First Products SEEDA-vator SE60 Installation and operation manual

OPERATOR’S

MANUAL & PARTS LIST

(SEE SEPARATE MANUAL FOR SEEDER CALIBRATION)

SEEDA-vator

MODEL SE60

FIRST PRODUCTS INC.

P.O. Box 1425

Tifton, Georgia 31794 U.S.A.

Phone (229) 382-4768

1-800-363-8780

Fax (229) 382-0506

Web: www.1stproducts.com Email: Sale[email protected]

Ser. 300 thru 434

Printed in U.S.A.

PBREV0104

1

INTRODUCTION

Thank you for purchasing a SEEDA-vator. This piece of equipment has been carefully

engineered and manufactured to provide years of reliable service.

The SEEDA-vator is one of the most unique and versatile pieces of equipment on the

market today. It is designed for seeding in existing turf and bare soil.

We recommend that you carefully read the owners and operators manual prior to opera-

tion. Also ensure that all future operators read this manual and become fully trained be-

fore allowing them to use or maintain this equipment. Time spent becoming acquainted

with the safe operation, performance, and maintenance of the SEEDA-vator will add

longer life and greater satisfaction to your new purchase.

This machine is designed with safety in mind. However, if the machine is handled care-

lessly and not as instructed it can be a dangerous piece of equipment. Observe all safety

information in this manual and decals on the equipment.

The illustrations and data used in the manual were current at the time of printing. The

manufacturer reserves the right to make changes or add improvements to its products at

any time without incurring any obligation to make such changes to products manufac-

tured previously.

REMEMBER SAFETY IS ALWAYS FIRST !

ATTENTION:

x Read and understand the instructions and warnings carefully before using this

machine.

x Read the warranty located on page 18. Fill in the required information on the

warranty registration provided and return to the address on the front of this

manual. The warranty registration must be returned to validate warranty.

2

TABLE OF CONTENTS

SAFETY SYMBOLS .......................................................................................................................3

SAFETY DECALS ..........................................................................................................................4

OPERATION SAFETY ...................................................................................................................5

OPERATOR INSTRUCTIONS - General .......................................................................................6

How The Swing Hitch Operates (Prior To Hitching To Tractor) .................................................6

Adjusting The Hitch To A Tractor ...............................................................................................7

Tine Depth With Roller Floating ..................................................................................................7

Tine Depth With Roller Pinned ....................................................................................................7

Transporting The Unit ..................................................................................................................8

From Lift Position To Operating ..................................................................................................8

From Operating To Lift Position ..................................................................................................8

Do Not Operate In Reverse...........................................................................................................8

Roller Scraper Usage ....................................................................................................................8

Tine Wear Limit............................................................................................................................8

Trial Run.......................................................................................................................................8

OPERATOR INSTRUCTIONS – Seeder ........................................................................................9

Seed Flow Control ........................................................................................................................9

Seeder Drive Control ....................................................................................................................9

Emptying The Hopper ................................................................................................................10

Unclogging Seed Tubes..............................................................................................................10

PRE-OPERATION CHECK LIST.................................................................................................10

MAINTENANCE SAFETY...........................................................................................................10

ROUTINE MAINTENANCE ........................................................................................................10

SE-60 ROTOR SHAFT SERVICE INSTRUCTIONS...................................................................12

Rotor Shaft Removal ..................................................................................................................12

Rotor Shaft Disassembly ............................................................................................................13

Rotor Hub Disassembly ..............................................................................................................13

Rotor Hub Re-Assembly.............................................................................................................14

Rotor Shaft Re-Assembly ...........................................................................................................14

Rotor Shaft Installation...............................................................................................................16

WARRANTY INFORMATION ....................................................................................................18

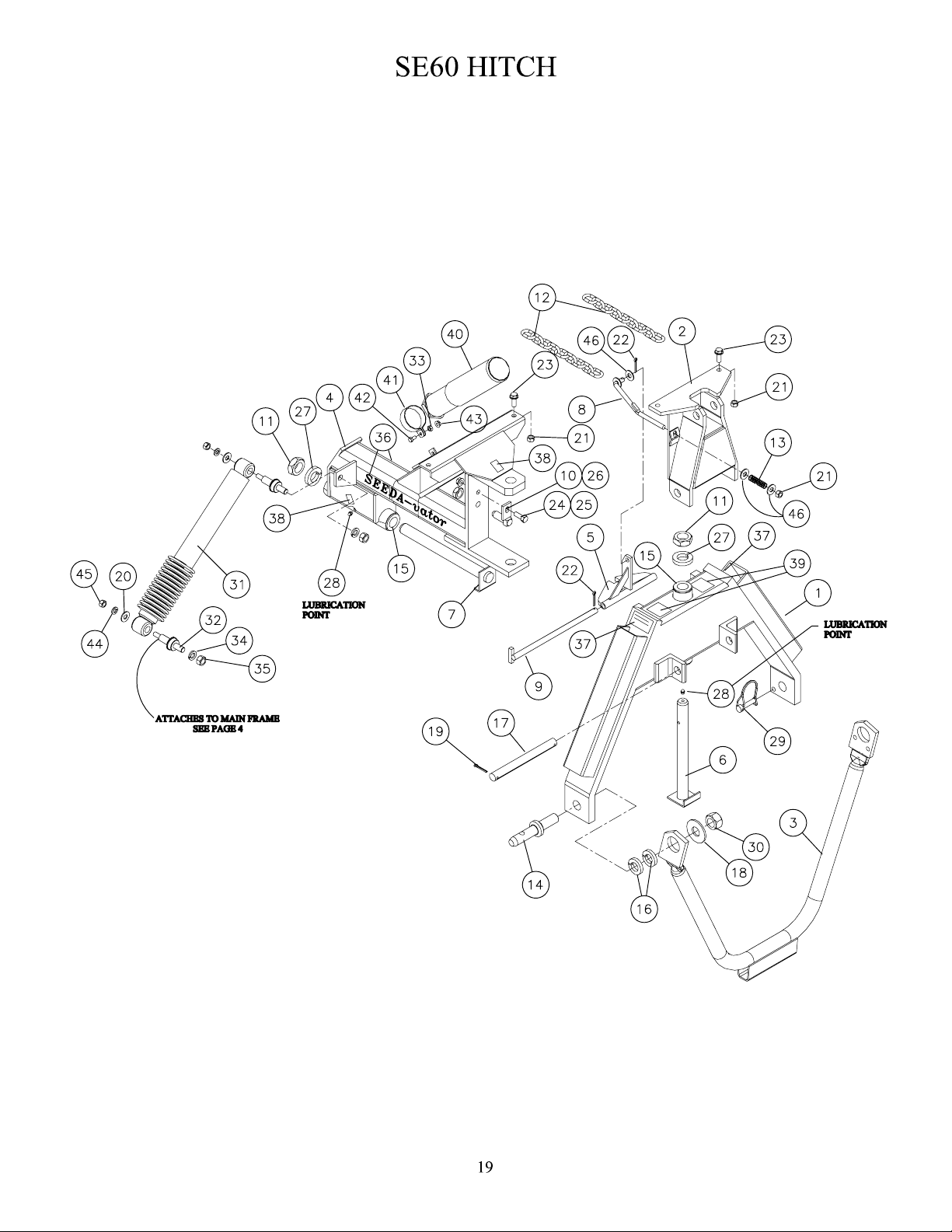

SE60 HITCH ..................................................................................................................................19

SE60 MAIN FRAME.....................................................................................................................21

SE60 ROTOR SHAFT ...................................................................................................................23

SE60 DRIVE LINE ........................................................................................................................24

SE60 ROLLER...............................................................................................................................25

SE60 RAKE ...................................................................................................................................26

SE60 SEEDER HOPPER MOUNTING ........................................................................................27

SE60 SEEDER DRIVE (Ground) ..................................................................................................28

SE60 SEEDER DRIVE (Electric) ..................................................................................................30

SE60 WIRING HARNESS ............................................................................................................31

SEED HOPPER PARTS LIST.......................................................................................................32

SEED HOPPER..............................................................................................................................33

SEEDA-vator Specifications ..........................................................................................................34

3

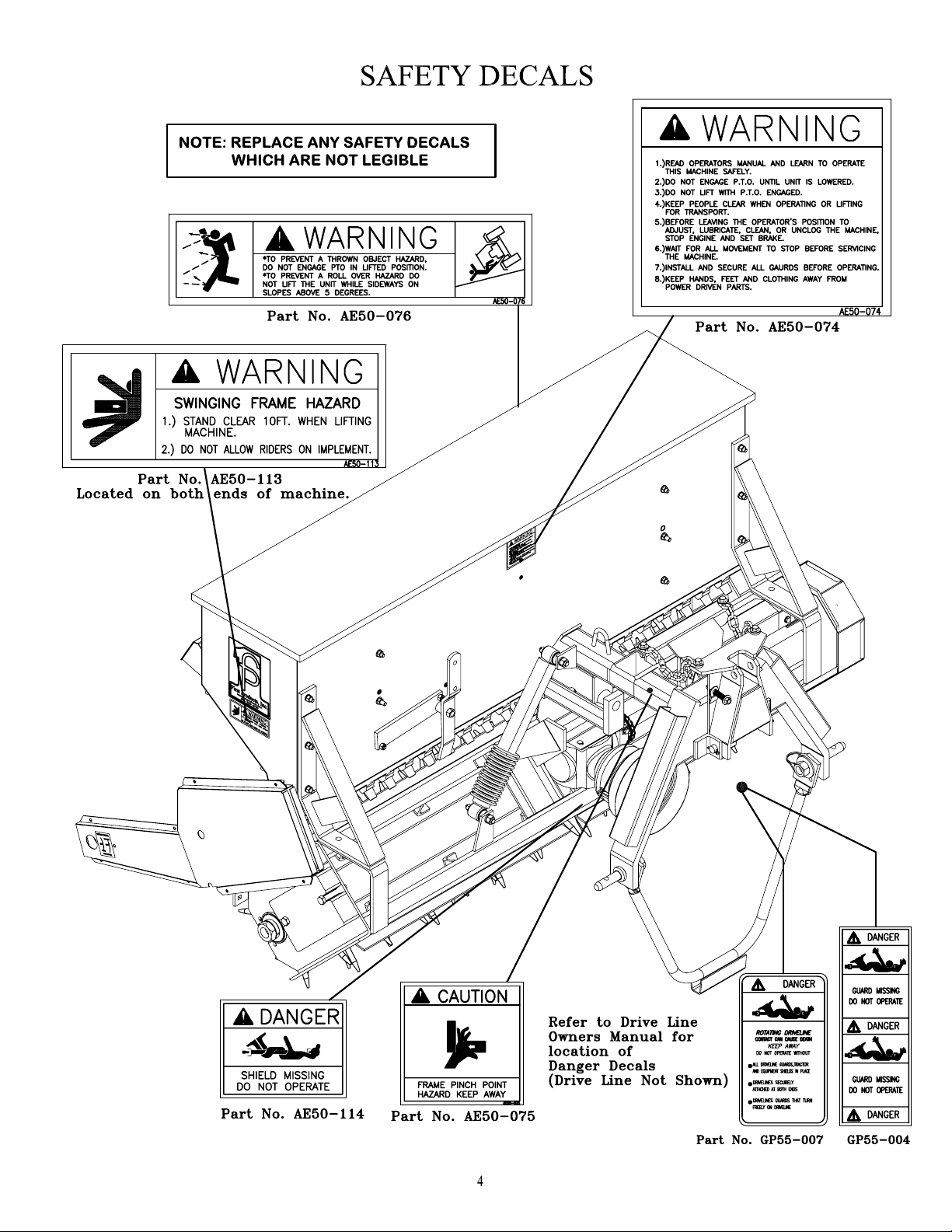

SAFETY SYMBOLS

This is a standard safety alert symbol meaning ATTENTION ! BECOME

ALERT ! YOUR SAFETY IS INVOLVED !

CAUTION Indicates hazardous situation, injury may

occur, used to alert against carelessness.

WARNING Indicates potentially hazardous situation.

Death or serious injury may occur if

proper procedures are not followed.

DANGER Indicates most hazardous situation. Death

or serious injury will occur if proper pro-

cedures are not followed.

5

OPERATION SAFETY

x Your Safety Is Always First! Familiarize yourself with the safety symbols and de-

cals on pages 3 and 4.

x All operators should read and understand the following sections of this manual

prior to adjusting, maintaining, hitching to, or operating the SEEDA-vator:

OPERATION SAFETY, OPERATOR INSTRUCTIONS, PRE-OPERATION

CHECKS, MAINTENANCE SAFETY, ROUTINE MAINTENANCE.

x In addition, remove and read the drive line safety and maintenance manual taped to

the drive line shield. After reading the drive line manual, place it inside this manual

for reference.

x For the safety and instruction of all operators, keep this manual stored in the tube pro-

vided on the SEEDA-vator at all times.

x Never attempt to adjust, maintain, or remove debris from this machine while the trac-

tor engine is running.

x After operating, always disengage the power take off and switch the engine off prior

to dismounting from the tractor or other power source and approaching the unit.

x Prior to starting, always inspect operating area for any hazards such as large rocks,

steep slopes, low tree branches or wires. Flag objects difficult to see such as irriga-

tion heads and water meters.

x Instruct all people in the work area to stay clear of the unit.

x Perform all pre-operation checks (page 10) prior to start up.

x Never engage the power take off while the rotors are off the ground. Always disen-

gage the power take off before lifting the unit. High-speed rotors create a flying ob-

ject hazard when they are lowered to the ground.

x Consult your tractor Operator's Manual regarding operation on slopes. Do not lift the

unit while the tractor is moving (or parked) sideways on slopes above 5q. The swing

hitch may allow the unit to swing to the downhill side and cause the tractor to roll

over. On slopes from 5qto 15qalways aim the tractor uphill before lifting the unit.

We do not recommend the unit being used on slopes above 15q.

x Use extreme care and maintain moderate ground speed when transporting or operat-

ing on slopes, over rough surfaces, or close to trees ditches and fences.

x Only operate during daylight hours or with good artificial light.

x The unit is not equipped for highway use. Be careful of traffic when operating near

or crossing roadways.

6

OPERATOR INSTRUCTIONS - General

x The SE-60 SEEDA-vator is designed to attach to a tractor with a category one three

point hitch, 540 PTO, and a minimum of 30 horsepower. However, the tractor must

have a lift capacity of 1950 lbs. at a distance of 24” to the rear of the lower lift points

to handle the unit loaded with 6.7 cu. ft. of 40#/cu. ft. seed.

x Before hitching to the unit familiarize yourself with all of the tractors control func-

tions. Be prepared to stop the tractor movement, PTO operation, and the engine

quickly in an emergency.

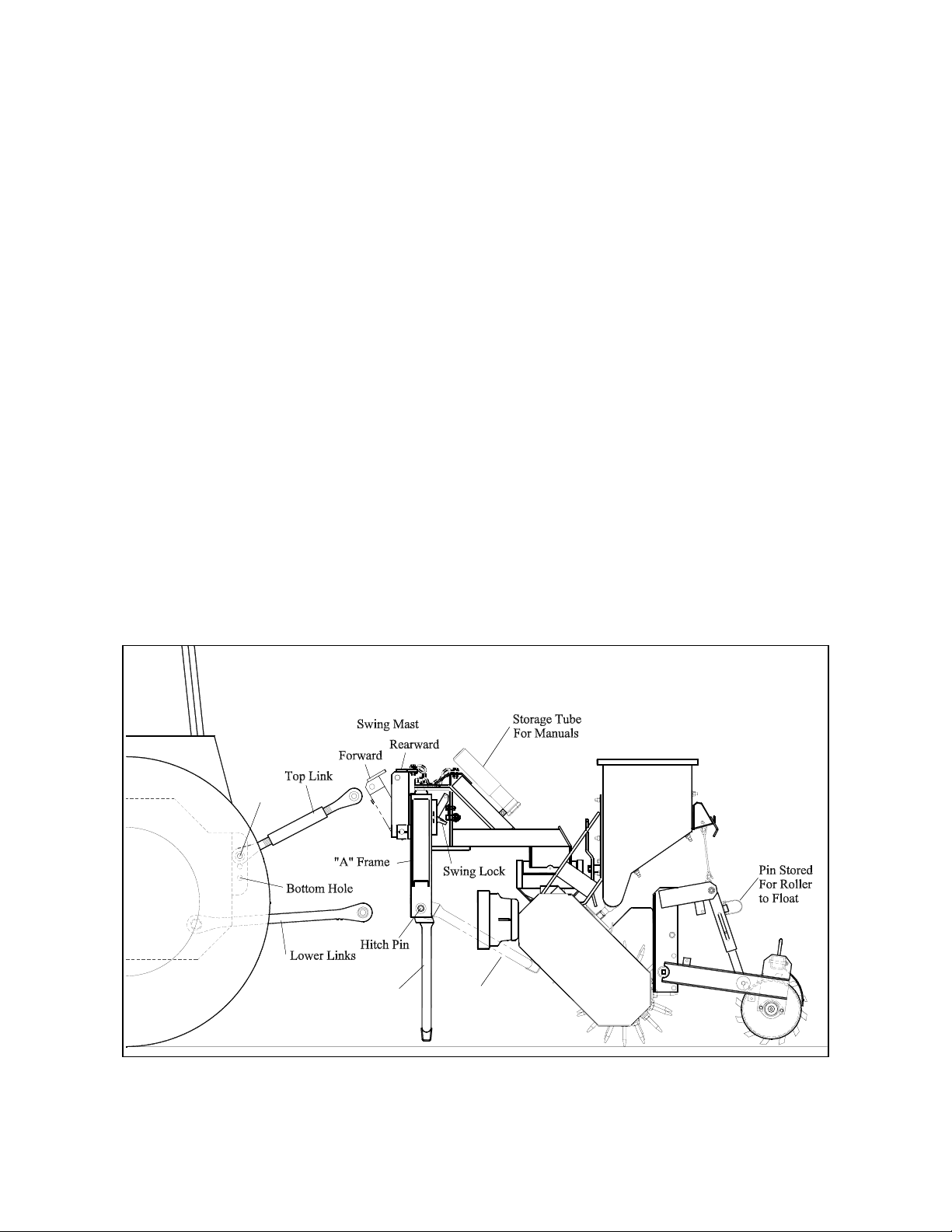

How The Swing Hitch Operates (Prior To Hitching To Tractor)

With the swing stand lowered and the swing mast rearward to disengage the swing lock,

grasp the hitch pins and rotate the “A” frame to simulate operation in a sharp turn. Re-

lease the hitch pins and slowly pull the swing mast forward as it would be pulled by the

top link during lifting. Notice how one mast chain tightens causing the “A” frame and

unit to realign as the compressed lock link spring engages the swing lock. Now push the

swing mast rearward against the lock link tab to disengage the swing lock and loosen the

chains to allow sharp turns again. This demonstrates how the top link of the tractor lift

system switches the unit between the trail and lift modes.

7RS+ROH

6ZLQJ 6WDQG

'RZQ

6ZLQJ 6WDQG

8S

Figure 1. Swing Hitch Operation

7

Adjusting The Hitch To A Tractor

(See Fig. 1 - Tractor and Unit on flat, hard surface with swing stand down and roller in

float position).

A category 1 hitch tractor is required with the lower links stabilized. With the unit swing

stand lowered connect the lower lift links to the “A” Frame Hitch Pins and top link to the

swing mast with the tractor end in the top hole. Push the lift control lever on the tractor to

the completely lowered position. Lengthen the adjustable top link until the swing mast

closes tight against the “A” Frame and the swing stand is lifted just clear of the ground.

This causes the combined weight of the unit and the tractor hitch components to be trans-

ferred to the tines. This extended top link also causes the unit to tilt backwards when lift-

ing allowing gravity to assist the mast chains in aligning the unit with the tractor.

Tine Depth With Roller Floating

With the roller in the float position, the tine depth is dependent on the relationship of

forward speed to PTO speed. [Tine depth is increased by lowering the forward speed

and/or increasing PTO (engine) speed.] The tines would usually penetrate 2” to 3 ½”

deep which causes more surface tillage than shallower tine depths. This arrangement

would most likely be used when seeding in existing turf or hard crusty bare soils. Since

the seed drops ahead of the tines, very few are buried too deep.

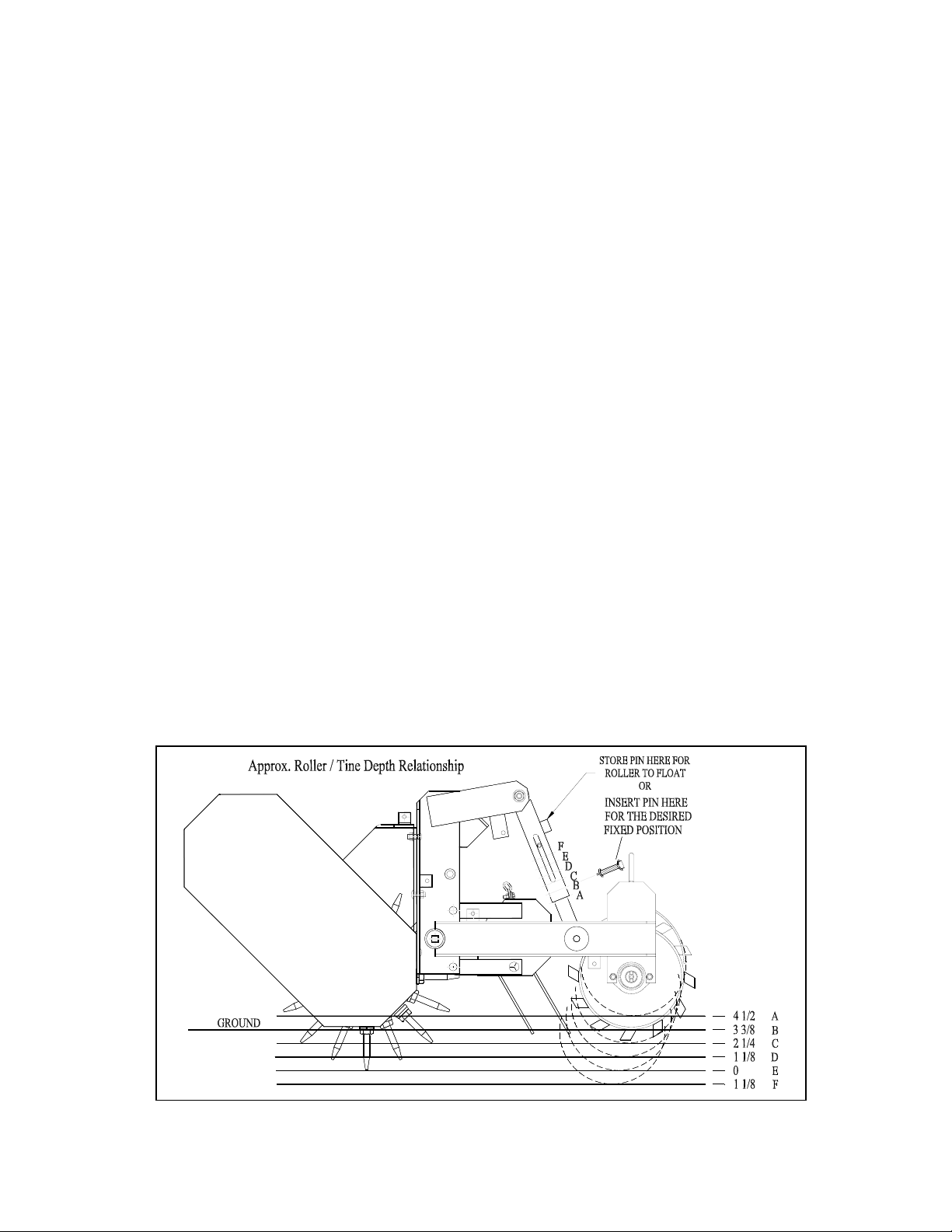

Tine Depth With Roller Pinned

With the roller pinned in various fixed positions, the tine depth is more precisely con-

trolled as shown in Figure 2. Extending the top link longer, which tilts the unit back-

wards, can reduce the actual tine depth in each pinned position. An advantage of tilting

backwards is that gravity assists the mast chains in aligning the unit with the tractor dur-

ing lifting. A pinned roller arrangement is usually used on soft bare soils where deep

tines running would cover the surrounding seed too deep.

Figure 2. Roller & Tine Depth Relationship

8

Transporting The Unit

As previously stated, an extended top link to tilt the unit backwards helps to align it with

the tractor during lifting. However, the backward tilt increases the potential for damage

to the unit on trailer ramps. To avoid damage without having to change the length of the

top link, move the tractor end of the top link from the top hole to the bottom hole. This

will tilt the unit forward for more clearance when lifted. Not changing the top link length

will save time at the next job site. On steep ramps it may also require the roller to be

pinned in the highest position for more clearance.

From Lift Position To Operating

When lowering for operation, lower slowly until the tines touch the ground. Then swiftly

push the lift control lever on the tractor to the completely lowered position to instantly

unlock the hitch. This is especially true when lowering the unit in a sharp turn. Failure

to do this may cause the swing hitch not to unlock, resulting in damage to the machine

and/or turf damage. In the event the unit should fail to unlock for trail mode, stop the

tractor and repeat the lowering procedure.

From Operating To Lift Position

WARNING: When operating diagonally downhill or transversely (sideways) on a

hillside slope above 5qthe mast chains will not swing the unit uphill to center and lock

on the tractor when the unit is lifted. Occasionally the unit will swing farther to the

downhill side of the tractor creating the hazard of tractor roll over. If the tractor ever

seems unstable, immediately lower the hitch and steer the tractor uphill or on a more

level surface where it will center and lock when lifted.

Do Not Operate In Reverse

Do not back the tractor up with the unit touching the ground. Always disengage the

PTO, raise the unit, back to desired location and then lower the machine and engage the

PTO.

Roller Scraper Usage

Generally the roller scrapers are only used when the ground does not have rocks, roots,

construction debris, etc that would clog and stop the rollers from turning.

Tine Wear Limit

Replace tines before the hex shoulder wears down to the extent the 15/16 deep tine

socket will not grip for removal.

Trial Run

The geometry of tractor lift linkages varies, and a trial run over uneven ground is recom-

mended. Ideally the swing lock will not engage when operating over the crown of a hill

and the tractor hitch is always free to float upward at all times. The tines should clear

curbs etc., when lifted. Refer to the pre-operation checklist prior to trial run.

9

OPERATOR INSTRUCTIONS – Seeder

The Gandy Seeder is equipped with a ground or electric driven fluted rotor that feeds seed to a

precision mated stainless hopper bottom and slide with adjustable holes at each of the 22 outlet

spouts.

CALIBRATION

TROUGH

HAIRPIN COTTER

SEED TUBE PIN

SEED DEFLECTOR

SEED TUBES

FLUTED ROTOR

SPOUT PLATE

RETAINING CLIPS

SPOUT PLATE

ROTOR SHIELD

TRASH SHIELD

HOPPER BOTTOM

SLIDE SUPPORT

SLIDE

Figure 3. Seeder

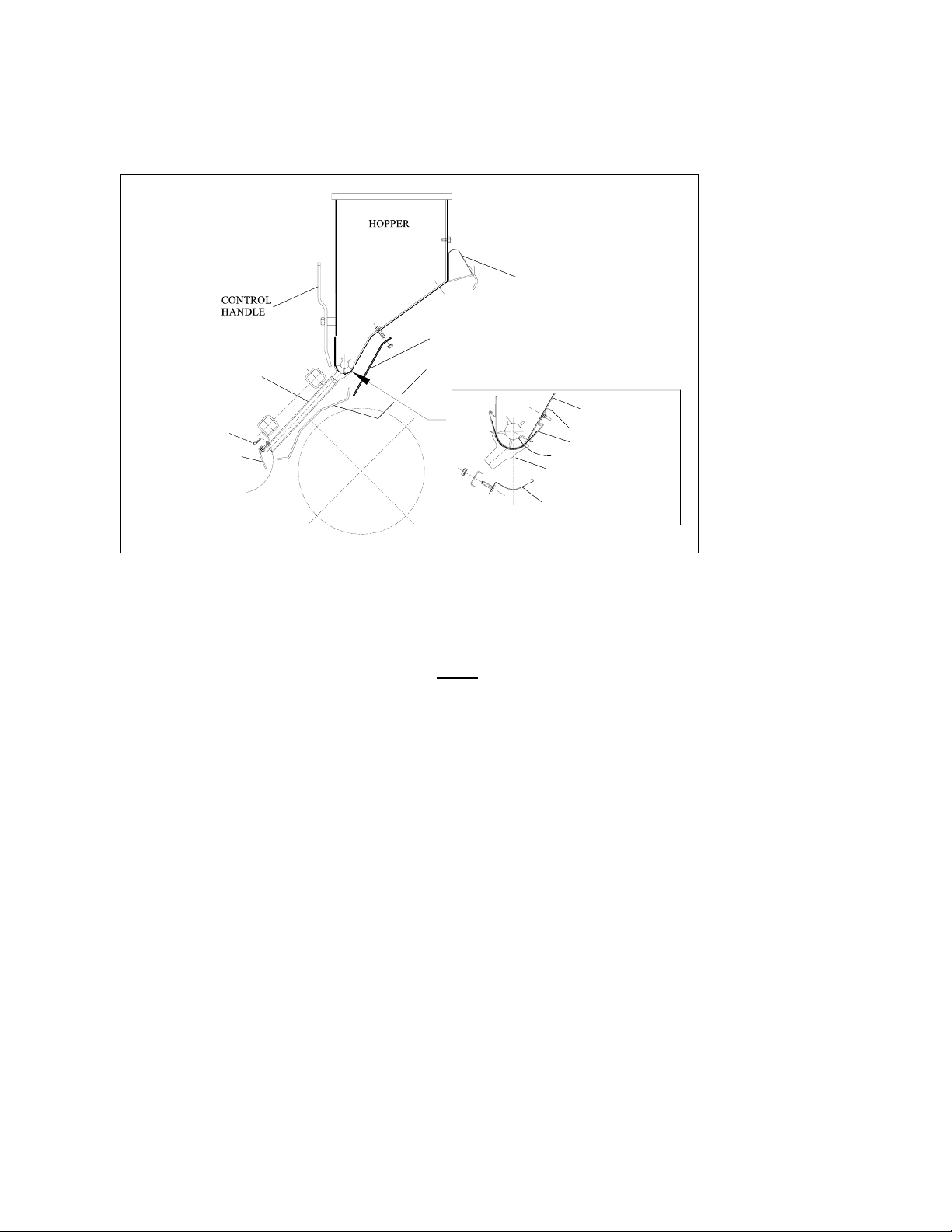

Seed Flow Control

The flow rate is controlled by a cam gauge that varies the size of the adjustable holes.

The seed flow is instantly turned off or on by closing and opening the hopper bottom holes with

the control handle on the right front of the hopper. NOTE: Fragile seeds may be damaged if

the electric or ground drive continues to turn the fluted rotor for very long with the flow

turned off.

The flow is gradually stopped or started by stopping or starting the rotation of the fluted rotor

while leaving the control handle in the open position. When the rotor is stopped, the seed con-

tained in the fluted rotor section above the adjustable holes will flow until the section is emptied.

When the rotor starts again, the seed won’t flow until the next fluted rotor section with seed ro-

tates over the adjustable holes.

Seeder Drive Control

On electric drive units the flow control rotor is stopped and started with a remote control switch

at the tractor seat.

On ground drive units (in conjunction with the roller) the fluted rotor stops when the SEEDA-

vator is lifted and starts when it is lowered. Also, the roller drive is provided with a clutch for

stopping the fluted rotor to allow tillage without seeding. Read decal on shield at right end of

roller (see page 28, item 24).

10

Emptying The Hopper

With the control lever and cam wide open, rotate the fluted rotor and catch the seed in the

calibration trough or on a plastic sheet. On ground driven hoppers, disengage roller clutch

(see page 29, item 24) then turn fluted rotor with a 5/8” socket, extension, and wrench on left

end of hopper.

Unclogging Seed Tubes

Remove the hairpin cotters holding the clogged tube and the tubes on either side then

feed the clogged tube up through the framework. Only remove the seed deflector for ac-

cess to the four tubes beneath the gearbox mount. (Refer to routine maintenance section

regarding more extensive cleaning).

PRE-OPERATION CHECK LIST

(With the SEEDA-vator lowered and the tractor engine switched off...)

x Replace any safety decals that are not legible.

x Be sure that the implement is hitched to the tractor properly with all pins in place.

x Pin the swing stand in the up position (see Fig. 1).

x WARNING:Be sure the driveline is correctly assembled. (The end stenciled

as the tractor end is connected to the tractor and not to the SEEDA-vator). Check to see

that the end yokes are locked to the tractor PTO and gearbox shafts. Drive shields must turn

freely on the driveline.

x See that all shields are correctly installed.

x Remove any items from seed hopper that would damage rotors or clog seed tubes.

x Remove any debris caught in the rotors.

x Check gearbox oil level before first operation and every 200 hours of operation thereafter.

(Refer to routine maintenance section.)

MAINTENANCE SAFETY

x Never attempt to clean, adjust, lubricate or perform any maintenance on the SEEDA-vator

while the tractor engine is running.

x SAFETY BLOCKS should be used to support the SEEDA-vator when in the raised position

during service.

x Lower the swing stand when unhitching from the tractor.

x When installing tines, performing any rotor shaft service, or removing debris from the rotors,

ensure that the rotor shaft does not rotate because a serious pinch injury could occur.

ROUTINE MAINTENANCE

x Check gearbox oil level before first operation and every 200 hours of operation thereafter.

With frame level, remove oil level plug on front left side of gearbox using 5/16” allen

wrench. If required, add 90w-gear oil through level plug until it appears at level plug. Re-

place plug securely.

11

x Grease drive line parts after the number hours use as shown in the above illustration.

x The hitch flex joints at the top of the “A” frame and above the gearbox (see page 19) should

be lubricated before first operation and weekly thereafter.

x After the first two hours of operation tighten all tines to 210-ft. lbs. Check for loose tines

daily.

x When replacing lost or worn tines use the 15/16” extra deep socket furnished in the extra tine

bag (additional sockets are available. Order # AE60T003).

x CHECK BELT TENSION after 4 hrs. of operation and every 40 hrs. thereafter. Also,

tighten belts if shaft hesitation is noticed during operation. Refer to decal on end of seed

hopper. Be sure to re-install belt shield after servicing.

x Use the applicable parts break down illustration pp.19-34 for maintenance, removal, and as-

sembly instructions.

x The SEEDA-vator shaft and rotor bearings are sealed and permanently lubricated requiring

no routine maintenance.

x Inside the hopper place a few drops of light oil weekly between the ends of the fluted roller

and the plastic bearings. Do not over oil.

x NEVER apply oil or spray lubricant to hopper bottom or slide.

x Extensive cleaning of the seeder hopper bottom, slide and spout plate (Fig. 3)

A. Remove the seed deflector and all of the seed tubes.

B. Remove the Trash Shield.

C. Remove spout plate retaining clips, cam gauge, and spout plate assembly.

D. Carefully note how the slide supports assemble to the hopper bottom and how they are

shifted endwise to control the clearance between the slide and hopper bottom. The clear-

ance is set at the factory and fixed with self-tapping screws into the hopper bottom. After

removing the screws, nuts, and plastic washers, the slide supports shift to the left to re-

move the slide.

E. Clean all components and wipe with a dry cloth. Do not apply oil or spray lubricants.

F. Re-assemble components in reverse order.

CAUTION

BE SURE ALL SAFETY SHIELDS ARE INSTALLED PRIOR TO RETURNING THIS

MACHINE TO SERVICE.

12

APPROX.

20

FIG. 4 FIG. 5

SE-60 ROTOR SHAFT SERVICE INSTRUCTIONS

(Clean the unit thoroughly with a pressure washer)

Rotor Shaft Removal

1. Hook hoist to mast chains (Fig. 4). WARNING:The hoist and extra chain or strap required

must be rated @ 2000 lbs. (or higher) capacity.

2. Lift unit to fold swing stand in up position.

3. Lower unit to move roller into fully extended position and pin.

4. Chain the Rake Assembly in up position (not shown).

5. Lift unit until rotor shaft is approximately 20” off the floor with the roller supporting the rear end

(Fig. 5)

6. Place Jack Stands under the Rotor Shaft Assembly for added safety. Locate stands between the 1st and

2nd Rotors from each end. Lower unit until Rotor Shaft contacts both stands. Keep hoist connected to

mast chains with very little slack.

7. Remove Belt Cover and Skid Shoe (see pages 21 & 22 in parts section).

8. Loosen Belt Idler & remove Belts.

9. On the opposite end of shaft from pulley, remove 3 of 4 bolts from bearing flanges (see Fig 12).

10. Remove all

4 bolts

from

bearing

flanges at

center

bearing

support.

11. Loosen the

3 nuts at

the top of

the center

bearing

support,

approx. 2

turns each.

12. Remove 3 of 4 nuts from bearing flanges at pulley end.

13. Lift Unit to remove Stands.

14. Lower unit until tines rest on floor (Fig. 4 – Less Belt Cover).

15. Remove remaining bolt from Step 9 and nut from Step 12.

16. Lift unit so tines are 1/4” above the floor then pull rotor shaft towards pulley end until bolts clear holes

in frame. NOTE: ROTATION OF SHAFT MAY BE NECESSARY FOR BOLTS TO CLEAR.

17. Lift unit high enough to allow shaft assembly to be rolled out for repair.

13

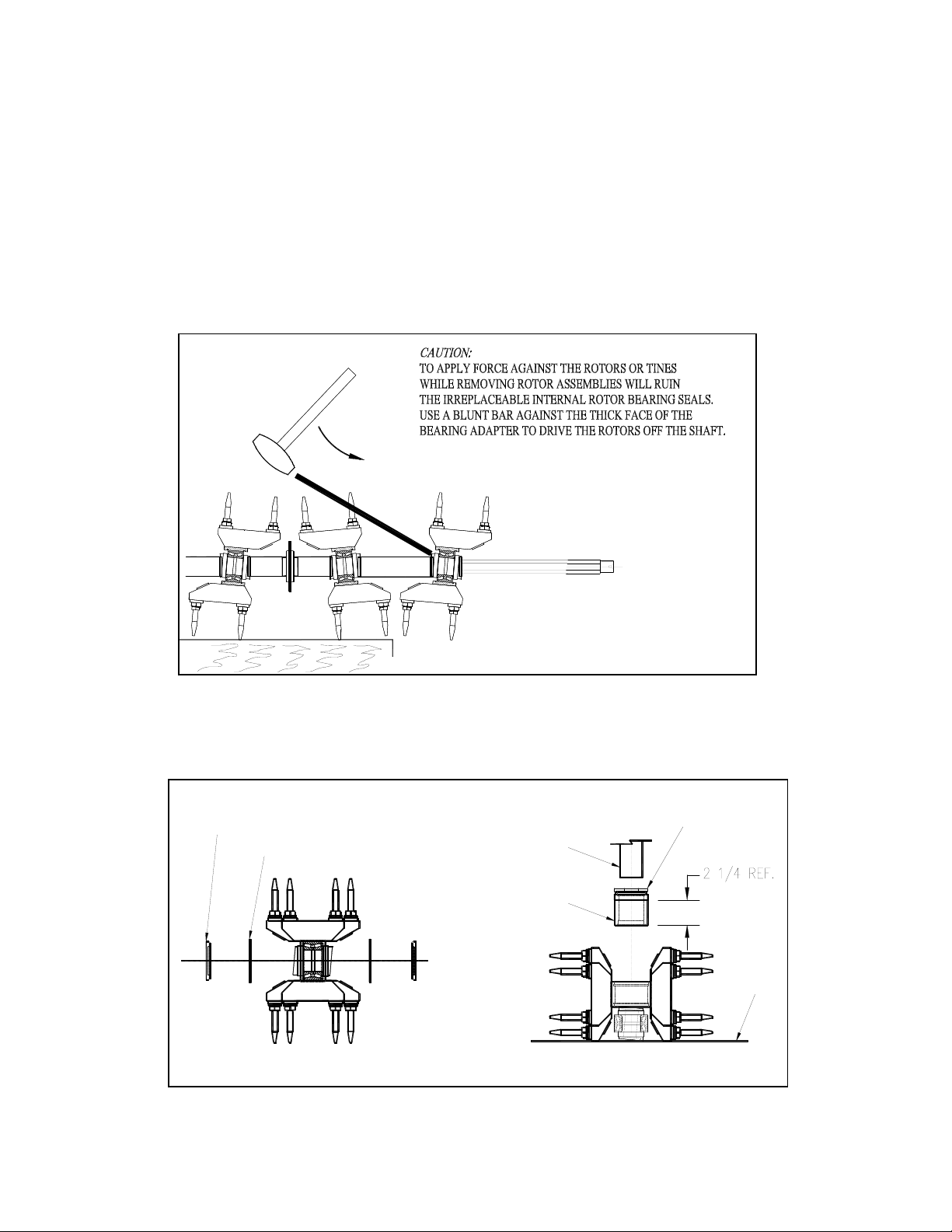

Rotor Shaft Disassembly

1. Remove the 1-1/8" hex jam nut from the shaft end nearest to the damaged component.

2. Only remove the rotors and spacers required to reach the damaged component. Wipe the shaft

clean before each rotor is removed. Each rotor bearing has two separate cones with a hex

bore adapter pressed in each. Each cone is held in position by an internal grease seal, which

allows the cones to be moved apart slightly. When they are moved apart any dirt allowed

inside the hex adapters can fall between the cones and contaminate the bearing. If the cones

are forced apart the internal seals become ruined and irreplaceable.

3. Clean and inspect parts as they are removed and set aside in their order of removal to simplify

re-assembly.

Rotor Hub Disassembly

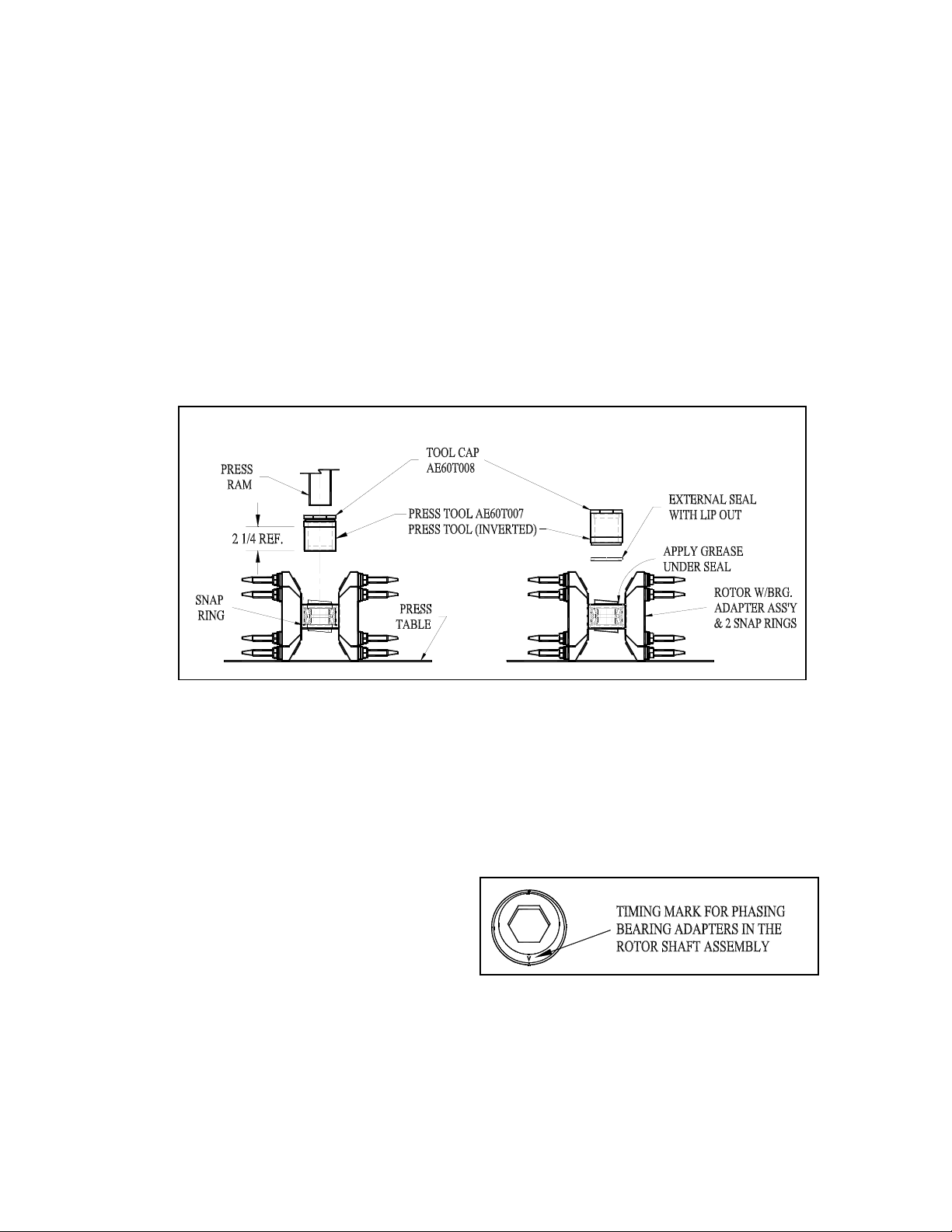

1. With a pry bar remove the external seals (Figure 7) on both sides. Generally, seals are

damaged and are not reused.

STEP 3

EXTERNAL SEAL - STEP 1

SNAP RING - STEP 2 PRESS

RAM

PRESS TOOL

AE60T007

TOOL CAP

AE60T008

PRESS

TABLE

2. Remove the snap rings on both sides.

3. Press used bearing and adapter assembly out.

Figure 7.

Figure 6. Rotor Shaft Disassembly

14

Fi

g

ure 9. Timin

g

Mar

k

Rotor Hub Re-Assembly

(keep all components clean to prevent bearing contamination)

1. Install internal snap ring in one side of rotor hub. Be sure snap rings expand full depth into

grooves.

2. Press new bearing and adapter assembly down tight against snap ring as shown in Fig. 8.

If bearing is loose in hub the rotor should be replaced.

3. Install snap ring in other end.

4. Apply a ribbon of general-purpose grease between the snap ring ID and bearing adapter OD

on both ends of the rotor hub.

5. With the press tool inverted to fit the external seals, press the seals in both ends of the rotor

with the lips out. Wipe off excess grease. Be sure seals are not bent or cut and are seated

firmly. If the seals are not tight, use a hammer and punch to stake the hub faces at

about 90

q

intervals.

Rotor Shaft Re-Assembly

(Read this section thoroughly before beginning)

CAUTION: IF THE BEARING ADAPTERS ARE NOT PRECISELY TIMED 180

DEGREES APART IN EACH ROTOR AND ALIGNED BETWEEN ROTORS, SERIOUS

DAMAGE WILL RESULT.

1. Rotate the adapters in each rotor so

the timing marks (See Figures 9, 10 &

11) are phased 180 degrees apart with

hex bores aligned.

2. Use marker pen to assist with

aligning timing marks between rotors.

Mark two rotor shaft flats 180 degrees

apart next to the threaded end (See Figure 10). The marked flats would have to

align with the timing marks on any rotors not removed during servicing.

Fi

g

ure 8.

15

Fi

g

ure 11. Rotor Sha

f

t Assembl

y

3. Install the required components in the sequence shown in Figure 11, double checking

the timing mark locations and spacer lengths (see following table) as each rotor is

installed.

SPACER LENGTH PART NO.

A 3 51/64” AE24-027

B 7 1/4” AE24-011

C 3 9/16” AE24-028

D 3 19/64” AE24-029

CAUTION: CLEAN THE ROTOR SHAFT THOROUGHLY REMOVING ANY BURRS

THAT WOULD KEEP THE ROTOR ASSEMBLIES FROM SLIDING ON FREELY. IF A

BEARING ADAPTER JAMS, THE INTERNAL BEARING SEAL COULD BE FORCED

OUT AND IT IS NOT REPLACEABLE.

Figure 10.

63$&(5

5(9 2/9 ('9 ,(:2)

%5 * $' $37(5 )$&(

7,0,1* 0$5 .

21%5 * $'$37(5

0$5.6+$)7)/$76

q$3$5 7

16

NOTE: THE SPACERS MUST BE FULLY SEATED IN EACH ADAPTER

COUNTERBORE BEFORE TIGHTENING. DO NOT FORGET TO PLACE THE

BEARING STAMPINGS ON EACH OF THE SHAFT BEARINGS DURING

REASSEMBLY. ALSO, THE 3/8" CARRIAGE BOLTS SHOULD BE PLACED IN THE

BEARING STAMPINGS ON THE DRIVE END OF THE SHAFT BEFORE THE PULLEY

IS REPLACED.

4. Replace the 1-1/8" hex jam nut and rotate each rotor occasionally as the nut is

torqued to 350 ft-lbs. If any rotor locks up, the bearing adapters in the rotor are

probably not phased 180 degrees apart or the spacers are not fully seated.

Rotor Shaft Installation

(with 2000 lb. rated hoist connected to mast chains)

1. Roll Rotor Shaft Assembly into position under frame bearing holes with pulley on drive end.

2. Carefully lower unit in small increments while keeping both bearing flanges on the side of the

frame end plates and center bearing support as illustrated. Note that the center bearing sup-

port is loose against the frame and can be tilted for alignment. Never assemble with the

bearing flanges separated around a Frame End or the Center Bearing Support.

3. Note that as the frame

ends and center bearing

support are carefully

lowered down beside

each pair of bearing

flanges it is necessary

to push the unit away

from the pulley end.

This allows the frame

end to pass the carriage

bolts sticking through

both bearing flanges

next to the pulley.

4. When the frame ends align with the carriage bolt holes and the bearing flanges, pull the unit

toward the pulley end to assemble nuts on carriage bolts.

5. Install bolts and nuts in center bearing support and other end plate being careful to align car-

riage bolt shoulders with the square holes in bearing flanges (hand tighten).

6. Lift unit until Rotor Shaft is approximately 20” off the floor (See Fig. 5).

7. Place Jack Stands under the Rotor Shaft Assembly for added safety. As during Shaft re-

moval, locate stands between the 1st and 2nd rotors from each end and lower unit until Rotor

Shaft contacts both stands. Keep hoist connected to mast chains with slight tension.

8. Tighten all bearing flange bolts 30-35 Ft-Lbs.

9. Tighten 3 bolts connecting center bearing support to frame 50-55 Ft. Lbs.

Figure 12. Rotor Shaft Re-assembly

17

10. Install and tighten drive belts. (Refer to decal on end of seed hopper)

Tighten both bolts in belt idler bracket 50-55 Ft. Lbs.

11. Install Skid Shoe and tighten bolts 30-35 Ft. Lbs.

12. Install Belt Cover and tighten bolts 8-12 Ft. Lbs.

13. Lift unit to remove Jack Stands.

14. Lower unit until force is removed from pins in roller linkages. Remove pins and store in float

position or use hoist to adjust linkages for inserting pins in another desired fixed position

(See Fig. 2, pg. 7).

15. Lift unit as required to lower swing stand.

18

WARRANTY INFORMATION

ONE YEAR LIMITED WARRANTY

FIRST PRODUCTS INC. WARRANTS THIS PRODUCT TO BE FREE OF DEFECTS IN

MATERIALS AND WORKMANSHIP FOR A PERIOD OF TWELVE MONTHS FROM THE

ORIGINAL DELIVERY DATE. THIS WARRANTY DOES NOT COVER PARTS CAUSED TO

BE DEFICIENT DUE TO NORMAL WEAR, MISUSE, ACCIDENTS, OR LACK OF PROPER

MAINTENANCE.

ANY PARTS THOUGHT TO BE DEFECTIVE MUST BE RETURNED TO THE

DEALER/DISTRIBUTOR FOR WARRANTY CONSIDERATION JOINTLY WITH FACTORY

REPRESENTATIVES. A RETURN AUTHORIZATION NUMBER MUST BE OBTAINED

AND CLEARLY MARKED ON ALL PACKAGES OF PARTS REQUIRING RETURN TO THE

FACTORY.

THE OBLIGATION OF FIRST PRODUCTS INC. UNDER THIS WARRANTY SHALL BE

EXCLUSIVELY LIMITED TO REPLACEMENT OF PARTS DETERMINED TO BE

DEFECTIVE BY FIRST PRODUCTS INC. WITH FREIGHT PREPAID. IN NO EVENT SHALL

FIRST PRODUCTS INC. BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH THE USE OF THIS PRODUCT.

FIRST PRODUCTS INC. RESERVES THE RIGHT TO MAKE CHANGES OR ADD

IMPROVEMENTS TO ITS PRODUCTS AT ANY TIME WITHOUT OBLIGATION TO MAKE

SUCH CHANGES OR IMPROVEMENTS ON PRODUCTS SOLD PREVIOUSLY.

Table of contents

Other First Products Farm Equipment manuals