D. Riser Tube - Install a riser tube and extend it at least one foot below frost line or

down to horizontal underground water line. For optimum water line protection, use

the 12” diameter insulated Ritchie Thermal Tube, part numbers and sizes are shown

to the right. Tube opening must be kept clear.

NOTE: The supply line touching the riser tube is the most common cause of

the supply line freezing. Do not surround the supply line with insulation,

wood, or other foreign material. Any foreign material in the tube may cause

frost to migrate to the supply line causing it to freeze.

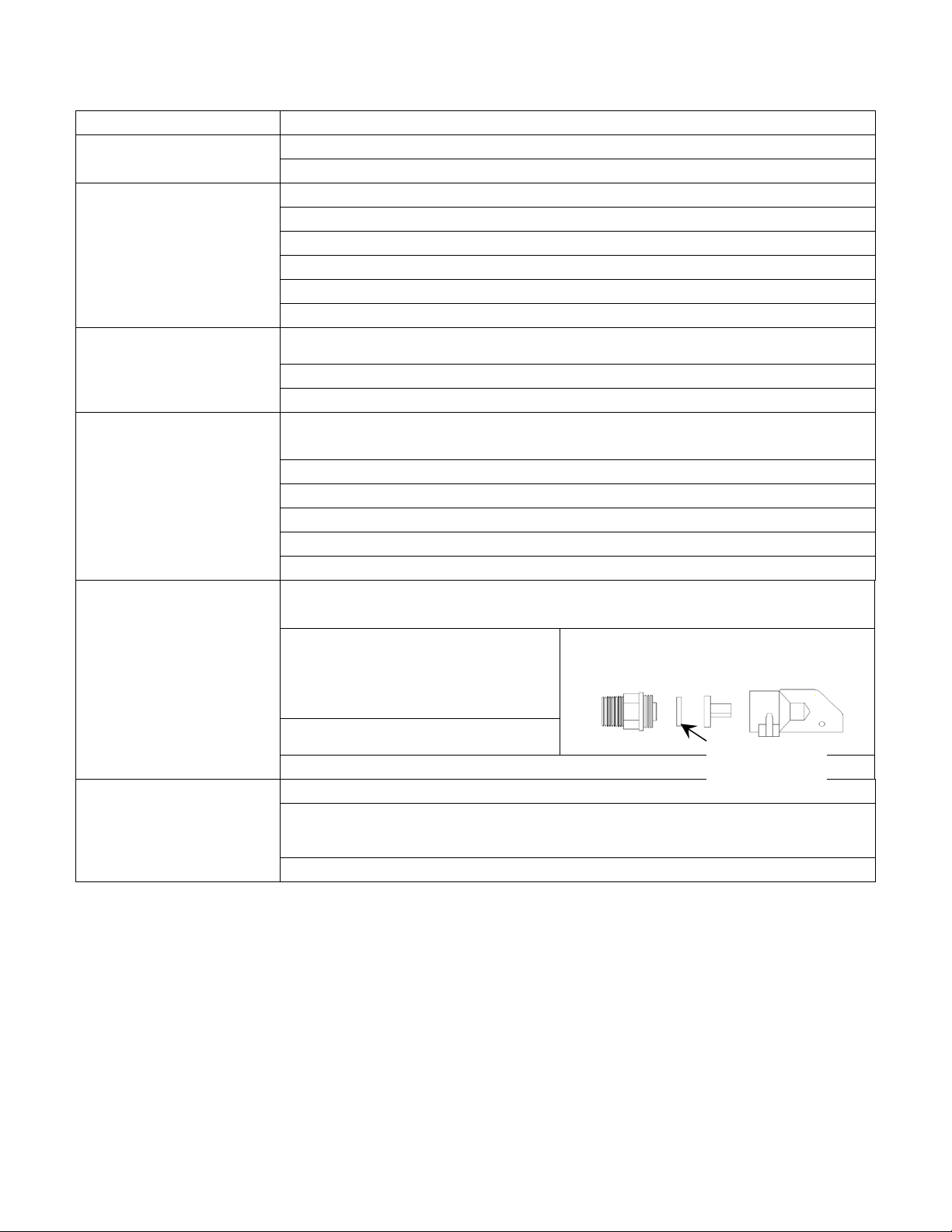

E. Mounting Platform - A concrete platform must be provided for all fountains. Use a minimum of 4” thick,

(6” recommended thickness), large enough to accommodate fountain, and additional 4” step (on top of the

platform) extending 18” out from each side of the unit. This will protect the unit from manure handling

equipment, as well as discouraging animals from defecating in the fountain. Extending the platform provides

animals a place to stand while drinking, consider the size of your animals when determining the dimensions of

your platform. The concrete step and platform should slope away from the fountain for drainage and should be

flush with the top of the thermal tube. A rough broom finish to concrete surface provides better footing for

livestock.

F. Preparing the Bottom - Apply the provided foam weather stripping to the bottom of the unit, along the

outside edge of the fountain.

G. Anchoring Fountain - CattleMaster Fountains have mounting pockets molded into the base. Use of Ritchie

part #16555, stainless steel anchor bolts (not included), is recommended.

Once you have verified the positioning of the fountain, drill, install, and tighten down anchor bolts. Use the large

washers provided to hold unit down. Tighten hold down anchors tight, but do not over tighten as this could

damage the plastic feet. NOTE: Do not drill holes for anchors before location can be verified with unit.

H. Hose Connection – Remove side panels and cover. Pull the bottom of the hose to the shut-off valve at the top

of the concrete. Leaving enough slack to be able to pull the valve assembly from the standpipe, cut hose to proper

length. Slip hose end on barb fitting and attached with hose clamp.

Hose should not touch insulation or outside surface of fountain.

Clamps and fittings are furnished to secure connections.

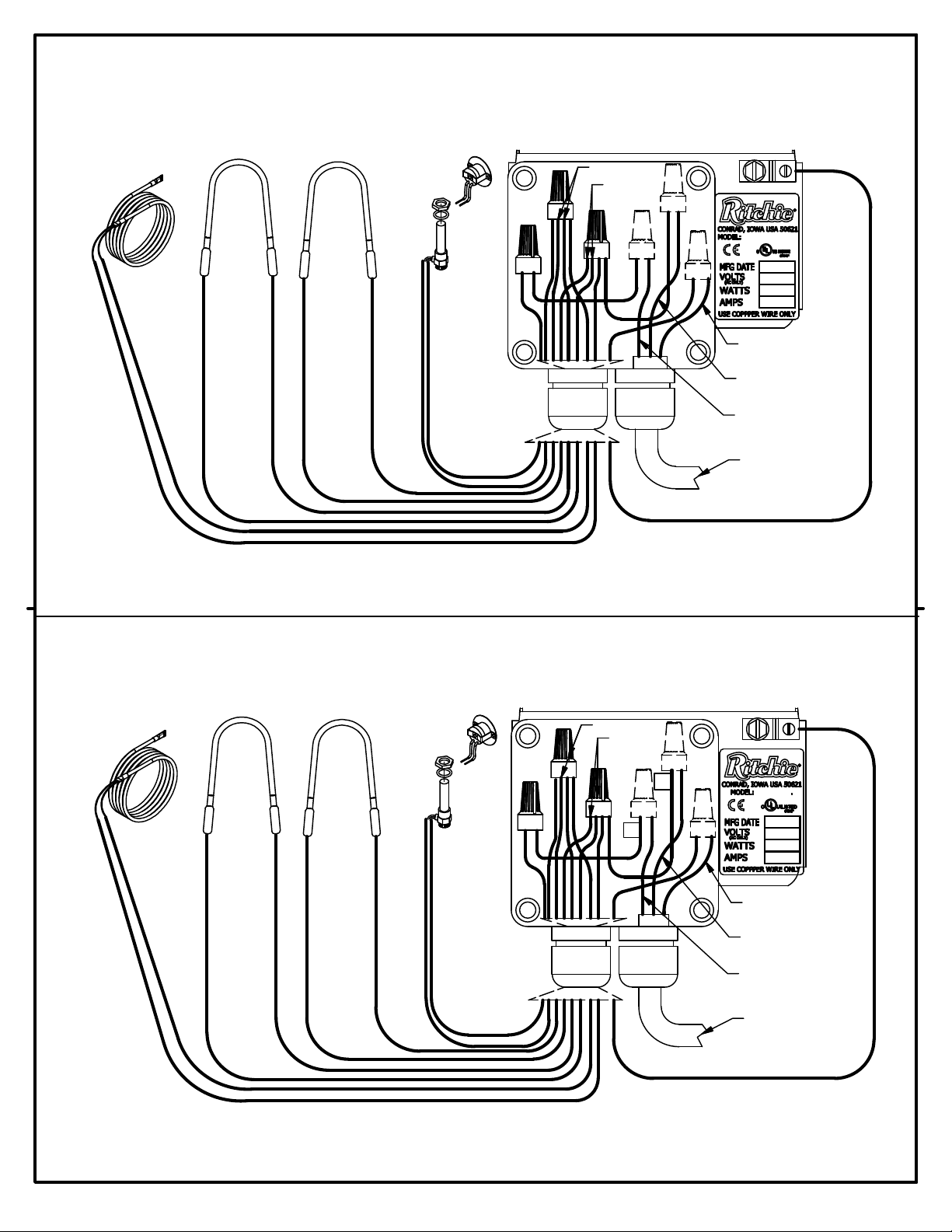

I. Cable Heater – Uncoil cable heater and loop around the valve.

Attach the remaining part of the cable heater to the water supply, as

far down the riser tube as possible with the cable twist ties provided.

This heater is watertight but should not be immersed in water. Heater

may cross over itself but should not be tightened at those locations.

CAUTION: Installation must not cause any strain on

heater wiring connections. Avoid heater damage caused

by hot spots due to its leads lying close to each other.

Also, do not wrap additional insulation around heater.

Part # Description

CattleMaster Series Instruction Manual