First Products UA60T Installation and operation manual

Model - Serial Number

UA60T - 1001 thru ____

Printed in U.S.A.

PB 0616

OPERATOR’S

MANUAL & PARTS LIST

Universal Aera-vator

MODEL UA60T

FIRST PRODUCTS INC.

164 Oakridge Church Road

Tifton, Georgia 31794 U.S.A.

Phone (229) 382-4768

1-800-363-8780

Fax (229) 382-0506

Web: www.1stproducts.com Email: Sales@1stproducts.com

Manual Part #: UA50-109

First Products UA-60T Operator’s Manual

Table of Contents bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

1

Operator's Manual

Introduction............................................................. 2

Safety...................................................................... 3

Safety Alert Symbol............................................ 3

Safe Operating Practices..................................... 3

Specifications........................................................ 10

Dimensions ....................................................... 11

Torque Requirements........................................ 11

Product Overview ................................................. 12

Operation .............................................................. 13

Pre-Start............................................................ 13

Operating Instructions....................................... 13

Maintenance.......................................................... 16

Recommended Maintenance Schedule(s)......... 16

Periodic Maintenance ....................................... 17

Check Engine Oil Level................................ 17

Check Air Cleaner......................................... 17

Check Battery Charge................................... 17

Check Hydraulic Oil Level........................... 18

Check Tire Pressure...................................... 18

Check for Loose Hardware........................... 18

Checking Rotor Shaft Tines.......................... 18

Check Condition of Belts.............................. 19

Lubricate Grease Fittings.............................. 19

Check Spark Plugs........................................ 19

Check Fuel Filter........................................... 19

Change Hydraulic System Filter................... 19

Clean Engine................................................. 20

Waste Disposal.......................................20

Motor Oil Disposal ....................................... 20

Battery Disposal............................................ 20

Rotor Shaft Service............................................... 21

Rotor Shaft Disassembly............................... 21

Rotor Hub Disassembly................................ 21

Rotor Hub Re-Assembly............................... 21

Rotor Shaft Re-Assembly............................. 21

WARRANTY INFORMATION .......................... 23

Parts Book

Power Transmission Accessories Group .......... 24

Power Transmission Group .............................. 25

Fuel Tank and Electrical Group........................ 27

Hydraulics Group.............................................. 29

Lift Axle Group ................................................ 31

Covers & Decals Group.................................... 32

Roller Attachment............................................. 33

Brush Attachment (Optional)............................ 34

Aera-vator Shaft................................................ 35

Multi-tine Shaft................................................. 36

Aera-slicer Shaft ............................................... 37

Multi-Spike Shaft.............................................. 38

Coring Shaft...................................................... 39

Lighting Group ................................................. 40

Troubleshooting.................................................... 41

Schematics............................................................ 43

Machine Electrical ........................................ 43

Control Electrical.......................................... 44

Lighting......................................................... 45

Hydraulics..................................................... 46

9

Introduction bbbb bbbbbbbb bbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

2

Introduction

Thank you for purchasing the First Products Aera-

vator. This machine is designed to withstand years

of continuous use and is manufactured by skilled

workers using quality materials. Proper assembly,

maintenance, and safe operating practices will

provide years of satisfactory service.

Using This Manual

This operator’s manual is designed to help

familiarize you with safety, assembly, operation,

adjustments, troubleshooting, and maintenance.

Read this manual and follow the recommendations

to help ensure safe and efficient operation.

Read the warranty located on page 23. Fill in the

required information on the warranty registration

card provided, and return it to the address on the

front of this manual. The warranty registration

must be returned to validate warranty.

To order a new Operator’s and Parts Manual (Part

number UA50-109), contact your authorized dealer

or write to the address listed below in the Owner

Assistance paragraph. Include the model and serial

numbers of your unit. In addition to this, you may

also download a copy of the Operator’s Manual

from our web site: www.1stproducts.com

The information contained within this manual was

current at the time of printing. Some parts may

change slightly to assure you of the best

performance.

Terminology:

“Right” or “Left” as used in this manual is

determined by standing behind the machine and

facing the direction of operation.

Definitions:

NOTE: A special point of information related to its

preceding topic. The author’s intention is that you

read and note this information before continuing.

IMPORTANT: A special point of information that

the author feels you must be aware of before

continuing with the instructions that follow.

Owner Assistance

If customer service or repair parts are required,

contact your First Products dealer. A dealer has

trained personnel, repair parts, and the equipment

needed to service your machine. These parts have

been specifically designed for your Aera-vator and

should only be replaced by genuine First Products

parts.

Serial Number Plate

Refer to Figure 1 for the location of your serial

number plate.

Figure 1: Aera-vator Serial Number Location

For prompt service, always use the serial

number and model number when ordering parts

from your First Products dealer. Fill in Model and

serial numbers of each unit you’ve purchased in the

section below. If for any reason you do not

understand any part of this manual or not satisfied

with service you received, discuss the matter with

your dealership service manager. For further

assistance, write to:

First Products, Inc

Attn: Product Support

164 Oakridge Church Road

Tifton, Ga 31794

Date Purchased_____________________________

UA60T Serial No.___________________________

Engine Model No. and Spec. No._______________

Engine Serial No .___________________________

Figure 1. Serial number Plate

First Products UA-60T Operator’s Manual

Safety bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

3

Safety

Safety Alert Symbol

This is the safety alert symbol. It means:

ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

DANGER: White lettering / Red background

Indicates an imminently hazardous situation, which,

if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme

situations, typically for machine components that,

for functional purposes, cannot be guarded.

WARNING: Black lettering / Orange background

Indicates a potentially hazardous situation, which, if

not avoided, could result in death or serious injury,

and includes hazards that are exposed when guards

are removed. It may also be used to alert against

unsafe practices.

CAUTION: Black lettering / Yellow background

Indicates potentially hazardous situation, which, if

not avoided, could result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Safe Operating Practices

Training

Read Operator’s manual and other training

material. If the operator(s) or mechanic(s) can

not read English it is the owner’s responsibility

to explain this material to them.

Become familiar with the safe operation of the

equipment, operator controls and safety signs.

All operators and mechanics should be trained.

Never let children or untrained people operate

or service the equipment. Local regulations

may restrict the age of the operator.

Preparation

Evaluate the terrain to determine if any thing is

needed to properly and safely perform the job.

Wear appropriate clothing including safety

glasses, substantial footwear, long trousers, and

hearing protection. Do not operate with long

hair, loose clothing or jewelry; these could get

tangled in moving parts.

Inspect the area where equipment is to be used

and remove all rocks, toys, sticks, wires, and

other foreign objects which can be thrown by

the machine and may cause personal injury to

the operator or bystanders.

First Products UA-60T Operator’s Manual

Safety bbbb bbbbbbbb bbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

4

First Products UA-60T Operator’s Manual

Safety bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

5

Operation

Operate only in daylight or good artificial light,

keeping away from hidden hazards.

Never operate the machine with damaged

guards, shields, or covers. Always have safety

shields, guards, switches and other devices in

place and in proper working condition.

DO NOT change the engine governor setting or

over speed the engine.

Stop engine, wait for all moving parts to stop,

and remove key:

oBefore checking, cleaning or working on the

machine.

oAfter striking a foreign object or abnormal

vibration occurs (inspect the machine for

damage and make repairs before restarting

and operating).

Stop engine, and wait for all moving parts to

stop:

oBefore refueling.

oBefore checking oil levels

NEVER carry passengers. Do not operate the

machine when people, children, or pets are in

the area.

Be alert, slow down and use caution when

making turns. Look behind and to the side

before changing directions.

Do not operate the machine under the influence

of alcohol and drugs.

Use extreme care when loading or unloading the

machine from a trailer or truck.

Use extreme caution when approaching blind

spots, corners, shrubs, trees, or other object that

may obscure vision.

First Products UA-60T Operator’s Manual

Safety bbbb bbbbbbbb bbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

6

Slope Operation

Use Extreme caution when operating and/or

turning on slopes as loss of traction and/or tip-over

could occur. The operator is responsible for safe

operation on slopes.

See the inside of the back cover to determine the

approximate slope angle of the area to be

operated on.

Remove or mark obstacles such as rocks, tree

limbs, etc. from the area. Tall grass can hide

obstacles.

Watch for ditches, holes, rocks, dips, and rises

that change the operating angle, as rough terrain

could overturn the machine.

Always avoid sudden starting or stopping on a

slope. If tires lose traction, turn off aerator and

proceed slowly off the slope.

Operating on wet grass or steep slopes can

cause sliding and loss of control. Wheels

dropping over edges, ditches, steep banks, or

water can cause rollovers, which may result in

serious injury, death, or drowning.

Do Not operate on slopes when grass is

wet.

Do Not operate on slopes greater than 15

degrees.

Do Not operate near drop-offs or near

water.

Reduce speed and use extreme caution on

slopes.

Avoid sudden turns or rapid speed

changes.

First Products UA-60T Operator’s Manual

Safety bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

7

Maintenance and Storage

Lift aerator out of ground, stop engine, and

remove key before adjusting, cleaning, or

repairing.

Keep power transmission components (belts,

pump, engine, etc.) free of debris. The debris

can become combustible which may result in a

fire.

Let engine cool before storing and do not store

near flame or any enclosed area where open

pilot lights or heat appliances are present.

Drain fuel from tank while storing.

Pin the cylinder lock-out bar into place and

carefully release pressure from components with

stored energy.

Never allow untrained personnel to service

machine.

Disconnect the negative terminal cable from the

battery before making any repairs. If battery is

required to be removed, always disconnect the

negative cable first and always connect the

positive first while reinstalling.

Charge battery in an open, well-ventilated area,

away from sparks and flames.

Keep all guards, shields, and all safety devices

in place and in safe working condition.

Check bolts frequently to maintain proper

tightness.

Check belts frequently for proper tensioning and

wear condition.

Check all moving components for worn or

deteriorating components that could create a

hazard.

All replacement parts must be the same as or

equivalent to the parts supplied as original

equipment.

Check fluid levels daily during operation. If

fluids are needed, fill with the correct fluids

specified.

Inspect all hydraulic hoses and adapters daily

for leaks or defects.

When brushes are attached, Anti-tip leg must be

extended before disconnecting hitch from tow

vehicle.

Anti-tip Leg

First Products UA-60T Operator’s Manual

Safety bbbb bbbbbbbb bbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

8

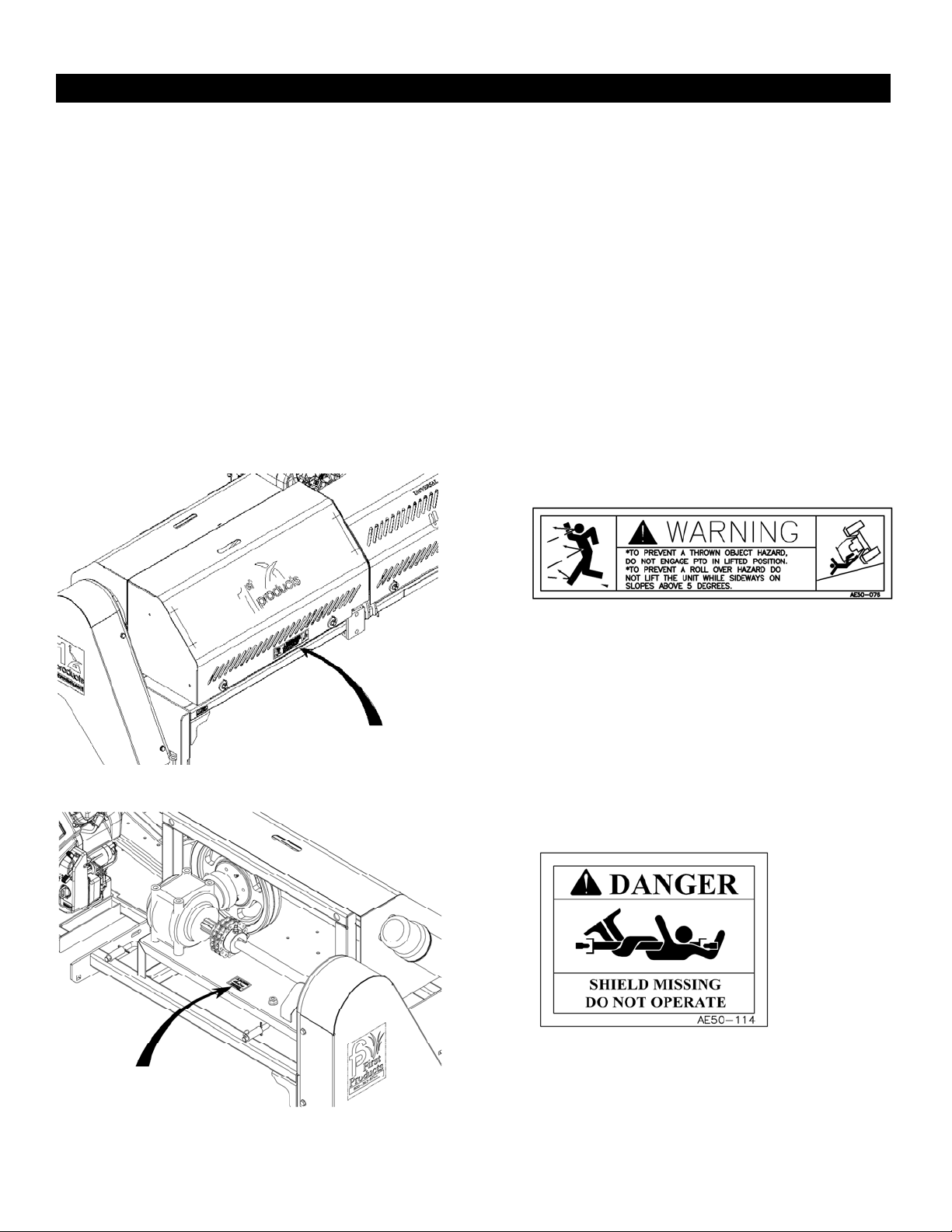

Safety and Instructional Decals

Keep all safety signs legible. Remove all

grease, dirt and debris from safety signs and

instructional labels.

Replace all worn, damaged, or missing safety

signs.

When replacement components are installed, be

sure that current safety signs are affixed to the

replaced components.

If an attachment or accessory has been installed,

make sure current safety signs are visible.

New safety signs may be obtained from your

authorized First Products, Inc. equipment dealer or

distributor.

Safety sign may be affixed by peeling off the

backing to expose the adhesive surface. Apply

only to a clean, dry surface. Smooth to remove

any air bubbles.

Familiarize yourself with the following safety

signs and instruction labels. They are critical to

the safe operation of your First Products

machine.

REAR COVER

AE50-076

THROWN OBJECT HAZARD

AE50-114

DANGER HAZARD

UNDER EXPOSED JACK SHAFT

AE50-114

AE50-076

First Products UA-60T Operator’s Manual

Safety bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

9

UA50-099

CYLINDER LOCK DECAL

AE50-074

G

ENERAL WARNING DECAL

FRONT COVER

First Products UA-60T Operator’s Manual

Specifications bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

10

Specifications

Engine

Engine Specifications: See your Engine

Owner’s Manual

RPM: Full Speed 3400 +/- 100 RPM (No Load)

Idle: 1600 RPM

Fuel System

Capacity: 5 gal. (18.9 L)

Type of Fuel: Regular unleaded gasoline, 87

octane or higher

Fuel filter: In-line 40 Micron

Honda P/N :16910-Z6L-003

Electrical System

Charging System: Flywheel Alternator

Charging Capacity: 20 amps

Battery Type, BCI Group U1

Battery Voltage: 12 Volt

Polarity: Negative Ground

Fuses: One 20 amp blade type

Safety System

Transport lock must be used when machine is

hauled from one venue to another

Operator Controls

The operator controls the lifting, lowering,

and aeration from a hand-held control box

with three switches (Figure 3).

The operator accesses the engine controls

via its control panel found opposite its oil

filter side.

oEngine Throttle Control

The throttle is used to control engine speed.

Moving the throttle lever upward will

increase engine speed and moving

downward will decrease engine speed.

oChoke Control

The choke is used to aid in starting a cold

engine. Pulling the choke outward will put

the choke in the “ON” position and pushing

the knob inward, will put the choke in the

“OFF” position. Do Not run a warm engine

with choke in the “ON” position.

oIgnition Switch

The ignition switch is used to start and stop

the engine. The switch has three positions

“OFF”, “RUN” and “START”. Insert key

into switch and rotate clockwise to the

“RUN” position. Rotate clockwise to the

next position to engage the starter (key must

be held against spring pressure in this

Figure 2. Transport Lock

Figure 3. Hand-held Control

First Products UA-60T Operator’s Manual

Specifications bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

11

position). The PTO switch must be in the off

position to start the engine.

oAuto Throttle Handle

With the Auto throttle handle in the down

position (locked position) the engine’s RPM

will increase as the machine is lowered into

the ground. As the unit is lifted the engine

will return to idle.

The auto throttle can be disengaged when

auto throttling is not required by raising the

auto throttle handle into the unlocked

position.

oHour Meter

The hour meter is connected to the ignition

switch to record the amount of run time on

the unit. The hour meter will work while the

engine is operating.

Transport Options

The UA-60T can be transported by using its

standard 2” ball coupler or its draw bar option.

Hydraulic Lift System

Hydraulic Pump: ½ Gal/Min Fixed

Displacement Gear Pump

Hydraulic Cylinder: 2” Bore with 8” Stroke

Hydraulic Oil Type: A68 Hydraulic Oil.

Hydraulic Oil Capacity: 1.7 gal. (6.4 L)

Tires & Wheels

Tires are 20 ½” on 8” wheels fastened with five

lug nuts on 5 ½” centers.

Tires have highway tread and are 16 ply with a

load rating F.

Dimensions

Overall Width: 95 ½” (Outside of Tires)

Overall Height: 48 ½” (Raised & Level)

Overall Depth: 36” (Tongue Removed)

80” (Back of Fender to

Tongue)

Torque Requirements

Engine Mounting bolts 38-40 ft-lbs

(51 – 56 N-m)

Wheel Lug nuts 90-95 ft-lbs

(122-129 N-m)

Tines in Rotor

Aera-vator Shaft 210-215 ft-lbs

(284- 291 N-m)

Implement frame to Tractor

mount bolts 111 – 115 ft-lbs

(150 -156 N-m)

1/4 UNC Standard Bolts 11 ft-lbs (14 N-m)

5/16 UNC Standard Bolts 21 ft-lbs (28 N-m)

3/8 UNC Standard Bolts 38 ft-lbs (51 N-m)

1/2 UNC Standard Bolts 85 ft-lbs (120 N-m)

5/8 UNC Standard Bolts 175 ft-lbs (235 N-m)

Figure 4. Standard 2” Ball Coupler

Figure 5. Draw Bar Option

First Products UA-60T Operator’s Manual

Operation bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

12

Product Overview

Before operating the UA-60T, it is necessary to

understand how the machine works and why it

functions in such manner.

The machine uses an engine to power two power

transmission components: Hydraulic pump &

Electric clutch. The hydraulic pump is used to lift

and lower the machine. The electric clutch engages

the rotor shaft and causes the tines to vibrate.

Hydraulic Circuit

When the engine is on, the pump is continuously

circulating hydraulic oil from the reservoir, to the

pump, to the valve block, and back to the reservoir.

When the operator presses the momentary switch

for the raise or lower function on the hand-held

controller (Figure 3) the fluid entering the valve

block is diverted to the cylinder causing the

machine to raise or lower. See Figures 6 and 7.

Automatic Throttle Activation

The engine throttle is tied to a cable-spring

assembly which is pulled when the lift cylinder is

extended, Figure 8. When the machine is lowered,

the cylinder extends; this action pivots the bracket

hooked to the spring and cable assembly. As the

cable is pulled, the engine speed is increased.

Likewise, when the machine is lifted, the cable is

retracted by a spring on the engine.

Aeration Mechanism

The UA-60T is designed to start aeration when the

electric clutch is turned on. With the Auto Throttle

Handle, Figure 8, position down, the engine will

automatically throttle up as it lowers to the ground.

Once the tines start to touch the ground, the electric

clutch may be engaged to start the patented

vibrating tines. To lower the machine without

throttling up the engine, simply lift the pivot catch

handle, Figure 8, and allow the stud to travel in the

slot while the machine lowers to the ground.

Figure 6. Hydraulic Circuit

Figure 7. Hydraulics

Fi

g

ure 8. Automatic Throttle Mechanis

m

First Products UA-60T Operator’s Manual

Operation bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

13

Operation

Note: The left and right sides of the machine are

defined as standing behind it and facing the

direction of operation.

Pre-Start

Fill fuel tank, for best results use clean, fresh

regular unleaded gasoline with an octane rating of

87 or higher.

Do Not add oil to gasoline.

Do Not overfill fuel tank. Never fill fuel tank so

that the fuel level rises above a level that is ½ inch

(13 mm) below the bottom of the filler to allow for

fuel expansion and prevent fuel spillage.

Make sure the operator understands the controls,

their locations, their functions, and their safety

requirements.

Refer to the Maintenance section and perform all

necessary inspection and maintenance steps.

Operating Instructions

Hitching Machine and Set-up

The UA-60T can be hitched to any working vehicle

desired for operation. The standard 2 inch ball

coupler is utilized for most applications. The

optional draw-bar attachment can be used in

situations where the 2” ball coupler is not feasible,

such as small utility tractors.

Once the machine is connected, the hand-held

control switch must be installed. Located under the

fuel tank, a socket receives the plug from the

control switch. Uncoil the switch and use ties as

necessary to ensure the cord does not make contact

with the vehicle in turns or the ground upon

lowering to the ground.

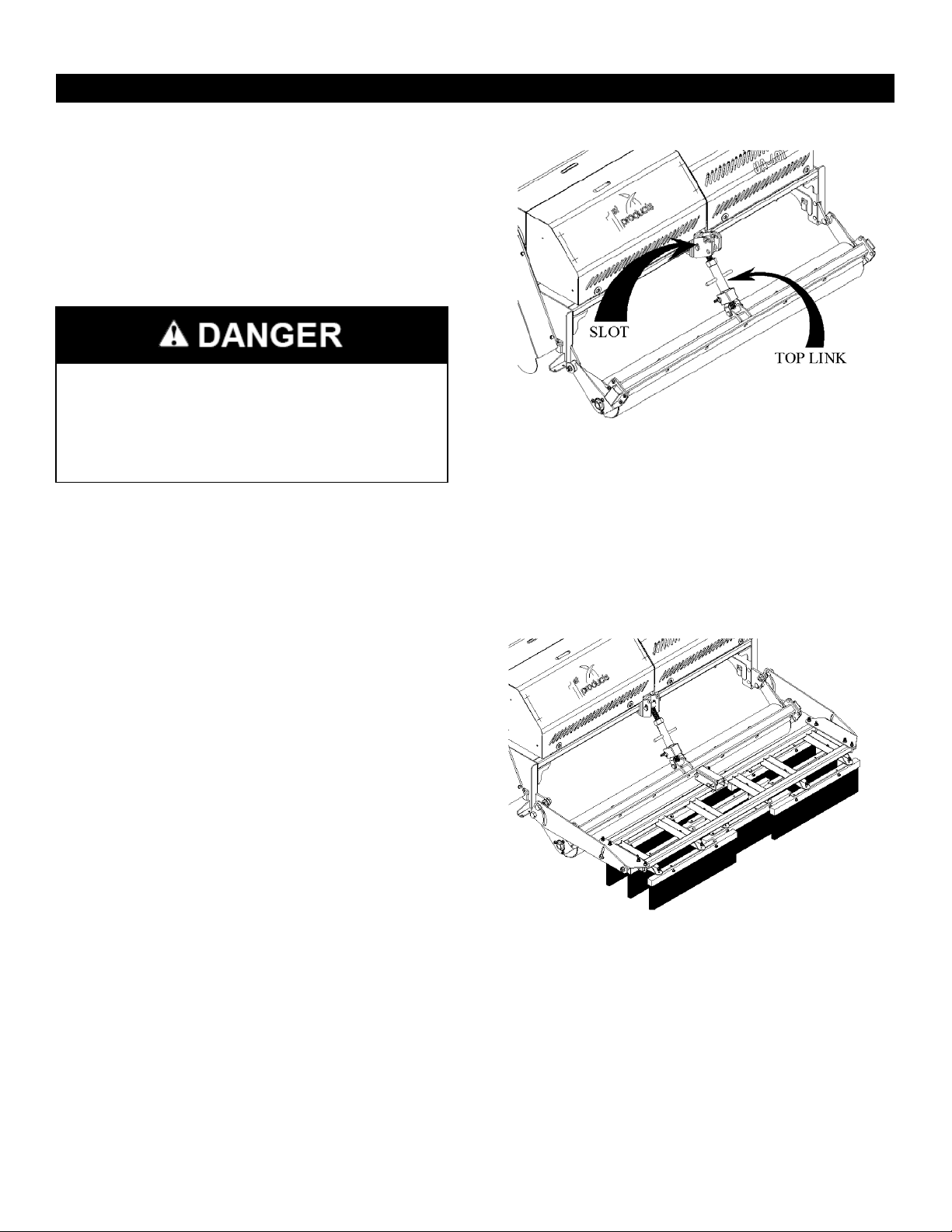

Leveling Aera-vator for Operation

The UA-60T is equipped with a top link connected

to the sway bar on the right side. This top link is

adjusted in or out to level the aerator during

operation.

1. With the machine hitched at the worksite, start

the engine.

2. Lift the Auto Throttle Handle to disengage the

throttle, Figure 8, and use the control box to

lower the machine to the ground.

3. Rotate the top link as necessary to level the

machine, Figure 9.

4. Raise the machine and engage the Auto Throttle

Handle for use.

Start the Engine

1. Before starting the engine, if the machine is in

the lowered position. The Auto Throttle

Handle, Figure 8, must be lifted to disengage

the throttle.

2. On a cold engine, pull the choke knob outward

into the “ON” position.

3. On a warm engine, leave the choke in the

“OFF” position.

4. Turn ignition switch to the “START” position.

Release the switch as soon as the engine starts.

IMPORTANT: Do NOT crank the engine

continuously for more than ten seconds at a

time. If the engine does not start, allow 60

second cool-down period between starting

attempts. Failure to follow these guidelines

can burn out the starter motor.

5. If the engine is difficult to start, the throttle can

be used momentarily. As soon as the engine

starts, cut the throttle down to the idle position.

6. If the choke is in the “ON” position, gradually

return choke to the “OFF” position as the engine

warms up.

Figure

9.

Leveling Aera

-

vator

First Products UA-60T Operator’s Manual

Operation bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

14

Aeration

With the engine running and the machine fully

lifted:

1. Ensure the Auto Throttle Handle is lowered

back into position to allow the throttle cable to

be pulled when machine is lowered to ground.

2. Tow machine to starting point on worksite and

lower using hand-held control switch, Figure 3.

3. Adjust the ground speed accordingly. Slow

down to allow tines to penetrate deeper. The

chain hanging on the left side of the machine is

a visual indicator for depth. If the chain is

touching the turf, full depth is achieved.

4. Press the control switch to lift the machine when

desired.

Operating the Attachments

The UA-60T is equipped to have both a solid roller

and a brush fastened to the frame. Attachments can

be seen in further detail in the parts list portion of

this manual.

The roller is seen is Figure 10. It is made to

primarily float using a slot located on the top

bracket on the frame. When down pressure from

the roller is desired, the top link is adjusted to lower

the roller downward until down pressure is achieved

and the pin is at the top of the slot.

The brush is shown in Figure 11. It is fastened to

the frame in a three-point hitch configuration to

allow smooth floatation. The brush easily locks

into place for transportation by simply lifting the

brush to the top of its range. The brush can be

modified to various widths and configurations to

conform to the user’s needs.

The movement of the rotors on the machine is

dangerous. Contact with rotor shaft can

cause serious injury or death. Do NOT put

hands or feet in the working area of the rotor

shaft while activated.

Figure 10. Roller Attachment

Figure 11. Brush Attachment

First Products UA-60T Operator’s Manual

Operation bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

15

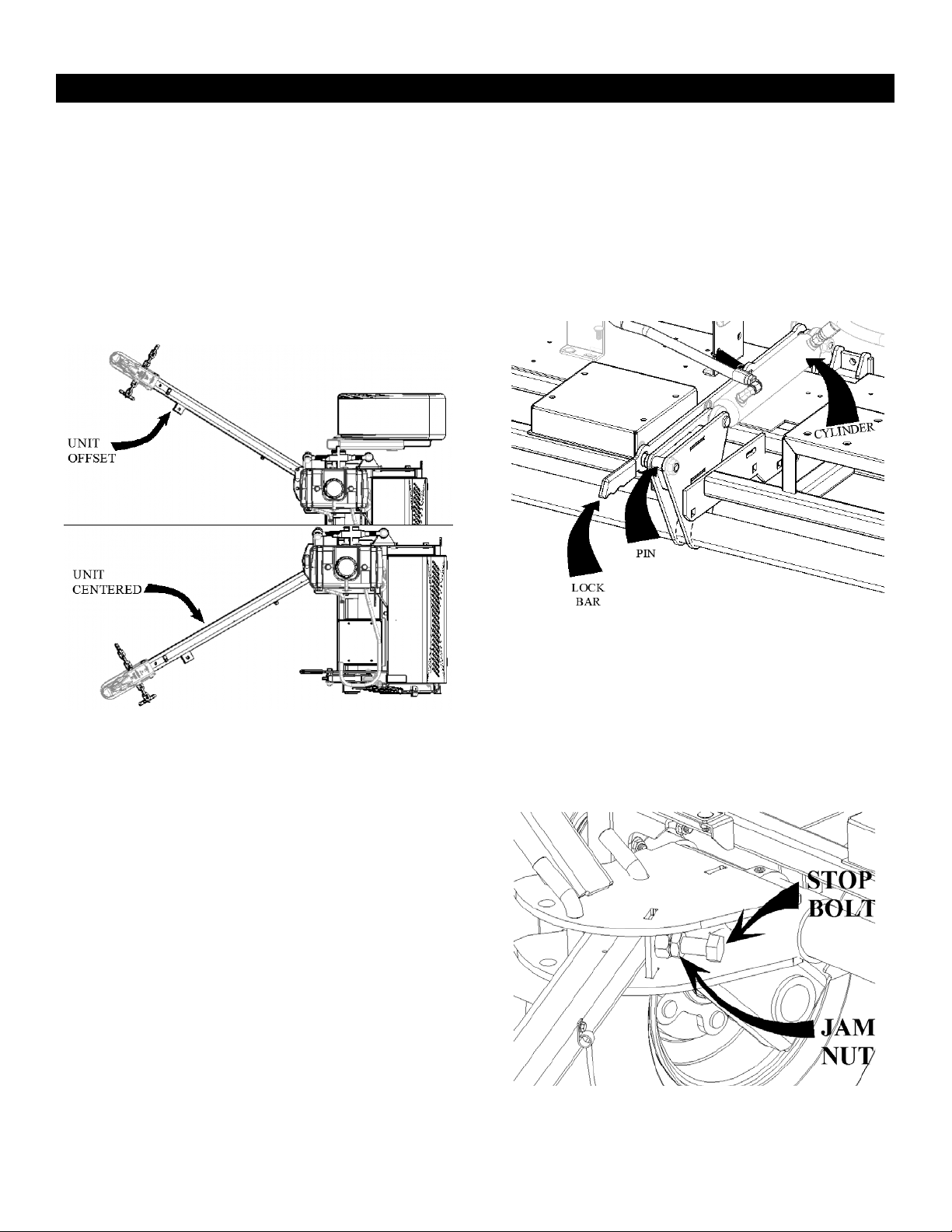

Offsetting unit

The unit may be operated either directly behind the

tow vehicle or offset to the side of the vehicle. The

unit can be offset by changing the tongue position,

Figure 12. The offset can be adjusted between the

two outer positions shown by aligning the holes in

the tongue with either of the sets of holes in the

Tongue Swivel.

Transporting unit

Before transporting the UA-60T from one location

to another, the red handled Cylinder Lock-Bar

located by the lift cylinder must be pinned to the

cylinder to prevent the machine from gradually

leaking down over time. The red handled Cylinder

lock-bar is seen in Figure 13.

The tongue of the unit should also be locked to its

centered position, Figure 12, with the stop bolt

being tightened against the tongue and locked into

place with the jam nut, Figure 14. The unit should

only be transported while centered behind the

tow vehicle with the stop bolt tightened.

Figure 12. Offsetting Unit

Figure 13. Cylinder Lock Bar

Figure 14. Stop Bolt Location

First Products UA-60T Operator’s Manual

Maintenance bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

16

Maintenance

Recommended Maintenance Schedule(s)

Maintenance Service

Interval Maintenance Procedure

After the first 5 hours Change the engine oil.

After the first 100 hours Check the Wheel Lug nuts.

After the first 250 hours Change the hydraulic filter.

Before Each use or daily

Check the engine oil level.

Check for loose hardware

Check for loose tines.

Clean debris off Engine exhaust and rotor shaft

Every 40 hours

Check Hydraulic Oil Level.

Check Tire pressures.

Check the condition of the belts.

Every 50 hours

Service the air cleaner. (May need more often under severe conditions. See

Engine Owner’s Manual for additional information)

Change the Engine oil and Oil filter.

Grease Lift Axle at Bushings (3 places).

Every 100 hours Check belts for wear & tear. Clean around belts and pulleys as necessary.

Monthly Check the battery charge.

Yearly Check the wheel lug nuts.

First Products UA-60T Operator’s Manual

Maintenance bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

17

Periodic Maintenance

Check Engine Oil Level

Service Interval: Before each use or daily

1. Engine must be level for checking oil. After

starting the engine, disengage the throttle from

the pivoting axle by lifting the Auto Throttle

Handle (Figure 8) while lowering the machine

to the ground.

2. Turn engine off.

3. Check with cool engine.

4. Clean area around dipstick. Remove dipstick

and wipe oil off. Reinsert the dipstick. Remove

the dipstick and read the oil level.

5. If the oil level is low, fill to the “FULL” mark

on the dipstick, Use oil as specified in the

Engine Owner’s Manual. Do Not over-fill.

Important: Do Not operate the engine with the

oil level below the “LOW” (or “ADD”) mark on

the dipstick, or over the “FULL” mark.

Check Air Cleaner

Service Interval: Every 50 hours-Service

the air cleaner. (may need more often

under severe conditions. See the Engine

Owner’s Manual for additional

information.)

1. Stop engine, wait for all moving parts to stop,

and remove key.

2. See Engine Owner’s Manual for cleaning

instructions.

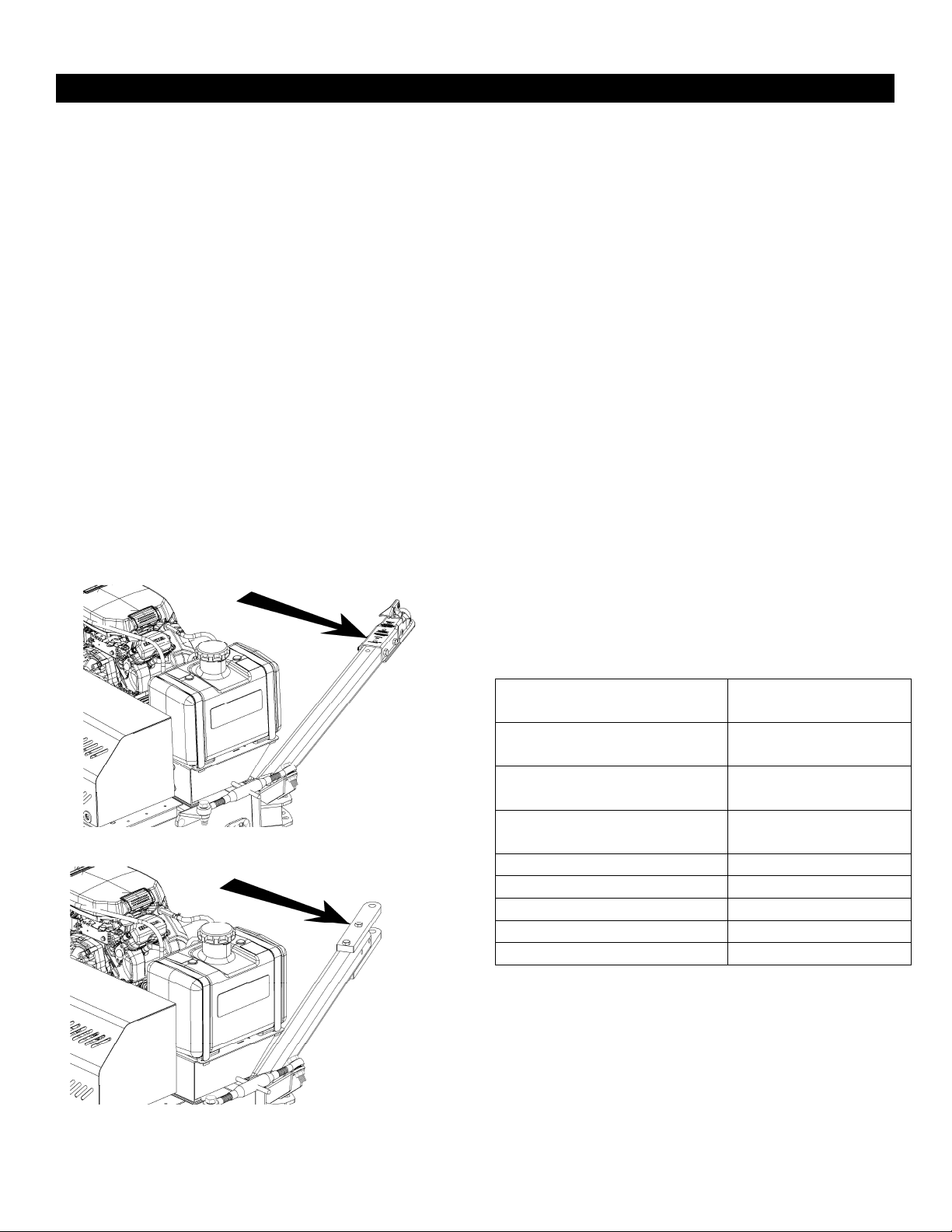

Check Battery Charge

Service Interval: Monthly

Allowing batteries to stand for an extended period

of time without recharging them will result in

reduced performance and service life. To preserve

optimum battery performance and life, recharge

batteries in storage when the open circuit voltage

drops to 12.4 volts.

NOTE: To prevent damage due to freezing,

battery should be fully charged before putting away

for winter storage.

Check the voltage of the battery with a digital

voltmeter. Locate the voltage reading of the battery

in the table and charge the battery for the

recommended time interval to bring the charge up

to a full charge of 12.6 volts or greater.

Important: Make sure the negative battery

cables are disconnected and the battery charger

used for charging the battery has an output of 16

volts and 7 amps or less to avoid damaging the

battery (see chart for recommended charger

settings).

Voltage

Reading Percent

Charge

Maximum

Charger

Setting

Charging

Level

12.6 or

greater 100% 16 volts/7

amps

No

Charging

Required

12.4 -

12.6 75-

100% 16 volts/7

amps 30

Minutes

12.2 -

12.4 50-75% 16 volts/7

amps 1 Hour

12.0 –

12.2 25-50% 16 volts/7

amps 2 Hours

First Products UA-60T Operator’s Manual

Maintenance bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

18

11.7-

12.0 0-25% 14.4

volts/4

amps 3 Hours

11.7 or

less 0% 14.4 volts/

2 amps 6 Hours

or More

Check Hydraulic Oil Level

Service Interval: Every 40 hours

Hydraulic Oil Level

1. Stop engine and wait for all moving parts to

stop. Make sure unit is on a level surface.

2. The hydraulic reservoir is located under the rear

left cover of the machine. Unscrew the cap and

clean the dipstick.

3. Reinsert the dipstick. Do not screw into place.

Remove the dipstick and read the oil level.

4. If the oil level is low, fill to the “FULL” mark,

Figure 15. Do Not overfill.

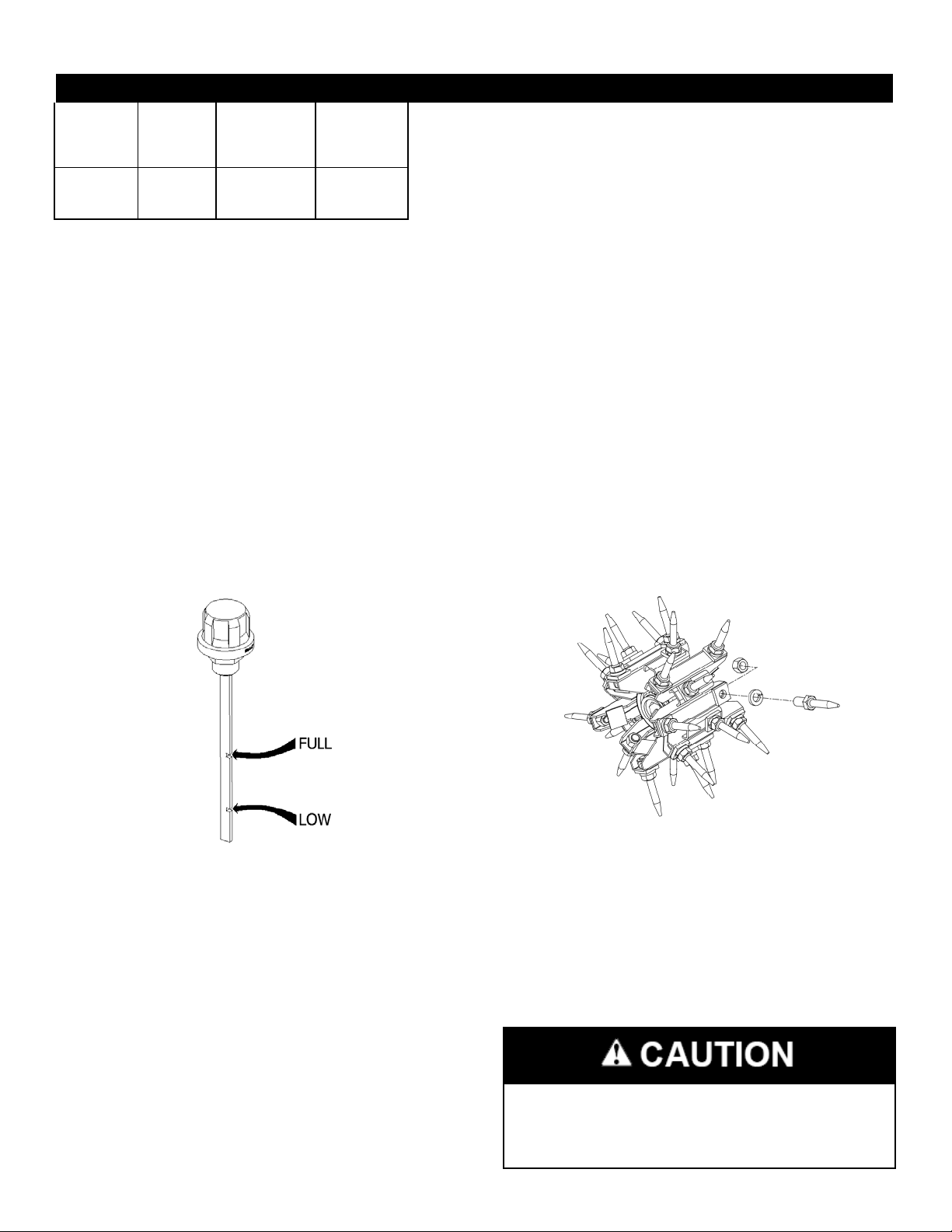

Figure 15. Dipstick Markings

5. Use only A68 Hydraulic Oil or appropriate

substitute.

Check Tire Pressure

Service Interval: Every 40 hours

1. Stop engine and wait for all moving parts to

stop.

2. Check tire pressure and make any necessary

adjustments.

Check for Loose Hardware

Service Interval: Before each use or daily

1. Stop engine, wait for all moving parts to stop,

and remove key.

2. Visually inspect machine for any loose

hardware or any other possible problem.

Tighten hardware or correct the problem before

operating.

Checking Rotor Shaft Tines

Service Interval: Before each use or daily

1. Ensure the rotor shaft is off the ground with the

lift cylinder completely retracted and engage red

handled cylinder lock bar.

2. Stop engine, wait for all moving parts to stop,

and remove key.

3. Clean rotor and shaft free from debris.

4. Inspect for loose of broken tines.

Figure 16. Rotor

5. Tines are assembled as shown in Figure 16. The

tines are removed and installed using an extra

deep impact socket (AE60T003), provided with

shaft. Torque tines to 210 ft-lbs.

For safety reasons, each maintenance

operation must be performed with the

machine off and key removed.

First Products UA-60T Operator’s Manual

Maintenance bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb

19

Check Condition of Belts

Service Interval: Every 40 hours

1. Stop engine, wait for all moving parts to stop,

and remove key.

2. Check under all covers to check belts going to

pump, gearbox, and rotor shaft.

3. Replace any belts in need of repair.

Lubricate Grease Fittings

Service Interval: Every 50 hours

1. Stop engine, wait for all moving parts to stop,

and remove key.

2. Lubricate all three fittings located on the lift

axle at each bushing. Refer to parts breakdown

of lift axle for assistance.

Check Spark Plugs

Service Interval: Every 160 hours

Remove spark plugs, check condition and reset

gaps, or replace with new plugs. See Engine

Owner’s Manual.

Check Fuel Filter

Service Interval: As required

A fuel filter is installed between the tank and the

engine. Replace when necessary.

Change Hydraulic System Filter

Service Interval: After the first 250 hours,

Yearly thereafter

1. Stop engine, wait for all moving parts to stop,

and remove key.

2. With the lift cylinder fully retracted, use the red

handled lock-out bar to pin the cylinder into

place and prevent the machine from leaking

down.

3. Carefully clean area around filter. It is

important that no dirt or contamination enters

the hydraulic system.

4. Use proper tools to slowly remove the hose and

fittings from the in-line filter. Pay special

attention to the direction the filter is oriented.

5. Install new filter using proper tools and torque

on adapters and fittings.

6. Operate machine for several minutes

7. Check oil level.

Note: Do Not change hydraulic system’s oil

(except for what can be drained when changing

filter), unless it is required due to contamination or

overheating. Changing oil unnecessarily could

contaminate hydraulic system.

Failure to lock out the lift cylinder while

performing maintenance on the hydraulic

system can result in serious injury.

Hydraulics fluids escaping under pressure

can penetrate skin and cause injury.

Keep your body and hands away from

pin hole leaks.

Hydraulics Couplers, hydraulic lines/valves,

and hydraulic fluids may be hot. If you

contact hot components you may be burned.

Wear gloves when operating the

hydraulic couplers.

Allow the machine to cool before

touching hydraulic components.

Do not touch hydraulic spills.

Table of contents

Other First Products Farm Equipment manuals