Fireye 45UV5 Series Operating and installation instructions

1

®

-14368%28238)

The information provided in this bulletin is directed to competent boiler and combustion service

technicians who are experienced in the installation and operation of Fireye Flame Safety equipment.

Persons not familiar with Fireye products should contact the nearest Fireye representative or other

qualified service group.

The 45UV5 scanners as well as all other Fireye scanners, are designed to be used exclusively with

the appropriate Fireye Flame Safeguard and Burner Management controls. The application of these

scanners to other than Fireye equipment should be reviewed for approval by Fireye.

%440-'%8-32

Fireye 45UV5 self-checking scanners are used to detect ultraviolet emissions from fossil fuel flames

such as natural gas, coke oven gas, propane, methane, butane, kerosene, light petroleum distillates

and diesel fuels.

These 45UV5 models are used only with the Flame-Monitor, BurnerLogix, D-Series, FlameWorx,

MicroM and some P-Series Fireye control models to provide flame safeguard and monitoring sys-

tems for supervised manual, semi-automatic and fully automatic single burner boilers, process ovens

and heaters.

46-2'-40)73*34)6%8-32

The 45UV5 scanners use a UV-eye detector. This detector is a sealed, gas filled, UV-sensitive tube

containing two electrodes connected to a source of AC voltage. When UV radiation of sufficient

energy falls upon the electrodes, electrons are released and the inter-electrode gas becomes conduc-

tive, resulting in an electric current flow from one electrode to the other. The current flow starts and

ends abruptly and is known as an “avalanche.”

A very intense source of UV radiation will produce several hundred avalanches or pulses per second.

With less radiation there will be fewer pulses per second. Upon total disappearance of flame, the

detector output ceases. Thus, the presence or absence of pulses is an indication of the presence or

()7'6-48-32

%2(

-278%00%8-32

*SV9:9:WIPJGLIGOMR 7GERRIV1SHIPW

9:9:

9:9:

9:ERH9:

*SVYWISRP][MXLHIWM REXIH*MVI]I

GSRXVSPW

*SV-RJVEVIH4LSXSGIPP7GERRIVWYWI7'

*SVRSRWIPJGLIGOMR 9:7GERRIVWYWI7'

7'

.90=

APPROVED

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

2

®

absence of flame; the frequency of the pulses is a measure of flame intensity. Pulses generated by the

scanner are transmitted to a compatible Fireye control via scanner wiring.

*)%896)7

The components are contained in a cast aluminum housing sealed with an oil-resistant gasket. The

quartz lens is a planoconvex design, resulting in increased sensitivity. Also included in the scanner is

an electromagnetic shutter that permits a self-checking circuit to verify that the scanner and signal

circuits are producing valid flame presence or absence information. During the shutter closed period,

the detector’s optical path is blocked from flame radiation, allowing the amplifier control to verify

the proper operation of the ultraviolet tube. While the shutter is open, flame presence or absence is

detected. The resultant scanner output (while flame is detected) is a continuous, periodically inter-

rupted, pulsed flame signal which is a prerequisite for energizing the associated Fireye control’s

Flame Relay.

74)'-*-'%8-327

FIGURE 1.

74)'-*-'%8-3278%&0)

NOTE 1: Flame-Monitor, EUVS4; D-Series, 72DUVS1T, 72DUVS4; MicroM, MEUVS1, MEUVS4; FlameWorx; MBUVS-301D, MBUVS-

311D, BurnerLogix, YB110UVSC.

NOTE 2: Models 1006,1007,1008 and 1009 have shutter drive circuitry within the scanner. Models 1005and 1105have shutter drive circuitry

in compatible control.

NOTE 3: When using FlameWorx modules, MBUVS-301D and MBUV-311D, refer to bulletin FWX-1001for proper wiring terminals.

NOTE 4: Controls no longer manufactured.

NOTE 5: 45-1005and 45-1105are NOTFM approved for use with 25RU8-4580,25SU5-4013/4113-4113T/4116T-4116/4119.

NOTE 6: Extended temperature range applies to engineering code 3 and higher.

13()023 8,6)%(7 231-2%07,988)6

838%0'='0)4)6-3(

:308%+),> 8)146%2+) 97)320=;-8,

'32863013()07

8)61-2%07

7,988)6

&0/

7-+2%06)( 1%< 1-2 7-+2%0 7,988)6

9:

248

6IKYPEXIHF]

G RXV P :('

:%'

°*

°'

°*

°'

69

79

88

d7IIR XI

d7IIR XIFYX

QYWXYWI

X

G RXV PWLYXXIV

%PP

1 HIPW

%PP

1 HIPW

9:

&74

:%'

9:

248 WIGGP WIH

WIG TIR

:%' :%'

°*

°'

7II

2 XI

°*

°' (7IVMIW

(9:73RP] 77 00

9:

&74 WIGGP WIH

WIG TIR

:%' :%' °*

°'

7IIR XI 77

7IIR XI

00

9:

&74 WIGGP WIH

WIG TIR

:%' :%' °*

°'

7IIR XI 77

7IIR XI

00

9:

248 WIGGP WIH

WIG TIR

:%' :%' °*

°' 7IIR XI 77

7IIR XI

00

3/8” -18 NPT OR

3/8” - 18 BSP-PL

45°

(51)

8 1/4" (210)

2"

(51)

MIN

CLEARANCE

PURGE AIRCONNECTION

4" (102)

111/16”

HEX.

(43)

1" - 11 1/2N.P.T.

(BSP-S1)

SIGHT PIPE

CONNECTION

HOUSINGMATERIAL:

ALUMINUM

REQUIRED

TOREMOVE

2

TYPE 45UV5

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

3

®

Housing Material: Cast aluminum

Weight: 7lbs. (3.2kg)

Housing Dimensions: See Fig. 1

Purge Air: 4 SCFM (113L/min) at 3/8 inch threaded housing inlet or 4 SCFM at 1inch wye fitting

in scanner sight pipe. Temperatures near the upper limit of the scanner operating range and/or use

with dirty duels may require up to 15 SCFM (425 L/min.).

Optical Range:2200 to 2600 angstroms. No response to infrared radiation or visible light.

Optical Field of View: 1inch per foot (25.4mm/305mm)

Operating Range: 72 inches (1830mm) or less.

-278%00%8-32

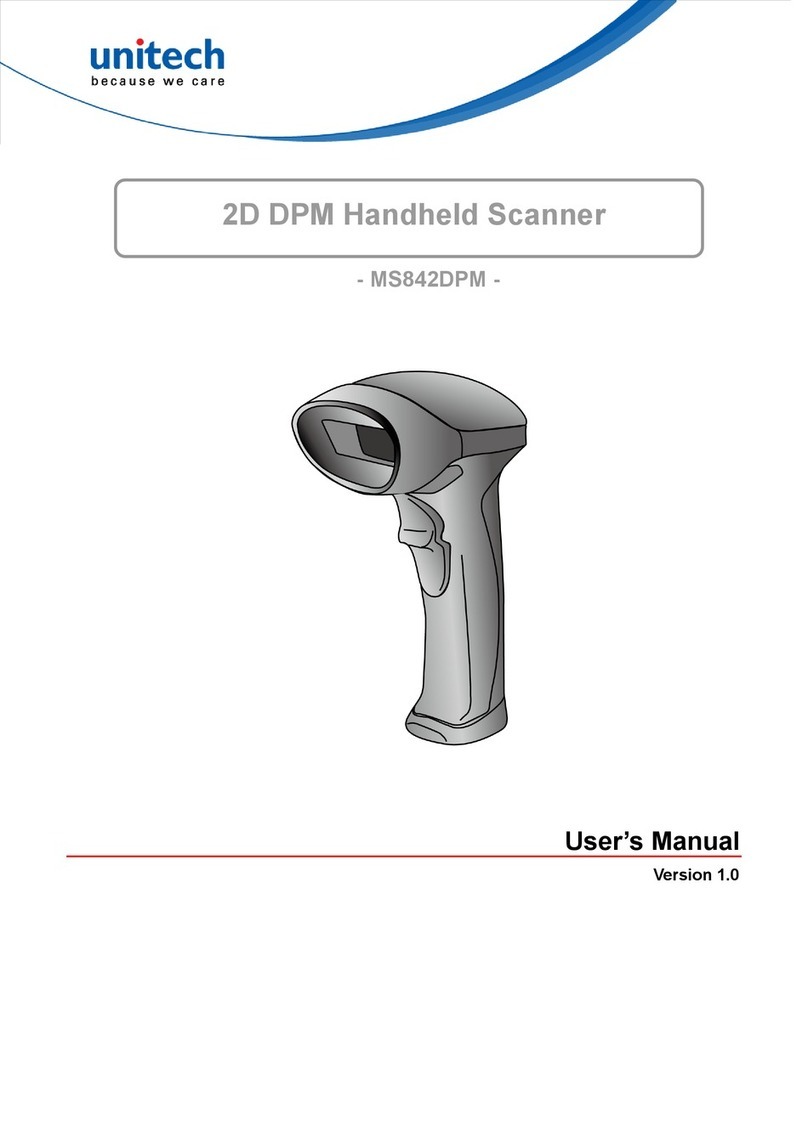

The best scanner sighting results are obtained when the scanner is aimed so that its line of sight inter-

sects the burner center line at a slight angle, as shown in Figure 2. The area of maximum ultraviolet

radiation is near the base of the flame envelope. When only one scanner is used per burner, the inter-

section should be made so the line of sight or viewing angle can also see the pilot flame. Consider-

ation must be given to burner secondary air rotation (some burners have clockwise air rotation and

others counter-clockwise). Figure 3illustrates how scanner location is influenced by the pilot posi-

tions and secondary air circulation. Physical obstructions such as air register blades should not fall in

the line of sight of the scanner.

FIGURE 2.

1.

ANACCEPTABLESCANNER LOCATIONMUST ENSURETHE FOLLOWING:

— Reliable pilot flame detection.

— Reliable main flame detection.

— Rejection of pilot flame too short or in the wrong position to ignite the main flame reliably,

thus prohibiting main fuel admission.

NOTE:Reliable signals must beobtained at all air flows and furnace loads (ranges of fuel firing).

PRIMARY

COMBUSTION

AIRREGISTER

BLADES

SCANNER

LINEOF

SIGHT

BURNER

THROAT

FLAME

ENVELOPE

SINGLE BURNER SCANNER SIGHTING

BURNER

CENTER LINE

BASE

ZONE

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

4

®

FIGURE 3.

2.

If combustion air enters the furnace with a rotational movement of sufficient velocity to deflect

pilot flame in direction of rotation, position the scanner 0to 30 degrees downstream of the pilot

burner and close to the periphery of the throat where the ultraviolet radiation is at a maximum.

(See Figures 2and 3).

3.

Having determined an appropriate location for the sight tube, cut a clearance hole for a 2inch

pipe through the burner plate. If register vanes interfere with the desired line of sight, the inter-

fering vane(s) should be trimmed to assure an unobstructed viewing path at all firing levels, see

Figure 4.

4.

Mount scanner sight pipe by either:

— Centering a Fireye No. 60-1664-3(NPT) or 60-1664-4 (BSP) swivel mount over the hole

and installing the sight pipe on the swivel mount,

or

— Inserting the end of the sight pipe into the hole, aligning the pipe to the desired viewing

angle and tack welding. (Welding must be adequate to temporarily support the weight of the

installed scanner). The sight pipe should be arranged to slant downward so that the dirt and

dust will not collect in it.

FIGURE 4.

5.

When a satisfactory sighting position has been confirmed by operational test, (see section on

alignment), the sight pipe should either be firmly welded in place or, if the swivel mount is used,

the base position should be secured by tightening the three hex head cap screw located on the

swivel mount ring. In certain older style swivel mounts, tack welding may be required.

6.

Excessive flame signal can affect flame discrimination and prevent the control connected to the

scanner from performing properly. To reduce the signal level of the tube, or improve flame dis-

crimination, orifices may be installed to decrease the scanner’s field of view and reduce its sen-

sitivity. Installation of the orifice disk is shown in Figure 6.

7.

The scanner viewing window must be kept free of contaminants (oil, smoke, soot, dirt) and the

scanner temperature must not exceed its maximum rating. Both requirements will be satisfied by

continuous injection of purge air.

The scanner mounting may be made with provision for purge air through the 3/8” opening as shown

in Figure 5, Item A or C, or through a 1" tee/wye connection as shown in Figure 5, Item B. Normally

only one of the two connections is provided with purge air and the other is plugged. When a Fireye

union is used as shown in Figure 5, the 1" tee/wye connection is used for the purge air (plug 3/8”

opening).

IGNITOR

SCANNER

MAIN BURNER

CCW ROTATION

SCANNER LOCATIONVS. SECONDARY AIR ROTATION

IGNITOR

SCANNER

MAIN

CCW ROTATION

BURNER

BUT THISNOT THIS NOT THIS

FLAME MUST COMPLETELY COVER SIGHT OPENING

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

5

®

Under normal temperature conditions, with clean burning fuels and moderate ambient temperature

conditions, purge air flow of approximately 4 SCFM (113 L/min) is generally adequate. A 0.1psig

positive pressure difference between the atmosphere and boiler pressure measured at right angle to the

purge air flow, should result in a purge air flow of 4 SCFM. Up to 15 SCFM (425 L/min) may be

required for fuels that may produce high levels of smoke of soot or for hot environments to maintain

scanner internal temperature within specifications.

NOTE:The maximum viewing field of the lens is one inch per foot.Do not use more than one foot of

one inch sight pipe.Increase sight pipe diameter one inch for everyadditional foot of sight pipe

length used,to avoid restricting the scanner’sfield of view.Temperature in the scanner housing

should not exceed those temperature limits listed in the specifications.Excessivetemperatures will

shorten scanner life.

FIGURE 5.

7'%22)6;-6-2+

All FIREYE controls are protected against short-circuited scanner input terminals. Following recom-

mendations apply for scanner-control wiring:The following recommendations apply for scanner con-

trol wiring:

d

Keep scanner wiring as short as possible.

d

Use wires rated for scanner voltage and its ambient conditions (temperature, humidity, oil resis-

tant, flame retardant, etc.)

d

Do not run scanner wires in the same conduit as other electrical wires.

r7;-:)013928

,)%8-2790%8-2+2-440)

78%2(%6(13928-2+

*368=4)73*7'%22)67

%-6)286=

496+)%2(

'330-2+

r7;-:)013928

,)%8-2790%8-2+2-440)

13928-2+*36

,-+,8)14

%440-'%8-327

496+)%-6)286=

'330-2+%-6)286=

496+)%2('330-2+

,)%8-2790%8-2+2-440)

r7-+,84-4)

&=38,)67

%-6)286=

496+)%2(

'330-2+

%08)62%8)78%2(%6(13928-2+

238%(.978%&0)

r7;-:)013928

,)%8-2790%8-2+2-440)

13928-2+*3674)'-%0

%440-'%8-327,-+,8)14

r409+

&=38,)67

,)%8-2790%8-2+2-440)

,)%8-2790%8-2+2-440)

7)%0-2+92-32;-8,59%68>

;-2(3;6)59-6)(;,)27'%22)6

0)27-7)<437)(83)<')77-:)

*962%')36;-2(&3<46)7796)

%4)6896)

r7;-:)013928

6)8%-2)6

'330-2+%-6)286=

496+)%2('330-2+

8))4-)')&=38,)67

8))4-)')&=38,)67

A

B

D

C

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

6

®

d

Avoid wire loops and poor groundings.

d

Keep high voltage ignition wires well away from scanner wires.

The 45UV5 self-check scanner has four 6foot (1800mm) leads:

9:

Two black leads which power the shutter from the associated control and two red leads which drive

the UV tube and carry the flame signal to the control amplifier.

9:

Two black leads which power the shutter via L1& L2and two red leads which drive the UV tube and

carry the flame signal to S1& S2on the control.

If it is necessary to extend the scanner wiring, the following instructions apply:

Scanner wires should be installed.in a separate conduit. The wires from several scanners may be

installed in a common conduit.

9:

1.

Selection of wire

—Use#14, 16, or 18 wire with 75 C, 600 volt insulation for up to 100 foot distances (signal

loss approximately 20% at 100 feet).

— Asbestos insulated wire should be avoided.

— Multiconductor cable is not recommended without prior factory approval.

—Extended Scanner Wiring. For extended scanner wiring up to 1500 feet, and for shorter

lengths to reduce signal loss, use a shielded wire (Belden 8254-RG62U) coaxial cable, or

equal for each red wire of the 45UV5. The ends of the shielding must be taped individually

on both ends and not grounded.

For multiple burner installations:

2.

Distances are decreased when more than one set of scanner leads are installed in a common con-

duit. For example, the maximum distance for 2scanners is 750feet and for 3or more scanners

the distance decreases to 500 feet.

3.

High voltage ignition wiring should not be installed in the same conduit with flame detector

wires.

WARNING:DO NOT CONNECT 45UV5 SCANNERS IN PARALLEL

16-24VDC TOCONTROL

SHUTTER

45UV5-1005, 1105

UV TUBE

560 VAC (RED)

BLACK L1, L2

SHUTTER

45UV5-1006, 1007, 1008, 1009

UV TUBE

RED S1. S2

ON CONTROL

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

7

®

45UV5-1005, 1105

1.

Up to 25 foot conduit run.

—Use#18AWG or heavier, 600V 90C minimum rated wire, installed in conduit.

2.

Over 25 to 300 feet maximum:

—Use#18AWG or heavier, 600v, 75C rated wire for the two black leads (shutter).

—Extended Scanner Wiring. For extended scanner wiring up to 1500 feet, and for shorter

lengths to reduce signal loss, use a shielded wire (Belden 8254-RG62U) coaxial cable, or

equal for each red wire of the 45UV5. The ends of the shielding must be taped individually

on both ends and not grounded.

For multiple burner installations:

3.

Distances are decreased when more than one set of scanner leads are installed in a common con-

duit. For example, the maximum distance for 2scanners is 750feet and for 3or more scanners

the distance decreases to 500 feet.

4.

High voltage ignition wiring should not be installed in the same conduit with flame detector

wires.

%0-+21)28%2(%(.9781)287

The following procedures are recommended to ensure optimum flame detection and discrimination.

Flame discrimination is the ability to see only one burner or one pilot with other burners or pilots

operating nearby. These procedures should be used whenever parts are replaced, when the scanner

has been moved, when the flame shape is altered (additional fuels, new burners, burner/register mod-

ifications) as well as on all new installations.

4MPSX*PEQI7GERRIV

1.

Apply power to scanner and associated control.

2.

Start pilot.

3.

Adjust scanner sighting to detect pilot flame in the manner shown in Figure 4.

4.

When flame is properly sighted, the flame signal should correspond to the acceptable ranges

indicated in the appropriate bulletin for each compatible FIREYEcontrol. If readings fluctuate

widely, readjust scanner sighting until highest, steadiest reading is obtained.

5.

When the proper signal reading has been obtained, make sure that the scanner and the associated

control do not respond to the ignition spark. This is accomplished by cutting off the fuel to the

pilot and attempting to start the pilot using the spark igniter. If the system responds to the spark,

the sighting should be realigned.

1EMR*PEQI7GERRIV

1.

Apply power to scanner and associated control.

2.

Start pilot.

3.

Adjust scanner sighting so that ignition spark and pilot flame are not detected. Test should be

conducted with maximum pilot flame and with both minimum and maximum airflow.

4.

Start main burner.

5.

Adjust scanner sighting to detect main burner flame. When sighting is correct (see above), the

signal should be read in the acceptable range for the control in use, without extreme fluctuations

6.

When proper signal is established, manually close off the main burner fuel supply. When burner

flame becomes unstable or is extinguished, the control should register a “flame failure” condi-

tion.

7.

Start an adjacent burner and vary its firing rate under normal airflow conditions. Make certain

that the main flame scanner on the burner not in service does not respond to adjacent burner

flame. Readjust sighting if necessary.

CAUTION:Minimum pilot is the minimum flame required to satisfactorily ignite the main

burner. Be sure to test for reliable signals under maximum airflow conditions when the pilot

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

8

®

7;-:)013928

The scanner swivel mount Part No. 60-1664-4 (BSP) 60-1664-3(NPT) is used to adjust the scanner

sighting angle after the scanner has been installed. The swivel mount is used as indicated the figures in

this document.

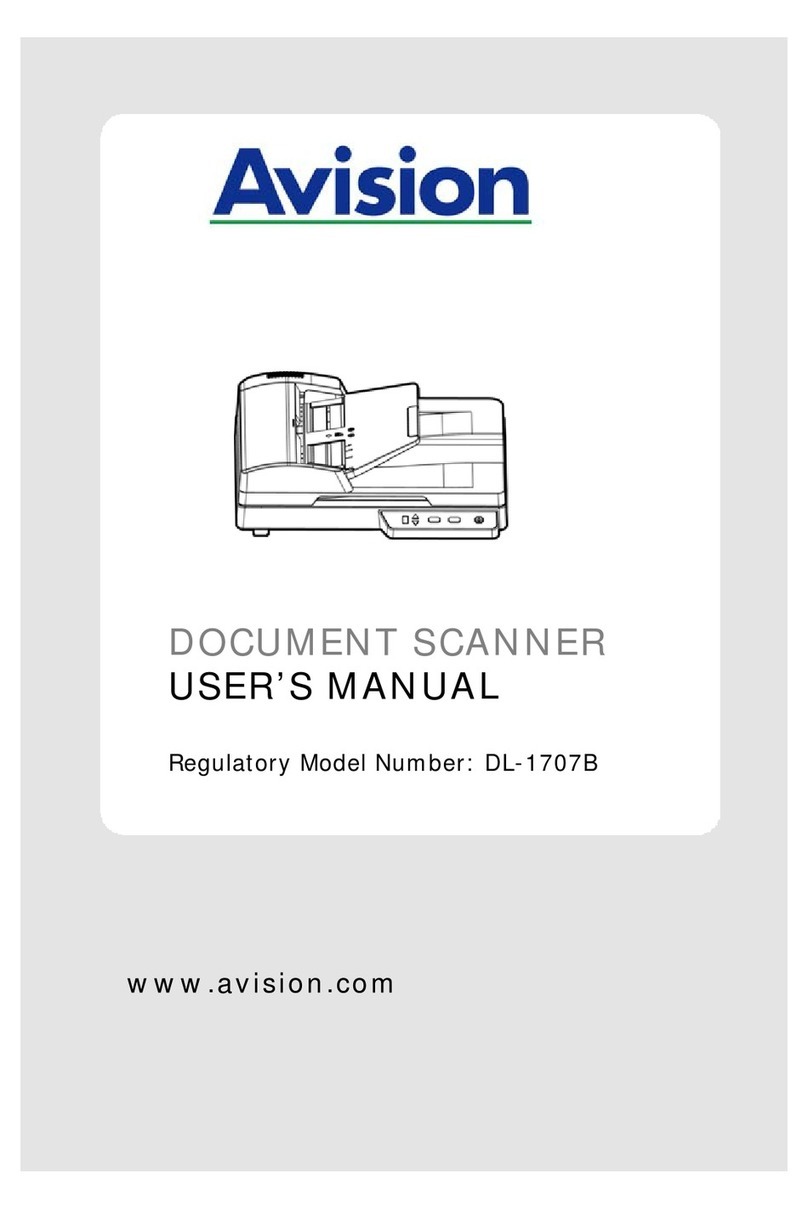

3VMJMGIW

The Orifice restricts the field of view (target area), reduces air flow, maintains air flow, maintain air

block, and increases discrimination between flame and background radiation. The orifice is secured

within the ball of a swivel mount with an orifice retainer or the orifice can be placed within a one inch

union (not provided).

The scanner should ideally sight a target area of 4 to 25 square inches (25-150cm2) of the flame front.

The flame front is a plane within the combustion space separating the region of unburned fuel from the

burning fuel.

Note:There isan inverserelationshipbetween discrimination and sensitivity.

,IEX-RWYPEXMR 2MTTPI

The heat insulating nipple Part No. 35-127-3(BSP); 35-127-1(NPT) prevents heat transfer from the

hot sight pipe to the scanner head.

7IEPMR 9RMSR[MXL5YEVX^;MRHS[

The sealing union (60-1199) is used whenever a union or seal is required for scanner piping. The size is

one inch US standard taper pipe thread (1" NPT). The sealing union has a quartz window to block off

the scanner from the furnace pressure and heat. When the sealing union is used, the 1" tee/wye is used

for the purge air inlet. Be sure the quartz window is properly seated to seal off the scanner. Do not over-

tighten union collar because damage to the window may result. For best results, hand tighten union col-

lar.

FIGURE 6.

1%-28)2%2')

1.

The control and scanner should be powered at all times (except for repair, cleaning or replacement)

to reduce any harmful effects of atmospheric humidity.

%08)62%8)496+)

%-679440=

r92-32 r409+

36496+)

%-679440=

*-)0(

3*

:-);

r7;-:)013928

*-)0(3*:-);

&%00

7;-:)013928

36-*-') 36-*-')

6)8%-2)6

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

9

®

2.

The scanner and sight pipe must be kept clean to prevent overheating and assure optical quali-

ties.

3.

When replacing or cleaning the UV tube, note the position of the tube pins. They are mounted

on a rectangular base so that the tube can only be inserted into the socket with the electrodes

broadside to the shutter window.

CAUTION:DISCONNECT ORSHUT OFF ELECTRIC POWER WHEN WORKING ON

SCANNER.

4.

Clean the quartz lens and tube with glass detergent or glass cleaning agents which contain no

abrasives. After cleaning, remove all cleaning films with a soft lint-free cloth. (Some cleaning

films may reduce or filter UV.)

5.

Use original FIREYEparts to maintain optimum operation. Recommended spare parts:

4EVX2YQFIV (IWGVMTXMSR

4-314-1`UVTube

61-2913Shutter Assembly with Lens

29-248Flange Gasket

82-95LensHolder

46-38 Lens

92-48Quartz window (Part of Union 60-1199)

FIREYEoriginal equipment factory replacement parts are available at various sub-assembly levels.

8639&0)7,338-2+8,)9:7)0*',)'/-2+7'%22)6

The UV self-checking scanner is a fail-safe device. If you are having a problem, make sure that you

are supplying proper voltage to the scanner tube and shutter.

— The two red leads to the tube from the control should be approximately 560VA C .

— The two black leads from the control to the shutter should be a pulsating 16-24 volt signal

for the 45UV5-1005 and 45UV5-1105 or line voltage for other 45UV5 models. If A or B is a

problem, replace the control or control amplifier. There are two failure modes of the UV

self-check scanner.

1.

UV tube failure

2.

Shutter failure.

Either of these failures will prevent the burner from operating.

-*8,)89&),%7*%-0)(

1.

In a semi-automatic FIREYEcontrol (70D40or FlameWorx) the system will not start if the tube

indicates flame when no flame is present. (Safe start check). Solution — replace UV tube only.

2.

In an automatic FIREYEcontrol 70D10, 70D20, 70D30, FLAME-MONITOR and MicroM

control, the control will lockout on safety (during the prepurge) if the tube indicates flame with

no flame present (Safe start check) “False Flame Purge” shown on FLAME-MONITOR control.

Solution — Replace UV tube only.

3.

In all systems if the scanner does not indicate the presence of flame (DC voltage on flame

meter) with the scanner looking at the pilot flame or a source of ultra-violet radiation (lighter or

propane torch) replace the UV tube.

-*8,)7,988)6,%7*%-0)(

In all systems during the pilot trial-for-ignition period the system will shut down and lockout if the

shutter has failed to close or open. Solution — save UV tube — replace scanner. Visual checks can

be made to detect shutter malfunction.

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

10

®

4%68291&)67%2(%'')7736-)7

FIGURE 7.

FIGURE 8.

9:7'%22)6

%9:89&)

&7,988)6

'7,988)60)27

(+%7/)8

)0)27,30()6

*+6311)8

+0)27%77)1&0=

,59%68>7'%22)60)27

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

11

®

FIGURE 9.

FIGURE 10.

%'')7736-)7

*-+96) 4%68

291&)6

()7'6-48-32

% 3VMJMGIr(MEQIXIV

& 3VMJMGIr(MEQIXIV

' 3VMJMGIr(MEQIXIV

( 3VMJMGIr(MEQIXIV

) 3VMJMGIr(MEQIXIV

* 3VMJMGIr(MEQIXIV

+ 3VMJMGIr(MEQIXIV

, 3VMJMGIr(MEQIXIV

- 3VMJMGIr(MEQIXIV

r;]I

r'P WI2MTTPI

%8,639+,-36-*-')7(-%83(-%

.36-*-')6)8%-2)6

/248,)%8-2790%8-2+2-440)

&74,)%8-2790%8-2+2-440)

059%68>;-2(3;J V7IEPMRK

9RM RWL [RMR*MK

2(-3()

%2487;-:)013928

&747;-:)013928

&2487)%0-2+92-32;59%68>;-2(3;

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

12

®

*-6)=) 7'

1ERGLIWXIV6 EH .90=

(IVV]2I[,EQTWLMVI97% 7YTIVWIHIW1EVGL

[[[JMVI]IG Q

®

238-')

When Fireye products are combined with equipment manufactured by others and/or integrated into

systems designed or manufactured by others, the Fireye warranty, as stated in its General Terms and

Conditions of Sale, pertains only to the Fireye products and not to any other equipment or to the

combined system or its overall performance.

;%66%28-)7

FIREYEguarantees for one year fromthe date of installation or 18 monthsfromdate of manufac-

ture of its products to replace, or, at its option, to repair any product or part thereof (except lamps,

electronic tubes and photocells) which is found defective in material or workmanship or which oth-

erwise fails to conform to the description of the product on the face of its sales order. THEFORE-

GOING IS IN LIEU OFALL OTHER WARRANTIES AND FIREYEMAKES NO

WARRANTYOFMERCHANTABILITYORANYOTHER WARRANTY,EXPRESS OR

IMPLIED. Except as specifically stated in these general terms and conditions of sale, remedies

with respect to any product or part number manufactured or sold by Fireye shall be limited exclu-

sively to the right to replacement or repair as above provided. In no event shall Fireye be liable for

consequential or special damages of any nature that may arise in connection with such product or

part.

Distributed By: M&M Control Service, INC. 800-876-0036 [email protected]

This manual suits for next models

10

Other Fireye Scanner manuals