Fintek iCOOL User manual

Soluzioni per il benessere ed il risparmio

www.finteksrl.com

TECHNICAL MANUAL

ICOOL/IWARM

Be

f

ore installin

g

the air conditione

r

care

f

ull

y

read the instruction

s

iCOOL/iWARM

Pompe di Calore Monoblocco

ad Alta Efficienza

Index

Index

1. Main Features

2Certification( C )

2.

3. Overall Dimensions

4. Explosion view and parts list

5. Rated technical data

6

Elbl

6

.

E

nergy

l

a

b

e

l

7. Installation

8. Electric wiring

9. Description of software operation

10

Pi

10

.

P

recaut

i

on

11. Ordinary maintenance

12. Problem and solution

1.Main features

Double ducted machine is different with the normal split type air conditioner, and there is no outdoor

unit, and installed with high wall. It is a special solution for commercial and residential buildings.

Th t i

d t t li i t it b h d ff t l k t th b ildi l

Th

e

t

w

i

n-

d

uc

t

sys

t

em e

li

m

i

na

t

es secur

it

y

b

reac

h

es an

d

o

ff

ers a grea

t

l

oo

k

t

o

th

e

b

u

ildi

ng, as on

l

y

2x200mm holes are required.

The benefits of no outdoor unit are: no sleeve, no louvers and no rust, ensuring low cost installation

and maintenance. The heat pump provides low operating costs when in heating mode.

• R410a gas, friendly refrigerant with high efficiency ozone.

•

Auto water evaporation in cooling and heating mode

Auto

water

evaporation

in

cooling

and

heating

mode

• Intelligent control technology.

• High-efficiency cooling and heating performance.

•Silent operation

• Full function LCD remote control

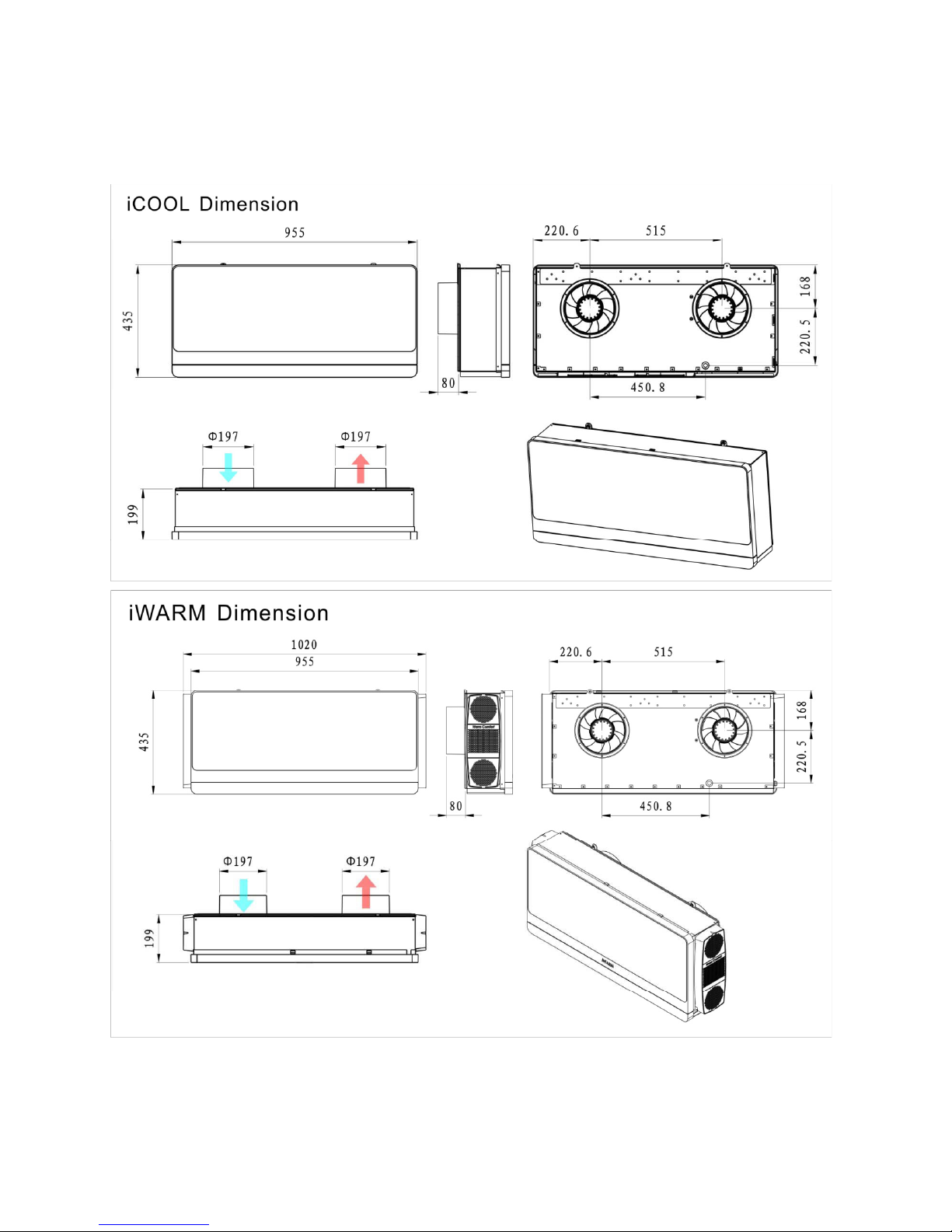

3. Overall Dimensions

Note : The external pipes are same, Ø197mm .

4. Explosion view and parts list

4.1 iCOOL Explosion view

iCOOL Parts list

No. in Explosive

View ),17(. code BOM English Name Qty

1 R133140024 Compressor and accessory 1

2 R122050360 Condenser assy. 1

3 R122060135 Capillary assy. 1

4 R122010207 Evaporator assy. 1

5 R122120281 4-way valve assy. 1

6 R131040178 Indoor motor 1

7 R131040175 Anticlockwise condenser fan 1

Cf

8 R131040176

C

lockwise condenser

f

an 1

9R131060068 Step motor (panel) 1

10 R131060066 Step motor (plap) 1

11 R131010509 Main PCB 1

12 R131160054 Compressor capacitor 1

13 R127030254 Compressor capitor holder

14

R131030006

3

way terminal block

1

14

R131030006

3

-

way

terminal

block

1

15 128060209 Wire protection ring 1

16 R131130003 Condenser fan capacitor 2

17 R139010035 Power plug protection ring 1

18 R132040139 Power plug 1

19 R128030549 PMMA 1

20

R128030543

Front panel

1

20

R128030543

Front

panel

1

21 R128030545 Front frame 1

22 R128030555 Outlet frame 1

23 R128030557 Flap1 1

24 R128030572 Flap2 1

25 R138140752 Insulation material for flap1 1

26 R128030547 Ste

p

motor box 1

p

27 R128030550 Linkage 1

28 R128030551 Connecting rod 1

29 R128030552 Coupler 1

30 R128030554 Short pin 2

31 R128030553 Long pin 5

32 R128030548 Air filter 1

33 R128030561 Outside grille 1

34 R128030286 Axis sleeve 2

35 R128050021 Tangential fan 1

36 R139050004 Axletree seat 1

37 R128060423 Bottom EPP 1

38 R128060422 Upper EPP 1

39 R128060424 Condenser cover EPP 1

40 R128060427 Front cover EPP 1

41 R128060426 Evaporator cover EPP 1

42 R128060425 Water cover EPP 1

43 R140140071 Bottom metal assy. 1

44 R127020799 Compressor installation plate 1

45 R127041004 Right metal plate 1

46 R127030288 Electrical box 1

47 R127020823 Support plate 1

48 R127080061 Wall bracket assy. 1

49

R127020801

Back metal plate

1

49

R127020801

Back

metal

plate

1

50 R127020803 Top metal plate 1

51 R127041005 Left metal palte 1

52 R127020796 Evaporator motor support 1

53 R127020798 Indoor motor holder 2

54 R138140753 Insulation material for flap2 1

55 R138140699 Bottom plate sponge 1

56 R138140700 Compressor bottom sponge 1

57 R138140725 Front cover EPP sponge 1

58 R138140716 Electrical box top sponge 1

59 R138140717 Electrical box side sponge1 1

60 R138140718 Electrical box side sponge2 1

61 R138140724 Right metal plate sponge 1

62 R138140696 Condenser insulation s

p

on

g

e1

pg

63 R138140698 Evaporator insulation sponge 1

64 R138140729 Wall bracket insulation sponge 1

65 R138140701 Back metal plate sponge 1

66 R138140573 Capacitor sponge 1

67 R138140723 Condenser fan insulation sponge 1

68 R138140720 Outlet frame sponge1 1

Of

69 R138140721

O

utlet

f

rame sponge2 1

70 R138140705 Top metal plate sponge 1

71 R138140706 Condenser cover EPP sponge 1

72 R138140704 Left metal palte sponge 1

73 R138140726 Front cover insulation sponge 1

74 R138140727 EPP insulation sponge 1

75 R139010076 Water plug 1

76 R128070006 Drainage pipe 1

77 R131020097 LED display 1

78 R131170067 Remote control 1

79 R128040261 Remote control seat 1

80 R131100001 Battery 2

4.2 iWARM Explosion view

No. in Explosive

View ),17(. code BOM English Name Qty

iWARM Parts list

1 R128030549 PMMA 1

2 R128030543 Front panel 1

3 R128030554 Short pin 1

4 R128030552 Coupler 2

5 R128030548 Air filter 1

6 R128030553 Long pin 5

7 R131020097 LED display 1

8 R128030545 Front frame 1

9 R128030547 Step motor box 1

10 R128030550 Linkage 1

11 R128030551 Connectin

g

rod 1

g

12 R131060068 Step motor (panel) 1

13 R128030557 Flap1 1

14 R128030572 Flap2 1

15 R128030555 Outlet frame 1

16 R131060066 Step motor (plap) 2

17 R127041116 Right metal plate 1

18 R131040178 Indoor motor 1

19 R127020796 Evaporator motor support 1

20 R127020798 Indoor motor holder 2

21 R128060423 Bottom EPP 1

22

R128050021

Tangential fan

1

22

R128050021

Tangential

fan

1

23 R122010207 Evaporator assy. 1

24 R128060422 Upper EPP 1

25 R128060427 Front cover EPP 1

26 R127020823 Support plate 1

27 R140140071 Bottom metal assy. 1

28 R127020799 Compressor installation plate 1

29 R128060425 Water cover EPP 1

30 R128060426 Evaporator cover EPP 1

31 R122060135 Capillary assy. 1

32 R133140024 Compressor and accessory 1

33 R122120281 4-way valve assy. 1

34

R122050360

Condenser assy

1

34

R122050360

Condenser

assy

.

1

35 R127030288 Electrical box 1

36 R131160054 Compressor capacitor 1

37 R127030254 Compressor capitor holder 1

38 R131030006 3-way terminal block 1

39 R131130003 Condenser fan capacitor 2

40 R131010509 Main PCB 1

41 R132040139 Power plug 1

42 R127041117 Left metal palte 1

43 R128060424 Condenser cover EPP 1

44 R127020803 Top metal plate 1

4

5

R127

0

2

080

1B

ac

k m

eta

l

p

l

ate

1

5

0 080

ac eta p ate

46 R131040175 Anticlockwise condenser fan 1

47 R131040176 Clockwise condenser fan 1

48 R138140701 Back metal plate sponge 1

49 R128030561 Outside grille 2

50 R128070006 Drainage pipe 1

51 R131170148 Remote control 1

52 R128040261 Remote control seat 1

53 R131100001 Battery 2

54 R127041118 PTC heater cover 2

55 R122230031 PTC heater assy. 2

56 R131050102 12VDC fan blade 4

57 R128040450 PTC fixing plastic box 2

58 R128020543 PTC air filter 4

59 R128020519 PTC inlet grille 4

60 R127090128 PTC protection net 2

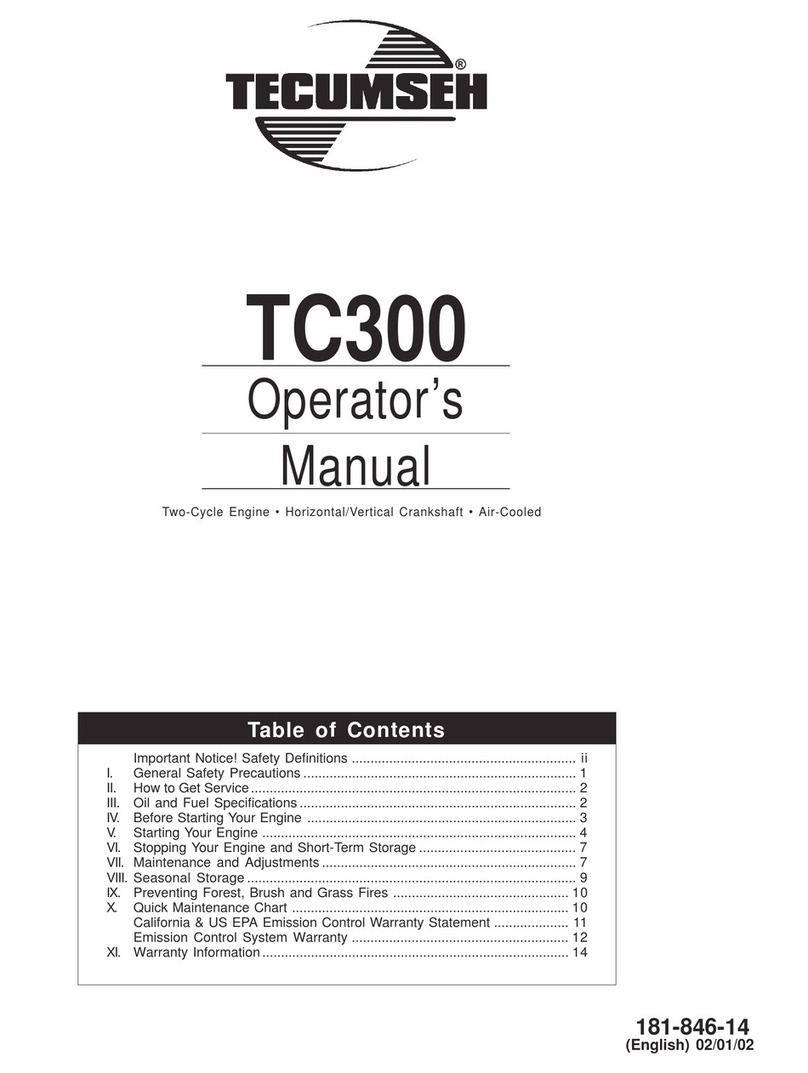

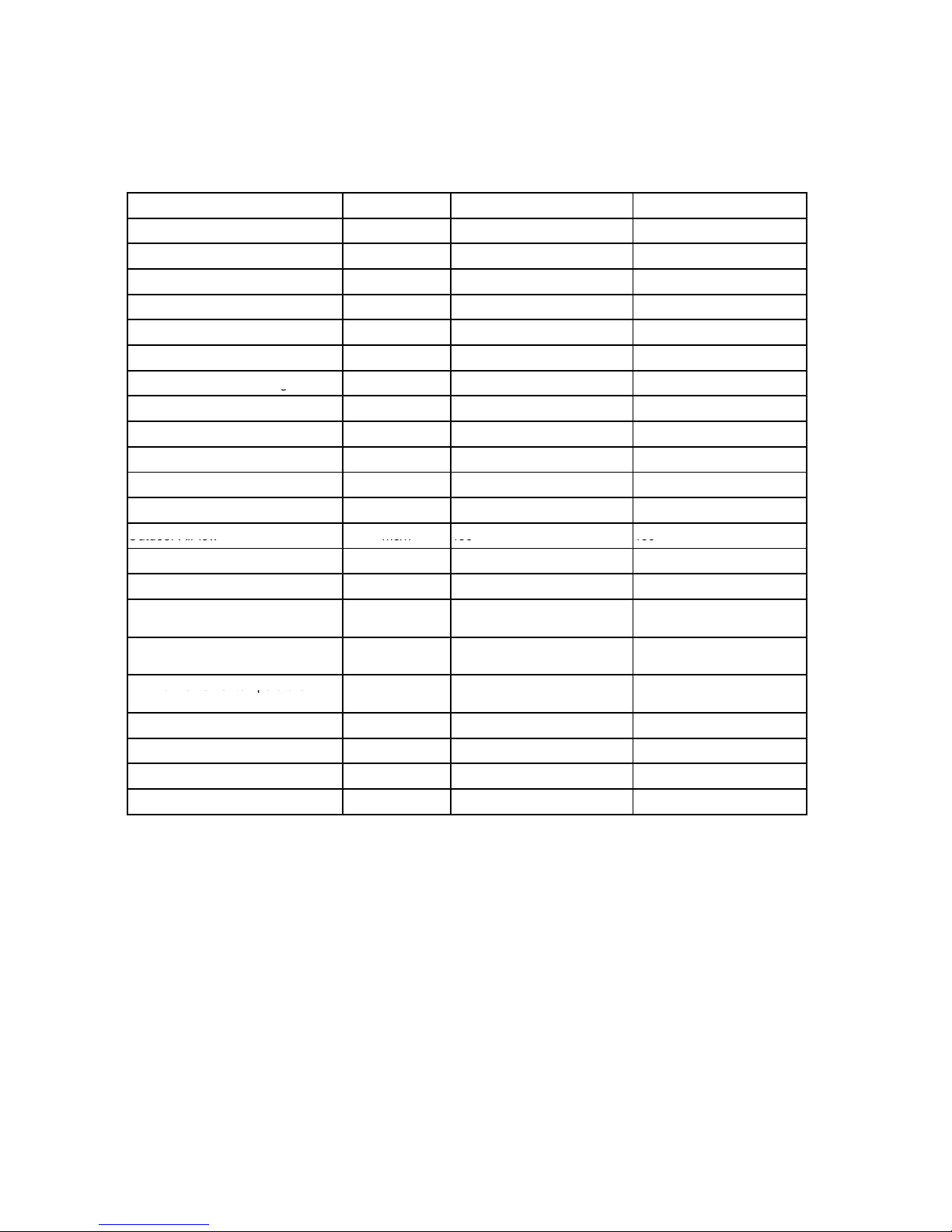

5.Rated technical data

Descriptions Unit ICOOL 2.3 IWARM 2.3

Cooling capacity W (Btu/h) 2360 (8050) 2360 (8050)

Heating capacity W (Btu/h) 2()2()

Rated voltage V 230 230

Frequency Hz 50 50

Electrical heater W (Btu/h) ------- 1600 (5500)

Absorbed power in cooling W 904 904

Absorbed current in coolin

g

A 3.9 3.9

g

Absorbed power in heating W

Absorbed current in heating A 4

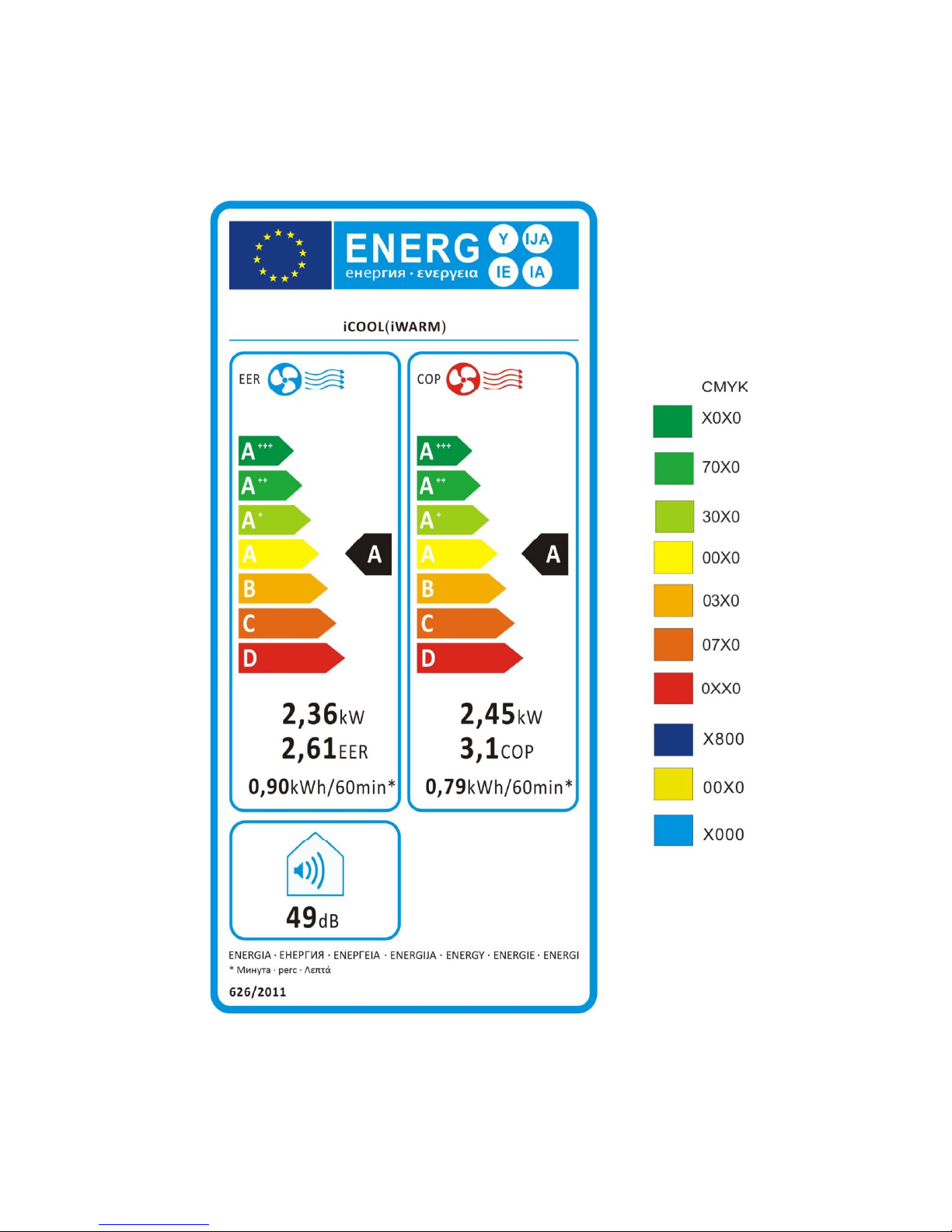

EER label ( Cooling Mode ) ABCDEFG AA

COP lable ( Heating Mode ) ABCDEFG A A

Indoor Air low m3/h 350 350

Outdoor Air low

m3/h

450

450

Outdoor

Air

low

m3/h

450

450

Noise lever ( SPL ) dB(A) 49 49

Dehumidification capacity L/24h 12.5 12.5

Optional temperature (remote

control) ć18-30 18-30

Maximum external temperature *** eC 43 43

Minimum external temperature HP

e

C

5

5

Minimum

external

temperature

HP

****

e

C

-

5

-

5

Fuse (T3,15L) V 250 250

Refrigerant / R410a g 640 640

Dimension H/W/D cm 43/95.5/19.5 43/102/19.5

Net Weight Kg 40 42

**The above data could be changed in order to improve the performance.

*** The machine can work at T3 condition , with max out door temperature 52

eC but the cooling performance will be reduced .

**** The machine can work at -15 eC , but the Heating performance will be

reduced .

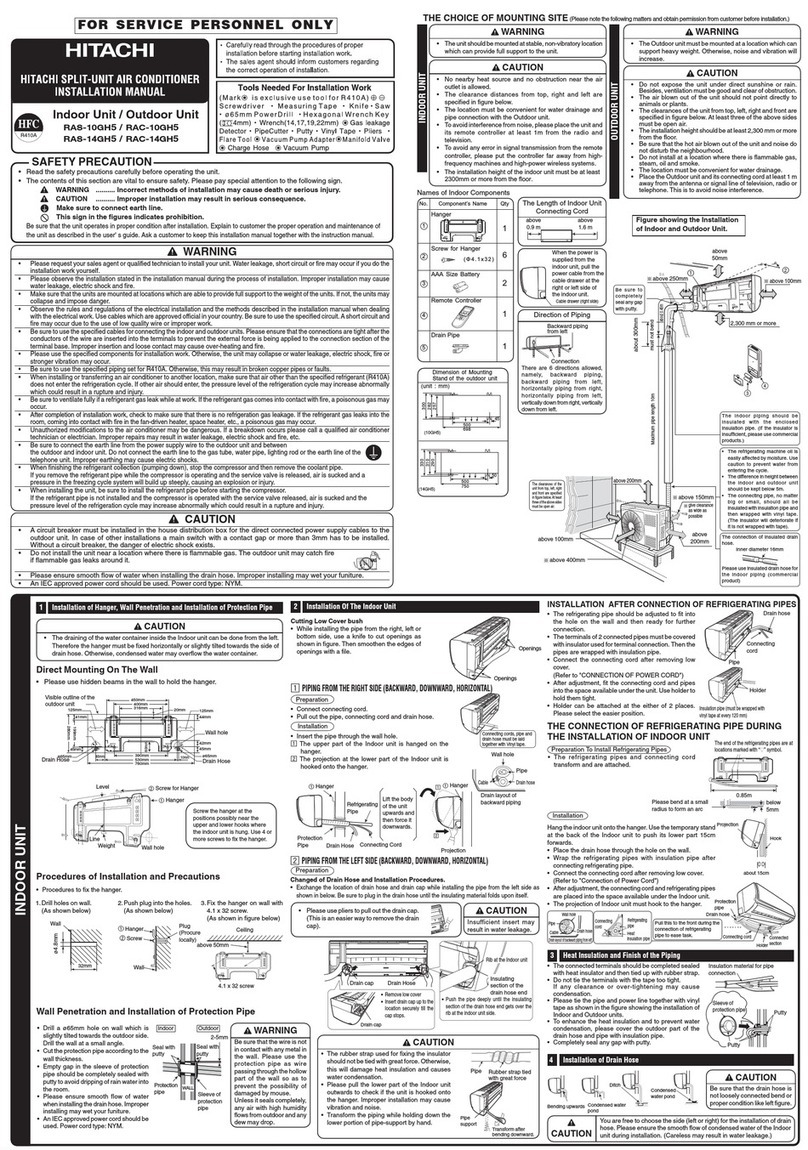

7. Installation

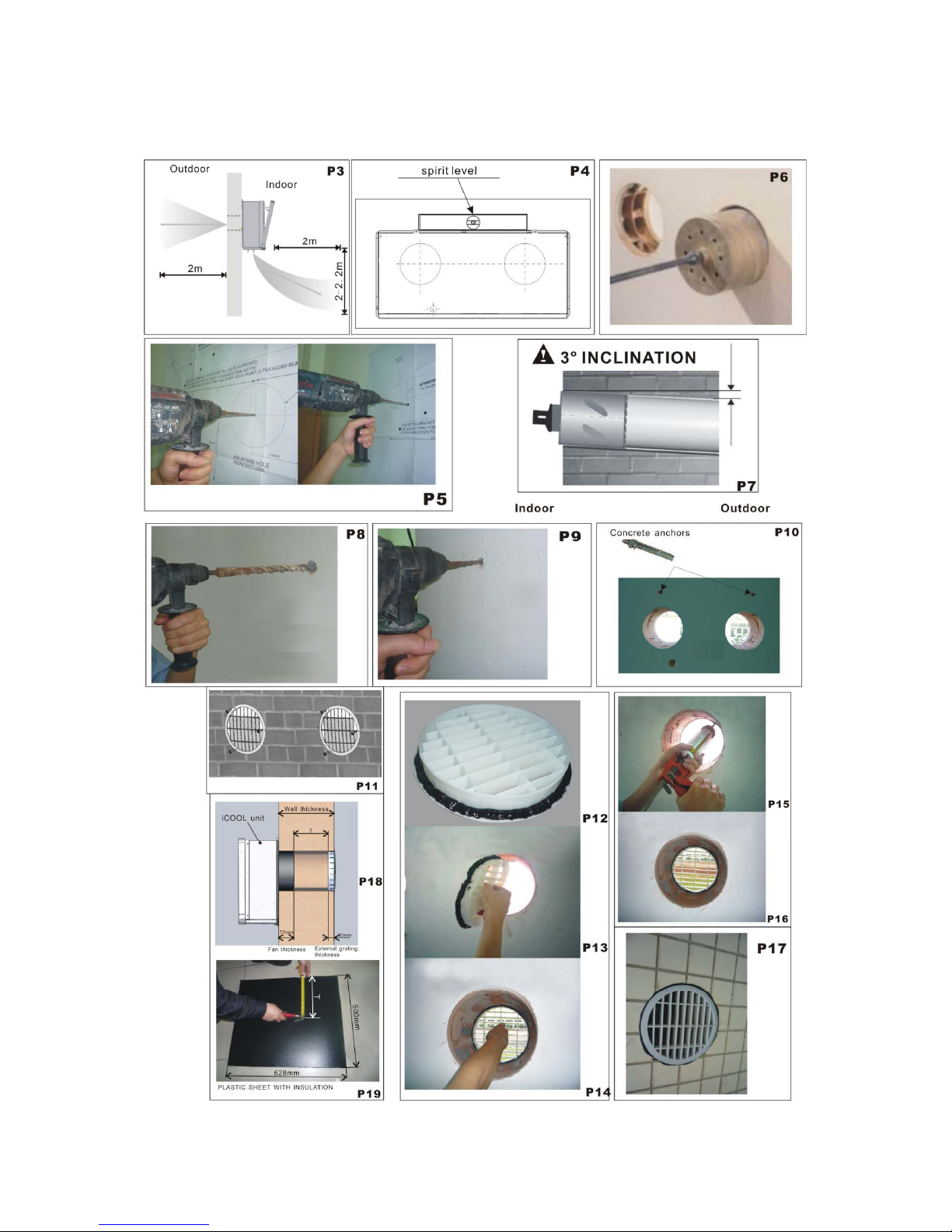

7.1 Positioning the air conditioner (P3)

To maintain the best performance from your air conditioner, prevent breakdowns or hazards, you

must position it correctly.Please follow the guidelines and instruction below in full, as failure to do so

could cause potential installation problems.

The air conditioner must be installed on an exterior wall that has access to the out side with a

minimum of 2 meters clearance to the outside.(See image P3)

The air conditioner must be fitted leaving room all around as illustrated in the paper template.

The wall on which the air conditioner is installed must be sturdy and able to withstand the weight for

the air conditioner.

After determining the best place for installation as described above. Please check to ensure that the

wall can be drilled in the chosen area without interferin

g

with other structures or installations

(

beams

,

7.2 Paper template (P4)

g(,

piers, pipes, wires, etc.).

Please also ensure that there are no obstacles on the outside of the wall, which may obstruct air

circulation through the drilled holes, for example:(plants and their leaves, slats or panelling, drain

pipes, overflows and gratings,etc.). Any obstruction could interfere with the correct performances of

the air conditioner.

Fasten the template to the wall once the following guidelines have been thoroughly checked.

• Do not drill any holes until you are completely confident that there are no obstacles in the area you

wish to drill and there are no obstructions, which could be hidden by the construction of the wall, for

example: electrical wiring, water&gas pipes or supporting lintels or beams.

• Ensure that a spirit level is used, as the air conditioner must be level.

• Follow the installation instructions in full.

•Fasten the template to the wall taking care to check the distance from the floor or ceiling.

•Use a pilot drill to mark the centre of each core hole to be drilled.(See image P5)

7.3 Drilling the wall(P6,P7,P8)

Please note:If you are drilling the hole above ground floor level, please ensure that an area has been

secured and while the holes are drilled the outside area is supervised until drilling has been

secured

and

while

the

holes

are

drilled

the

outside

area

is

supervised

,

until

drilling

has

been

completed.

Intake and outlet holes

• This operation should be carried out using the proper tools ( diamond tip or core borers drills with

high twisting torque and adjustable rotation speed).

•Find the holes center drilled before, use a core boring head having a diameter of 200mm to drill the

two holes for intake and outlet the air.

Thi ti h ld b i d t i th t l (di d ti b d ill ith hi h

•

Thi

s opera

ti

on s

h

ou

ld

b

e carr

i

e

d

ou

t

us

i

ng

th

e proper

t

oo

l

s

(di

amon

d

ti

p or core

b

orers

d

r

ill

s w

ith

hi

g

h

twisting torque and adjustable rotation speed).

Note: It is recommended that the holes must have a slightly downward inclination of 3-5 degree to

prevent any backflow of water from the pipes.

Drainage hole (P8)

This air conditioner has a system to drain the condensate moisture automatically. Please read

carefully the following instruction.

Drill a hole through the wall measuring 30mm in diameter in the position shown in the paper template,

Drill

a

hole

through

the

wall

measuring

30mm

in

diameter

in

the

position

shown

in

the

paper

template,

marked the center before. Drainage occurs by gravity. For this reason, it is essential for the drain line

to have a minimum downward inclination at least 3 degrees throughout its length. With this solution,

you can drain the condensate moisture to a suitable place to do not cause any problems to your

neighbours.

This drainage method is more common use, and the discharge pipe goes outside where there is no

problem to connect or to discharge it, this solution is OK for hot country and normal cold temperature

outside.

Wllb kthl (P9)

W

a

ll

b

rac

k

e

t

h

o

l

es

(P9)

Drill the holes for anchoring the unit to the wall using preferably the 2 holes with 10mm diameter

showed in black on the paper template. As the unit is installed on high wall, it is recommended that the

bolts should be fixed very well.

7.4 Fastening the anchors (P10)

Insert the concrete anchors into the holes for the unit and tighten them inside the wall

Insert

the

concrete

anchors

into

the

holes

for

the

unit

,

and

tighten

them

inside

the

wall

.

The anchor bolts provided require 10mm holes; the wall should be inspected to determine if provided

bolts are useful or if it is necessary to use a different anchorage. The manufacture is not liable in case

of underestimation of the structural consistency of the anchorage made at the time of installation.

7.5 Fitting the gratings

After drilling the holes, the plastic gratings supplied with air conditioner need to be fitted on the wall.

1.When gratings is easy accessibility, you could fix the gratings from outside, it is recommended to

fasten it to the wall with wall plugs and screws with a diameter of 6mm, and keep the fins in vertical

position. (See image P11 )

2. When the air conditioner is installed in the high space, and impossible to reach the gratings from

outdoor side, you could fix the gratings from inside.

Put the silicon gel around of the soft grating, like Fig17.Then fold the outer grating in half, insert your

arm inside the hole with the grating. Let the grating unfold and pull the grating toward you. With a little

i d i l i h 2 i ill fi h d f h h l (P12 13 14)

pat

i

ence an

d

man

i

pu

l

at

i

on, t

h

e

2

grat

i

ngs w

ill

fi

t t

h

e en

d

o

f

t

h

e

h

o

l

es.

(P12

,

13

,

14)

After fixing the outside grating,we could inject more gel inside the space between the grating and wall.

(See P15,16)

The black silicon gel is just for reference, we could use white or transparent color gel to fix the outdoor

grille.(P17)

The above installation solution is just for solid wall.

7.6 Fixing plastic sheet and insulation

After fixing the outside grating,insert the plastic sheet with insulation supplied with the conditioner

into the holes.The sheets must be 107mm shorter than the thickness of the wall.(See P18)

Use an ordinary cutter for the operation. (See P19)

Roll the sheet and insert it into the hole, paying attention to the splicing line, which must always

face up wards.(See P20)

7.7 Connecting drainage pipe

Connect the drain pipe(from rubber terminal) to the air conditioner (back side) after unplugged the

black rubber cu

p

(

see P21

)

.

p( )

With this solution, you can drain the condensate moisture to a suitable place to do not cause any

problems to your neighbours.

1. When the machine is installed in normal climate or hot area, we can connect the drainage pipe

to outside, with a proper place. (See P22)

2. When the machine is installed in very cold area, the water in drainage pipe is frozen easily in

winter, we could connect the drainage pipe inside the wall, and connect with a proper

place.(See P23)

7.8 Fitting the air conditioner on anchors

After checking again that the fastening anchors are securely fastened to the wall, and that any

necessary preparations for electric connection and condensate drainage have been made, fasten

the air conditioner to its supporting anchors.(See P24)

Lift it up by holding the sides at the bottom, slightly insert the outside fan rings into the two big

holes on the wall.

(

See P25

)

The air conditioner can now be

p

ushed firml

y

a

g

ainst the wall

,

then lift

() p yg

,

the unit and make sure the anchors and unit match well. (See P26)

Inspect carefully the installation to make sure that the insulating back panel must fit firmly against

the wall and there are no fissures at the back of the air conditioner.

Fixing two nuts with top of the machine, to make sure the unit is installed well. (See P27,28)

Note:

1. The appliance shall not be installed the laundry.

2. The appliance must be positioned so that the plug is accessible.

3. The appliance shall be installed in accordance with national wiring regulations.

7.9 Power cord connection

For every unit, there would be a power cord on the left side(P28).Connect the plug with the socket,

and operate the unit.

8. ICOOL/IWARM Electric wiring

9.1 Main technical index

PCB h ld t th f ll i i t

9. Description of software operation

PCB

s

h

ou

ld

mee

t

th

e

f

o

ll

ow

i

ng requ

i

remen

t

s:

• Measured from the receiverˈreceiving distance of remote control should 8mˈreceiving

angle60econe angle˗

• Discrepancy of temperature controlf1ć˗

• Discrepancy of time control5min/24h˗

• Discrepancy of indoor PG fan speed˖f10rpm˗

Rd l

AC230

f

20%

0H

•

R

ate

d

power supp

l

y˖

AC230

f

20%

ˈ5

0H

z˗

• PCB should conform to RoHS.

9.2 Definition

•RT˖room temperature.

•IPT˖indoor coil temperature.

•ST˖setting temperatureˈrange 1830ć

•OPT˖outdoor coil temperature.

• NTC data˖R25=5.0Kȍf1% B25/50=3470f1%

9.3 Mode introduction

931Automode

9

.

3

.

1

Auto

mode

After running the unit by ON/OFF key or choose the auto running mode by remote control, it will fix its

running mode by judging room temperature (see below table):

Indoor temp. Indoor temp.20

ć

20

ć˘

indoor

˘

25

ć

indoor25

ć

Running mode heating fan cooling

St d d fi d

20

ć

22

ć

25

ć

St

an

d

ar

d

fi

xe

d

setting temperature

20

ć

22

ć

25

ć

Note:

1. When Auto mode is selected, unit would check room temperature first and work with fixed mode as

above accordingly. Every 6 minutes, unit would check room temperature again, running mode would

be changed according with update room temperature.

2

If working mode is changed by remote control unit has 3 minutes delay protection for compressor

2

.

If

working

mode

is

changed

by

remote

control

,

unit

has

3

minutes

delay

protection

for

compressor

.

3. Fan speed selection: For Dry mode, fan speed is fixed with low speed. For Cooling, Heating and Fan

mode, fan would work with set speed.

4. Unit has protection function, including 3 minutes delay function, Anti-cold function before heating,

Over heating protection during heating function, Anti-frozen during cooling mode, E1,E2,E3,E4

protection.

This manual suits for next models

1

Table of contents

Other Fintek Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Samsung

Samsung AR18NSWSPWKXCV Service manual

Kenmore

Kenmore 405.84086 Use & care manual

Mitsubishi Electric

Mitsubishi Electric MFZ-KA25VA Service manual

Sharp

Sharp AU-1802Y Operation manual

Mitsubishi Electric

Mitsubishi Electric City Multi Series Technical & service manual

Haier

Haier HSU-10VNJ17 Operation manual