FirstLook ADS ES 300 User manual

DIAGNOSTIC PULSE SENSORS

Automotive Injector Diagnostic Sensor

Quick Setup Guide

Model ADS ES 300

SenX Technology

5315 Sunset Drive

Midland, MI 48640

www.senxtech.com

Phone 1 866 832 8898

U.S. Patent Nos. 6,484,589 & 6,609,416

Version 2.1

FirstLook®

2

The supplied quick disconnect fittings allow the FirstLook®Fuel

Injection Sensor to be used with virtually any commercially

available Fuel Pressure Test Kit and adaptors.

Using the FirstLook®sensor is in addition to the necessary electrical tests

that need to be performed before condemning any injector. This sensor

checks flow of a given injector. With that said low flow can come from

a voltage drop in the injector circuit, or a faulty driver in the PCM. The use

of a low amps current probe and or a voltage drop test to confirm circuit

integrity is crucial to get the full picture of what is going on with any

injector. Remember low flow can be caused by an electrical problem as

well as a flow problem within the injector. It is up to you to determine

where the low flow problem area is. What this sensor does is locate which

injector is having the problem. To get the whole picture one needs to

know both the electrical and the physical information to make this

decision. This sensor will finally give you the piece of the puzzle you have

never had before.

IMPORTANT: The sample line and sensing cavity must be

purged of air for the signal to be a true reaction to pressure

changes in the fuel rail.

The physical difference between injectors.

It is important to discuss some of what you might find using

this sensor to head off any false conclusions.

First, practice on a

known good vehicle. Depending on how you trigger your scope (#1

injector, #1 ignition or cam sensor) you will notice that #l injector can

start from before the trigger point or after the trigger point. The best

way to know for sure is to have the correct firing order for the engine.

Next with the key off, disconnect one of the injectors. Follow the firing

order and see if the pattern reflects the cylinder you think it is. With this

confirmed you can be very confident you have located the problem

injector. Now it is up to you to diagnose if it is the injector itself or an

electrical problem with the harness or PCM.

You will find that with practice you will develop your own routine procedure

depending on whether you favor using a current ramping probe, ignition

or even voltage signature to sync the firing order of the injectors.

Connect FirstLook® Injection Sensor using the quick disconnect fitting

supplied in the kit and when necessary the appropriate fitting from your

fuel pressure test kit to connect to the fuel injection rail of vehicle being

tested.

3

WARNINGS

DO NOT MODIFY THE SENSOR AND CONNECTOR

ASSEMBLY

DO NOT USE ON DIESEL ENGINES

ALWAYS WEAR OSHA APPROVED EYE PROTECTION

NO SMOKING, NO OPEN FLAMES, NO ELECTRICAL

SPARKS

USE EXPLOSION PROOF ELECTRICAL DROPLIGHTS

LOOSEN GAS CAP AND RELIEVE FUEL PUMP

PRESSURE

TIGHTEN ALL CONNECTIONS TO ELEMINATE

LEAKS

AVOID FUEL CONTACT WITH HOT ENGINE PARTS

FOLLOW OUR INSTRUCTIONS AND AUTO MAKERS

TEST PROCEDURES

WRAP ADAPTER IN SHOP TOWEL BEFORE

DISCONNECTING

WIPE UP FUEL SPILLS AND PUT RAGS IN APPROVED

CONTAINER

REMOVE ANY FUEL IN THE SENSOR HOSE BEFORE

STORING

4

Turn ignition on and check for leaks. If no leaks are detected

proceed with tests.

The best way to understand how the FirstLook® Fuel Injection Sensor works

is to start with a known good engine. See how the injectors work at both

idle and during the 1500 RPM load test. Next disable an injector and run the

same test. Always remember injector problems can also be caused by a bad

electrical driver. It is just as important to know the electrical condition of

your injectors as it is to know their mechanical condition. Current ramp

testing of the fuel injector electrical system is the best way to verify proper

electrical condition. An engine with oversize fuel rails can cause you to see

two different sets of patterns. The injectors closest to you will appear to have

different waveforms than the injectors on the opposite side of the engine.

Remember what you are looking for is a repeatable pattern. The Nissan

fuel rail below notes this type of waveform. The firing order here is 1-2-3-

4-5-6. You will see 1, 3, 5 appear differently than 2, 4, and 6. This is a

normal condition on many cars. The bad injector is marked between

the

cursers. See

www.senxtech.com

for more.

5

Scope settings for Idle Test

Idle test... 650 to 700 RPM...Scope settings.

Voltage settings... +1 Volts to —1 Volts

Time base ... 200 ms

Start engine and allow to warm up to operational temperature. Observe wave

forms for irregular injector operation.

Good injector waveform not triggered

96 Jeep 6 Cylinders

96 Accord 2.2 bad injector triggered from injector #1

6

Scope settings for 1500 RPM...Power Brake Test

Power brake test...1500 RPM...Scope settings.

Voltage settings... +1 volts to -1 Volts

Time base...100ms

Put vehicle in gear and

apply brakes,

slowly increase RPM to 1500. Most flow

problems will show up as irregularities in the scope pattern at 1500 RPM.

Good waveform not triggered 96 Jeep 6 Cylinders

96 Honda Accord 2.2 Bad Injector triggered from Injector #1

7

For most complete view of Fuel Injection System.

1. Trigger scope using injector #1 as reference point

2. Connect low current probe to the wire feeding voltage to the injectors.

3. Hook up FirstLook® Fuel Injection Sensor to fuel rail.

Run both Idle test and 1500 RPM Power Brake test. This lets you look at

the system at idle and under a working load. With the current probe

hooked to the main line supplying voltage to the injectors you also can see

the current draw conditions for the injectors. The current draw waveforms

will track with the injector pulse wave forms allowing you a complete look at

the fuel injector system and helping to determine if problem is electrical

drivers or actual fuel flow issues with the injectors.

Trigger Current Probe FirstLook®Sensor

8

Support

For support questions or warranty assistance contact:

SenX Technology

5315 Sunset Drive

Midland, MI 48640

Phone 866 832 8898 Fax 989-832-8908

Or visit our website at www.senxtech.com

Warranty

SenX Technology, LLC warranties the products described herein for a period of 1 year

under normal use and service from the date of purchase, that the product will be free of

defects in material and workmanship. This warranty does not cover ordinary wear and

tear, abuse, misuse, overloading, altered products, or damage caused by the purchaser

connecting the unit incorrectly.

THERE IS NO WARRANTY OF MERCHANTABILITY. THERE ARE NO WARRANTIES WHICH

EXTEND BEYOND THE DESCRIPTION HEREIN. THERE ARE NO WARRANTIES EXPRESSED OR

IMPLIED OR ANY AFFIRMATION OF FACT OR REPRESENTATION EXCEPT AS SET FORTH

HEREIN.

REMEDY

SenX Technology, LLC sole responsibility and liability, and purchaser's exclusive

remedy shall be limited to the repair or replacement at SenX Technology option,

of a part or parts not conforming to the warranty. All products requiring warranty

service shall be returned to SenX Technology within I year of purchase, shipping

prepaid. SenX Technology will return repaired or replaced products to the

purchaser via prepaid ground transportation. In no event shall SenX Technology

be liable for damages of any nature, including incidental or consequential

damages, including but not limited to any damages resulting from non-conformity,

defect in material or workmanship.

Neither SenX Technology LLC nor its affiliates shall be liable to the purchaser of

this product or third parties for damages, losses, costs, or expenses incurred by

the purchaser or third parties as a result of: accident, misuse, or abuse of this product

or unauthorized modifications, repairs or alterations to this product, or failure to

strictly comply with SenX Technology's operating and maintenance instructions.

FirstLook®and SenX®Technology are trademarks of SenX Technology, LLC

No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written permission of SenX Technology, LLC.

Table of contents

Other FirstLook Accessories manuals

Popular Accessories manuals by other brands

Leviton

Leviton O3C15-IDW Installation instructions and owner's manual

Philio Technology Corporation

Philio Technology Corporation PAT12-A manual

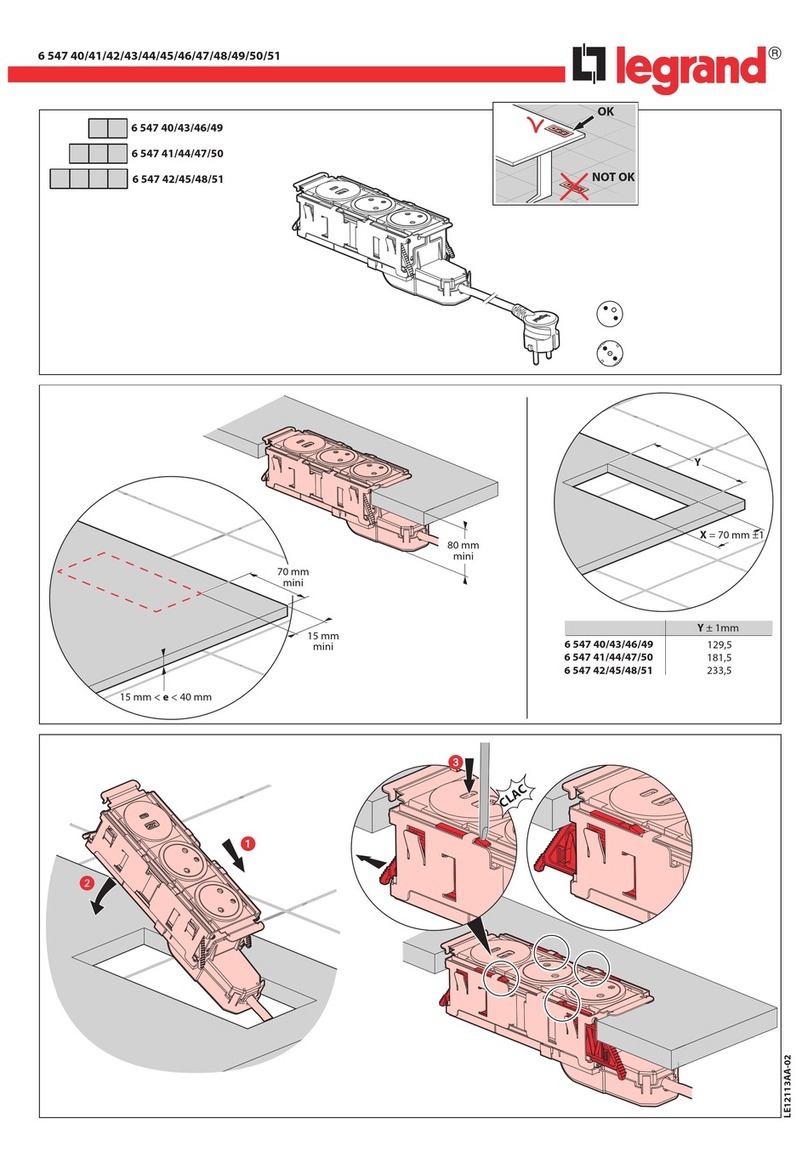

LEGRAND

LEGRAND 6 547 40 quick start guide

culiau

culiau Customizer user manual

Rohde & Schwarz

Rohde & Schwarz R&S NRQ6 user manual

STEINEL

STEINEL IS 2180 ECO installation instructions

Siemens

Siemens SIMATIC RF300 System manual

Rechner Sensors

Rechner Sensors N-132/1-10 Operating instuructions

Davis Instruments

Davis Instruments Grounding Kit install guide

Seifert

Seifert SlimLine Pro KG 8512 instruction manual

Intec

Intec CI-24 installation guide

Waterpik

Waterpik WP-100 Series user manual