6

0039-Radlagere120306.doc hu-rq

Chapter

3

© 2011 KLANN-Spezial-Werkzeugbau-GmbH, Germany

Instruction Manual

2. Product Description:

KL-0039-..Series Wheel Bearing Tool

2.1 Mechanical Drive

KL-0040-3008 Pull Spindle M20

Overall length: .......................................................................... 290 mm

Drive:................................................................................. (waf) 19 mm

Max. load:........................................................................................ 20 t

KL-0039-2030 Pull Spindle M20

Overall length: .......................................................................... 420 mm

Drive:................................................................................. (waf) 19 mm

Max. load:........................................................................................ 20 t

KL-0040-3009 Clamping Nut M20

Overall length: ............................................................................ 50 mm

Drive:................................................................................. (waf) 30 mm

KL-0039-1011 Retainer Adaptor

for Mechanical Spindle

This tool is necessary to retain the various KL-0039-.. or KL-0043-..

press/support sleeves if these are to be inserted by using the

mechanical drive.

The built-in ball bearing allows for accurate and professional working,

even under intensive load.

KL-0039-1002 Retainer Adaptor

for Clamping Nut and Pressure Spindle

This adaptor is designed to retain the various pressure-/support

sleeves of the KL-0039-.. or KL-0043-..Series.

Locating-Ø for clamping nut or pressure spindle: ....................... 20 mm

2.2 Hydraulic Drive

KL-0040-2500 Hydraulic Cylinder

Due to its special design as a tubular piston cylinder and the possibility

to be used in conjunction with various spindles, the hydraulic cylinder

KL-0040-2500 is suitable for pulling and pushing operations.

Note: Hydraulic pump KL-0215-35 M25 (accessory) is required to

drive the hydraulic cylinder.

KL-0039-1920 Pull Spindle M20 with Clamping Nut

Overall length: .......................................................................... 590 mm

Working travel: ......................................................................... 390 mm

Max. load:........................................................................................ 20 t

KL-0039-1003 Retainer Adaptor

for Hydraulic cylinder

This tool is necessary to retain the various KL-0039-.. or KL-0043-..

pressure-/support sleeves if these are to be inserted by using the

hydraulic cylinder KL-0040-2500.

(Connecting thread: M42 x 2)

KL-0039-1002 Retainer Adaptor

for Clamping Nut and Pressure Spindle

This adaptor is designed to retain the various pressure-/support

sleeves of the KL-0039-.. or KL-0043-..Series.

Locating-Ø for clamping nut or pressure spindle: ....................... 20 mm

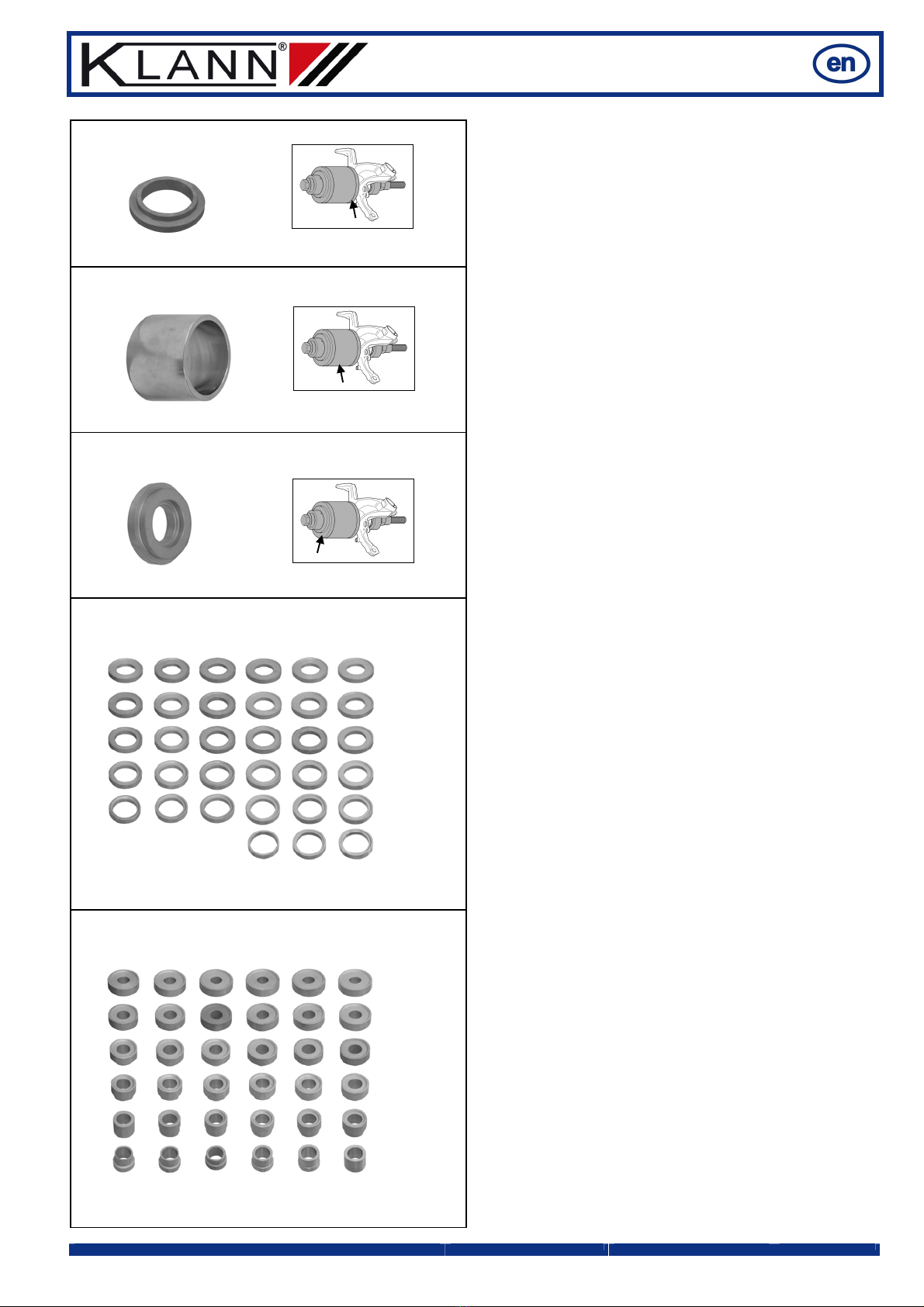

Fig. 1: KL-0040-3008 Pull Spindle M20

Fig. 2: KL-0039-2030 Pull Spindle M20

Fig. 3: KL-0040-3009 Clamping Nut M20

Fig. 4: KL-0039-1011 Retainer Adaptor

for mechanical spindle

Fig. 5: KL-0039-1002 Retainer Adaptor

for clamping nut and pressure spindle

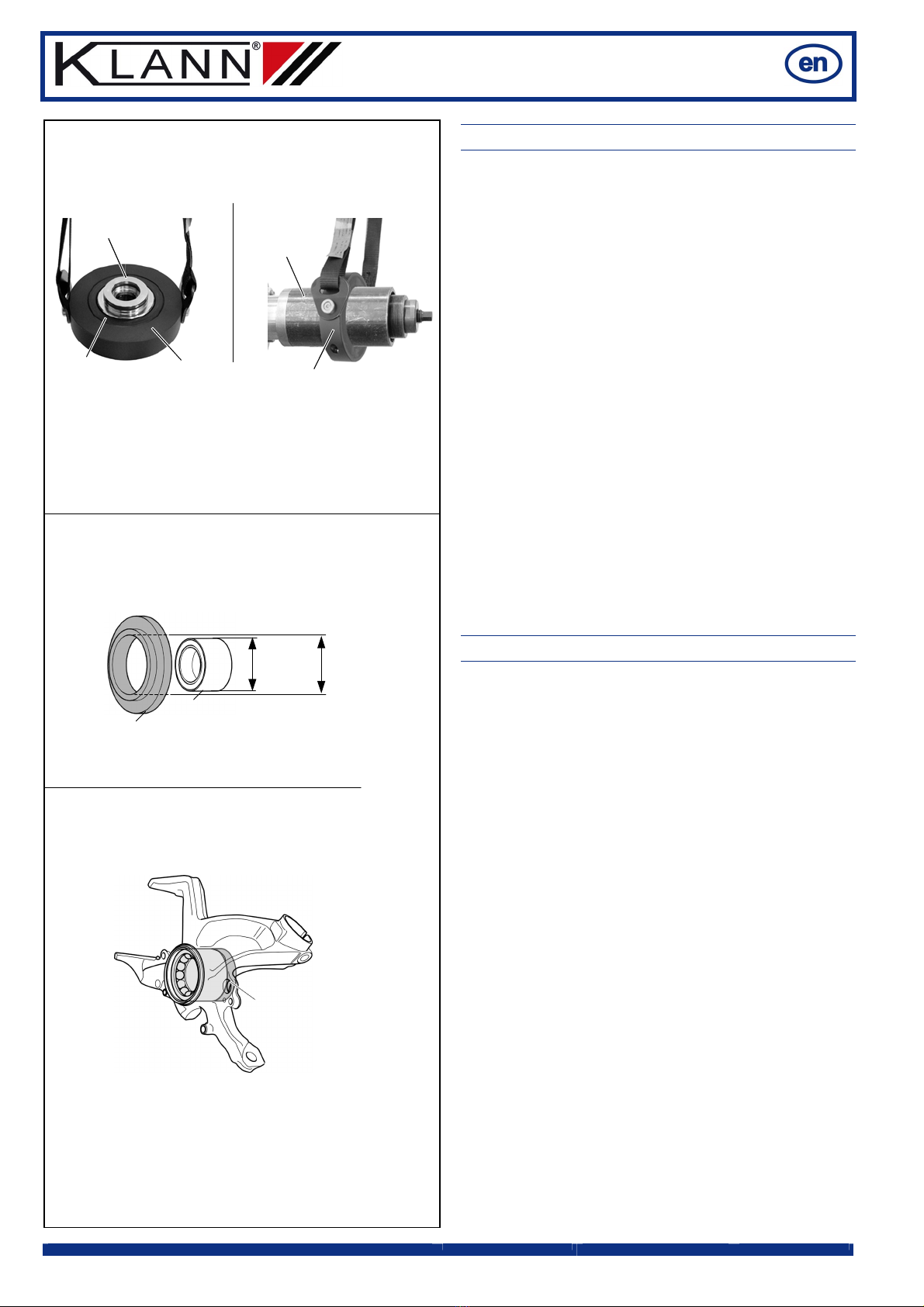

Fig. 6: KL-0040-2500 Hydraulic Cylinder

Fig. 7: KL-0039-1920 Pull Spindle with clamping nut M20

Fig. 8: KL-0039-1003 Retainer Adaptor

for hydraulic cylinder

Fig. 9: KL-0039-1002 Retainer Adaptor

for clamping nut and pressure spindle

Connection 3/8"

Thread M42 × 2

Thread

2¼"-14UNS

Pulling side

Pushing side