5

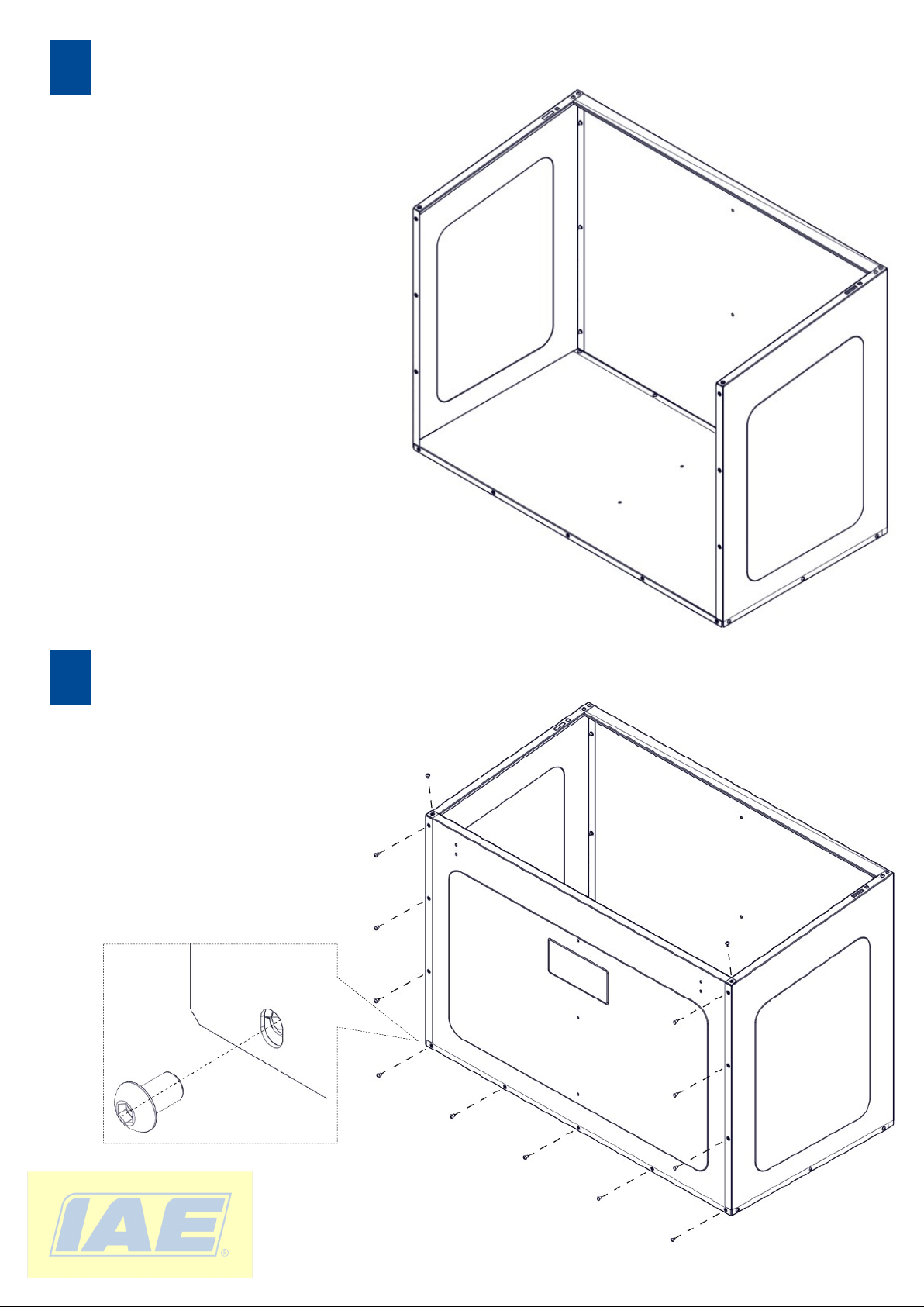

INTENDED USE

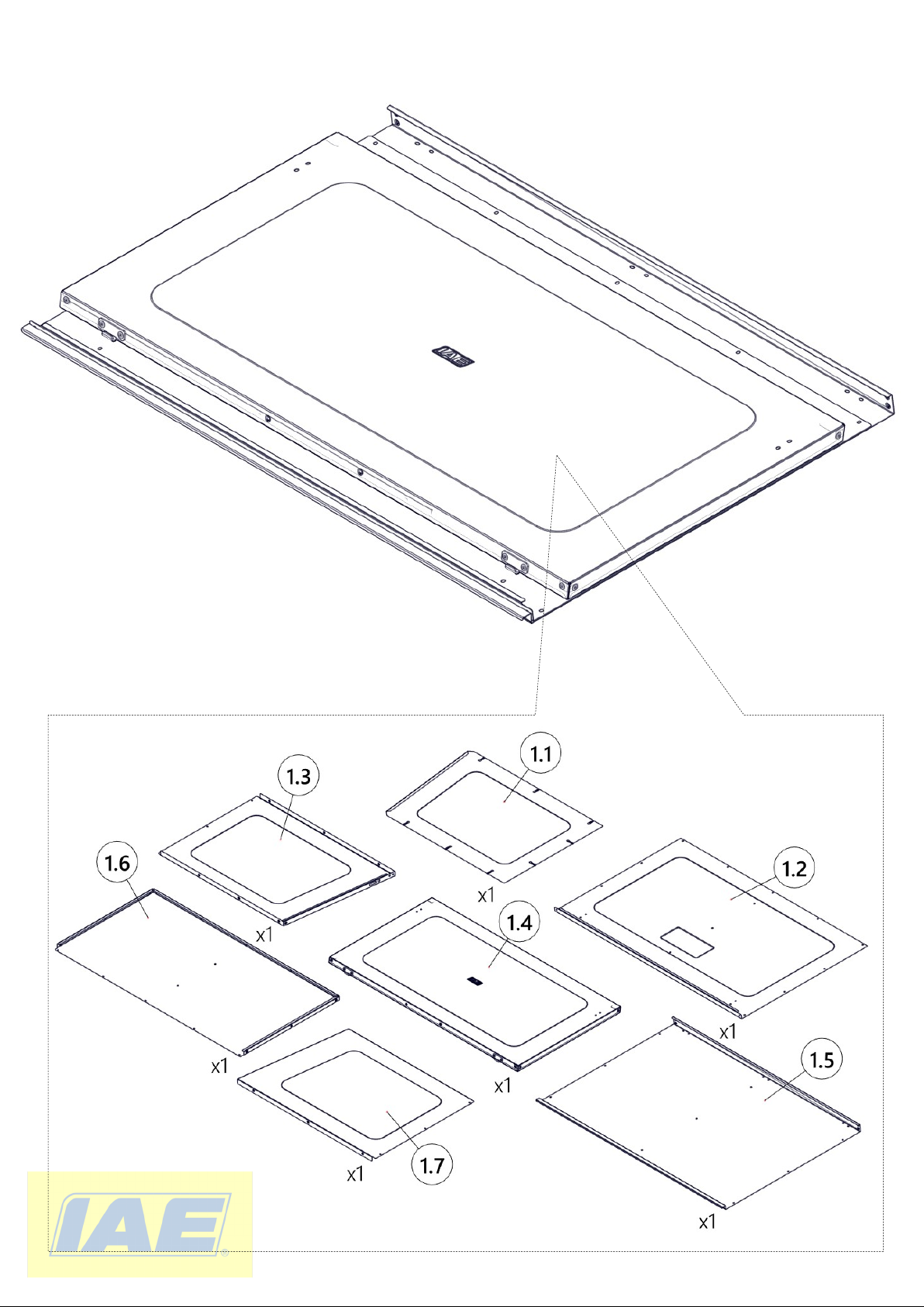

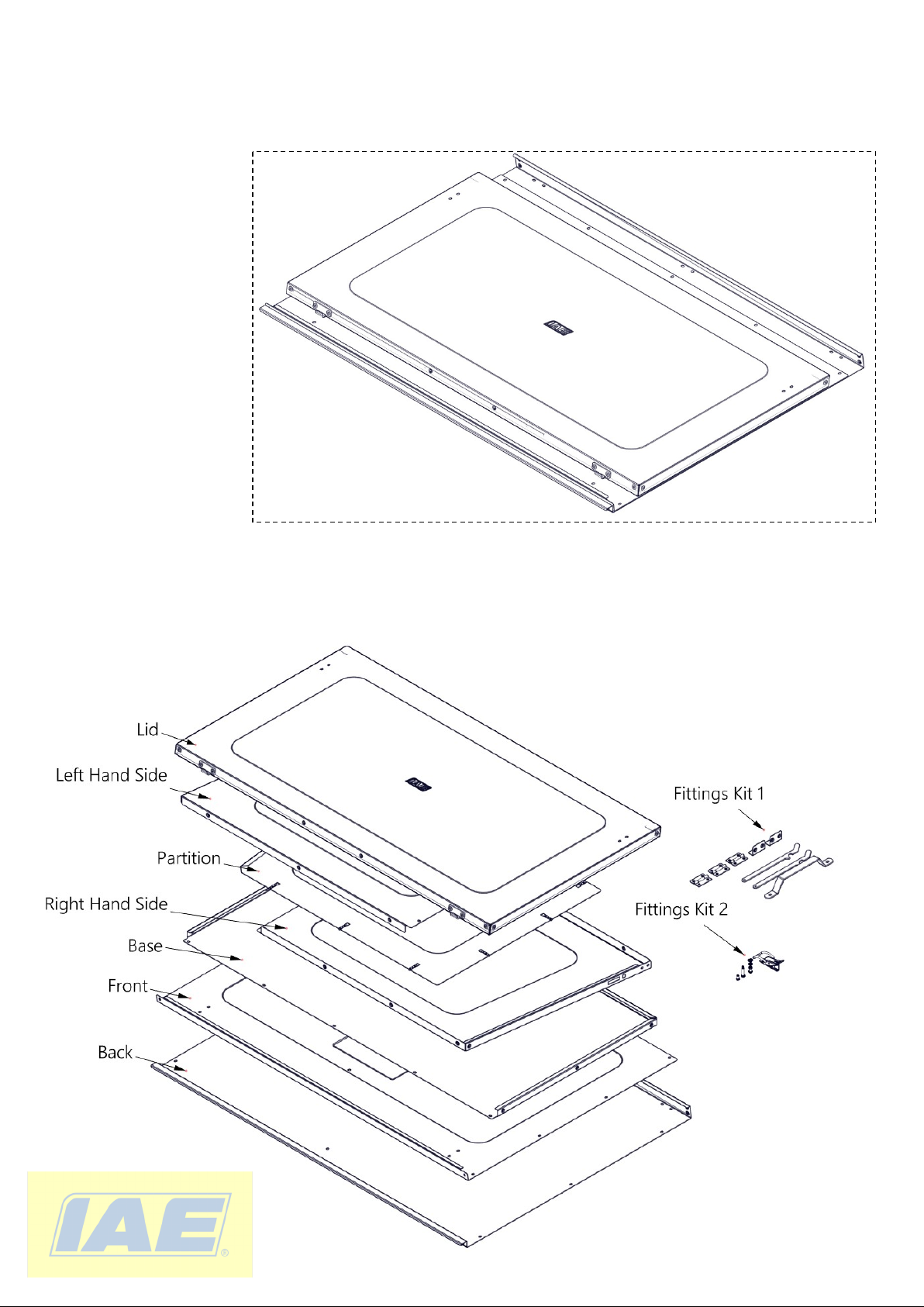

The IAE plain corn bin is manufactured from pre-galvanised sheet, ideal for indoor storage of

corn or other animal feed. Not waterght, but will keep feed free from rodents and other

contaminants.

TECHNICAL DATA

Item Number: 1002137 | 1002140 Weight: 45Kg | 60Kg

Dimensions: 1200mm (630 litres) | 1600mm (840 litres)

SAFETY INFORMATION

PLEASE TAKE NOTE OF THE FOLLOWING SAFETY PRECAUTIONS BEFORE USE. ANY HARM OR

INJURY WHICH OCCURS FROM THE LACK OF COMPLIANCE WITH THESE HEALTH AND

SAFETY MEASURES WILL BE THE RESPONSIBILITY OF THE OPERATOR.

¨ IMPORTANT! Read these instrucons carefully before use and keep them for future

reference.

¨ Situate this product on a level, solid surface.

¨ CAUTION! When handling heavy equipment, some stages of installaon may require at

least two people.

¨ DO NOT lean on or exert undue pressure on the product.

¨ CAUTION! Check posture when liing/manoeuvring the equipment or associated parts.

¨ ALWAYS Check the product for damage before each use.

If you have any quesons or comments regarding the product, we will be glad to hear them

either through our website www.iae.co.uk or by contacng your local IAE dealership.

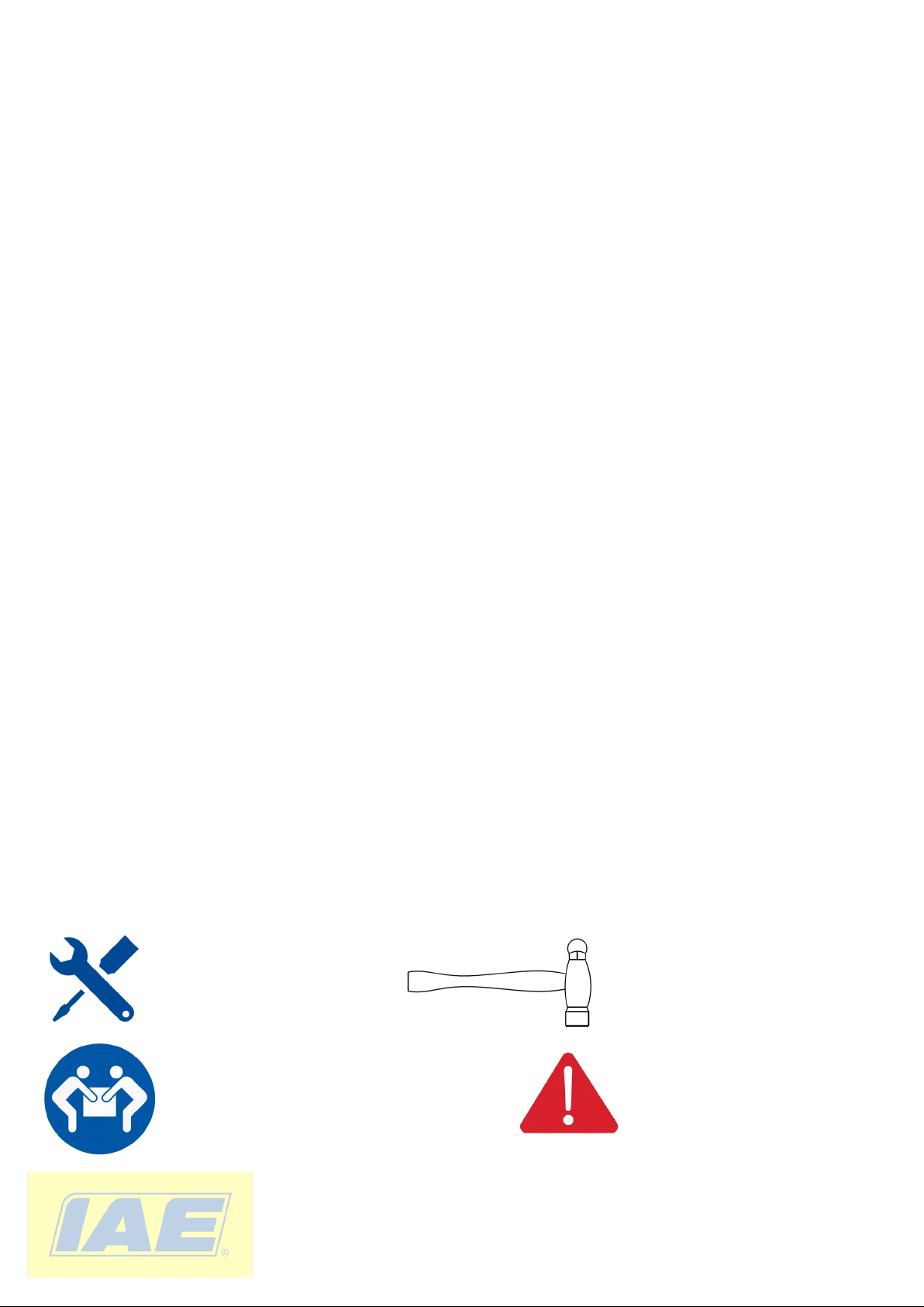

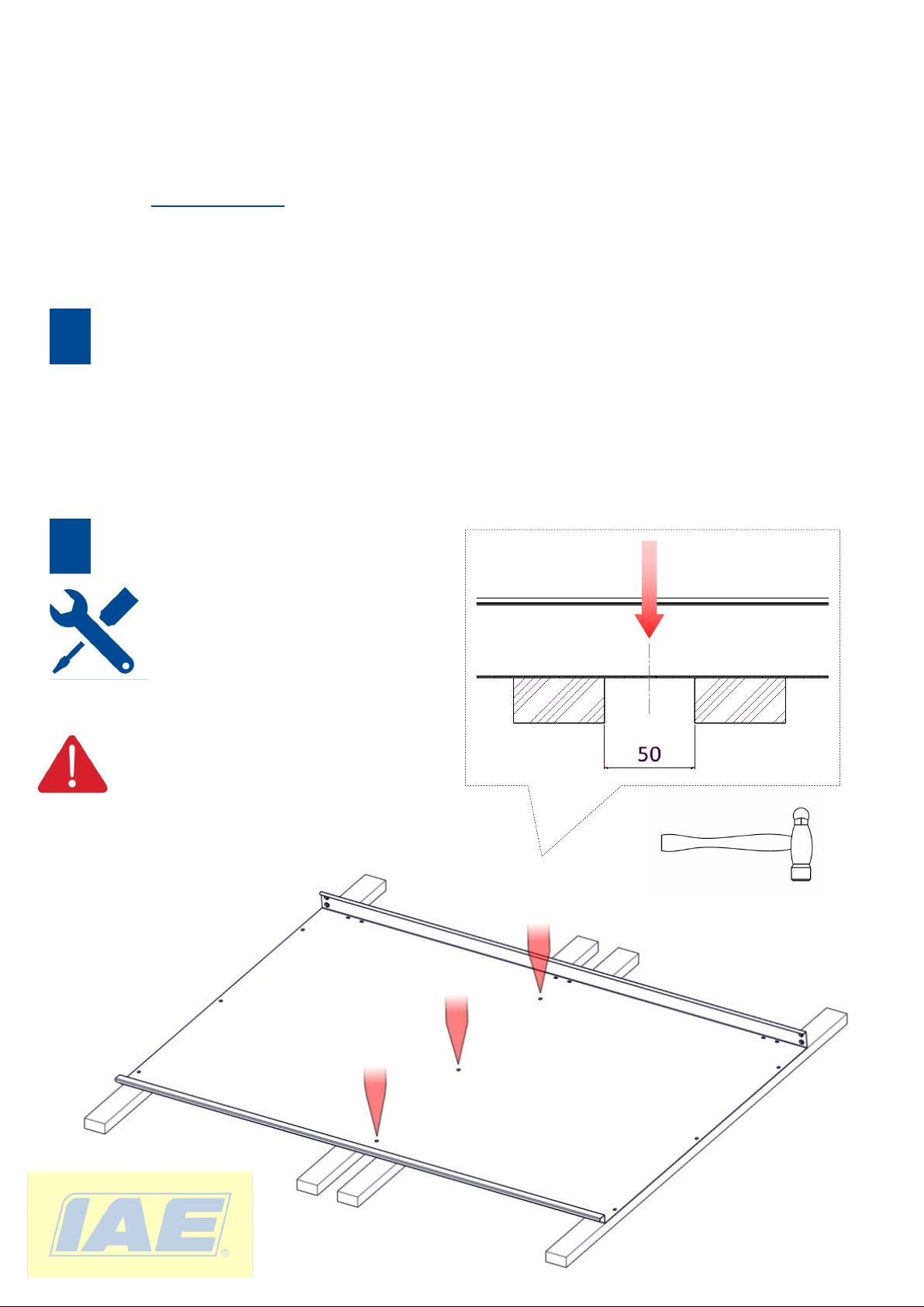

LIST OF SYMBOLS USED

MAY REQUIRE HAMMER

TWO PERSON LIFT WARNING

TOOLS REQUIRED