First Power Stinger Owner's manual

PATENT

PENDING

Owner / Operator’s Manual Rev B.2

Version 1

8941 Dutton Dr,

Twinsburg, Ohio

44087

330-963-2050

Table of Contents

Stinger® Kit Overview

………………………………………………………………………………

1

Operation Guide

…………………………………………………………………………………….

2

GoPro® Camera Installation and Usage

……………………………

……………..

7

Battery Replacement

……………………………………………………………………………..

9

Replace Transmitter Battery ……………………………………………………

9

Replace Receiver Batteries ……………………………………………………….

10

Stinger® Fluid Overview

…………………………………………………………………………

1

3

Recommended Maintenance and Safety

…………………………………

…

……

1

4

Specifications and Certifications

………………………………………

…………………

1

5

Warranty Information

…………………………………………………………………………….

16

Parts Diagram

…………………………………………………………………………………………..

17

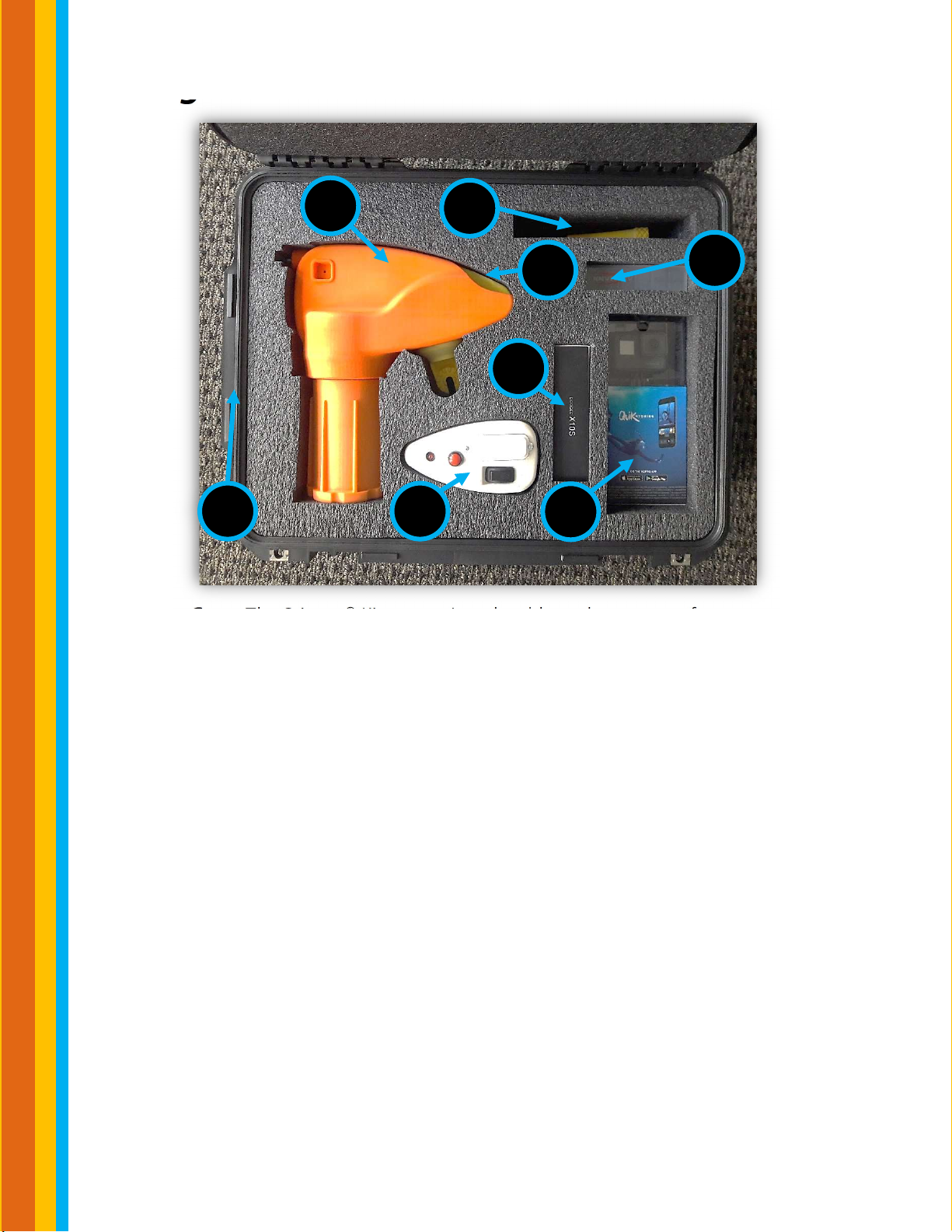

Stinger® Kit Overview

1

|

©

2 0 1 9 F i r s t P o w e r G r o u p L L C

Stgr

-

Manual

-

V1 Rev. B.2

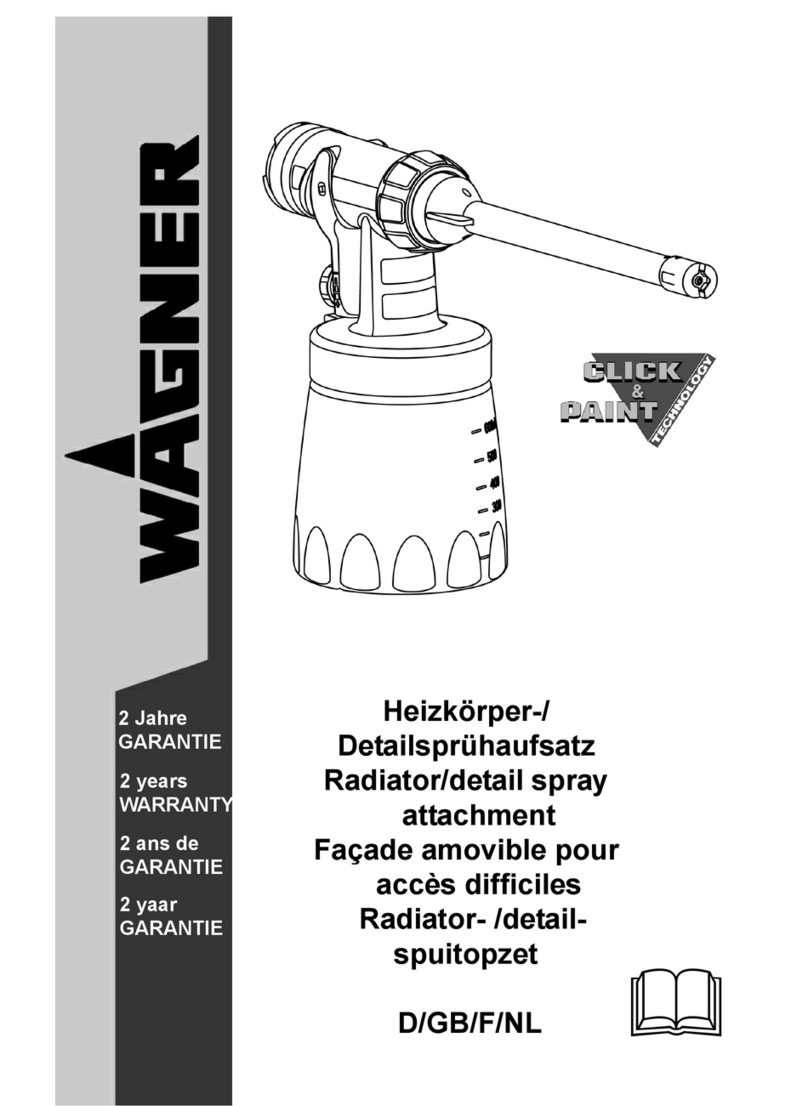

1. Case: The Stinger® Kit comes in a durable and waterproof case.

2. Main Assembly: Non-conductive housing that safely protects the can

from an electric arc and houses the plumbing and valve to route the

Stinger® fluid to the nozzle.

3. Receiver: Allows for remote communication between the main

assembly, Key Fob and the transmitter to turn the dispense on and off.

4. Transmitter: Allows for Stinger® fluid to be sprayed through a press of a

button from a safe location.in the Transmitter and Receiver.

5. Nozzles: The kit comes with a spray nozzle and 2 spare spray nozzles.

These nozzles are used to disperse the Stinger Fluids in a direct stream.

6. GoPro® Camera: Captures live video of where the Stinger fluid is being

sprayed.

7. Smartphone: Used to display video from the GoPro® Camera.

8.

Batteries: Six 9V batteries are provided in addition to the batteries

installed in the Receiver and Transmitter.

5

2

3

4

8

6

7

1

Operation Guide

2

|

©

2 0 1 9 F i r s t P o w e r G r o u p L L C

Stgr

-

Manual

-

V1 Rev. B.2

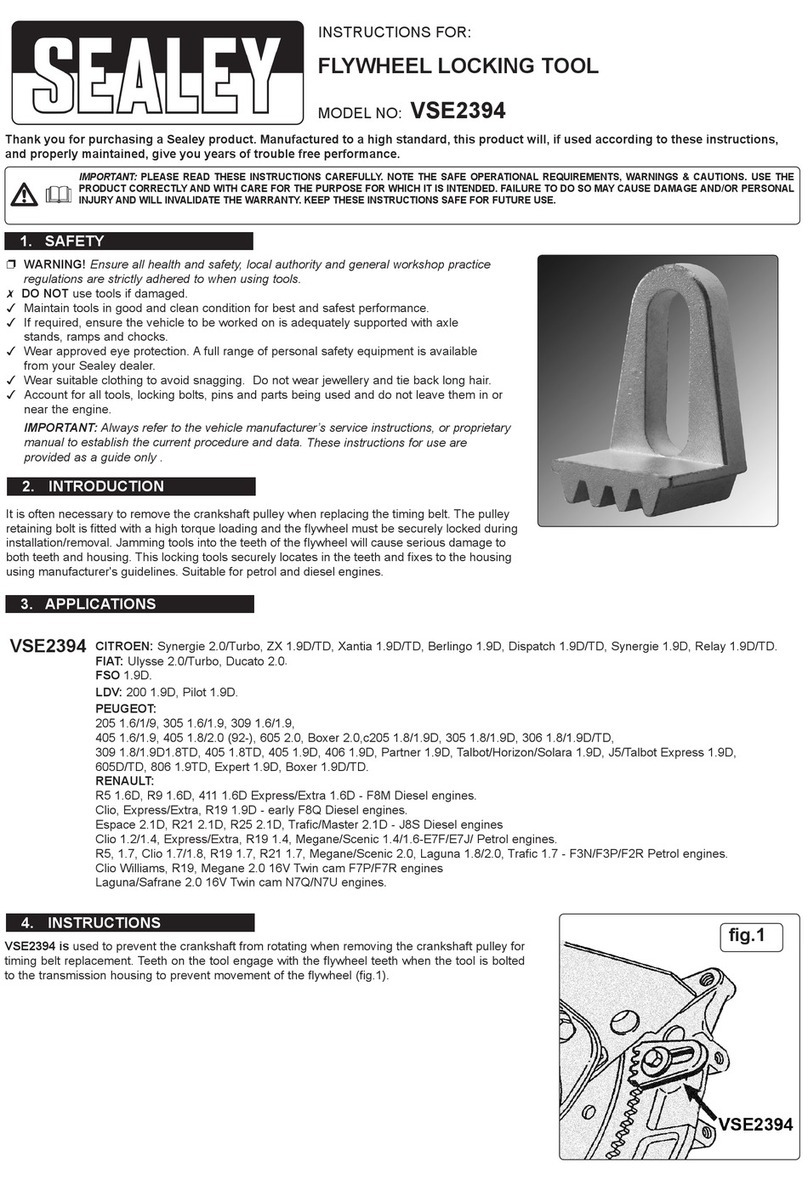

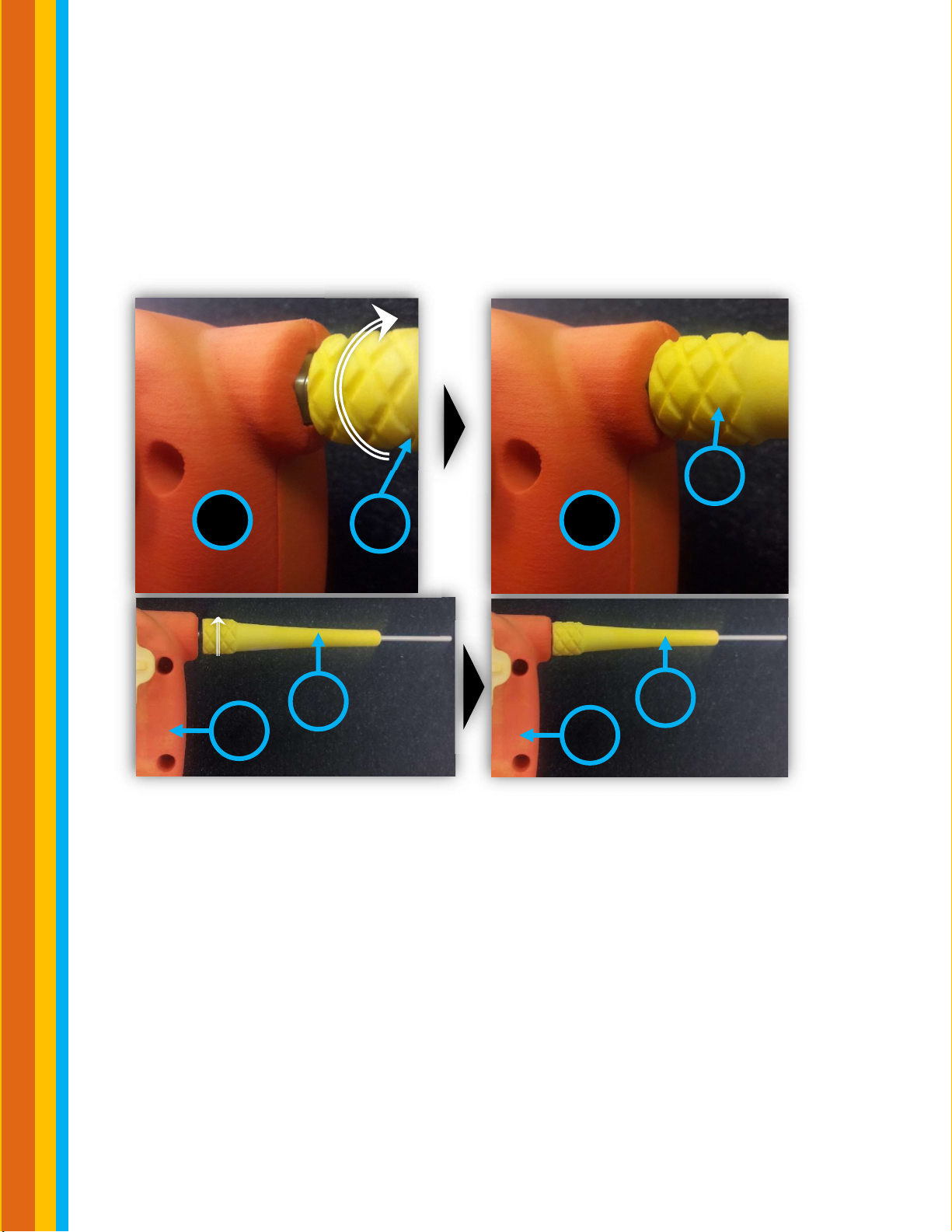

Step 1: Take the Main Assembly (2) out the Case (1). Typically, the Receiver (3)

is left in the Main Assembly (2). If the Receiver (3) is not installed, installed it

using the procedure shown on page 16. Begin with screwing a Nozzle (5) into

the threaded insert on the Main Assembly (2). Twist with your hand until the

Nozzle (5) stops turning which is shown in the after images.

2

5

2

5

2

5

2

5

Before

After

Operation Guide

3

|

©2019 FirstPower Group LLC

Stgr

-

Manual

-

V1 Rev. B.2

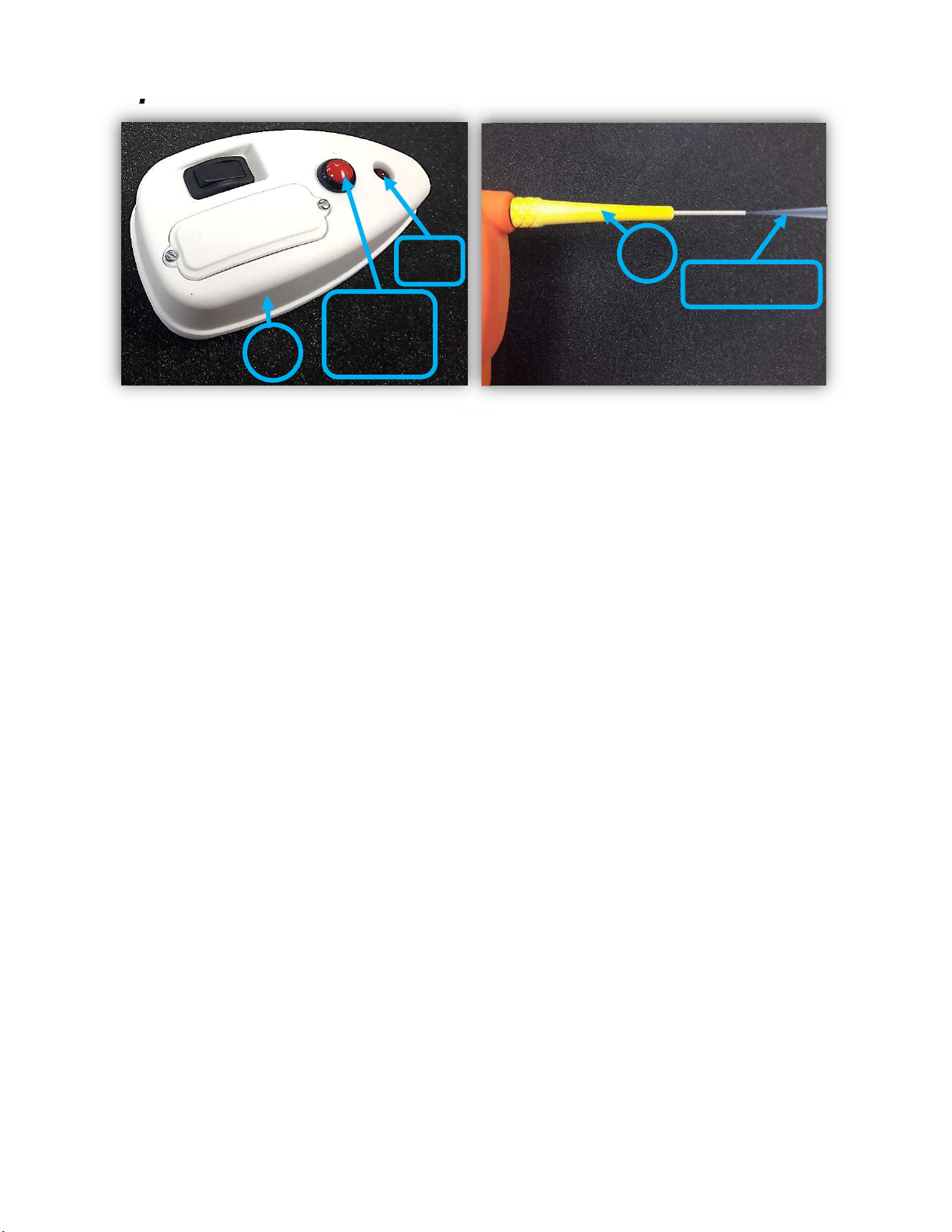

Step 2: Unscrew the Can Cap on the

bottom of the Main Assembly (2) in the

direction indicated.

Step 3: Fully screw in the threaded top

of the appropriate Stinger® Fluid Can

(1FR™, 2C™,3PAO™) with your hand

until hand tight. It is normal to hear a

pressure release sound before the can

is fully screwed in. Typically, you should

give the can another ½ turn after

hearing the pressure release.

Warnings: If it is hard to screw in the

can, remove the can and try again. DO

NOT FORCIBLY SCREW IN THE CAN. If

the can isn’t fully screwed in, the Can

could leak or

fail inside the Can Housing. The Stinger® can only be used with proprietary

Stinger® fluids, DO NOT attempt to insert other cans into the Stinger®.

Step 4: After installing a can, be sure

to fully screw the orange Can Cap to

the Main Assembly (2) until hand tight.

2

Can

Cap

2

Can

Housing

Can

2

Can

Cap

Operation Guide

4

|

©2019 FirstPower Group LLC

Stgr

-

Manual

-

V1 Rev. B.2

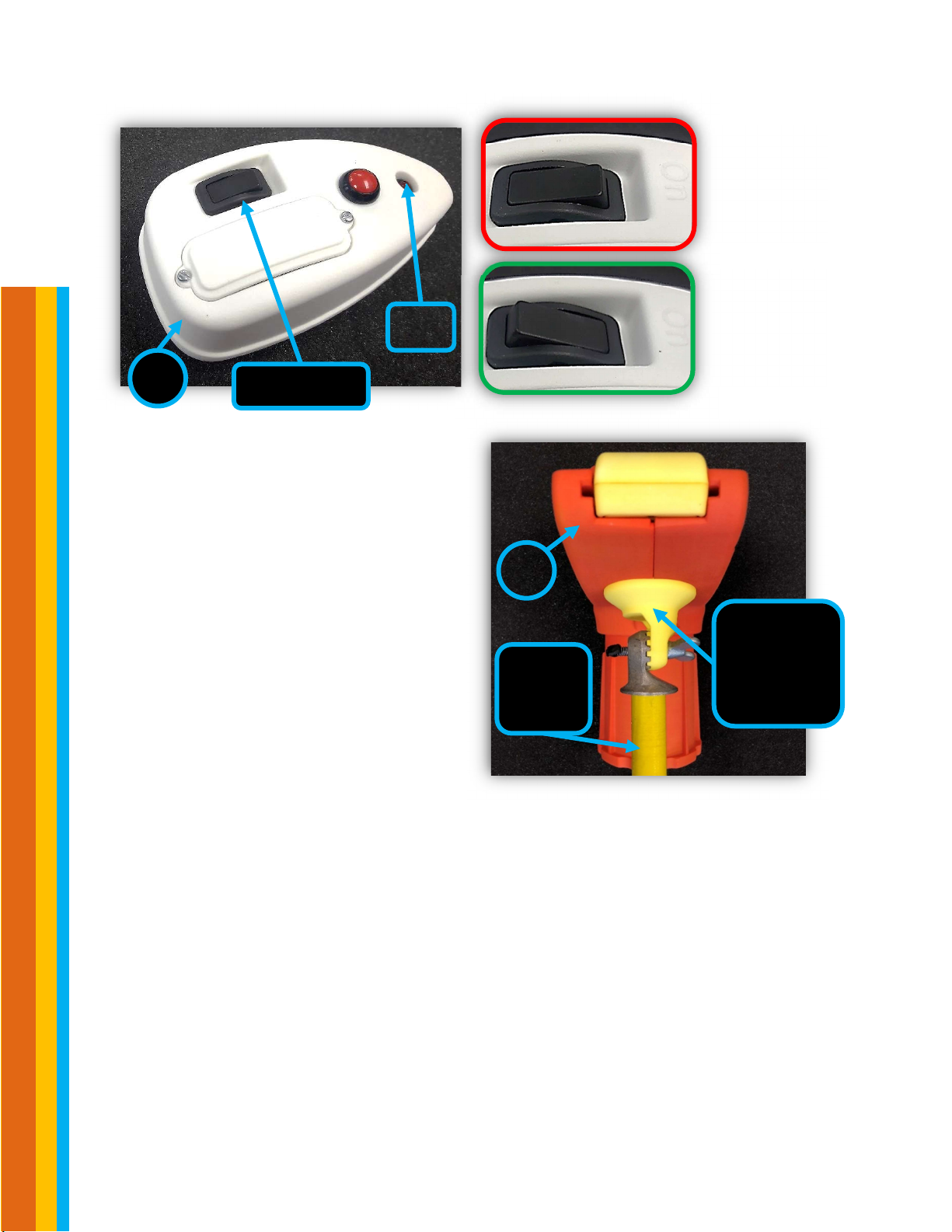

Step 5: Power on the Receiver (3) in the Main Assembly (2) by flipping the Switch

from the Off Position to On Position.

Step 6: Test fluid stream into a

rag away from equipment for

proper function.

Step 7: Next, power on the Transmitter (4) by flipping the switch from the OFF

position to the ON position. After switching the Transmitter ON, the LED will go

ON for about 1 second, off for about 1 second, and then ON again for about 1

second to indicate it has powered up OK. Wait until the LED has gone through

the flashing process to press the red button. If the LED doesn’t go ON when the

switch is flipped to the ON position, the transmitter may not be functioning.

Warning: Any transmitter will control all powered receivers within range. Make

sure that all other Stingers that are not in use have their receivers and

transmitters turned off.

2

3

Switch

Switch in

the OFF

Position

Switch in

the ON

Position

Operation Guide

5

|

©2019 FirstPower Group LLC

Stgr

-

Manual

-

V1 Rev. B.2

Step 8: Attach the fully assembled

Stinger® to the hot stick using the

yellow universal toothed hot stick

adapter (Hot Stick Adapter). Be sure to

attach the Main Assembly (2) at an

appropriate angle to easily aim stream

of Stinger fluid to the desired location.

We recommend you practice moving

and operating the stinger when the hot

stick is fully extended before using it in

the field.

Step 9: Press the Button on the Transmitter (4) to dispense the liquid. The liquid

will continuously stream out of the Nozzle (5) while the Red button is pressed. If

the LED does not go ON when the button is pressed, the Receiver may be not

functioning.

Hot

Stick

Adapter

Hot

Stick

2

4

Switch

LED

Switch in

the ON

Position

Switch in

the OFF

Position

Operation Guide

6

|

©2019 FirstPower Group LLC

Stgr

-

Manual

-

V1 Rev. B.2

Step 10: Turn the switches on the Receiver (3) and Transmitter (4) to the OFF

position after use (see Steps 5 and 6 to see what each switch position looks like).

Remove the Nozzle (5) from the Main Assembly (2). Place the Transmitter (4),

and Nozzle (5) back in the Case (1).

Step 11: Remove the can cap then, unscrew the can. Make sure the Main

Assembly (2) is upright to prevent the Stinger® fluids from leaking onto your

clothes when the can is unscrewed. Then reinstall the can cap.

5

Spray

4

Red

Button

LED

Operation Guide

7

|

©2019 FirstPower Group LLC

Stgr

-

Manual

-

V1 Rev. B.2

Step 12: Place the Main Assembly (2) with the Receiver (3) into the Case (1) and

close the Case (1). Make sure this manual is in the Case (1) if the Stinger is not in

use.

2

Can

1

3

2

GoPro® Camera Installation and Usage

8

|

©

2 0 1 9 F i r s t P o w e r G r o u p L L C

Stgr

-

Manual

-

V1 Rev. B.2

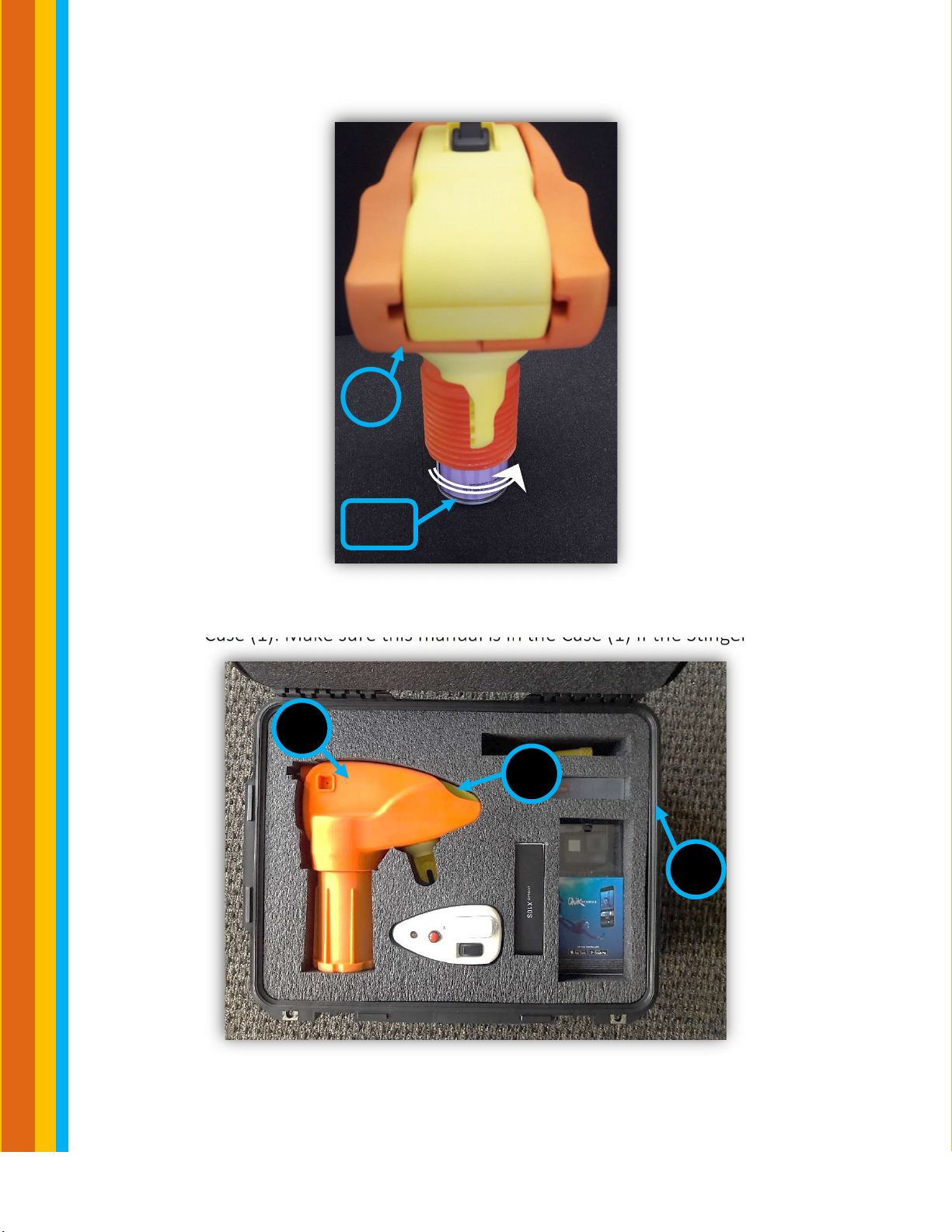

Step 1: Lift the grey Rubber Locking Plug that is a part of the GoPro® Camera (6)

so that it is touching the back of the camera.

Step 2: To easily slide the

GoPro® Camera (6) into

the Camera Mount on the

Main Assembly (2) shown

on the next page, gently

pinch the black plastic Clip

Ends.

6

Clip Ends

6

Rubber

Locking

Plug

6

Rubber

Locking

Plug

Before

After

This product and/or service is not affiliated with, endorsed by or in any way associated with

GoPro Inc.

or its products and services. GoPro, HERO, Session, Karma and their respective logos are trademarks

or registered trademarks of GoPro, Inc.

GoPro® Camera Installation and Usage

9

|

©2019 FirstPower Group LLC

Stgr

-

Manual

-

V1 Rev. B.2

This product and/or service is not affiliated with, endorsed by or in any way associated with GoPro Inc. or its

products and services. GoPro, HERO, Session, Karma and their respective logos are trademarks or registered

trademarks of GoPro, Inc. . (See- https://gopro.com/en/us/shop/cameras/hero7-silver/CHDHC-601-

master.html) for pairing.

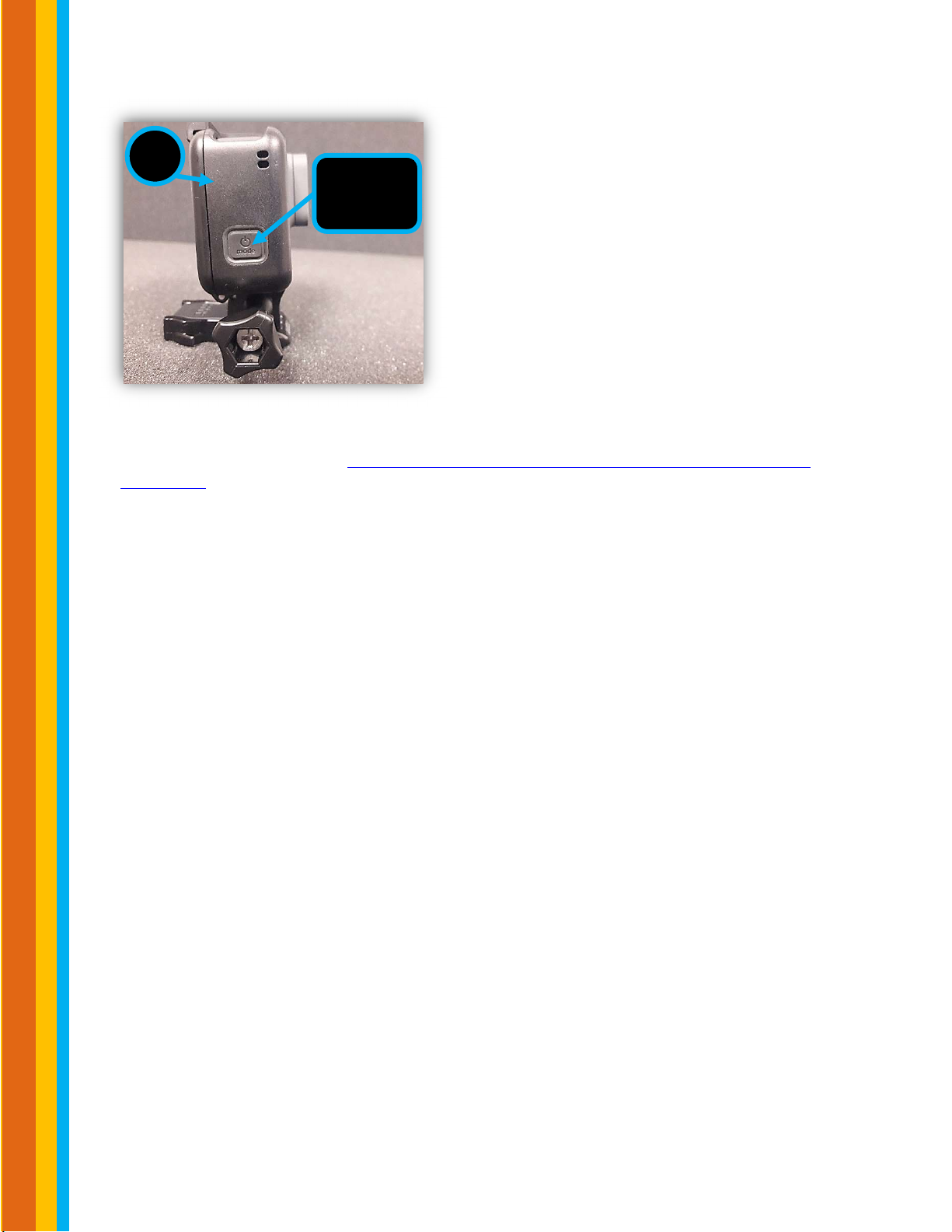

Step 5: After use, gently remove the camera from the Main Assembly (3) and turn it

off. Steps 1-4 for reference. Place the Smartphone (6) and the camera back into the

Case (1)

6

Power

Button

Battery Replacement

10

|

©

2 0 1 9 F i r s t P o w e r G r o u p L L C

Stgr

-

Manual

-

V1 Rev. B.2

Replace Transmitter Battery

The status of the batteries is indicated by the transmitter LED when the button is

not pressed. If the LED flashes red 1 time every 3 seconds, then transmitter has

low battery voltage. If the LED flashes red 2 times every 3 seconds, then the

receiver has low battery voltage. If the LED flashes red 3 times every 3 seconds,

both have low battery.

Step 1: Make sure that the

Transmitter is turned off. Then use a

#4 flat head screwdriver to unscrew

each screw on the battery door. Be

sure to not completely unscrew the

screws from the battery door or else

the washers will detach.

Step 2: Use standard Alkaline 9V

batteries for replacement. Remove old

battery and carefully replace with 1

new 9V battery. Put the battery door

securely back on and verify the

transmitter works by flipping the on

switch, the red light should blink

twice.

LED

Button

Flat Head

Screws

Battery

Door

Battery

Door

Alkaline

9V

Battery

LED

Battery Replacement

11

|

©2019 FirstPower Group LLC

Stgr

-

Manual

-

V1 Rev. B.2

Replace Receiver Batteries

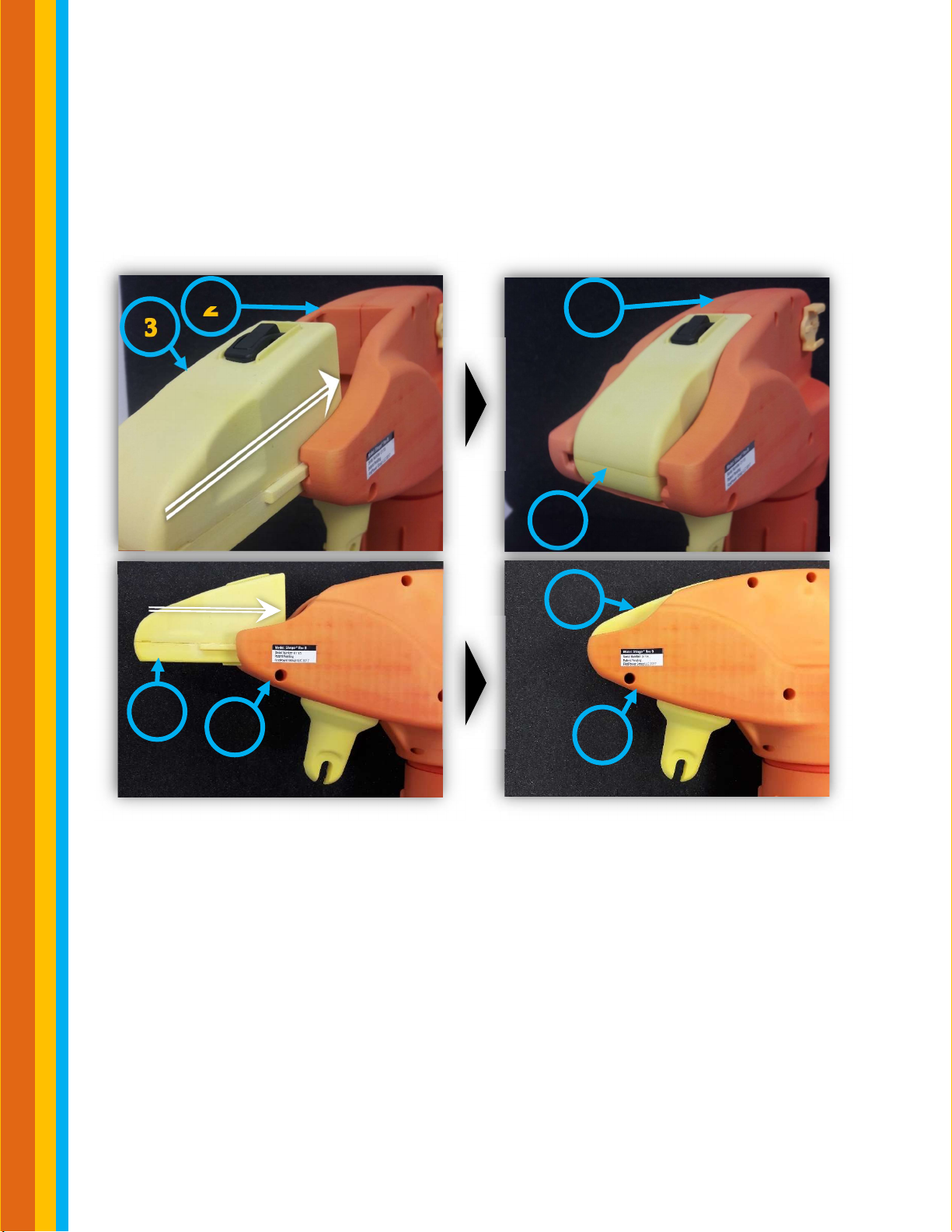

Step 1: Remove the Receiver (3) from its initial position shown in the “Before”

figures. Gently slide it out the back of the Main Assembly (2) which is presented

in the “After” figures.

2

3

3

2

3

2

3

2

Before After

Battery Replacement

12

|

©2019 FirstPower Group LLC

Stgr

-

Manual

-

V1 Rev. B.2

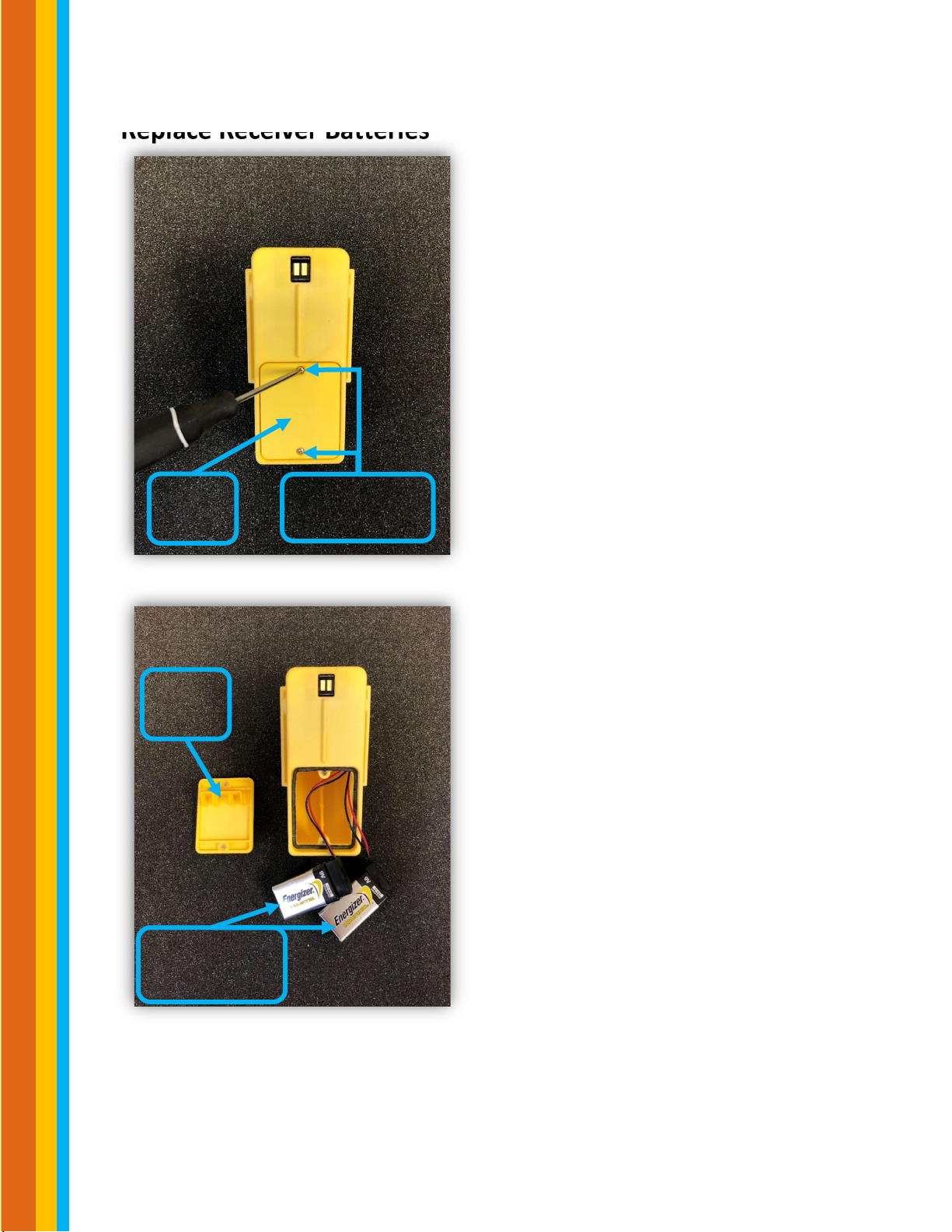

Replace Receiver Batteries

Step 2: Make sure that the Receiver is

turned off. Then use a #2 Philips

screwdriver to unscrew each screw on

the battery door. Be sure to not

completely unscrew the 2 screws from

the battery door or else the washers

will detach.

Step 3: Use standard Alkaline 9V

batteries for replacement. Remove the

old batteries and carefully replace with

2 new 9V batteries

Philips Head

Screws

Battery

Door

Battery

Door

Alkaline 9V

Batteries

Battery Replacement

13

|

©2019 FirstPower Group LLC

Stgr

-

Manual

-

V1 Rev. B.2

Replace Receiver Batteries

Step 4: Make sure the battery wires are

routed as shown on this photo. This will

prevent wire damage and allow proper

battery door installation. Battery door

must be installed flush. Screws must be

recessed after installing. DO NOT

FORCE screws in, if they don’t easily

screw in so they are recessed, unscrew

and re-install.

Battery

Door

Alkaline 9V

Batteries

Battery Replacement

14

|

©2019 FirstPower Group LLC

Stgr

-

Manual

-

V1 Rev. B.2

Step 4: Finally, insert the Receiver (3) back into the back of the Main Assembly

(2) as shown in the “Before” figures. Confirm the that Receiver (3) is fully

inserted into the Main Assembly (2) as shown in the “After” figures.

2

3

3

2

3

2

3

2

Before After

Stinger® Fluid Overview

15

|

©

2 0 1 9 F i r s t P o w e r G r o u p L L C

Stgr

-

Manual

-

V1 Rev. B.2

1FR - Penetrant

Stinger® Fluid 1FR is a fast-acting penetrant

that frees corroded disconnect switches,

bushings, and bolts. 1FR has a proprietary

threaded top which only allows it to be

used in the Stinger®. Simply apply to a

seized joint and let sit for 20-30 minutes to

ensure penetration and repeat if needed.

This fluid can be used on energized

equipment.

2C - Cleaner

Stinger® Fluid 2C is a switch and contact

cleaner. 2C has a proprietary threaded top

that allows it to only be used in the

Stinger®. This fluid can be used on

energized equipment. DO NOT use on

polycarbonate plastics, this cleaner can

harm plastics.

3PAO - Lubricant

3PAO is a high-quality synthetic lubricant,

containing anti-wear additives. It is great

for lubricating seized parts, such as gears

and knuckles. After using 1FR to open the

switch, 3PAO may be used to make the

switch move freely and ensure it closes

properly. This fluid can be used on

energized equipment.

Recommended Maintenance and Safety

16

|

©

2 0 1 9 F i r s t P o w e r G r o u p L L C

Stgr

-

Manual

-

V1 Rev. B.2

Recommended Maintenance

Extend the life of the Stinger® by not storing outdoors or in extreme

conditions

Wipe the Stinger® using a clean lint-free cloth after each use.

o DO NOT USE CHEMICAL SOLVENTS AS THIS WILL VOID WARRANTY.

THIS WILL COMPROMISE THE DIELECTRIC PROPERTIES OF THE

STINGER®.

o DO NOT SUBMERGE THE STINGER® THIS WILL VOID WARRANTY

Power off Receiver and Transmitter when not in use.

Remove can from inside Stinger® when not in use.

Remove batteries when stored long term.

Safety

Stinger®

Do not operate with line clearance without the can cap installed

Make sure to practice operating the Transmitter while holding the hot

stick. Also, practice getting used to the weight of the Stinger®.

Always make sure that the Receiver is fully inserted into the Main

Assembly to avoid it falling out with rough usage.

Stinger® Fluids

If any fluids contact skin, please wash the area of contact immediately and

with soap and water.

Do not ingest any of the fluids, if ingested please contact emergency

services.

Do not store fluids near extreme heat or cold because cans are under

pressure.

Specifications and Certifications

17

|

©

2 0 1 9 F i r s t P o w e r G r o u p L L C

Stgr

-

Manual

-

V1 Rev. B.2

The Stinger®:

Dimensions: 10” X 4.25” X 14.6”

Weight: 4 lbs

Material: dielectric resin

o ASTM D149 tested to 221 kV/in

The Stinger® passes a Proximity High Voltage Withstand test to 230kV

Stinger® Fluids:

All Stinger® Fluids have passed ASTM 3065D for non-flammability when

applied using the Stinger®

Warranty Information

18

|

©

2 0 1 9 F i r s t P o w e r G r o u p L L C

Stgr

-

Manual

-

V1 Rev. B.2

The Stinger® is warranted for one year from the date of purchase with a factory

warranty. This warranty applies to parts and labor for any defects that are

corrected in our shop when the product has been returned for repair. Pass

through warranties provided where applicable.

Table of contents