Fire Chief FSW1 Manual

INSTALLATION

& OPERATING

INSTRUCTIONS

FSW1

Kitchen

STOVE

GUARD

2

2

THANK YOU FOR CHOOSING THE

FIRECHIEF KITCHEN STOVE GUARD

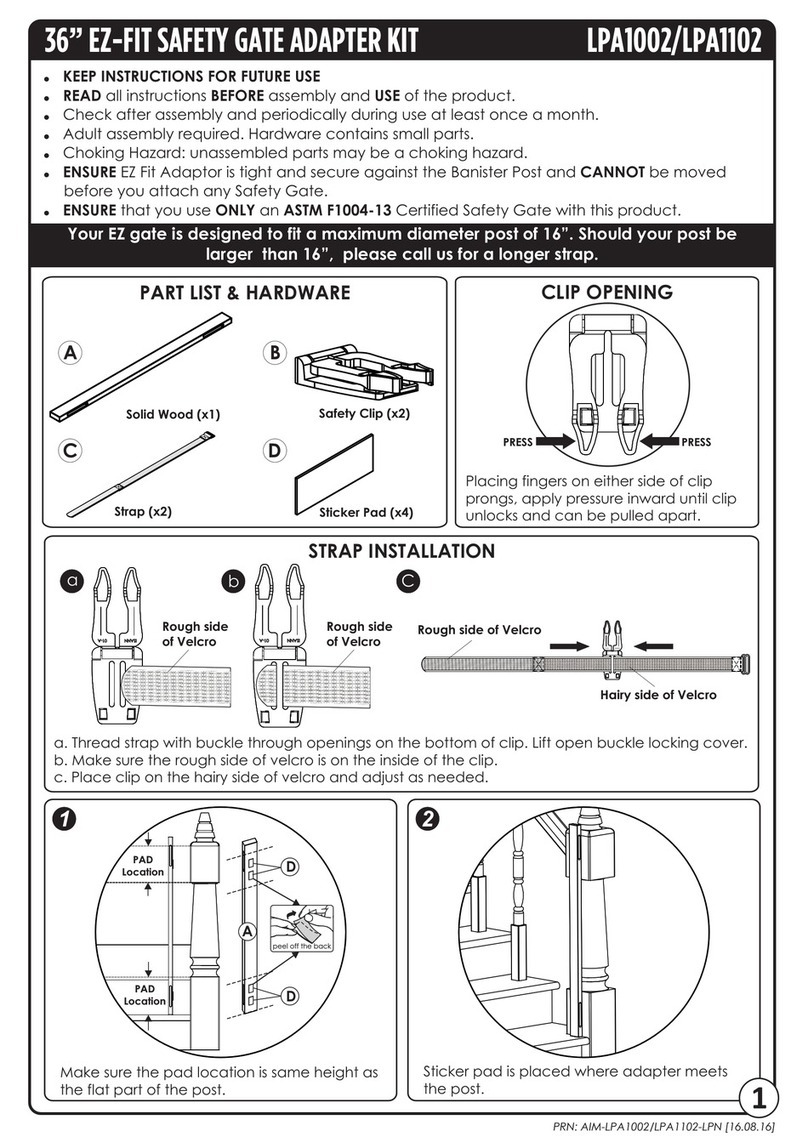

PACKAGE CONTENTS:

•Heat Sensor SGS1010

•Battery (CR2032)

•IR lens extension

•Control Unit SGC510-2

•Junction Box SGI510-2JF

• Main manual

• Cupboard sticker

•Screws

Firechief Stove Guard is a safety product for domestic kitchens. The Stove Guard consists of a

state-of-the-art Heat Sensor that monitors the cooker from above, and a Control Unit that cuts

the power to the cooker if a dangerous situation occurs. The Control Unit is installed behind

the cooker or inside a kitchen cabinet close to the cooker. Be sure to read this manual prior to

commencing installation.

SAFETY RULES

Firechief Stove Guard does not prevent all potentially dangerous situations, but it makes the use of

the cooker signicantly safer. Never leave the cooker unattended. Always check compliance with

local regulations.

• For indoor use only.

• Do not use in a professional kitchen.

• Do not hold the Heat Sensor close to ears. It will emit a loud

sound when the alarm is triggered or in test mode, which can

cause hearing damage.

• Do not leave children alone with the product or any of its

parts or packaging. There is a risk of choking.

• Do not disassemble the product.

• Do not immerse the Heat Sensor in water.

• The Stove Guard will not emit an alarm if the temperature

of the cooker is too low to identify a dangerous situation,

or if the cooker has an automatic limitation of temperature

increase.

• The Stove Guard will not completely isolate the cooker. It

must never be used to turn o the cooker's power supply for

service/repair.

• Do not short-circuit, charge, open or heat the batteries.

There is a risk of explosion.

The operating instructions, accessories and stickers must accompany the product. Follow the safety guidance for

safe use of Stove Guard. If you have questions about the product, ask a specialist or refer to rechiefglobal.com

SGS1010

SGC510-2

SGI510-2JF

INSTALLATION & OPERATING INSTRUCTIONS 3

TECHNICAL SPECIFICATIONS

IR lens

(Lens extension for

ceiling installations)

Button

Battery lid

(Battery 1 x CR2032)

Signal LED

should face towards user

• Voltage 230–400 VAC

• Extremely low energy

use (approx. 1 W)

• Automatic electrical

switch

• For safe connections

up to 10 mm2

wires

• Alarm signal 80 dB(A) @ 1 m • RF 433 MHz • Patented technology

• Fulls BS EN 50615:2015 Standard for stove guards (Eurons Expert Services Oy)

THE HEAT SENSOR

THE CONTROL UNIT THE JUNCTION BOX

PLEASE NOTE THE HEAT SENSOR AND CONTROL UNIT

ARE FACTORY PAIRED. DO NOT SEPARATE THEM

2

4

PLEASE NOTE THE HEAT SENSOR AND CONTROL UNIT

ARE FACTORY PAIRED. DO NOT SEPARATE THEM

CONTROL UNIT

It is a statutory requirement that the Junction Box is installed by an

authorized electrician. The power to the cooker must be disconnected

throughout the entire installation.

Disconnect the power

Switch o the power at the

consumer unit.

Note! Do not turn on the

Consumer unit before the Heat

Sensor is set up and ready for a

function test.

Connecting the Junction Box

For correct installation of the Junction Box, refer to the wiring diagram on

page 5. The Control Unit will then plug & play into the Junction Box.

2

Watch the lm:

https://youtu.be/s7ato2xYQUY

Test alarm

1

POWER

OFF

INSTALLATION & OPERATING INSTRUCTIONS 5

Alternative 1

Alternative 2

Stove Guard's maximum supply current allowed is 32 A

and the appropriate diversity factor is 100%. The diversity

factor applies to Stove Guard installations with parallel

connected relays. Type 1, or equivalent circuit breaker

(MCB) shall be used for protecting the Stove Guard supply.

The circuit breaker shall have capability of interrupting the

supply current within 100 ms at 4 x load.

COOKER CONNECTION

For indoor use only.

Do not use in a professional kitchen.

The Control Unit must be installed

by an authorised electrician.

2

6

1. INSTALLATION

INSTALLATION LOCATIONS

P. 6 -7 P. 8 - 9

INSTALLATION

INSTALLATION OF THE HEAT SENSOR

INSTALLING THE STOVE GUARD

Follow these instructions for correct installation.

STEP 1:

Installation of

the Heat Sensor

p. 4–12

STEP 2:

Installation of

the Control Unit

p. 4-12

STEP 3:

Function test

p. 13

The recommended location to install the

Heat Sensor is directly above the centre of

the cooker, under the cooker hood. The Heat

Sensor can also be mounted on a wall with

a mounting bracket or on the ceiling. The

enclosed tting instructions should be followed

to ensure correct installation.

1a

Installation under cooker hood

1b Wall mounting

1c Ceiling mounting

RECOMMENDED OPTIONAL

Firechief Kitchen Stove Guard Wall

Bracket 140-0003 (FSWB) required

for wall installations - available

separately.

For ceiling installations, the

supplied IR lens extension must

also be tted. See page 11-12.

Installation plate

with adhesive tape

Heat Sensor

Optional IR lens

extension (black)

INSTALLATION & OPERATING INSTRUCTIONS 7

15cm

Zone 2 Zone 1

Radius 15 cm

Min 10 cm

Min 5 cm for

LED lamp

Zone 1 is immediately

above the middle of the

cooker plates. Max 15 cm

from the centre.

Zone 1

COOKER HOOD

Measure the installation height. The Heat Sensor should

be centred above the cooker, preferably within Zone 1

(see diagram at bottom of the page). It can be attached

to the grease lter. It is also important to ensure the

minimum distance from any lights underneath the hood is

10 cm (5 cm is enough for LED lamp).

Please note: Zone 1 is recommended for best

performance.

1

Measure distance

SELECTING THE MOUNTING LOCATION

If there is a metal mesh grease lter on the cooker hood,

make sure it is free of grease and dry.

Carefully remove the protective lm from the installation

plate. Press for at least a minute while attaching installation

plate to allow adhesive to work.

For ease of battery tting and heat sensor adjustment, the

heat sensor can be removed from the installation plate and

re-attached via it’s magnetic fastening.

2

MOUNTING THE INSTALLATION PLATE

Allow the Heat Sensor to reach room temperature before starting

the installation. The power to the cooker must be switched o (at the

consumer unit). See table on page 8 for guidance on the appropriate

mounting location and follow instructions 1–4.

COOKER HOOD UNDERSIDE

MOUNTING ZONES

OVERVIEW OF COMPARABLE ‘ZONES’

ON HOB AREA

2

8

INSTALLATION UNDER

COOKER HOOD

P. 6 -7

STARTING THE HEAT

SENSOR

Insert the battery and check step 4

before placing the Heat Sensor on

the installation plate.

Briey press the button. The

LED should ash green.

CHECK INSTALLATION HEIGHT

If the distance from cooker to Heat Sensor is more than 60 cm, the Heat

Sensor's sensitivity level must be adjusted manually.

Please refer to the table below together with the information on page 7 of

the User Guide. Also watch the video on sensitivity conguration below.

3

Watch the lm:

https://youtu.be/oy-hrT7nTQM

Setting the sensitivity level

4

Watch the lm:

https://youtu.be/SAeFdB3nP3s

Installation

DISTANCE FROM COOKER

TO HEAT SENSOR

COOKER SIZE SENSITIVITY LEVEL CONFIGURATION

0–60 cm wide 61–90 cm wide Sensitivity

setting

Acknowledgement

“beep(s)”

Zone

1

Zone

2

Zone

1

Zone

2

81–100 cm OK OK OK OK 3 presses

76–80 cm OK OK OK OK 4 presses

71–75 cm OK OK OK OK* 5 presses

65–70 cm OK OK OK OK* 6 presses

61–64 cm OK OK OK OK* 7 presses

60 cm Factory setting OK OK OK OK* 8 presses

55–59 cm Factory setting OK OK OK* OK* 8 presses

45–54 cm Factory setting OK OK* OK* OK* 8 presses

OK = The installation complies with BS EN 50615 Cat. B standard test plan.

OK* = The installation may not in all cases meet all BS EN standard requirements. Please note: The sensitivity level of the Heat Sensor is

conrmed by the appropriate sound pattern sequence

only and not the LED ashes.

INSTALLATION & OPERATING INSTRUCTIONS 9

80 cm

WALL

SELECT THE REQUIRED LOCATION AND MOUNT THE BRACKET

Wall mounting requires a bracket 140-0003 (FSWB), sold separately. The bracket can be fastened to the wall using

adhesive tape or screws.

See the detailed mounting instructions in the bracket package. Make sure that the bracket is positioned correctly so that

the Heat Sensor faces towards the centre of the cooker.

MOUNTING THE

INSTALLATION PLATE

Carefully remove the protective lm from the

installation plate. Press for at least a minute

while attaching installation plate to allow

adhesive to work.

For ease of battery tting and heat sensor

adjustment, the heat sensor can be removed

from the installation plate and re-attached via

it’s magnetic fastening.

1

Mounting height on the wall above the cooker

Max 90 cm wide cooker.

Recommended: 80 cm

Alternatively: 65–79 cm*

See mounting instructions provided separately with the bracket.

* For wall mounting with a distance less than 80 cm between the Heat Sensor and the cooker, the installation will not in all

cases meet all BS EN standard requirements.

3

2

Allow the Heat Sensor to reach room temperature before starting

the installation. The power to the cooker must be switched o (at the

consumer unit). See table on page 10 for the mounting location and follow

instructions 1–5.

2

10

WALL MOUNTING

WITH BRACKET

P. 8 - 9

4 5

STARTING THE

HEAT SENSOR

Insert the battery and check step 5

before placing the Heat Sensor on the

installation plate.

Briey press the button. The LED

should ash green.

SET THE SENSITIVITY LEVEL

Set the Heat Sensor's sensitivity level according to the mounting height

(as described in the table below) by evenly pressing the Sensor's button.

The factory setting for the sensitivity level is 45–60 cm above the cooker.

Please refer to the table below together with the information on page 7 of

the User Guide. Also watch the video on sensitivity conguration below.

Watch the lm:

https://youtu.be/oy-hrT7nTQM

Setting the sensitivity level

Watch the lm:

https://youtu.be/SAeFdB3nP3s

Installation

DISTANCE FROM COOKER

TO HEAT SENSOR

COOKER SIZE SENSITIVITY LEVEL CONFIGURATION

0–60 cm wide 61–90 cm wide Sensitivity

Acknowledgement

“beep(s)”

80 cm Recommended OK OK 3 presses

70–79 cm OK* OK* 3 presses

65–69 cm OK* OK* 4 presses

OK = The installation complies with BS EN 50615 Cat. B standard test plan.

OK* = The installation may not in all cases meet all BS EN standard requirements.

Please note: The sensitivity level of the Heat Sensor is

conrmed by the appropriate sound pattern sequence

only and not the LED ashes.

INSTALLATION & OPERATING INSTRUCTIONS 11

CEILING

1REPLACE LENS

Carefully lift the lens with a screwdriver. Insert the IR lens

extension (included) as shown in the picture. The extension

should point directly upwards at an angle of 90°.

If the extension moves around, check that it has been inserted

the right way round.

2

Measure distance

FINDING THE MOUNTING POSITION

Measure the distance between the cooker and ceiling. Place the

Heat Sensor directly above the center point of the cooker. Make

sure that the surface is clean and dry.

MOUNTING THE INSTALLATION PLATE

Make sure that the ceiling is free of grease and dry.

Carefully remove the protective lm from the installation plate.

Press for at least a minute while attaching installation plate to

allow adhesive to work.

For ease of battery tting and heat sensor adjustment, the Heat

Sensor can be removed from the installation plate and re-attached

via its magnetic fastening.

3

Allow the Heat Sensor to reach room temperature before use.

The power to the cooker must be switched o (at the consumer unit).

See table on page 12 for the mounting location and follow instructions 1–5.

2

12

CEILING MOUNTING WITH

IR LENS EXTENSION

P. 6 -7

45

STARTING THE HEAT

SENSOR

Insert the battery and check step 5

before placing the Heat Sensor on

the installation plate.

Briey press the button. The LED

should ash green.

SET SENSITIVITY LEVEL

Set the sensitivity level according to the mounting height (as described in

the table below) by evenly pressing the Sensor's button. The Heat Sensor's

sensitivity level must always be adjusted when installing it on the ceiling. Please

refer to the table below together with the information on page 7 of the User

Guide. Also watch the video on sensitivity conguration below.

Watch the lm:

https://youtu.be/oy-hrT7nTQM

Setting the sensitivity level

Watch the lm:

https://youtu.be/SAeFdB3nP3s

Installation

DISTANCE FROM COOKER

TO HEAT SENSOR

COOKER SIZE SENSITIVITY LEVEL CONFIGURATION

0–60 cm wide 61–90 cm wide Sensitivity Acknowledgement

“beep(s)”

140–180 cm OK OK 2 presses

Recommended: Immediately above the middle of the cooker.

Alternatively: Farther out into the room with bracket. See the bracket package for mounting instructions.

OK = The installation complies with BS EN 50615 Cat. B standard test plan. Please note: The sensitivity level of the Sensor is conrmed by the

appropriate sound pattern sequence only and not the LED ashes.

INSTALLATION & OPERATING INSTRUCTIONS 13

P. 6 -7 P. 8 - 9

FUNCTION TEST

The installation is completed when the function test has been passed.

The Heat Sensor will then give an alarm in a dangerous situation. The

user manual, accessories and stickers should be stored close to the Stove

Guard for future reference.

Return the power

Switch on the power at the

consumer unit.

Perform function test

Wait 30 seconds after switching

on the power. Press and hold the

button until the Heat Sensor emits

a “beep” ( ) and the red LED

ashes. Release the button.

The Control Unit will switch o the

cooker and give an alarm

signal every 5 seconds. The Heat

Sensor will also emit a test alarm

after a few seconds.

Note! Ensure that there is no

power going to any of the cooking

plates.

Reset the alarm

It is important to reset the alarm

after a function test to return

power to the cooker. Reset the

test alarm by pressing the button

once.

Check that the cooker can be

turned on (or that there is

voltage in the Control Unit).

If the Heat Sensor does not

respond or if the test alarm

cannot be reset, see page 9 of the

User Guide, points 5 and 6.

1 2 3

Installation is now ready.

When connecting the Stove Guard for the rst time it is recommended to wait 15 minutes before normal

cooker use to allow the Stove Guard to perform nal system checks.

POWER

ON

2

14

P. 6 -7 P. 8 - 9

WARRANTY

The warranty applies from the date of purchase.

This warranty does not aect your legal rights. The

warranty covers the use of the product under normal

circumstances in private households and housing

associations.

The warranty is limited to replacement of defective

components.

The warranty applies only when the product is used

according to the instructions. It does not cover damage

caused by misuse, improper handling, use of force,

batteries, dust, dirt, water or other environmental factors.

If you have a warranty claim, contact your retailer for

instructions. We only accept authorized returns with a

complete description of the defect. After the warranty

period, you will be charged for repairs and it may not

always be possible to have the product repaired.

Warranty claims do not extend the original warranty

period, and the warranty on spare parts expires at the

same time as the product warranty. Unless otherwise

provided by law, the manufacturer shall not be liable

for additional claims, including for personal or material

damage arising from the use of the product or its decient

function or malfunctioning.

DISPOSAL

Information about disposal of electrical and

electronic waste (private households): The

Waste Electrical and Electronic Equipment

Regulations (2013) (S.I. 2013/3113) / EU

Directive 2012/19/EC on recycling of waste

electrical and electronic equipment.

This symbol on the Stove Guard and associated

documents means that this product should not be

disposed of with normal household waste. For proper

handling and recycling, this product must be delivered to a

separate collection point where it will be accepted free of

charge. The product can be returned to your local retailer

when purchasing a corresponding new product.

Proper disposal of this product helps to save valuable

resources and prevent potentially harmful eects on

human health and on the environment, which may

otherwise occur in the event of improper handling of

waste.

UK Declaration of Conformity

As the product’s manufacturer, we declare under

our sole responsibility, that this product SGK5010-

2JF is in accordance with the following regulations:

• Radio Equipment Regulations 2017 (S.I. 2017/1206)

• Electrical Equipment (Safety) Regulations 2016 (S.I.

2016/1101)

• Electromagnetic Compatibility Regulations 2016 (S.I.

2016/1091)

• Restriction of the Use of Certain Hazardous Substances

in Electrical and Electronic Equipment Regulations 2012

(S.I. 2012/3032)

• The Waste Electrical and Electronic Equipment (WEEE)

Regulations (2013) (S.I. 2013/3113)

The Model is a combination of the Sensor Unit

SGS1010, the Control Unit SGC510-2 and the

Installation Set SGI510-2JF.

The Control Unit is certied according to the following

standard: BS EN 60730-1:2016+A1:2019 (Automatic

Electrical Controls for Household and Similar Use, Part

1: General requirements)

The Installation Set (connectors, socket-outlets,

plugs, sockets) is certied according to the following

standards and technical specications: BS EN 60670-

1:2005+A1:2013, BS EN 60670-22:2006 + BS EN

60998-1:2004

The other designated standards and the technical

specications are the following:

• Devices for Fire Prevention for Hobs (Cooktops): BS

EN 50615:2015 (the Stove Guard standard, tested as a

Category B device)*

• Household and Similar Electrical Appliances: BS EN

60335-2-31:2014 (Part 2-31: Particular requirements for

range hoods and other cooking fume extractors): Clause

30: Resistance to heat and re (the Sensor Unit)

• Automatic electrical controls – Part 1: General

requirements: BS EN 60730-1:2016+A1:2019 Clause

H.27: Abnormal operation, fault conditions for low-power

circuits (the Sensor Unit)

• Restriction of Hazardous Substances (RoHS): BS EN

50581:2012

INSTALLATION & OPERATING INSTRUCTIONS 15

• Electromagnetic Compatibility (EMC) Standard for Radio

Equipment and Services: ETSI EN 301 489-1 V2.1.1

(Electromagnetic compatibility and Radio spectrum Matters

(ERM); ElectroMagnetic Compatibility (EMC) standard

for radio equipment and services; Part 1: Common

technical requirements) and ETSI EN 301 489-3 V2.1.1

(Part 3: Specic conditions for Short-Range Devices (SRD)

operating on frequencies between 9 kHz and 246 GHz)

(the Sensor Unit)

• Electromagnetic Compatibility and Radio Spectrum Matters

(ERM) – Short Range Devices (SRD) Operating in the

Frequency Range 25 MHz to 1 000 MHz: ETSI EN 300

220-1 V3.1.1 (Part 1: Technical characteristics and methods

of measurement) and ETSI EN 300 220-2 V3.1.1 (Part 2:

Harmonised Standard for access to radio spectrum for non

specic radio equipment) (the Sensor Unit)

EU Declaration of Conformity

As the product’s manufacturer, we declare under

our sole responsibility, that this product SGK5010-

2JF corresponds to:

• Radio Equipment Directive (RED) 2014/53/EU

• The Low Voltage Directive 2014/35/EU

• The RoHS Directive on the Use of HazardousSubstances

2015/863/EU

....and the following harmonized standards and technical

data are used:

• Fire prevention devices for hobs EN 50615:2015 (Cat. B)*

• EN 60730-1:2016+A1:2019 (Control Unit); Clause H.27

(Sensor)

• Device Requirements EN 60335-2-31:2014, Clause 30

• EN 60670-1:2005+A1:2013, EN 60670-22:2006 + EN

60998-1:2004

• Electromagnetic Compatibility and Radio Spectrum Matters

(ERM) EN 300 220-1 V3.1.1, EN 300 220-2 V3.1.1

• Electromagnetic Compatibility (EMC) EN 301 489-1 V2.1.1

and EN 301 489-3 V2.1.1

• RoHS EN 50581:2012

* BS EN 50615: 2015 British/European standard for stove

guards, approved 05.01.2015, available 06.03.2015. The

full title of the standard: Household and similar electrical

appliances. Safety. Particular requirements for devices

for re prevention and suppression for electric hobs

(cooktops). Tested by an independent, accredited testing

laboratory (Eurons ExpertServices Finland).

T: 0330 999 0019

E: sales@rechiefglobal.com

www.rechiefglobal.com

Date issued: V2 4/7/22

PAIRING DEVICES

The units are already paired at the factory. When replacing the Heat

Sensor or the Control Unit, the devices must be paired again.

Note! The Heat Sensor must be

placed on the installation plate

during pairing.

1. Check that the cooker is

connected to the power

supply.

2. Press and hold the reset

button rmly for 20 seconds.

The Control Unit will emit

two sets of clicks and buzzes

(approximately after 5 and 20

seconds). Release the reset

button after the second set of

clicks and buzzes.The Control

Unit is now ready to be paired.

3. Press and hold the NEW Heat

Sensor button until it emits

a “beep” ( ) and a red LED

ashes. The Control Unit makes

a buzzing sound and the Heat

Sensor emits a “beep” ( ).

4. After 5 seconds, the Heat

Sensor gives an alarm (rst

one "beep" and after a while

continuous beeping).The Control

Unit and the Heat Sensor are

now successfully paired.

5. Reset the test alarm by pressing

shortly the Heat Sensor button.

Check that the cooker can be

turned on. If the Heat Sensor

does not respond or if the test

alarm cannot be reset, see FAQ,

page 9 of the User Guide, points

5 and 6.

Reset

button

REPLACING SENSOR

AND CONTROL UNIT

Table of contents

Other Fire Chief Home Safety Product manuals