Fireye InTouch IT1000 User manual

1

DESCRIPTION

The Fireye®inTouch Type IT1000 provides continuous monitoring of the Flame-Monitor, MicroM

and BurnerLogix Y & Z flame safeguard controls. In the event of a lockout, the inTouch system

reports the condition causing the lockout and also the make, model and location of the equipment

over the wireless GSM cellular network using a wide variety of delivery methods, i.e. telephone, fax,

e-mail, pager (alphanumeric, numeric). The user also configures which individuals will receive a

message regarding certain operating conditions.

The inTouch system also provides additional inputs to monitor up to 4 each of both dry contact

inputs and AC powered input. The inputs can be connected to additional ancillary devices located in

a boiler room that are considered critical to proper operation. These may include compressor out of

range, water on the floor, float levels, freeze conditions, etc. The inTouch system can be configured

to provide distinct messages for each monitored point. Two each of the dry contact and AC voltage

inputs can be configured to alarm on contact close or open or on voltage present or absent.

Also, every 24 hours, the inTouch system will transmit to the server message center information

about itself and the controls connected. This information transmitted contains system hours, burner

cycles, burner hours and total lockouts.

The inTouch Wireless Monitoring System provides many operational characteristics including:

Immediate notification of lockout

•24/7 monitoring

•Direct interface to Flame-Monitor, MicroM or BurnerLogix

•Utilizes cellular network – GSM

•Monitors up to 10 Flame Safeguard Devices

•Monitors 4 dry-contact inputs, selectable alarm on open or close

•Monitors 4 AC inputs, selectable alarm on no voltage or voltage

•Selectable 4800/9600 baud rate

•Battery back-up

•Service button, test message

•24 Hour heartbeat status

•User configurable messages

•NEMA 4 housing

•Low monthly service charge

TYPE IT1000

WIRELESS MONITORING SYSTEM

for FLAME-MONITOR

MicroM and BurnerLogix

FLAME SAFEGUARD CONTROLS

WIRELESS MONITORING SYSTEM

INT-1000

APRIL 12, 2017

2

SPECIFICATIONS

Power:

Input Voltage: 85 - 120VAC 50/60 Hz

Battery Backup: 9.6 VDC NICAD

Environment

Operating Temperature: -40 to 160°F (-40 to 70°C)

Storage Temperature: -40 to 160°F (-40 to 70°C)

Enclosure

Type: NEMA-4 suitable for outdoor mounting

Dimensions: 7 1/8"W x 9 5/8"H x 3 1/2"D (18 x 24.5 x 8.9cm)

Material: UV Resistant ABS Grey

Knockouts: 3 bottom, 3 rear (1/2", 3/4" concentric)

Inputs

RS485,

Modbus RTU Protocol: 4800/9600 baud, selectable

4 AC Inputs: 24-120VAC; 3mA

4 Switch: Dry contact closures

Radio

Transmit: 900 - 1800 MHz

Receive: 900 - 1800 MHz

Output: 1.5 Watts

Antenna: Quad Band GSM Antenna

2.25

1.13

8-5/16

9.87

3-3/8

#0.40

3 PLACES

3-3/4

2

2

1-1/16

3

ORDERING INFORMATION

Table 1: ACCESSORIES

FCC WARNING

WARNING: This equipment generates, uses, and radiates radio frequency energy and if not

installed and used in accordance with the instructions manual, may cause interference to

radio communications. It has been tested and found to comply with the limits for a Class A

computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to

providereasonableprotectionagainst suchinterference when operatedina commercialenvi-

ronment. Operation of this equipment in a residential area is likely to cause interference. If

this is the case, the user, at his own expense, will be required to take whatever measures may

be required to correct the interference.

The inTouch System continuously monitors each Flame-Monitor, MicroM and/or BurnerLogix con-

nected by requesting its status using modbus protocol. Up to 10 Fireye controls can be connected to

the inTouch System and a poll to each address is made once per second. If the Fireye control reports

that it is in a lockout condition or if the control fails to report, the inTouch immediately transmits this

information to the Fireye message center. The message center then transmits this specific informa-

tion to the destination previously configured by way of several different methods. The methods

include telephone, fax, e-mail, pager (alphanumeric, numeric).

For proper operation, the inTouch System must be installed and then configured over the Fireye

web-site, www.fireye.com. Each inTouch system is shipped with a designated base address. This

address is used as the base reference for all Fireye controls subsequently connected. When attaching

Fireye controls, each control must have a unique address within the range of 0 through 9. When con-

figuring the inTouch over the web-site, the device installed will be the base address of the inTouch

plus the unit address of the Flame-Monitor, MicroM or BurnerLogix control. For example, if the

inTouch base address was 330 and three (3) controls with unit address of 0, 1, and 4 were being

connected, the devices installed on the web-site would be 330 (330 + 0), 331 (330 + 1) and 334

(330 + 4). The ancillary dry-contact or AC inputs are attached to the base address, by default.

The lockout message transmitted is the same message the Flame-Monitor, MicroM or BurnerLogix

Y & Z would have on its local display. Refer to bulletin E-1101, MC-5000 BL-1001 and /or

BLZ-1001 for lockout message information and description. If an E300 Expansion Module is used

with the Flame-Monitor or a YZ300 is used with the BurnerLogix, the lockout message pertaining to

the E300 or YZ300 lockout will be transmitted. Additionally, any lockout message can be re-pro-

grammed on the message server to match the user’s application.

Each inTouch unit is limited to 40 messages per day and a maximum frequency of 1 message

per minute. Up to 10 alarm messages can be stacked, pending transmission.

PART NUMBER DESCRIPTION

IT1000 Monitor up to 10 Flame-Monitors, MicroM or BurnerLogix Y & Z controls, 4 dry-con-

tact, 4 AC input. Complete with 3 Quad Band GSM antenna and communication cable.

PART NUMBER DESCRIPTION

N018042-10 Remote Quad Mount Antenna without mounting kit (includes 10 ft coax cable)

N018040-KIT Remote Quad Mount Antenna with mounting kit (includes 10 ft coax cable)

N200233-00 Remote mount U bolt - 1/2” OD pipe size (included in remote mounting kit)

N250339-00 Remote mounting bracket (included in remote mounting kit)

59-509-10,-15,-20,-25 Coax cable extension

ED-512-2,-4,-8 Cable with RJ12 connector used to connect BurnerLogix and Flame-Monitor to ED-610

ED-610 Telephone jack adapter board for multi-dropping controls

4

INSTALLATION

Connecting the Antenna

•A Quad band GSM antenna is provided with the unit. Optional high gain antennae (see ACCES-

SORIES) can be ordered if the site in question has weak cell coverage.

•The antenna connections on the enclosure are factory installed to prevent water from entering

the enclosure.

DO NOT change any of these existing connections.

•Simply screw either antenna to the connector (see Figure 1) on the top of the enclosure. Be sure

the connection is tight.

Startup Procedure

•Take the transmitter to the area where the equipment to be monitored is located.

•The transmitter will be able to send messages in locations where GSM cell phones will work. If

the equipment is in an area where an GSM cell phone cannot get a signal, it is unlikely the trans-

mitter will be able to get a signal. (NOTE: A remote antenna is available, see next section).

•Plug in the battery pack into the battery pack connector (see below). Connect AC power to the

appropriate terminals located in the lower right corner.

•The transmitter will begin a startup routine. The startup time will vary but may last up to several

minutes as the transmitter establishes a connection to a cell site and registers a message.

•During the startup routine, the Signal Strength Indicator 7-segment LED display segments will

rotate. Initially, the middle display segment will not be lit. When the middle segment comes on,

the transmitter has successfully completed the first half of the startup routines.

Dipswitch Settings

The inTouch unit contains 4 user configurable dipswitches. Some dipswitch settings take effect

during the power up initialization sequence. Changing a dipswitch on the fly may require a power

on/off sequence.

SWITCH OFF ON

ONE (1) Do not report end of lockout Report end of lockout

TWO (2) 4800 Baud Rate 9600 Baud Rate

Note: All connected controls must have the same baud rate.

THREE (3) For dry contact inputs 3 & 4 , alarm on close For dry contact inputs 3 & 4, alarm on open

FOUR (4) For voltage inputs 7 & 8, alarm with voltage present For voltage inputs 7 & 8, alarm with no voltage present

5

FIGURE 1.

Checking Cell Coverage

•Once the startup procedure is complete, the Signal Strength Indicator display will show the cell

signal strength the transmitter registers at its current location.

•The cell signal strength can range from 0 to 9.

•The higher the signal strength number, the better the signal.

•A signal strength less than 3 will not provide reliable message transmission. A remote antenna

may be required.

1

2

3

4

5

6

7

8

1. Antenna

2. Socket Modem (GSM)

3. Antenna cable connection

4. Processor module (internal)

5. Option button (alarm silence)

6. Service button (snooze)

7. Status lights

8. Input indication lights

9. Relay indication lights

10. Fuse, 1 amp, 250 volt, fast blow, 3AG*

11. AC Power supply 23, 24 (85-120 VAC, 60 Hz)

‡

12. Use this knockout for Class I leads

†

13. Device wiring 22 (earth ground)

14. Voltage inputs 13-20 (24-120 VAC or 5-48 VDC)

10*

11

1219

1314

15

16

18 17

20

23

21

24

22

15. Terminal blocks (use 12-18 AWG for connections)

16. Dry contact inputs 5-12 (do not apply voltage)

17. Relay inputs (not used)

18. Relay inputs (not used)

19. Use this knockout for Class II leads

20. DC power supply connection (12 or 24 VDC)

21. Battery pack connector (not connected in DC-powered

installations)

22. Signal strength (LED) indicator (0-9=signal strength,

F=service mode)

23. Modbus RS-485 RJ11

24. DIP switches

24. S-485 RJ11 communication ports or factory test

ports

24. DIP switches; see Section 2.10

* A blown fuse usually indicates a problem that needs to be corrected. Do not relace the fuse without

identifying and correcting the problem.

9

12 43

113 14 15 16 17 18 19 20 21 22 23 24

23456789101112

6

Checking Fireye Service

•A coverage map is available at the Fireye web site (www.fireye.com) under Coverage Maps.

Simply enter the zip code where you wish to install the transmitter to determine if coverage is

available.

•The transmitter sends out a sample message and then waits for a return signal to determine if

Fireye service is available at this site.

•If the transmitter registers Fireye coverage, then the yellow status light (see below) will flash

once per second and the signal strength will be displayed.

Location

•The transmitter can be located either indoors or outside.

•Walk around the equipment or the equipment room with the transmitter powered by the battery

pack.

•Place it in several sample mounting locations and check the signal strength.

•If planning to mount the transmitter directly on a piece of equipment, check locations where the

antenna rises above or is directed away from the equipment.

•Once the mounting location with the strongest (highest number) signal strength is found, remove

the battery pack connection.

Mounting

•Choose a surface which is flat and strong enough to hold the transmitter.

•Antenna must clear the top of the equipment by 2 inches minimum.

•The temperature range the transmitter will experience should not exceed -40°F to 140°F (-40°C

to 60°C).

•The transmitter enclosure has one keyhole mounting tab extending from the top of it and two

mounting tabs extending underneath. Use all three tabs to secure the unit.

•DO NOT drill any holes into or through the enclosure.

•Filed wiring to the inputs must be a minimum of AWG and a maximum of 12 AWG.

Wiring Guidelines

•Remove the black inside cover which is secured with a screw at each corner of the enclosure.

•The Input terminals and Lights will now be visible.

•The enclosure is equipped with 6 knockouts. DO NOT make any other holes in the enclosure.

•All Class 1 wiring (AC input wiring) should enter the enclosure through a different knockout

from Class 2 wiring (dry contact, communication). Refer to the NEC handbook

•After removing a knockout, seal it with a watertight fitting if the transmitter is being mounted

outdoors.

Power Connections

•The rightmost three (3) input terminals are for the power connection.

•Whenever possible, power the transmitter from the same source as the equipment is powered.

This will ensure the Power Loss message will occur when the equipment and the transmitter

lose power.

•Connect back-up battery before wiring main power.

•The transmitter can accept an input voltage range from 85 to 120VAC, 50/60Hz.

Connecting a Remote Antenna

•Remote antenna mounting kits are also available. Extension cables are available in 10, 15 20 and

25 ft. increments, but we do not recommend more than a 50 ft. extension. Please check www.fir-

eye or contact the factory.

•The antenna connections on the enclosure are factory installed to prevent water from entering

the enclosure. DO NOT change any of these existing connections. Disconnect the standard

antenna cable from the radio when installing a remote antenna.

7

Record Equipment Information

•Either fill in the enclosed MONITORED EQUIPMENT I.D. CARD with the fields described

below or call your home office with all the following information:

•The Location Name for the piece of equipment being monitored.

•The exact Street Address, and the City, State, and Zip code where the transmitter is located.

•The Local Contact Phone and Name should be the phone number and name of the person(s)

who would need to be contacted to gain access to this transmitter.

•The Device ID number located on the black protective cover inside the transmitter. This is also

preprinted on the INSTALLATION card.

•The Equipment Name for the piece of equipment being monitored. Try to be as specific as possi-

ble, especially if there are multiple pieces of equipment which will have transmitters installed at

a single site. Possible examples are North Roof Top AC, Boiler-5, Store A Refrigeration 3, etc.

•The Equipment Manufacturer, Model, and Serial Number. This information should be sufficient

to identify repair or replacement parts before a service person is dispatched to the site.

IMPORTANT: If this transmitter has not been configured previously, DO NOT leave the site

without recording the Device ID number. Without this number, the device cannot be config-

ured at the web site.

Testing

•To complete the test, the transmitter must be configured at the Fireye web site (see Configuring

the Device Messaging section). Note that while the following test is recommended, the transmit-

ter will send out a Heartbeat message every night. Therefore, it is possible to wait until the next

morning to determine if the transmitter sent out a message.

•The yellow status light should be flashing once per second (see Figure 2 on page 7). This indi-

cates the transmitter registers service, is available and is ready to send. The green status light

should not be on.

•Press the Service Button and then release it.

•The yellow light should now come on. The green light will flash several times. When the green

light flashes quickly for approximately 2 seconds, the message has been sent.

•After the message has been successfully sent, the green light will once again be off, and the yel-

low light should flash every second showing the transmitter is ready to send another message.

•Check the Fireye website to be sure the message was received.

FIGURE 2.

STATUS LIGHTS

No Service Available

Service Available, Ready to Transmit

Transmitting Message

Successful Transmission

YELLOW

YELLOW

YELLOW

YELLOW

GREEN

GREEN

GREEN

GREEN

OFF

OFF

FLASHING

OFF

ON

FLASHES

ON

FLASHES

Once/Second

Once or Twice

2 Second Rapidly

8

Connection to Fireye Controls

Each Flame-Monitor programmer module, engineering code 38 or greater for EP modules and

engineering code 4 or greater for EPD modules, comes standard with modbus protocol. The MicroM

control requires having the proper daughter board installed into the chassis. Refer to bulletin E-1101,

MC-5000, BL-1001 and BLZ-1001 respectively for more information. Connection to the Flame-

Monitor and BurnerLogix requires the use of an ED512 cable and ED610 multiport adapters. The

MicroM daughter board comes equipped with a terminal block for easy connection to twisted

shielded cable. The Flame-Monitor and MicroM controls are fixed at 4800 baud. The BurnerLogix

has selectable baud rates. All connected devices must have the same baud rate.

Flame-Monitor Hookup

•It is assumed the Flame-Monitor is mounted in a burner cabinet remote from the inTouch device.

Refer to Figure 6 on page 10 for an illustration overview.

•Plug the ED512 cable into either of the telephone style jacks located in the upper left corner of

the EP or EPD programmer module. Refer to Figure 3 on page 8

•Connect the other end of the ED512 into the mating connector located on the ED610.

•In accordance with local wiring codes, connect the twisted shielded pair (Belden P/N 8761) to

terminals 9 and 10 of the ED610 adapter and run the cable to either the next device to be multi-

dropped or to the inTouch device. Refer to Figure 6 on page 10 for suggested wiring diagram.

•Feed the cable into one of the knockout locations under the protective cover.

•Splice the twisted shielded cable onto a telephone style connector using the black (A) and yel-

low (B) wires. Plug the RJ11 type connector in either communication port of the inTouch

device.

•Replace the protective plastic cover.

•Configure the unit address of the Flame-Monitor.

•Set dipswitch 2 on inTouch to 4800 baud.

•Verify communications.

FIGURE 3. FLAME MONITOR CONECTORS

EP STYLE PROGRAMMER RJ12 CONNECTORS FOR ED512 CABLE

9

MicroM Hookup

It is assumed the MicroM is mounted in a burner cabinet remote from the inTouch device.

•In accordance with local wiring codes, connect the twisted shielded pair (Belden P/N 8945) to

the appropriate terminals located on the MicroM daughter board.

FIGURE 4. MICROM DAUGHTER BOARD

•Run the cable to either the next device to be multi-dropped or to the inTouch device.

•Feed the cable into one of the knockout locations under the protective cover.

•Splice the twisted shielded cable onto a telephone style connector using the black (A) and yel-

low (B) wires. Plug the RJ11 type connector in either communication port of the inTouch

device.

•Replace the protective plastic cover.

•Configure the unit address of the MicroM.

•Set dipswitch 2 on inTouch to 4800 baud.

•Verify communcations.

BurnerLogix Hookup

•It is assumed the BurnerLogix is mounted in a burner cabinet remote from the inTouch device.

Refer to Figure 6 on page 10 for an illustration overview.

•Plug the ED512 cable into either of the telephone style jacks located in the underside of the

YB110 or ZB110 module. Refer to Figure 5 on page 10

•Connect the other end of the ED512 into the mating connector located on the ED610.

•In accordance with local wiring codes, connect the twisted shielded pair (Belden P/N 8761) to

terminals 9 and 10 of the ED610 adapter and run the cable to either the next device to be multi-

dropped or to the inTouch device. Refer to Figure 6 on page 10 for suggested wiring diagram.

•Feed the cable into one of the knockout locations under the protective cover.

•Splice the twisted shielded cable onto a telephone style connector using the black (A) and yel-

low (B) wires. Plug the RJ11 type connector in either communication port of the inTouch

device.

•Replace the protective plastic cover.

•Set baud rate on inTouch dipswitch 2 to match the baud rate of BurnerLogix controls. (Note: All

devices must be the same baud rate).

•Configure the unit address of the BurnerLogix.

•Verify communications.

SERIAL COMMUNICATIONS

A

B

REMOTE DISPLAY

RJ45 JACK

REMOTE RESET

(RS485)

(+)

(-)

10

FIGURE 5. BURNERLOGIX CONNECTORS

FIGURE 6. WIRING FOR MODBUS PROTOCOL

Alternate Hook-up Method

To connect the inTouch to a Flame-Monitor or BurnerLogix without the use of the ED610, connect

the supplied cable from the inTouch to the ED512 directly or to a telephone handset type cable that is

commercially available.

FIGURE 7.

Verifying Communication

After all Fireye controls are properly connected and individually addressed, their connection to the

inTouch device can be verified by depressing and releasing the OPTION button 3 times. The 7-seg-

ment LED display will switch to a dash (—) symbol followed by the addresses of the devices it is

successfully communicating. The display will then show the dash symbol followed by the signal

strength power level it is receiving.

%1//5%1//5 ':2':2

470%*-470%*-

YB110 or ZB110

RJ12 CONNECTORS

FOR ED512 CABLE

ED610

10 9 8 7 6 5 4 3 2 1

J5

J1

ED610

10 9 8 7 6 5 4 3 2 1

J5

J1

E110

ED512-2, -4, -8

FLAME-MONITOR

BELDEN 8761

E110

ED512-2, -4, -8

FLAME-MONITOR

CLEAR

BLACK

TO RJ12 CONNECTOR ON

EP/EPD PROGRAMMER

TO RJ12 CONNECTOR ON

EP/EPD PROGRAMMER

J2

J2

FERRITE

CORE FERRITE

CORE

BLACK (A)

YELLOW (B)

SHOWN SHOWN

GREEN (NOT USED)

INTOUCH CABLE

ED512

(CUT OFF OND END)

BLACK (A)

YELLOW (B)

BLACK

RED

GREEN

YELLOW

11

SNOOZE Feature

To allow for regularly scheduled testing of boiler/burner safeties such as flame failure, low water cut

out, air flow checks, etc., without alarm messages being transmitted, the inTouch provides a

SNOOZE feature. During the SNOOZE period the inTouch will not respond to any alarm or reset

events.

The SNOOZE period lasts for 120 minutes and will automatically cancel if left uninterrupted. The

SNOOZE feature can be cancelled at anytime after safety tests are satisfactorily performed.

To active the SNOOZE feature, press the SERVICE button. A service message will be dispatched

and the display LED will change from its current signal strength reading to ‘F’. The automatic 120

minute SNOOZE period will now begin.

To de-active the SNOOZE period and resume normal operation, do nothing and this function will

cease after the 120 time out period or press the SERVICE button. The display LED will indicate the

current signal strength reading.

Auxiliary Device Connection

The inTouch system provides for the connection of 4 dry contact and 4 AC inputs, see Fig. 1 . These

can be used to transmit messages when a contact is detected as closed/open or power is applied/not

applied to the AC inputs. The AC inputs. The AC inputs accept voltages from 24 to 120 VAC at

3mA. Refer to dipswitch selection for dry contacts 3 & 4 and voltage inputs 7 & 8.

These can be used to connect to other equipment located in a boiler room such as other flame safe-

guard equipment that provide alarm output only. Dry contact devices used to detect empty fuel tanks,

condensate spills or water on the floor can be connected and give instant alarm when unwanted

events occur.

The messages transmitted can be configured to exactly what is causing the alarm condition. For

example, the default message Input 1 Activated can easily be changed to transmit Air Flow Input

Open. See the section on message configuration for more information.

M

M

AIR FLOW INPUT CONDENSATE INPUT AUX 1 USER DEFINED AUX 2 USER DEFINED

COMPRESSOR

RELAY

FAN RELAY FAN INPUT

COMPRESSOR INPUT

FAN MOTOR

COMPRESSOR

COMPRESSOR RELAY

LO PRESSURE LIMIT

HIGH PRESSURE LIMIT

HIGH PRESSURE INPUT LO PRESSURE INPUT

AIR FLOW OK CONDENSATE SPILL

12

CONFIGURING THE DEVICE MESSAGING

After you have received a Fireye inTouch User ID and password, continue with the steps below to

configure transmitter messages. If you have not, either contact the Fireye inTouch Account holder to

receive your User ID and password, or follow the steps in the next section to set up a Fireye inTouch

Account.

Access the Fireye Web Page

•The Fireye inTouch web page can be found at www.fireye.com.

•Navigate your way to the inTouch section.

•Note that any time you want to return to the home page just click on the inTouch logo in the

upper left.

•

Logging In

•Fill in the assigned User ID and Password. These are encrypted for security purposes.

•Click on Submit button.

FIGURE 8.

User Information

•If this is the first time you are using this User ID, then you will automatically see the Edit User

Info screen shown in Fig. 7. Otherwise, you can access this screen by clicking on the menu item

Edit user Info or, if you know the User Info is correct, move on to the next step.

•The information on this screen refers to the address where the user can be contacted. Do not use

this screen to input information on where the transmitter is located.

•All fields with check boxes are required.

•The four fields marked Phone, Fax, E-mail, and Pager will be the default locations where mes-

sages will be delivered. When setting up a particular unit, the values you input will automati-

cally appear in the delivery fields (make sure required fields are entered). This makes

configuring new units fast and easy. However, each message must be configured separately, and

the locations where each message will be sent can be modified as required.

•Once you have completed the form, click on the Submit button.

Enter the assigned User ID

and Password

Click on the Submit button

13

FIGURE 9. USER INFO

Device Summary

•When you have successfully logged in, you will be in the Device Summary screen (see Fig. 11).

•If you have any existing transmitters, they will appear in a list.

•To add your new device, click on the menu item Install New Device (see Fig. 8).

THESE ARE

THE DEFAULT

LOCATIONS FOR

MESSAGE

DELIVERY

CLICK HERE WHEN

YOU HAVE

COMPLETED THE

FORM

THE ADDRESS

PROVIDED

SHOULD BE THE

ADDRES OF THE

USER OF THIS

DEVICE

14

Input the Device ID number

•Before you can enter setup a new transmitter, you must know its ID number.

•The ID number for the transmitter is on a label on the radio and should be printed on the Moni-

tored Equipment card which was provided with the unit.

•Enter the ID number and click the Submit button.

FIGURE 10. INSTALL NEW DEVICE

New Equipment Location

•The New Equipment Location form (see Fig. 9) refers to the equipment this transmitter is moni-

toring. If there are multiple pieces of equipment with transmitters in a single location, the infor-

mation supplied should be sufficient to identify this particular piece of equipment from any

others.

•All the information should be recorded on the MONITORED EQUIPMENT I.D. CARD pro-

vided.

•All the fields marked with check boxes are required.

•Do not use abbreviations such as St for Street or Rd for Road if you plan to use the voice mes-

sage delivery.

•Do not use uppercase letters for words if you plan to use for voice message delivery (example -

use “flow” not “FLOW”) as the synthesized voice will annunciate the individual letters not the

word.

•The address fields should have the address where the transmitter is installed.

•The contact information should contain the name and phone number of the individual(s) who

can provide access to the particular piece of equipment.

•The bottom four fields identify the equipment. It is important to get as much information about

the equipment being monitored as possible. The information should be sufficient so a service

person can get any appropriate parts for maintenance or repair before going to the equipment

site.

•A sample e-mail message containing all the equipment information is shown on later in this sec-

tion.

THE DEVICE ID IS MARKED

ON THE RADIO IN THE INTOUCH

UNIT AND ON THE

INSTALLATION CARD PROVIDED

CLICK HERE AFTER ENTERING

DEVICE ID NUMBER

15

FIGURE 11. NEW EQUIPEMENT INFORMATION

BE AS SPECIFIC AS POSSIBLE

THIS IS THE ADDRESS OF THE

EQUIPMENT THE TRANSMITTER

IS MONITORING

THIS INFORMATION SHOULD BE COMPLETE

ENOUGH TO ALLOW A SERVICE PERSON TO

GET THE APPROPRIATE PARTS BEFORE

COMING TO THE EQUIPMENT SITE

CLICK HERE WHEN

THE FORM IS

COMPLETE

CHOOSE FLAME-MONITOR, MircoM or BurnerLogix

16

Message Delivery

The default information entered in the Edit User Info (see Fig. 7) form will appear in the New Device

Delivery form. You can use the default values or you can change them.

You can change where each type of message is sent and the message wording by clicking on Mes-

sage Delivery on the menu bar and editing the information (see Fig. 13). To access Message Delivery

menu, first click on View and Edit Device then click on Location Name. If you do not change them,

then each message sent will be delivered to the Phone, Fax, E-mail, and/or the Pager specified in

this form.

You MUST click on a check box on the right to enable a delivery method, and at least one MUST be

checked.

The Delivery Attempts field indicates how many times Fireye will attempt to deliver a message if the

message is not successfully received. When the message is delivered successfully, no more attempts

will be made.

If the message is not successfully delivered after the specified number of Delivery Attempts, an

e-mail will be sent to the e-mail address of the Account holder (as set in the form Open an Account

shown in Fig. 14). This will alert the Account holder that the User information may need to be

changed or updated.

•The Retry Interval is the time period Fireye will wait between attempts to deliver the message.

FIGURE 12. MESSAGE DELIVERY OPTIONS

Click on each type for

detailed instructions

Transmitter

messages will be

delivered via any

of these modes

when SET box is

checked.

Number of

unsuccessful

delivery attempts and

the time between them

Click here after you enter

and checked off desired

delivery methods

At least one method must be

checked to enable

17

Transmitter is now included in the Device Summary

•You will now return to the Device Summary screen as shown below.

•The basic information on your transmitter will appear.

FIGURE 13.

Device Information

•Clicking on the Location field (shown above) will bring up the Device Information screen

(Fig. 12).

•A summary of the information which was entered in Fig. 8 (New Equipment Information)

appears. If any of the information is not correct, click on the button Edit Device Location to

make changes.

•Click on the menu item Message Delivery to edit message descriptions and to select where each

type of message will be delivered.

Click on this field to see the messages and

detailed information for any transmitter

18

FIGURE 14. DEVICE INFORMATION

Device Messages

•Clicking on the menu item Message Delivery will bring up the Device Messages screen as

shown in Fig. 13.

•Each unit comes with predefined default messages. The description of the message can be

changed for your specific application. Click on any field in the Description column to change it.

•Each specific message can be configured to be sent to various addresses using different delivery

methods.

•To change an existing delivery address, click on any field in the Delivery Address column to

change it. Note the only acceptable characters are A-Z, a-z and 0-9. Units of measurement, such

as degrees or pounds should be spelled out and not abbreviated.

•To add a new delivery address for a message, click on the Add field.

•To remove a delivery method and address for a specific message, click on the Delete field.

CLICK HERE FOR GRAPHICAL

VIEW OF EQUIPMENT USAGE

CLICK HERE FOR

LAST 90

LOCKOUTS OR

HEARTBEATS

19

FIGURE 15.

TO MAKE ANY

CHANGES, CLICK

ON EDIT, DELETE

OR ADD

20

Check the Transmitter

•Check that the service button message will be sent to the appropriate address with the appropri-

ate delivery method as described above.

•Have someone at the transmitter site press the Service Button (Fig. 1). If you do not have some-

one to press the Service Button, you can wait until the next morning and check the Heartbeat.

•The Device Information screen will show the message that the service button has been pressed.

•Also check that all the other appropriate messages were received. A sample e-mail message

appears below. Make sure the appropriate individuals were paged, that the appropriate faxes

were sent, and the appropriate phone calls were made.

Check the messages

•Confirm the equipment information is correct including the name, model, make and address.

•Confirm the contact information is correct. The contact information should be the name and

phone number of the individual(s) who can provide access to the equipment.

From: Fireye

Sent: Sunday, May 20, 2001 9:08 PM

Subject: May 20 2001 9:08PM (6852/40413)

Service Button on: Boiler 1 at: Calley's Crab

Shack,

102 Waterfront Ave, Wilmington, DE.

Contact: Hearty Seaman at: (302)555-5555

(Make: Model:)

www.fireye.com

Wireless Monitoring... Online

Table of contents

Other Fireye Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Zenner

Zenner zelsius C5-ISF Installation and operating instructions

Rohde & Schwarz

Rohde & Schwarz R&S NGU Series Getting started

Velleman

Velleman DVM853 user manual

Kubler

Kubler CODIX 134 operating instructions

Sper scientific

Sper scientific AquaShock 850046K user manual

VOLTCRAFT

VOLTCRAFT VC-1310 operating instructions

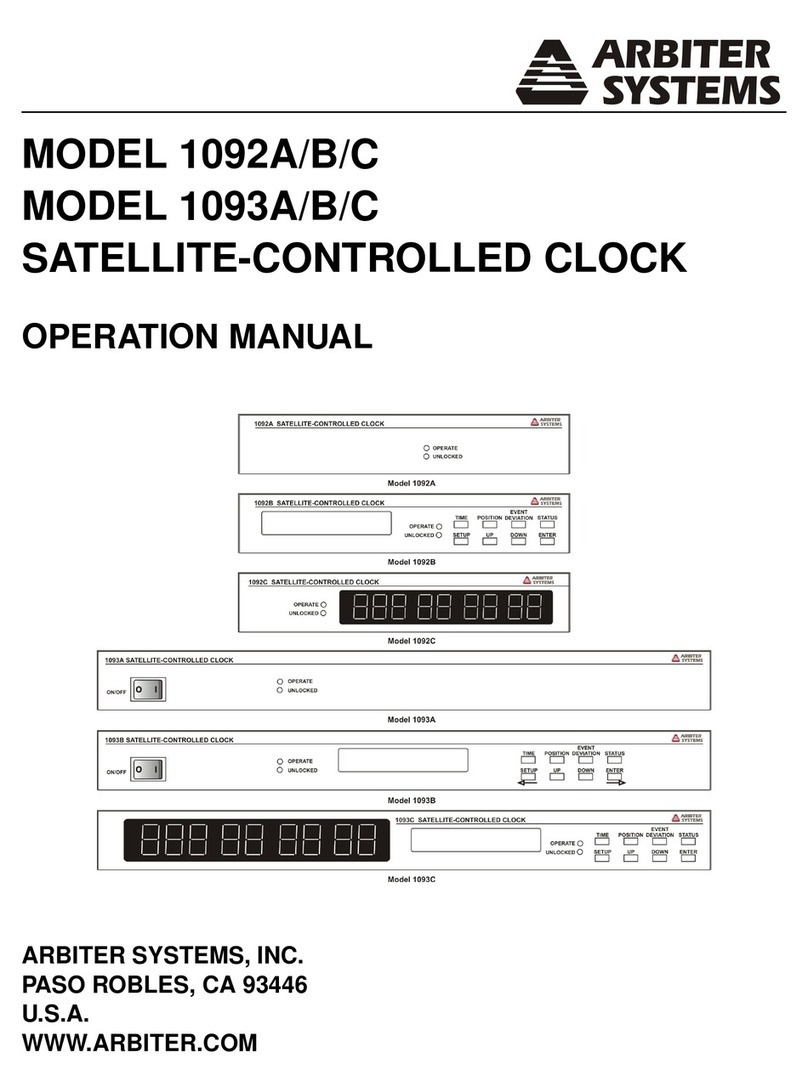

Arbiter Systems

Arbiter Systems 1092A Operation manual

Lennox

Lennox Smart Air Quality Monitor Installation and setup guide

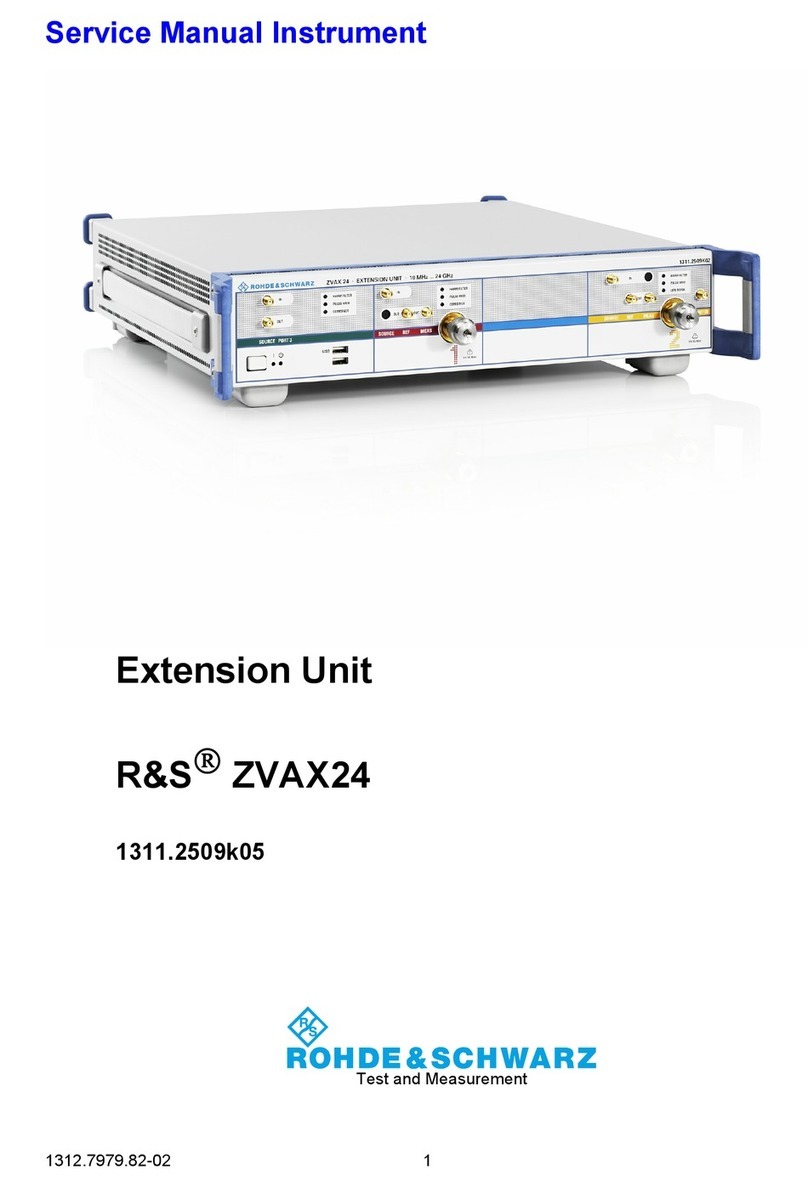

Rohde & Schwarz

Rohde & Schwarz ZVAX24 Service manual

TESTO

TESTO 470 instruction manual

TSI Instruments

TSI Instruments AirAssure quick start guide

GeoMax

GeoMax Zoom80 Series user manual