24,1* 57,4 230/50 3 41

VCS -F-B-20V 4360 40,7/33,4* 58,6 230/50 4 57

VCS -F-B-10W 2150 25,2/20,6* 53,6 230/50 2 29

VCS -F-B-15W 3230 40,9/33,9* 57,4 230/50 3 43

VCS -F-B-20W 4300 54,5/45,2* 58,6 230/50 4 60

VCS -F-C-10S 2860

- 55,6 230/50 3 24

VCS -F-C-15S 3990

- 59,5 230/50 4 37

VCS -F-C-20S 5040

- 60,9 230/50 5 51

VCS -F-C-10E 2790 9,0 55,6 400/50 16 28

VCS -F-C-15E 3890 13,5 59,5 400/50 23,5 40

VCS -F-C-20E 4920 18,0 60,9 400/50 31 53

VCS -F-C-10V 2680 20,7/16,9* 54,7 230/50 3 30

VCS -F-C-15V 3740 31,7/26,0* 57,9 230/50 4 43

VCS -F-C-20V 4720 42,6/35,0* 58,9 230/50 5 60

VCS -F-C-10V 2610 28,4/23,2* 54,7 230/50 3 32

VCS -F-C-15V 3640 44,1/36,5* 57,9 230/50 4 46

VCS -F-C-20V 4600 56,9/47,1* 58,9 230/50 5 63

Weight

Type

Heater

output

Acoustic pressure

level

Power

voltage

Total

current

4,0

7,5

Air flow

Maximum door

height

PARAMETERS OF THE

HEATERS

KEY CODE

Electric heater

Water heater

SM - power control in standatd delivery)

DM - manual control with electronic regulation

DA - automatic/manual control with electronic regulation

LW - LONWORKS (building management system)

S - No heater

E - Electric heater

V - Standard water heater

W - Multiple water heater

10, 15, 20 - Length of the air curtain 1; 1.5 and 2 meters

B, C - Power range

Air curtain to be installed into ceiling - FINESSE

12/09 page 03

Inlet air temperature +18°C

All figures measured at maximum speed.

Water flow Pressure loss on

the water side

Pressure loss on

the water side

Water flow

(°C) (I/s) (°C)

(I/s)

VCS -F-B-10V 32,5 0,17 3,13 39,5 0,22 4,39

VCS -F-B-15V 34,2 0,28 3,54 71,4 0,35 4,93

VCS -F-B-20V 35,4 0,39 5,46 42,7 0,48 7,54

VCS -F-B-10W 41,8 0,24 1,71 50,4 0,30 2,37

VCS -F-B-15W 44,5 0,4 5,67 53,3 0,48 7,71

VCS -F-B-20W 44,6 0,53 9,42 53,3 0,65 12,83

VCS -F-C-10V 30,8 0,20 3,85 37,5 0,24 5,41

VCS -F-C-15V 33,3 0,31 4,06 40,4 0,37 5,65

VCS -F-C-20V 35,1 0,41 5,92 42,4 0,50 8,18

VCS -F-C-10W 40,2 0,27 2,11 48,5 0,33 2,94

VCS -F-C-15W 43,9 0,43 6,48 52,5 0,52 8,83

VCS -F-C-20W 44,6 0,56 10,18 53,2 0,68 13,86

Type

Temperature drop 80/60°C Temperature drop 90/70°C

t t

Electric heater

Water heater

OPERATION

INSTRUCTIONS

[°C] [kW] [A]

11,9 9 13

11,9 13,5 19,5

11,9 18 26

9,5 9 13

10,2 13,5 19,5

10,8 18 26

PowerMaximum electric

heat output supply

Type t

VCS-F-B-10E

VCS-F-B-15E

VCS-F-B-20E

VCS-F-C-10E

VCS-F-C-15E

VCS-F-C-20E

The right for changes reserved ©2VV, spol. s r.o.

VCS - F - B - 10 S - SM

General packing sheet of the air curtain Air curtain type sheet

INSTALLATION Principles of the air curtain location and corect function.

- Air curtain should be placed as close to the edge of the door

opening as possible

- Air curtain should be wider than the curtained opening for at

least 50 mm

- Air curtain can be hung by threaded rods or directly to the

ceiling structure by screws. There is no need of any space to

be kept between the air curtain case and the ceiling

structure. (See “ Conditions for safety and proper function of

the air curtain”)

Air curtain is fixed to the ceiling by 4 threaded rods, which are

not included delivery.

- It is necessary to ensure proper in the supply at the site

according to the exact type of use of the air curtain and

based on its electric parameters (see “Electric installation”)

- When using water heated air curtain, please ensure

connection of the flow and return pipes. (see “Water heat

exchanger connection”)

- It is necessary to cut or otherwise make a hole according to

the hereunder mentioned dimensions (4)

- Drill four holes into the ceiling construction according to the

dimensions scheme (see “Dimensions”) for hanging of the

air curtain to 4 anchoring points.

- Screw the air curtain directly to the ceiling without any space

between its casing and ceiling, or use four threaded bars to

reach the required distance from the ceiling, according to the

situation on the site (see “Conditions for safety and proper

function of the air curtain”).

12/09 page 04

Grommets for power cables

to the air curtain and

temperature sensor.

VCS3-F-...-10 / 15 / 20

1090 / 1490 / 1990mm

370mm

Inlet Outlet

In case the Conditions for

operation are maintained,

it is possible to install the air

curtain directly on the ceiling.

!

1. Front view

2. Side view

4. Opening in the ceiling

3. Detail of air curtain connection

to the threaded rods.

1” water inlet and outlet

410

304

361

B

A

250

300

4xM8

DIMENSIONS

OPERATION

INSTRUCTIONS

Length Connection Width Height

A B

[mm] [mm] [mm] [mm]

1100 1073 410 300

1500 1473 410 300

2000 1973 410 300

1100 1073 410 300

1500 1473 410 300

2000 1973 410 300

Type

VCS-F-B-10

VCS-F-B-15

VCS-F-B-20

VCS-F-C-10

VCS-F-C-15

VCS-F-C-20

Switch the mains off before any work to be done on the air curtain ! If the air curtain is equiped with electric heater be carefull

of burning when the air curtain has been heating before ! Before connecting the electric system or before any other work

inside the air curtain it is necessary to remove the grille as follows:

The mains must be switched off before any work is to be done on the air curtain !

Take a screwdriver and stand under the air curtain. There are red-marked bolts in the corners of the inlet part of the grille

(see also “Air curtain description”).

2. Hold the grille by one hand to avoid its drop down and possible injury caused by.

3. Turn both bolts 90° and tilt the grille slowly

1.

TILTING OF THE GRILLE

Possibility of water heat exchanger regulation

SMU water mixer

Outdoor temperature sensor

OSMU controller of water mixer

Door contact

Room temperature sensor

DA control panel

Thermostatic valve with capillary

(mixing by throttling)

Simplest regulation of the temperature by manual

change of the hot water flow through the air curtain.

It does not enable changing of the setting due to the

complicate access to the valve.

Three-way zone valve ZV-3 with spatial thermostat TER-P

(mixing by ON-OFF system)

Simple automatic regulation of the outlet temperature by room

thermostat, on which it is possible to change the required room

temperature. Valve must be installed according to the delivered

technical documentation.

1.

2. 3.

2. 3.3.

3

3

4

4

5

5

6

6

2

2

1

1

12/09 page 05

1.1.

SMU water mixer

(regulation by mixing)

This is the most comfortable way of

regulation and enables step-less

automatic temperature regulation.

It is possible to follow the current

room temperature by the water

mixer controller and to set the

required temperature. Water

mixer must be installed according

to the delivered technical

documentation.

1.

Connection of the heat exchanger

Connection of hot and cold water

Channel for Duct sensor

It is possible to regulate the water heat exchanger in three possible ways with the optional accessories components.

Installation must be executed according to the design pursuant to the applicable national standards and by an authorised

person in plumbing. Design and choice of the single variant is up to the customer and it is based on the type of air curtain and

the local conditions on the site.

It is recommended to use flexible hoses (optional accessories) for water heat exchanger connection for a better installation.

connection and pressure test of the heat exchanger must be executed by an authorised person in plumbing.

Applicable national regulations and standards must be kept !

- heat exchanger can be used for water of maximum pressure 1,6 MPa and maximum temperature +100°C

- the order of connection of hot and cold water to the heat exchanger outlets does not matter, in case there is at least

minimum water pressure in the heating system. We do recommend to connect flow and return pipes as shown below.

- It is necessary to hold the outlets of the heat exchanger by pliers to avoid its damage (see Fig.)

- we do recommend the fitting of gate valves on the inlet / outlet connections to isolate for servicing see chapter “Servicing

of internal parts of Air curtain”

- it is possible to use the DVCT temperature sensor P12L1000 which will be located into the channel in the air curtain

(see Fig.)

-

CONNECTION OF

WATER HEAT

EXCHANGER

WATER HEAT

EXCHANGER

REGULATION

OPERATION

INSTRUCTIONS

Hot water

Cold water

The right for changes reserved ©2VV, spol. s r.o.

CONNECTION OF THE

CONTROLLER

There are two types of control delivered to the air curtain. Power - (SM) and electronic (DM, DA) ones. Power control is

connected by means of power cable (specification according to the wiring diagram) to the terminal board of the electronic

motherboard (Fig. 1) and to the controller to the switch terminals, according to the wiring diagram on the controller box

(Fig. 2). Electronic control is to be connected to the electronic motherboard by delivered data cable (code - KABEL 05)

terminated by one-line connector.

- One end of the electronic cable is to be connected to “CONTROL” connector of the electronic board, the other end is to be

connected to electronic board of the controller (Fig. 3).

- To ensure the proper function of the air curtain (at DA and DM control) the original cable delivered by the manufacturer

must be used.

- Recommended maximum length of the cable is 50 meters (at DA and DM control).

- Cable should not be laid together with the power ones and should be laid in enough distance from them (according to the

appropriate standard, however not closer than 150 mm) !!!

- Always check if the connector clicked-in at the low-voltage control system.

- Insulation of the cable may not be damaged at fixing the cable to the wall.

- When you will not connect the cable after its installation of the air curtain and the controller, cover the ends of the cable by

insulation strip to protect them against possible mechanical damage or short-circuit.

- Low-voltage cable connector may not come in contact with water or any other liquid.

Power control SM Electronic control DM, DA

12/09 page 06

The mains must be switched off before any work is to be done on the air curtain !

Electric connection of the air curtain must be executed according to the professional

design of a qualified designer of electric systems. Installation must be done by a

qualified electrician only. Applicable national standards and regulations must be kept.

- Air curtain must be connected by NTSC system, i.e. with zeroing conductor always connected.

- Connection point for the electric installation is under the grille (see “Air curtain description”)

- Use Phillips screwdriver for the opening of electronic board. Wiring diagram of the air curtain

with all external sensors varies according to the type of the air curtain and it is necessary to

follow the appropriate wiring diagram mentioned in Par. “Electric wiring diagrams” or stuck on

the air curtain body panel.

- Check before the start of installation for loose connectors or cables and if the terminals

marking corresponds to that on the wiring diagram. When of any doubts will you please

contact your supplier and do not connect the air curtain in any case.

- Electric parameters are stated on the index plate locate on the air curtain case.

- Air curtain electric connection must be secured by appropriate circuit breaker according to its

electric parameters. Due to safety reasons it is not recommended to over-design the circuit

breaker.

- Notice: When of fire it is necessary to extinguish the air curtain by CO fire extinguisher. Never

2

use water !!

-

ELECTRIC CONNECTION

OF THE AIR CURTAIN

INSTALLATION AND CONNECTION

SM CONTROL

DM, DA CONTROLS

- Bring the cable from the air curtain to the installation place first.

- Push the cables throw the grommets and connect them according to the wiring diagram in the control panel box. Watch the

numbers of the single terminals in the controller and on the connection terminal board in the air curtain. It is necessary the

cables are connected to the right terminals and the numbering in controller corresponds to that in the electric wiring

diagram.

- Connect the second end of the cables to the terminals of air curtain, exactly according to the wiring diagram located in the

air curtain, or at the end of this manual.

OPERATION

INSTRUCTIONS

1.

2.

1. 2. 3.

"CONTROL”

1. 2. 3. 4.

1. 2. 3.

A lot of external control parts can be connected to the air curtain, according to

the single type of control system (see “ Possibilities of single control systems”)

- Air curtain must be disconnected from the mains during before any

external items are connected to.

- All external control items must be connected exactly according to the

wiring diagram and they must be used according to its determination.

- Connectors must be connected to the electronic boards by using

reasonable force and always normally to the socket.

- Cables delivered by us must be used to the single elements, if they are not

delivered, the further mentioned cable specification must be met.

Door contact

Room thermostat TER-P

Door contact is used for air curtain control by opening / closing of the door. When the door is opened, the air curtain is

switched on. When the door is being closed, the behaviour of the air curtain depends on the certain type of control

system. Door contact can be used together with all types of control systems. For the detailed description of the function

see “Operation - single control system types”. When of the air curtain with SM control system it is necessary to remove

first the “LINK”, which connects the terminals of door contact (*) ! When of the air curtain with DM, DA control systems,

there is no “LINK”.

Room thermostat is used for switching the electric

heater in the air curtain ON and OFF according to

the pre-set temperature (version DA). For version

DM, SM - it is used for air curtain control ON/OFF.

Location of the thermostat depends on the

requirements of the user. When the user wants to

follow more the temperature of air coming out from

the air curtain, we recommend to place the

thermostat as close to the air curtain as possible to

ensure it is affected by the air flow. On the other

hand, if the customer wants to follow the air in the

room, it is good to place the thermostat in that part

of the room, where is the user mostly present.

Minimum recommended distance of the thermostat

from floor is 1200 mm.

CONNECTION OF

EXTERNAL CONTROL

PARTS

Door contact (DS)

for SM control system

Door contact (DK)

for DM, DA control system

- potential-free contact with maximum voltage 12 V

- two-wire cable of 0,5 mm cross section

- maximum length of the cable 50 m

- connection contact

- power contact with maximum voltage 230 V / 50 Hz

- two-wire cable of 1,5 mm cross section

- maximum length of the cable 50 m

- disconnection contact

Door contact Door switch

1 2

20 21

- potential-free contact with maximum voltage 12 V

- two-wire cable of 1,5 mm cross section

- maximum length of the cable 50 m

1200 mm

Room thermostat

for SM

Room thermostat

for (DM), DA

1 3

26 27

12/09 page 07

Connector socket

°C

OPERATION

INSTRUCTIONS

CONTROL

10.

1

1 2

DK DK

1

DK DK

1 3

20 21

(

(

The right for changes reserved ©2VV, spol. s r.o.

4. 5. 6.

7.8.9.

CLICK

Check before putting the air curtain into operation, if the following preconditions of the installation are fulfilled:

- Installation conforms with the conditions of “Safety and air curtain operation conditions” chapter

- Mechanical installation conforms with the conditions of “Installation” chapter

- Electrical installation conform with the conditions of “Electric connection of air curtain” and “Controller connection“

chapters.

- In case of air curtain equipped with water heat exchanger also the conditions listed in chapter “ Water heater

connection” must be kept.

- Operators of the air curtain must be trained and received the Maintenance and operation manual.

PUTTING THE AIR

CURTAIN INTO

OPERATION

POSSIBILITIES OF THE

SINGLE CONTROL

SYSTEMS

12/09 page 08

SM DM DA

Two steps of heating output

(electric version)

Possibility of door contact connection

Room thermostat connection

Filter clogging signal (presostat)

Electric heater overheating signal

Possibility to chain up to 6

air curtains together

YES

YESYES

NO

NO

NO

NO

NO

NO

NO

YES* YES

YES

YES

YES* YES

YES* YES

YES YES

YES YES YES

Three steps of fan speed

Time switch connection

Outdoor temperature sensor

YES

YES*

YES*

YES*

°C

ALARM

FILTER

1 2..

*Just one of the temperature sensors

°C

OPERATION MANUAL

°C

Time switch is used to switch the air curtain ON /

OFF according to the pre-set time schedule. The

time schedule can be set for the all office days in

the week. Switch can be fixed to the DIN-batten

and it is recommended to put it somewhere into

the switchboard. Time switch must be powered by

a separate connection. For detailed information on

the setting of the switch and its programming see

“Time switch controlling”.

Time switch SH

Temperature sensor follows the outdoor

temperature and provides this information to the

electronic system, which controls the air curtain

accordingly in the automatic mode. This sensor is

delivered, including the interconnection cable, to

DA control system only, it is a standard part of

delivery. For detailed description of the function see

“Operation DA control system”.

Outdoor temperature sensor

- potential-free contact with maximum voltage 12 V

- two-wire cable of 1,5 mm cross section

- maximum length of the cable 50 m

- time switch power supply cable three-wire

of 1,5mm diameter, 230V / 50 Hz

- potential-free contact with maximum voltage 12 V

- three-wire cable of 0,35 mm cross section

- maximum length of the cable 5 m

(standard part of DA control system delivery)

- 17 - silver wire

- 18 - red wire

- 19 - white wire

Time switch for

(DM), DA

Time switch for SM

1 2

22 23

Outdoor temperature sensor

17 18 19

PE

OPERATION

INSTRUCTIONS

1

1 2

DK DK

20 21

(

(

12/09 page 09

There are the following push buttons on the E/DM

controller for electric heater: The air curtain is

switched ON and OFF by push button A. The fan

speed is set by three buttons B, C, D, two levels of

electric heat exchanger output are set by buttons E,

F. Switching of the air curtain, set fan speed and set

output of electric heat exchanger are signalled by

diode light above each button. Electronic system

does not allow the unsuitable combination of push

buttons. It means that it is not possible to switch the

electric heat exchanger without switching the fans on

first. At minimum fan speed it is not possible to set

maximum output of electric heat exchanger (buttons

B and F together)!

When door switch is used, it overtakes the function of

switching the air curtain ON and OFF. In case the doors open, it ensures switching the air curtain ON with the pre-set fans

speed and level of electric output. After the door closes the air curtain remains ON for about 30 seconds and then it is

switched OFF. This function is here as a protection when of frequent switching ON / OFF at frequent passes through the

door. When the air curtain has been heating before it was switched OFF by the door switch, it will stay in operation for about

60 seconds. So about 30 seconds it will stay running with heater ON and for another 30 seconds just the fans will operate for

cooling of the electric heater.

Function - cooling the electric heater down

When the air curtain will be in operation including electric heater and the operator will switch it OFF by button A, just the

electric heater will switch OFF and the fans will remain working for about 30 seconds longer.

Water heater or no heater - type V/SM

Electric heating - type E/DM

There are the following push buttons on the V/DM

controller for water heating: The air curtain is

switched ON and OFF by push button A. The fan

speed is set by three buttons B, C, D. Switching of the

air curtain and set fan speed are signalled by diode

light above each button. In case door switch is used, it

overtakes the function of switching the air curtain ON

and OFF. When the door is opened, the control

system starts the air curtain with pre-set speed of

fans.

When the door closes, the door switch ensures

switching OFF of the whole air curtain after about 30

seconds. Any other switch, i.e. thermostat, time

switch, etc. can be used instead of door switch.

Air curtains with DM control system, with water

heating and without heating - type V/DM

ON / OFF

Fan speed 3 (maximum)

Fan speed 2

Fan speed 1 (minimum)

Heating power level 2 (maximum)

Heating power - level 1 (minimum)

Meaning of the symbols

ON / OFF

Fan speed 3 (maximum)

Fan speed 2

Fan speed 1 (minimum)

Meaning of the symbols

DM CONTROL SYSTEM

SM CONTROL SYSTEM

Electric heating - type E/SM

OPERATION

INSTRUCTIONS

The right for changes reserved ©2VV, spol. s r.o.

1

OFF

2

3

3 2

2 1

OFF

1

2

3

When door switch is used, it overtakes the function of

switching the air curtain ON and OFF. When the switch is in

any other position than “OFF”, the door switch switches the

air curtain ON again when the door is opened. When the

door closes, the door switch ensures switching OFF of the

whole air curtain. Any other switch, i.e. thermostat, time

switch, can be used instead of door switch.

When door switch is used, it overtakes the function of

switching the air curtain ON and OFF. When the switch is in

any other position than “OFF”, the door switch switches the

air curtain ON again when the door is opened. When the

door closes, the door switch ensures switching OFF of the

whole air curtain. Any other switch, i.e. thermostat, time

switch, etc. can be used instead of door switch.

AE F

B C D

A

B C D

There are the following push buttons on the E/DA

controller for electric heater: The air curtain is

switched ON and OFF by push button A. Automatic

operation mode is switched on by button B, manual

one by button C. The fan speed is set by three buttons

D, E, F, two levels of electric heat exchanger output

are set by buttons G, H. Switching of the air curtain,

set mode, set fan speed and set output of electric heat

exchanger are signalled by diode light above each

button. Electronic system does not allow the

unsuitable combination of push buttons. It means that

it is not possible to switch the electric heat exchanger

without switching the fans on first.

At minimum fan speed it is not possible to set

maximum output of electric heat exchanger

(buttons D and H together)!

Manual mode :

The functions are set by appropriate buttons marked

by graphic symbols in the manual mode (set by

button C). The connected external switches and

outdoor temperature sensor are ignored in this mode.

However, you can se the required fan speed by

buttons D, E, F and required output of the electric heat

exchanger by buttons G, H.

Automatic mode :

In the automatic mode (switched by button B)

depends the operation of the air curtain on the connected sensors /switches and the buttons D, E, F, G, H are inoperative.

How the function of the automatic control system for the air curtain with electric heater depends on the connected auxiliary

sensors/switches is clear from the following tables.

12/09 page 10

Electric heating - type E/DA

Meaning of the symbols

ON / OFF

Automatic mode

Fan speed 3 (maximum)

Fan speed 2

Fan speed 1 (minimum)

Filter clogged

Manual mode

Heating power level 2 (maximum)

Heating power - level 1 (minimum)

Overheating heater

Function of the air curtain with connected outdoor temperature sensor and without any other

external switches

Electronic control system controls the fans speed and the electric heater output according to the outdoor

temperature see following Table. Reading accuracy - +/-3°C.

Function of the air curtain with connected outdoor temperature sensor and with door switch

When the door switch is used, the electronic control system respects, if the door is opened or closed - see

following Table. When the door is closed, the electronic system sets the slowest speed and lowest heating

output. When the door opens, the fans speed as well as the heating output is increased according to the

outdoor temperature. When the doors are closed again, the automatic system reduces the speed of fans

to the original speed with about 30 seconds delay. When the door is opened within this time period, the

delay function is cancelled and reactivated after the doors are closed again. When manual mode is on, the

door switch and outdoor temperature sensor are ignored. Reading accuracy - +/-3°C.

Function of the air curtain with connected outdoor temperature sensor and with door switch and

with room thermostat

Best air curtain function and maximum power savings are ensured when of using of door switch in

combination with room thermostat and outdoor temperature sensor. Thermostat can be used also for air

curtains with water heat exchangers, where it does not control its output, it is true, but it ensures the

switching the air curtain OFF in case the required temperature in the room has been reached. Fans speed

and output of the electric heater are controlled by the electronic system, which evaluates the signals from

external switches and sensors see following Table. Reading accuracy - +/-3°C.

Outdoor temperature

5

°C 5

10

°C 10

15

°C

3. / 2. 2. / 2. 2. / 1.

Doors opened

Doors state

Doors closed 2. / 2. 1. / 1. 1. / 1.

15

20

°C

1. / 0

1. / 1.

20

°C

2. / 0

0 / 0

<

<

Fan speed level / Electric heater output level

Outdoor temperature

Fan speed level / Electric heater output level

5

< °C

3. / 2.

<

20 °C

2. / 0

5 10 °C

2. / 2.

10 15 °C

2. / 1.

15 20 °C

1. / 0

DA CONTROL SYSTEM

AUTOMATIC MODE - E/DA

CONTROL SYSTEM

AUT

°C

°C

°C

°C

OPERATION

INSTRUCTIONS

A

G

B

D

C

E F

H

12/09 page 11

There are the following buttons on the CV/DA

controller. The air curtain is switched ON and OFF by

button A. Automatic mode is set by button B, manual

one by button C. Fan speed in three levels is set by

buttons D, E, F. Switching of the air curtain, set mode

and set fan speed are signalled by diode light above

each button.

Manual mode :

The functions are set by appropriate buttons marked

by graphic symbols in the manual mode (set by button

C). The connected external switches and outdoor

temperature sensor are ignored in this mode. So you

can se the required fan speed by buttons D, E, F.

Automatic mode :

In the automatic mode (switched by button B)

depends the operation of the air curtain on the connected sensors /switches and the buttons D, E, F are inoperative. How

the function of the automatic control system for the air curtain with water heat exchanger depends on the connected

auxiliary sensors/switches is clear from the following tables. The output of the water heat exchanger must be regulated.

With water heater and with no heater - type V/DA

Function of the air curtain with connected outdoor temperature sensor and without further

external switches.

The electronic control system here controls the fan speed according to the outdoor temperature.

Reading accuracy - +/-3°C.

Function of the air curtain with connected outdoor temperature sensor and with door switch

When the door switch is used, the electronic control system respects, if the door is opened or closed -

see following Table. When the door is closed, the electronic system sets the slowest speed and lowest

heating output. When the door opens, the fans speed as well as the heating output is increased

according to the outdoor temperature. When the doors are closed again, the automatic system reduces

the speed of fans to the original speed with about 30 seconds delay. When the door is opened within this

time period, the delay function is cancelled and reactivated after the doors are closed again. When

manual mode is on, the door switch and outdoor temperature sensor are ignored. Reading accuracy -

+/-3°C.

Meaning of the symbols

Automatic mode

Manual mode

Filter clogged

Fan speed 3 (maximum)

Fan speed 2

Fan speed 1 (minimum)

ON / OFF

Outdoor temperature

5

°C 5

10

°C 10

15

°C 15

20

°C

3 2 2 1

Opened

Doors

Closed 2. 1 1 1

<

Fan speed level

<

20

2

0

°C

Outdoor temperature

5

<

<

°C 5 10 °C 10 15 °C 15 20 °C 20 °C

Fan speed

3

2 2 1 2

°C

AUTOMATIC MODE - V/DA

°C

°C

°C

Function of the air curtain with connected outdoor temperature sensor and with door switch

and with room thermostat

Best air curtain function and maximum power savings are ensured when of using of door switch in

combination with room thermostat and outdoor temperature sensor. Thermostat can be used also for

air curtains with water heat exchangers, where it does not control its output, it is true, but it ensures the

switching the air curtain OFF when the required temperature in the room has been reached. Reading

accuracy - +/-3°C.

reached

Pre-set temperature

on the thermostat

Doors

Opened 3. / 1. 2. / 1.

3. / 2. 2. / 2.

0 / 0 0 / 0

2. / 2. 1. / 1.

not reached Opened

reached Closed

not reached Closed

5 10 °C5 °C

<

Fan speed level / Electric heater output level

Outdoor temperature

2. / 1. 1. / 0

2. / 1. 1. / 0

0 / 0

0 0 /

1. / 1. 1. / 1.

10 15 °C 15 20 °C 20 °C

<

2. / 0

2. / 0

0 / 0

0 / 0

Function - cooling the electric heater down:

When the air curtain will be in operation including electric heater and the operator will switch it OFF by button A, just the

electric heater will switch OFF and the fans will remain working for about 30 seconds longer.

AUT

OPERATION

INSTRUCTIONS

The right for changes reserved ©2VV, spol. s r.o.

AB

D

C

E F

12/09 page 12

There are two levels of protection as standard part of any air curtain. The first one is the operation thermostat with automatic

reset and the second is the safety thermostat equipped with manual reset facility. In majority of overheating cases is the

protection ensured by the operation thermostat, which disconnects the electric heater from operation and after cooling down

connects its back automatically. This failure is not signalled anyhow on any type of controller. It can be recognised by means

that the air curtain does not heat although it should do so according to the setting of the controller.

The reasons of the overheating of the heater may be namely:

- Clogged filter and thus lower air flow - it is necessary to clean the filter (see “Air curtain maintenance”)

- Insufficient space in front of the inlet grille (see “ Principles of the air curtain location”) it is necessary to ensure proper

installation

- Failure of one or more fans in the air curtain - call the service centre to change the fan.

In any case of heater overheating it is necessary to find out the reason and to remove it. When it is a cause of any internal

failure in the air curtain, it is necessary to call the authorised service centre.

When when the safety thermostat is activated, the heater is disconnected , the air curtain stops to heat and when of DA

control system ALARM signal is ON on the control panel.

The cause of safety thermostat activation is usually just one:

- failure of operation thermostat - it is necessary to stop operation of the air curtain

completely, to disconnect it from mains and to call the authorised service centre. In no

case try to remove the defect yourselves !

After service of the air curtain (done by an authorised person), removal of the cause and

inspection or exchange of the operation thermostat, it is necessary to push the RESET

button located on this thermostat in the air curtain (e.g. by use of screwdriver). Remove the

grille first (see” Tilting of the grille”) and then push the reset button. - see Figure.

OVERHEATING OF

ELECTRIC HEATER

ALARM

OPERATION

INSTRUCTIONS

CHAINING OF THE AIR

CURTAINS

BUILDING MANAGEMENT

SYSTEM (BSM)

Chaining of the air curtains is possible just in case of DM and DA control systems. It is possible to interconnect up to 6 air

curtains, including the controlling (MASTER) one. When of chained air curtains, the function of controller and external

switch (door contact, thermostat, time switch) exactly the same as when of one air curtain.

Each air curtain has its own electric power supply. All chained air curtains operate in an identical mode.

Central control of air curtains:

It is possible to deliver a module to the air curtains equipped with DA control system, which

enables to connect the air curtain to the central control system of the building.

World standard LonWorks has been chosen for FINESSE air curtains. This system uses a

standard protocol LonTalk, thanks to that the air curtain with module supporting LonWorks

can operate round the world. Will you please call your supplier about the details and basic data

important for the integration into the system. When of chaining the air curtains, it is enough to

equip the MASTER air curtain with the LonWorks module.

Outdoor temperature

reached

Pre-set temperature

on the thermostat Doors

opened 3 2

3 2

0 0

2 1

not reached opened

reached closed

not reached closed

5 10 °C 10 15 °C5 °C

<

Fan speed level

2 1

2 1

0

0

1 1

15 20 °C 20 °C

<

2

2

0

0

Summary of the function of door contact for the run out of the air curtain

The air curtain has been switched off by the operator

Air curtain with water heating

Heating ON Heating OFF Heating ON / OFF

SM control system 0 s 0 s 0 s

DM control system about 30 sec (fans only - cooling down)

about 30 sec (fans only - cooling down)

0 s 0 s

DA control system

Manual mode / Automatic mode 0 s 0 s

Air curtain with water heating

Door closing Heating ON Heating OFF Heating ON / OFF

SM control system 0 s 0 s

DM control system 30 sec (standard run of the air curtain)

+ 30 sec(fans only - cooling down) = about 60 sec about 30 s

about 30 s

0 s

about 30 s

about 30 s

DA control system

Automatic mode 30 sec (standard run of the air curtain)

+ 30 sec(fans only - cooling down) = about 60 sec

Air curtain 1

DM or DA controller

Any switch (door contact, time switch, thermostat) - DM

Air curtain 2 Air curtain 3 Air curtain 6

MASTER SLAVE MASTER SLAVE MASTER SLAVE MASTER SLAVE

°C

DA

OFF

OFF

12/09 page 13

FAN OVERHEATING

CLOGGED FILTER SIGNAL

When one electric motor is overheated and thermo-contact stops it, other motors remain in operation. Thermo-contact is

automatic one, so when the motor cools down, the thermo-contact returns to its original position and the fan starts again.

This situation is not indicated on any type of control systems. This state can be recognised by reduced air curtain output and

in case the air curtain heats, the air flow temperature in the place of fan failure rises up. This failure cannot be considered to

be a normal one. It is necessary to check the air curtain and to find out the reason of fan failure. The reasons are usually as

follows:

- Clogged filter and thus lower air flow it is necessary to clean the filter (see “Air curtain maintenance”)

- Insufficient space in front of the inlet grille (see “ Principles of the air curtain location”) it is necessary to ensure proper

installation.

- Defective fan this is the less frequent cause. It is necessary to call the authorised service centre and to change the fan.

When a filter is clogged in any air curtain, signal FILTER appears (on DA type control systems only). In case the signal is on,

it means that the filter is clogged so it prevents the air curtain to operate properly and so it is necessary to clean or change the

filter. As to other control systems than DA, you recognise the clogged filter by its higher noise level and by reduction of its air

output (see “Air curtain maintenance”).

E

FILTER

USE AND SETTING OF TIME SWITCH

OPERATION

INSTRUCTIONS

After electric connection of time switch the shown keys have to be pressed simultaneously.

Reset (Total clearance of the time switch).

Just after the reset you have to decide how do you want to use the switch:

1. Switch OFF/ON in pre-set time intervals the same for all weekdays (use „Easy setting“)

2. Switch OFF/ON in pre-set time intervals depending on selected day(s) in a week

(use “Setting for individual selected day”).

HOW TO START ?

Electrical connection of the time switch shall be made by an authorized person according to the national regulations

and directives. Manipulations and modifications on the switch will result in loss of warranty.

Note: In spite of an internal safety control, unusual strong noise fields could cause a disturbance of the microprocessor-

controlled time switch.

Interference can be avoided if the following details are considered during installation :

- the device should not be installed close to inductive consumers

- there has to be layed a separate line for the mains supply (if necessary mains suppresion filter)

- inductive consumers should have to be interference suppressed (varistor, RC-section)

After having cleared the interference a reset of the time switch is necessary.

Current time/

switch ON/OFF time

Weekday(7 = Sunday)

Hours setting

Weekday setting

Time setting

Program entry / recall

Response time number for the weekday

indicated (1 ON, 1 OFF, 2 ON, 2 OFF,

3 ON, 3 OFF) H = Holiday program

The point indicates permanent

control ON or OFF

Indication of actual switch position

ON = Switch ON, OFF = Switch OFF

Minutes setting

Switching between automatic or

manual control

INSTALLATION

d h m

h

For return from program mode you can choose these two ways :

1. press button

2. if there is no interruption (no action) on time switch for 40 seconds it returns automatically

For possibility of choosing between two basic settings (see “How to start”) you have to first press Reset.

CONTROL PRINCIPLE

After Reset is done you can set the current time. You need to keep the button + press >>h<< (for setting hours) and

press >>m<< (for setting minutes). Arrow that displayes actual selection of the day will appear above symbol 1-7.

Attention: If you want to use “Easy setting” (see point 1 in chapter “How to start”) do not

press button >>d<< during setting the time !

This easy program offer 6 different pre-set time intervals Switch ON/Switch OFF

(6 ON/OFF) without selection of the weekday. These pre-set time intervals will repeat every day the same.

EASY SETTING (1-7)

DS 1800

1 2 3 4 5 6 7 1 7

DS 1800

TIME GUARD

1 2 3 4 5 6 7 1 7

d h m

h

H

OFF

The right for changes reserved ©2VV, spol. s r.o.

12/09 page 14

OPERATION

INSTRUCTIONS

After Reset is done you can set the current time and current day (this is the difference from “Easy setting”). You need to

keep the button + press >>h<< (for setting hours), >>m<< (for setting minutes) and >>d<< for selection of weekday.

Actual selection of weekday is displayed by moving of arrow above numbers of the weekday (7 = Sunday). It is possible

to pre-set 4 different time intervals Switch ON/Switch OFF (4 ON/OFF) for the weekdays.

For entry into the program mode you have to press >>p<<. With itteration of this button you

continue to step between ON (Switch ON) and OFF (Switch OFF) in selected time interval

and other intervals also. Order of time intervals and the state Switch ON/ OFF is displayed

on the right side of the time.

PROGRAMMING

SETTING FOR

INDIVIDUAL SELECTED

DAY

DS 18

1 2 3 4 5 6 7 1 7

1

OFF

ON

If you have selected “Easy setting” at the beginning, then for selection of the time for the selected time interval press

>>h<< (for setting hours) and >>m<< (for setting minutes). But if you have selected “ ”,

then first you have to select the weekday(s) in current time interval press >>d<<, blinking

arrow will move above selected weekday. For confirmation of selection

press and arrow will stop blinking (weekday is entered). If you need the same interval for

more weekdays press >>d<< again and confirm with pressing .

After selection of weekday(s) you will continue with setting of the time for the interval.

Setting of the time is the same as in chapter (“Easy setting”). For recall of pre-set time intervals press button >>p<<.

Attention: There are in general 4 time intervals ON/OFF for all weekdays. Each time interval can be choosen for one or

more weekdays. But it is not possible to set one of the intervals different for Monday or Saturday (interval is the same).

For example if you set the first time interval on 15:30 ON and 18:00 OFF for selected weekdays it is already reserved and

it can not be used for other days in different time (for that you have 3 more time intervals).

Recall, change or clearance

For entry into program mode and listing between time intervals press >>p<<. Change of the weekday press >>d<< and

select another day or pass already selected to cancel it. Confirm selection by pressing . If you need to clear whole time

interval, simultaneously press >>h<< + >>m<<. Afterwards press .

Setting for individual selected day

DS 18

1 2 3 4 5 6 7 1 7

1

OFF

ON

It is used to interrupt pre-set time intervals from 1 up to 45 days. In basic state with dispaying of current time press button

>>h<< and keep it. Display shows 00. Additionally pressing you step up the days. The holiday program starts at 00:00

h of the following day and is indicated by >>H OFF<<.

After set period is gone the switch will automatically continue in pre-set intervals in

automatic mode. During holiday program you can change the length (numbers of the day)

or cancel It by setting to 00. Recall of setting holiday period press >>h<<.in basic state with

current time.

SETTING OF HOLIDAY

PROGRAM

It is possible to control Switch ON/OFF of the switch manually. The time switch must be in basic state with current time. By

pressing you switch between ON/OFF. Keep pressing button + press step by step >>m<< and you will change

between states “Permanently ON”, “Permanently OFF”, “Automatic mode with pre-set intervals ”.

PERMANENT CONTROL

Summer (changeover + 1 hour press) >>d<< + >>h<< simultaneously.

Winter (changeover - 1 hour: press) >>d<< + >>m<< simultaneously.

SUMMER / WINTER

MODE

L

1 L2 N

M

~

N

DS 1800

1 2 3 4 5 6 7 1 7

ON

Permanently ON

DS 1800

1 2 3 4 5 6 7 1 7

OFF

Permanently OFF

DS 1800

1 2 3 4 5 6 7 1 7

OFF

Automatic mode with

pre-set intervals

DS 18

1 2 3 4 5 6 7 1 7

ON

d h m

h

1

2

12/09 page 15

We do recommend at least after half a year of the operation (according to conditions

more early) to inspect the air curtain and to clean the filters from dust and to clean the

dust from the inner space of the air curtain. In case of lack of that maintenance the

efficiency and durability of the air curtain may be reduced !

The air curtains equipped with the DA control system there is FILTER signal on the

controller. In case this signal is ON, it means the filter is so clogged that the proper

function of the air curtain is endangered and so it is necessary to clean or even replace

the filter. As to other control systems than DA, you recognise the clogged filter by its

higher noise level and by reduction of its air output. Filter is fitted to the inlet cover.

Disconnect the air curtain from the mains before any service works !

Exchange of the filter:

- Tilt the grille (see “Tilting of the grille”)

- Remove the filter from the inner part of the grille

- Change the filter, wash it in detergent or clean the dust by vacuum cleaner (see Fig.)

With respect to the technical design of the air curtain it is easy to change the water or

electric heat exchanger, to change fan or transformer of the air curtain. However all these

works must be done by authorised and trained person only.

Disconnect the air curtain from the mains before any service works !

In case you need to access the fans or to the transformer, the following works are

to be done:

- Tilt the grille (see “Tilting of the grille”)

- by using Philips screwdriver remove the steel sheet holder with electronic system or

interconnecting terminal board and move it out a piece.

- By using Philips screwdriver release the bolts which fix the heater and tilt it out (see

Fig.) In case of water heater, the water must be drained out and disconnected from the

interconnection hoses.

- Warranty service and regular service must be ensured by either the supplier or by

some of the authorised service organisations, the list thereof is available at the

supplier. Ordering the service, it is necessary to describe the trouble and to announce

the data from index plate.

- Standard 24 months warranty period is granted for FINESSE air curtains

SERVICING INSIDE THE

AIR CURTAIN

SERVICE

WARRANTY

AIR CURTAIN MAINTENANCE

OPERATION

INSTRUCTIONS

TECHNICAL DATA Operating voltage: 230V, +/- 10%

Mains frequency: 50Hz

Own consumption: max. 7VA

Contact rating: 10 A, 250V ~ , cos n =1 // 2 A, 250V ~ , cos n = 0.6

Time base: quartz

Memory locations: 4/6 (week 4 ON/OFF, week 6 ON/OFF)

Minimal switching interval: 1 minute

Accuracy: =< +/- 2 seconds / day at 20°C

Admisible ambient temperature: from - 10°C up to + 40°C

Type of enclosure: IP 20 as per EN60529

Ensure that the power supplied to the product is within the specified voltage range of the product.

The time switches are in accordance witth European directives 73/23/EEC (Low-Voltage Directive) and 89/336/EEC

(EMC-Directive). If the time switches are used together with other devices in an installation, take care that the complete

installation does not cause a radio interference.

The right for changes reserved ©2VV, spol. s r.o.

12/09 page 16

Manufacture of FINESSE air curtains is very well controlled. There are many inter-operations inspections during the

process and the final inspection at the end, when all the functions of the air curtains are checked. After the functionality of the

air curtain is proven, then it can be dispatched to the customer. Our experience show that 99% of the claims is caused by

incorrect installation or connection. So it is necessary the air curtains are installed by persons acquainted with this manual

and the electric connection or water heat exchanger connection is done by authorised and specialised person.

Future troubles can be thus avoided.

Disconnect the air curtain from the mains before any service works !

General inspection when of malfunction.

1. Check the electric wiring, if it conforms to diagram in this manual or to that on the air curtain case.

2. Check the mains. Measure the voltage and current, if they conform to these on the index plate (on the air curtain case).

The zero conductor must be connected, too!

3. Check if any wire is not loose from the terminal.

4. Check if the connectors of the cable between controller and control electronic board properly fit to the connecting sockets

and if the correct connector (“CONTROL”) is used on the board (DA, DM versions). Try to use other cable supplied by the

manufacturer and try the function of the air curtain again (DA, DM) When the air curtain still does not work, change the

controller and try the air curtain again. Check the connection of wires into the controller at SM control type (the numbers of

terminal boards must fit) according to the wiring diagram.

5. There is a fuse in a holder on the connecting board. The rated value is printed ot the sticker below it. Remove the fuse by

using of screwdriver and check if blown. If so, change it for another one of the same rated value (see Fig.)

6. There is a fuse on the electronic board. Check if blown. If so, change it for another one of the same electric value.

7. Check all installation preconditions according to this manual are kept.

8. When all the effort to start the air curtain failed, call to the authorised service centre and provide them with all possible

details, e.g. type of the air curtain, type of control system, place of installation, mechanical and electrical conditions of

installation, duration of operation, etc.

Do not ever try to interfere into internal wiring of the air curtain or to modify any component thereof to avoid

permanent damage to the air curtain !

Other possible defects and troubles:

Air curtain blows but does not heat ?

This could happen under certain circumstances in case the air curtain is equipped with DA control system and is running in

automatic mode. Exact description of single states can be found in chapter “Air curtain operation”

- The other possible cause of malfunction of the electric heater is that the operation thermostat with automatic reset has

switched the overheated heater off. This situation is not indicated on any type of control systems. When the heater cools

down, it is automatically restarted. In any case, it is necessary to find the reason of overheating, which can be namely:

- Non-keeping of recommended distances at installation of the air curtain (see “ Conditions of operation and safe

function”.

- Clogged filter. It is necessary to clean or replace the filter (see “Air curtain maintenance”)

- Defective fan. It is necessary to call the authorised service centre and to change the fan.

- Just one phase connected. It is necessary to connect the air curtain to all three phases according to the wiring diagram.

The air curtain dos not provide enough amount of air ?

This situation can happen in case the thermo-contact of one of the fans stops its operation due to overheating or the fan itself

is damaged. It is necessary to remove the cause or replace the fan this must be done by authorised person only.

Filter may be clogged. This defect announces itself by higher noise level generated by the air curtain. It is necessary to clean

the filter or replace it (see “Air curtain maintenance”). Other possible cause of that may be the non keeping of the

recommended distances at installation of the air curtain (see “ Conditions for safety and proper function of the air curtain”).

Air curtain does not blow air at all ?

This could happen under certain circumstances in case the air curtain is equipped with DA control system and is running in

automatic mode. Exact description of single

states can be found in chapter “Air curtain operation”. The other possible cause of this malfunction is the defect of

transformer in the air curtain. This is often accompanied by bad smell coming out from the air curtain. Check the transformer,

in case of the defective one it must be changed by authorised person only. Also could happen that all the fans are

overheated or broken. However this is very rare case.

Controller to the air curtain does not work ?

Check proper wiring to the controller. When of SS control system check the connection of all wires to the proper terminals.

Often two cables can be exchanged and in such a case the controller does not work. When of DM and DA control systems it

“CONTROL” is necessary to connect the control cable to CONTROL terminal on the electronics board. Notice: Do not

connect to SLAVE terminal. Always use original cable delivered by the manufacturer for interconnection of DM and DA

controllers. Check the cable if it is not damaged (see “GENERAL INSPECTION”).

TROUBLESHOOTING

OPERATION

INSTRUCTIONS

Terminal board

(SM)

Cable from controller

to “CONTROL” at DM, DA

Fuse on the electronic

board

Main fuse

CLICK

Wiring diagram

12/09 page 17

Can the controller be connected to the air curtain by more than 50 m ?

When there is longer interconnection cable, it always depends on the local conditions. Control cable should be never laid

together with the power ones. It should be laid from them at least in a distance prescribed by the standard to avoid jamming.

In case of extreme distances it is possible to ask for delivery of cable with higher shielding level.

How will an air curtain behave, when one of the sensors is wrongly connected ?

It is the same like there is no sensor. Just in case of door contact, which is connected wrong and the control system is of SM

type, the air curtain will operate like the door is opened.

Hight noise and reverberation of the air curtain ?

This defect could be recognised in lower air volume, unpleasant metal sound and reverberations. The main cause of this

problem is clogged filter. In some applications the filter can be clogged after one week. The clogged filter is indicated on the

diod placed on the remote control of DA regulation (see “AIR CURTAIN MAINTENANCE”).

If there is vibrating of the air curtain, scrub of the impeller, smell of melting isolation or you have found leaking of

the water exchanger you must switch Off the air curtain immediately and call the service !!!

OPERATION

INSTRUCTIONS

WIRING DIAGRAMS

SM

DM, DA

N PEL

1~ 230V

MAIN POWER SUPPLY DOOR CONTACT

L1

L1

3~ 400V

L3 N

NL3

L2

L2

0 V, INPUT

PE

PE

max.8 mA

20 21 2322

EXTERNAL CONTACT

OFF=OFF

ON=ON

max.8 mA

0 V, INPUT 0 V, INPUT

TIMER

AIR CURTAIN

2726

ROOM THERMOSTAT

TEMPERATURE

ON=UNDER

OFF=OVER

max.8 mA

T (°C)

OUTSIDE TEMPERATURE

SENSOR

5V DC, INPUT

1918

T (°C)

17

white

brown

silver

5 m

5V DC, OUTPUT

6

max.50 m

SLAVE CURTAIN

(CONTROL)

MASTER, CURTAIN

+1(SLAVE)

MASTER, CURTAIN

(CONTROL)

PANEL

max.50 m

6

24V DC, INPUT

max.3,5mA

max.12mA

DM DA

PWM signal

INPUT

LONWORKS

NETWORK

LON LON

TWISTED

PAIR

°C

°C

1 2..

OFF=DOOR OPEN

ON=DOOR CLOSED

MAIN POWER SUPPLY

L3L2L1 PEN

L3L2L1 PEN

3~ 400V

1~ 230V L N PE

DK2

DK1

Door contact

230V~, Input

max.10 A

AIR CURTAIN

ON=DOOR OPEN

OFF=DOOR CLOSED

A B C D

VCS x-10S,V,W- 3 x 0,5 3 x 0,5 3 x 0,5 3 x 0,75

VCS x-15S,V,W- 3 x 0,5 3 x 0,5 3 x 0,5 3 x 1,5

VCS x-20S,V,W- 3 x 0,5 3 x 0,5 3 x 0,75 3 x 2,5

VCS x-10E- 5 x 2,5 5 x 2,5 5 x 2,5 -

VCS x-15E- 5 x 4 5 x 6 5 x 6 -

VCS x-20E- 5 x 6 5 x 6 5 x 6 -

Version

Type of air curtain

List of cables used for the main power (number of wires (pieces) x diameter of wire (mm2))

All the wiring diagrams displayed in the manual are only informative. When assembling the product follow exclusively the label

values, instructions and diagram placed directly on the product, or supplied with the product.

VCS-F-B...E, VCS-F-C...E

CONTROL PANEL CP-SM-E2-2

a - 1

b - 2

c - 3

d - 4

e - 5

f - 6

012345

x

x

x

xxxx

x

x

xx

x

f

e

d

c

b

a

6

5

4

3

2

1

42 31 6 7

DK

5

max 10A

VCS-F-B...W, VCS-F-C...W

CONTROL PANEL CP-SM-V-2

a - 1

c - 3

d - 4

f - 6

1234

x

x

1

3

4

6

42 31

xxx

x

max 10A

5

a

c

d

f

230V~, INPUT

230V~, INPUT

Luftschleier FINESSE

BEDINGUNGEN FÜR

DIE SICHERHEIT UND

DAS FUNKTIONIEREN

DES LUFTSCHLEIERS

UMWELTSCHUTZ

MONTAGEANLEITUNG

KONTROLLE NACH DER

LIEFERUNG

Die vorliegende Bedienungsanleitung enthält wichtige Informationen und Sicherheitshinweise. Um die richtige

Funktionsweise und eigene Sicherheit gewährleisten zu können, sind vor der Montage des Luftschleiers die

nachstehenden Hinweise durchzulesen und zu beachten ! Der Hersteller behält sich das Recht auf Änderungen inkl.

technischer Dokumentation. Die am Produkt befindlichen Schaltbilder haben Vorrang vor den Schaltbildern aus dieser

Anleitung ! Irgendwelche Änderungen oder Angriffe in die innere Schaltung sind nicht zugelassen und haben Verlust der

Garantie zu Folge. Wir empfehlen das von uns gelieferte Zubehör zu verwenden. Falls ein anderes Zubehör bzw. andere

Regelung als Original verwendet wird, kann dies zur Beschädigung des Produktes führe. Der Hersteller trägt keine

Verantwortung für Schäden, die durch die Benutzung von nicht-originalem Zubehör (nicht- originaler Regelung) oder

durch unsachgemäße Benutzung des Zubehörs oder der Regelung verursacht wurden. Zur Steuerung der Drehzahl der

Ventilatoren kann kein Frequenzumrichter verwendet werden.

- Unsere Gesellschaft arbeitet stets an der Entwicklung neuer Technologien und Lösungen mit dem Ziel, die Energie

einzusparen und die Naturschätze zu erhalten, und somit einen positiven Beitrag zur Milderung der Umweltbelastung in

effektiver Weise zu leisten.

- Machen Sie das Gerät unbrauchbar, bevor Sie es entsorgen. Auch alte Luftschleier enthalten Rohstoffe, die wieder

verwendbar sind. Es ist empfehlenswert, das Gerät bei einer dafür spezialisierten Stelle entsorgen zu lassen; dann

können wiederverwendbare Materialien zum neuen Einsatz kommen.

- Der Luftschleier befindet während des Transports in einer Schutzverpackung. Alle benutzten Verpackungsmaterialien

sind umweltfreundlich und erneut verwendbar oder verwertbar. Leisten Sie einen aktiven Beitrag zum Umweltschutz,

indem Sie auf die richtige Entsorgung und die Wiederverwertung der Verpackungsmaterialien achten.

- Damit alle Funktionen voll ausgenutzt, die Energie eingespart und eine lange Nutzungsdauer des Luftschleiergerätes

gewährleistet werden können, sollten die in dieser Anleitung aufgeführten Weisungen beachtet werden.

- lesen Sie, bitte diese Anleitung durch, bevor Sie mit der Montage beginnen und das Gerät benutzen, und beachten Sie

die in ihr genannten Hinweise. Hier finden Sie nicht nur wichtige Informationen für die Montage und den Einsatz sondern

auch jene, die die Sicherheit und die Wartung des Luftschleiers betreffen.

- in unmittelbarer Nähe des Gerätes sowie in einem Abstand bis zu 100 mm nach allen Richtungen können sich nur

feuerfeste Materialien befinden (sie brennen nicht, glühen nicht, verkohlen nicht) oder schwer entflammbare

Gegenstände (sie brennen nicht, glühen und verkohlen überwiegend - z.B. Gipskarton). Diese Materialien dürfen jedoch

die Saug- und Ausblasöffnungen nicht verdecken. Für den sicheren Abstand der entflammbaren Stoffe von den

elektrischen Produkten gelten landesspezifische technische Normen.

Für einen sicheren Abstand der Oberflächen von Bauwerken, des Bodenbelags und der Gegenstände aus brennbaren

Materialien zum Luftschleiergerät mit Elektroheizung gilt:

- die sichere Entfernung der brennbaren Stoffe in Richtung Lufthauptstrom (hinter dem Ausblasspalt) beträgt 500 mm

- die sichere Entfernung der brennbaren Stoffe oberhalb des Luftschleiers ist 500 mm

- die sichere Entfernung der brennbaren Stoffe in anderen Richtungen beträgt 100 mm

- nehmen Sie einen defekten Luftschleier nie in Betrieb.

- die Montage und der Anschluss des Luftschleiergerätes muss von einer qualifizierten Person entsprechend der

Montageanleitung und den einschlägigen Richtlinien durchgeführt werden. Bei Nichtbeachtung dieser Anleitung und

Richtlinien besteht die Gefahr, dass Ihrerseits keine Garantieansprüche mehr geltend gemacht werden können.

- die Anleitung sollte für evtl. weitere Benutzer sorgfältig aufbewahrt werden.

- die Luftschleier Finesse sind für den Betrieb in trocknen Innenräumen mit Umgebungstemperaturen von 0°C bis +40°C,

für den Transport von Reinluft ohne Fettgehalt, Chemikaliendämpfe und andere Verunreinigungen gedacht.

- die relative Luftfeuchte sollte 80% nicht überschreiten.

- die elektrische Schutzart des Luftschleiergerätes mit Ansauggitter ist IP20.

- das Bedienpersonal sollte unterwiesen und mit dieser Anleitung vertraut gemacht werden.

- wurde das Gerät bei Temperaturen transportiert, die von den Betriebstemperaturen unterschiedlich sind, so ist es

ausgeschaltet unter den Einsatzbedingungen mindestens 1 Stunde zu belassen, damit es im Geräteinneren zum

Temperaturausgleich kommen kann.

- bei Einrichtungen, die für die ~400V-Spannung bestimmt sind, muss sich im Sinne der Anforderungen der EN 292-

2+A1:2000, EN 60335-1:1997 in deren Nähe ein Schlüsselschalter mit einem Kontaktmindestabstand von 3 mm

befinden, sofern der Anschluss nicht mittels Gabelstecker erfolgt.

- An die Stromzuleitung muss der Hauptschalter gelegt werden, der alle Netzpole trennt.

Für den Transport wird ein Holzlattenverschlag verwendet, der das Luftschleiergerät gegen Transportschaden schützt. Bei

der Handhabung sind mechanische Schäden am Produkt zu vermeiden - z.B. durch Herunterfallen. Das Luftschleiergerät

ist mit einem trocknen Innenraum mit 0 bis +40°C Umgebungstemperatur zu lagern.

- nach Eingang des Gerätes prüfen Sie dessen Verpackung auf Beschädigungen.

- vergleichen Sie die Angaben auf dem Verpackungsetikett mit dem von Ihnen bestellten Produkt. Stimmen die Angaben

auf der Etikette nicht, oder weist die Verpackung Beschädigungen auf, so packen Sie das Gerät bitte nicht aus, teilen Sie

den Schaden sofort dem Lieferanten mit und bei beschädigter Verpackung ziehen Sie den Frachtfü

hrer hinzu. Bei nicht rechtzeitig geltend gemachter Reklamation, können später keine Garantieansprüche erhoben

werden.

- prüfen Sie die Übereinstimmung der technischen Daten auf dem Typenschild. Stimmen die Daten nicht, dann verfahren

Sie nach dem vorhergehenden Punkt.

DE

12/09seite 01

Änderungsrechte vorbehalten ©2VV, spol. s r.o.

BESCHREIBUNG DES

LUFTSCHLEIERGERÄTES

LUFTSCHLEIERARTEN

* Die Werte werden bei einer Lufteintrittstemperatur von +18°C und einem Temperaturgefälle von 90/70°C / 80/60°C gemessen

** Schalldruckpegel im Abstand von 3 Metern sauseitig gemäß EN-ISO 3743-1 und EN-ISO 3744.

Die Werte gelten für den maximalen Luftstrom.

Kabeldurchfüh-rungen für die

Hauptzuleitung

Öffnungen zum

Aufnehmen der

Gewindestangen

Reset-Taste zum

Ansprechen des

Temperaturbegrenzers

mit manuellem Reset

(el. Version siehe

„Überhitzung des

elektrischen

Heizregisters“)

Halterungen zum Öffnen

des Gitters mit Hilfe des

flachen Schraubenziehers

Ventilatoren des

Luftschleiers

Elektrischer oder

Wasserheizregister

aufklappbar

Anschluss des

Wasserheizregisters

von der Seite G 1*

Trafo für die Ventilatoren,

bzw. Presostat, der die

Filterverstopfung meldet

Klemmenleiste für den

Anschluss der Hauptzuleitung

und Steuerplatine

[m] [m3/h] [kW] [dB(A)]** [V/Hz] [A] [kg]

VCS -F-B-10S 2240

VCS -F-B-15S 3360

VCS -F-B-20S 4480

VCS -F-B-10E 2220

VCS -F-B-15E 3330

VCS -F-B-20E 4440

VCS -F-B-10V 2180

VCS -F-B-15V 3270

VCS -F-B-20V 4360

VCS -F-B-10W 2150

VCS -F-B-15W 3230

VCS -F-B-20W 4300

VCS -F-C-10S 2860

VCS -F-C-15S 3990

VCS -F-C-20S 5040

VCS -F-C-10E 2790

VCS -F-C-15E 3890

VCS -F-C-20E 4920

VCS -F-C-10V 2680

VCS -F-C-15V 3740

VCS -F-C-20V 4720

VCS -F-C-10V 2610

VCS -F-C-15V 3640

VCS -F-C-20V 4600

-

-

-

9,0

13,5

18,0

18,5/15,1*

29,4/24,1*

40,7/33,4*

25,2/20,6*

40,9/33,9*

54,5/45,2*

-

-

-

9,0

13,5

18,0

20,7/16,9*

31,7/26,0*

42,6/35,0*

28,4/23,2*

44,1/36,5*

56,9/47,1*

54,8

58,9

60,5

54,8

58,9

60,5

53,6

57,4

58,6

53,6

57,4

58,6

55,6

59,5

60,9

55,6

59,5

60,9

54,7

57,9

58,9

54,7

57,9

58,9

230/50

230/50

230/50

400/50

400/50

400/50

230/50

230/50

230/50

230/50

230/50

230/50

230/50

230/50

230/50

400/50

400/50

400/50

230/50

230/50

230/50

230/50

230/50

230/50

2

3

4

15

22,5

30

2

3

4

2

3

4

3

4

5

16

23,5

31

3

4

5

3

4

5

21

34

48

25

37

51

27

41

57

29

43

60

24

37

51

28

40