Fisher-Rosemount Chempure Series User manual

Chempure™ Series

Continuous Flow

Analyzers

Instruction Manual

P/N 51-Chemp

May 1997

Chempure

CAUTION

This product generates, uses and can radiate

radio frequency energy and thus can cause radio

communication interference. Improper installation,

or operation, may increase such interference. As

temporarily permitted by regulation, this unit has

not been tested for compliance within the limits of

Class A computing devices, pursuant to Subpart

J of Part 15, of FCC Rules, which are designed to

provide reasonable protection against such inter-

ference. Operation of this equipment in a residen-

tial area may cause interference, in which case

the user at his own expense, will be required to

take whatever measures may be required to cor-

rect the interference.

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Your purchase from Rosemount Analytical, Inc. has result-

ed in one of the finest instruments available for your par-

ticular application. These instruments have been

designed, and tested to meet many national and interna-

tional standards. Experience indicates that its perform-

ance is directly related to the quality of th installation and

knowledge of the user in operating and maintaining the

instrument. to ensure their continued operation to the

design specifications, personnel should read this manual

thoroughly before proceeding with installation, commis-

sioning, operation, and maintenance of this instrument.

• Failure to follow the proper instructions may cause any

one of the following situations to occur: Loss of life; per-

sonal injury; property damage; damage to this instru-

ment; and warranty invalidation.

• Ensure that you have received the correct model and

options from your purchase order. Verify that this man-

ual covers your model and options. If not, call 1-800-

854-8257 or 714-863-1181 to request correct manual.

• For clarifications of instruments, contact your

Rosemount representative.

• Follow all warnings, cautions, and instructions marked

on and supplied with the product.

• Use only qualified personnel to install, operate, update,

program and maintain the product.

• Educate your personnel in the proper installation, oper-

ation, and maintenance of the product.

• Install equipment as specified in the Instruction section

of this manual. Follow appropriate local and national

codes. Only connect the product to electrical and pres-

sure sources specified in this manual.

• Use only factory documented components for repair.

Tampering or unauthorized substitution of parts and

procedures can affect the performance and cause

unsafe operation of you process.

• All equipment doors must be closed and protective

covers must be in place unless qualified personnel are

performing maintenance.

WARNINGS

ELECTRICAL SHOCK HAZARD!!

• Installation of cable connections and servicing of

this product require access to shock hazard volt-

age levels.

• Main power and relay contacts wired to separate

power sources must be disconnected before

servicing.

• Don not operate or energize instrument with

case open!

• Non-metallic cable strain relief do not provide

grounding between conduit connections! Use

grounding type bushings and jumper wires.

• Electrical installation must be in accordance with

the National Electrical Code (ANSI/NFPA-70)

and/or any other applicable national or local

codes.

• Operate only with front and rear panels fastened

and in place over terminal area.

• Safety and performance require that this instru-

ment be connected and properly grounded

through a three-wire power source.

• Proper relay use and configuration is the responsibility

of the user.

Rosemount Analytical Inc.

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 863-1181

http://www.RAuniloc.com

CHEMPURE MANUAL TABLE OF CONTENTS

SECTION TITLE.......................................................................................................................... PAGE

1 Introduction............................................................................................................... 1

2 Unpacking ................................................................................................................. 1

3 Instrument Description............................................................................................ 2

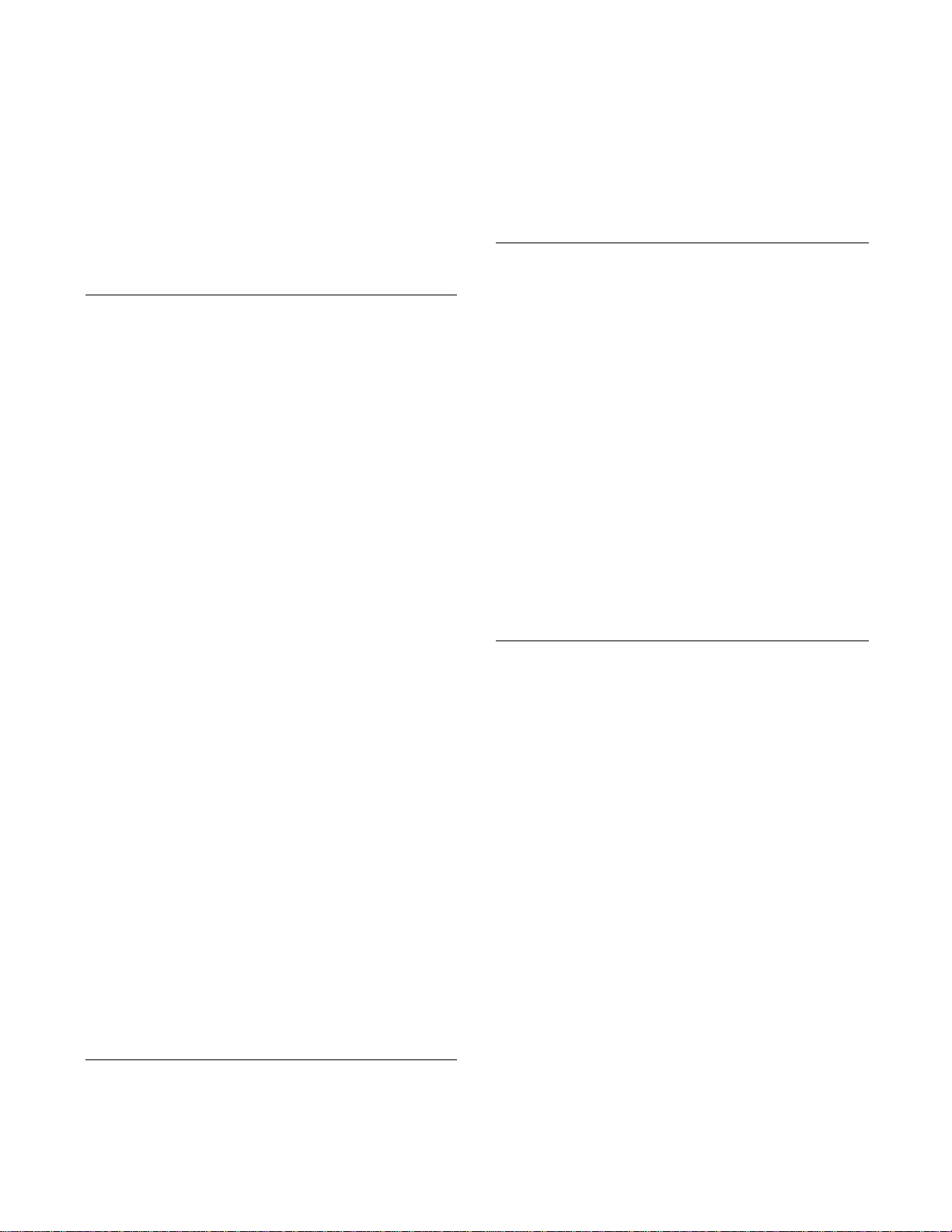

3.1 Analyzer Front View.................................................................................................... 2

3.1.1 Main Cabinet .............................................................................................................. 2

3.1.2 Reagent Cabinet ........................................................................................................ 2

3.2 Keypad Panel............................................................................................................. 4

3.2.1 Panel........................................................................................................................... 4

3.2.1 Keypad ....................................................................................................................... 4

3.3 Electronics Panel........................................................................................................ 5

3.3.1 Electronic Panel.......................................................................................................... 5

3.3.2 CPU Board..................................................................................................................6

3.3.3 Fault/Analog Board..................................................................................................... 6

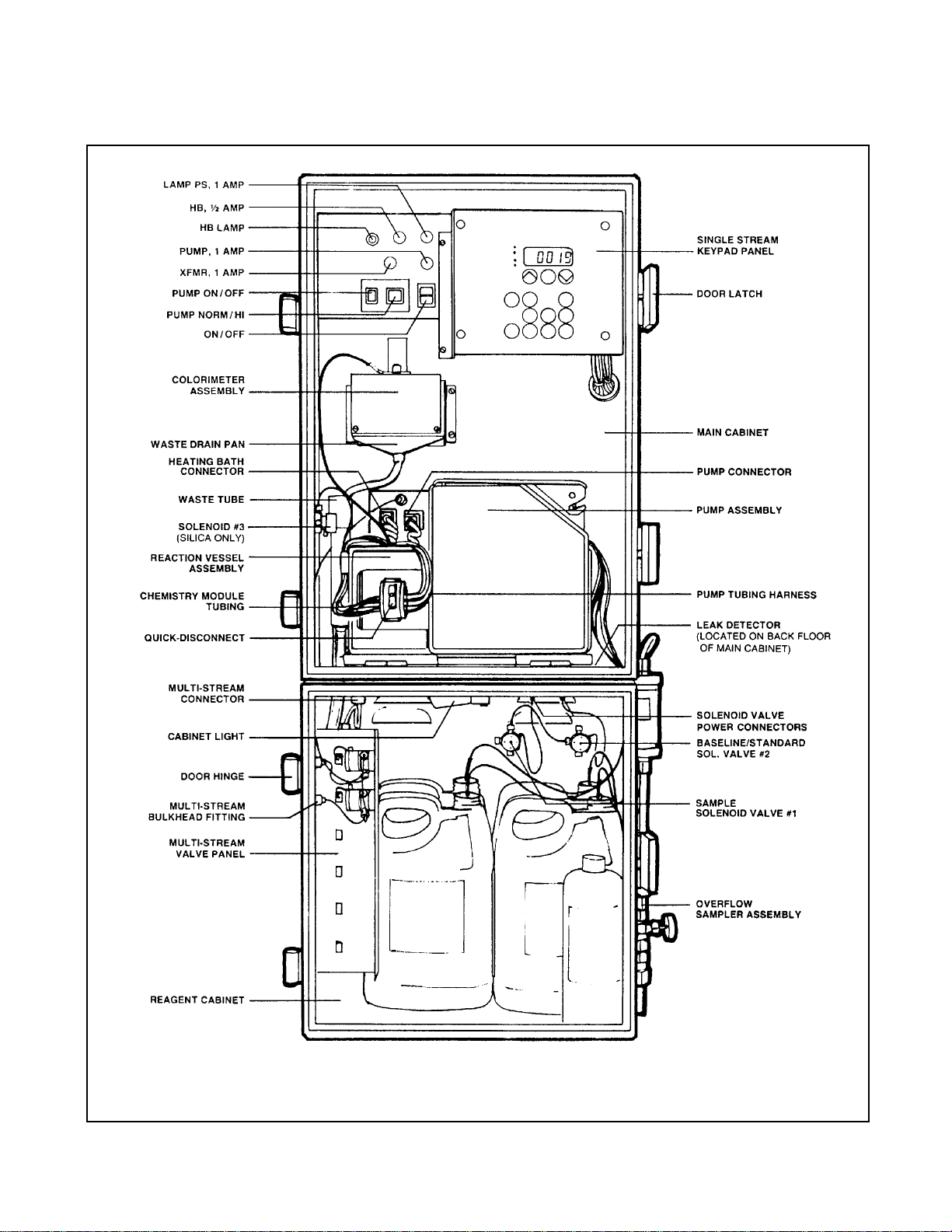

3.4 Colorimeter................................................................................................................. 7

3.5 Pump and Reaction Vessel Assembly ..................................................................... 8

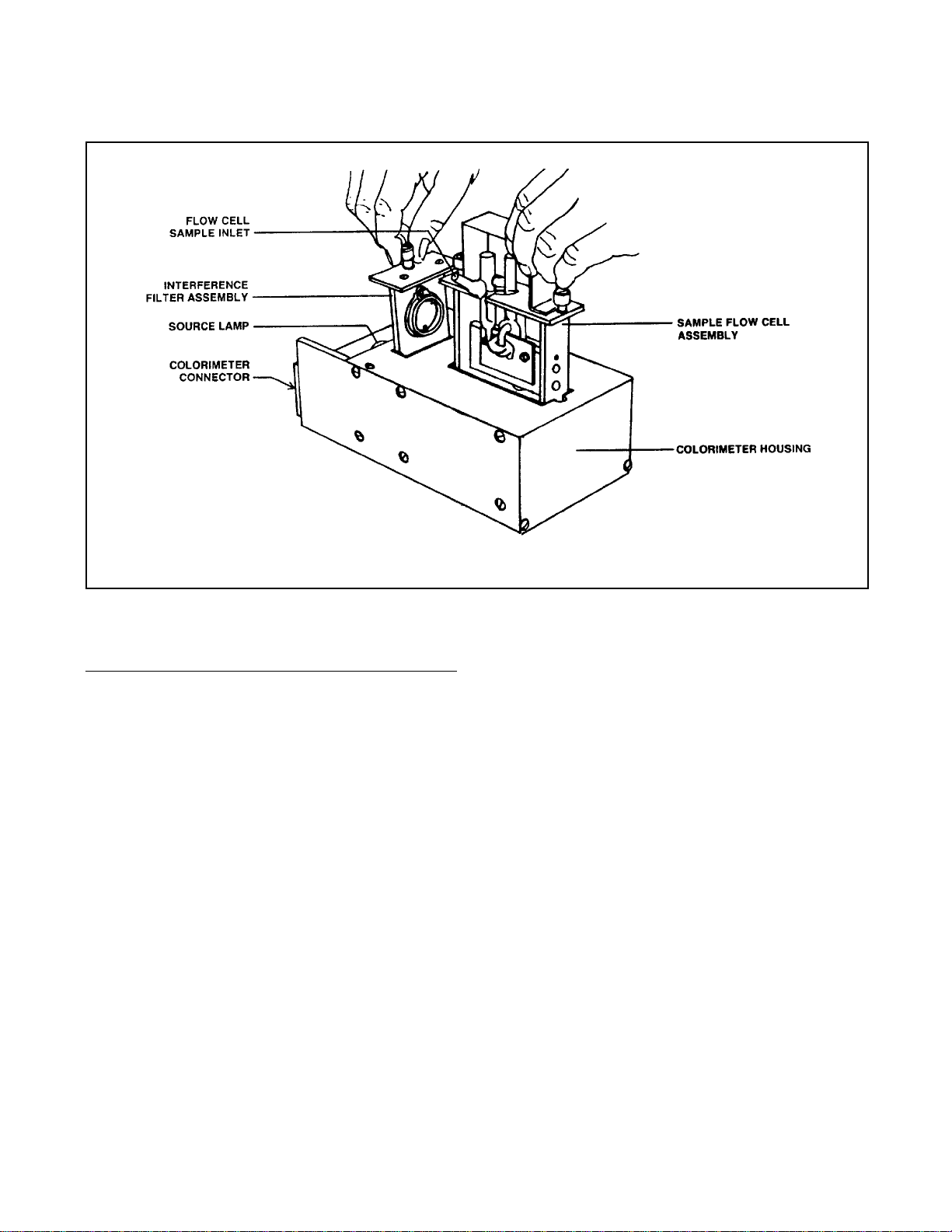

3.6 Back of Main Cabinet................................................................................................. 9

3.7 Input/Output Panel ..................................................................................................... 9

3.8 Computer Interface ................................................................................................... 10

3.9 Overflow Sampler Assembly...................................................................................... 11

4 Installation................................................................................................................. 12

4.1 Main Cabinet Mounting ............................................................................................. 12

4.1.1 General recommendations ........................................................................................ 12

4.2 Reagent Cabinet Mounting........................................................................................ 12

4.3 Waste Tube Installation............................................................................................... 12

4.4 Overflow Sampler Assembly...................................................................................... 13

4.5 Electrical Connections ............................................................................................... 13

4.6 Colorimeter ................................................................................................................ 15

4.7 Pump and Reaction Vessel Assembly ..................................................................... 15

4.8 Pump Tubing Harness................................................................................................ 16

4.9 Fluidics ....................................................................................................................... 17

4.10 Reagents ....................................................................................................................17

5 Using the Analyzer................................................................................................... 18

5.1 Operational Overview................................................................................................. 18

5.2 Keypad Lock.............................................................................................................. 18

5.3 Entering Numeric Values............................................................................................ 18

5.4 Specific Analyzer Chemistry...................................................................................... 18

6 Start-Up ..................................................................................................................... 19

6.1 Overflow Sampler Assembly...................................................................................... 19

6.2 Fluidics........................................................................................................................ 19

6.3 Reagents .................................................................................................................... 19

6.4 Power.......................................................................................................................... 19

6.5 Pump........................................................................................................................... 19

6.6 Heating Bath............................................................................................................... 19

i

Chempure™

TABLE OF CONTENTS

ii

CHEMPURE MANUAL TABLE OF CONTENTS

SECTION TITLE.......................................................................................................................... PAGE

7 Calibration and Operation....................................................................................... 20

7.1 Auto Calibration.......................................................................................................... 20

7.2 Manual Baseline Correction....................................................................................... 20

7.3 Manual Fullscale Calibration...................................................................................... 20

7.4 Sample Analysis......................................................................................................... 20

8 Shutdown .................................................................................................................. 21

8.1 Overnight Shutdown................................................................................................... 21

8.2 Shutdown for a Few Days or More............................................................................. 21

8.3 After Overnight Shutdown.......................................................................................... 21

8.4 After Shutdown For a Few Days or More................................................................... 21

8.5 If Shutdown With Reagents in Tubing........................................................................ 21

9 Accessories............................................................................................................... 22

9.1 Chart Recorder........................................................................................................... 22

9.1.1 Span Adjustment........................................................................................................ 22

9.1.2 Multi-Stream Analysis................................................................................................. 23

9.2 Alarms......................................................................................................................... 23

9.3 Multi-Stream Analysis................................................................................................. 24

9.3.1 Installation................................................................................................................... 24

9.3.1.1 Multi-Stream Circuit Board......................................................................................... 24

9.3.1.2 Keypad Panel and Display Board Assembly............................................................ 24

9.3.2 Multi-Stream Solenoid Valves..................................................................................... 25

9.3.2.1 Overflow Sampler Assembly...................................................................................... 25

9.3.3 Set-Up......................................................................................................................... 25

9.3.4 Sample Analysis......................................................................................................... 26

9.3.4.1 Automatic Multi-Stream Analysis............................................................................... 26

9.3.4.2 Manual Multi-Stream Analysis.................................................................................... 26

9.4 IF-100 In-Line Filter..................................................................................................... 26

9.5 Computer Interface .................................................................................................... 26

9.5.1 Normal Data Output Format....................................................................................... 26

9.5.2 Data Configuration ..................................................................................................... 27

9.5.3 RS232-C Pin Configuration........................................................................................ 27

9.5.4 RS232-C Start-Up....................................................................................................... 27

9.5.5 RS232-C Function Commands.................................................................................. 27

9.6 Printer Interface.......................................................................................................... 28

9.6.1 Pin Configuration........................................................................................................ 28

9.7 Printer Operation ........................................................................................................ 28

9.7.1 Setting Printer Internal Clock...................................................................................... 28

9.7.2 Single Stream Operation............................................................................................ 29

9.7.3 Multistream Operation................................................................................................ 29

9.8 Relay Output Option................................................................................................... 29

9.8.1 Relay Output Contact Rating..................................................................................... 29

9.8.2 Relay Output Option (Multistream)............................................................................ 29

TABLE OF CONTENTS (CON’T)

iii

CHEMPURE MANUAL TABLE OF CONTENTS

SECTION TITLE.......................................................................................................................... PAGE

10 Preventive Maintenance.......................................................................................... 30

10.1 Maintenance Schedule.............................................................................................. 30

10.1.1 Weekly ........................................................................................................................ 30

10.1.2 Monthly ....................................................................................................................... 30

10.1.3 Quarterly..................................................................................................................... 30

10.1.4 Yearly .......................................................................................................................... 30

10.2 Maintenance Procedures........................................................................................... 30

10.2.1 NaOH Fluidics Wash (Silica Only) ............................................................................. 30

10.2.2 Pump Tubing Harness Replacement......................................................................... 30

10.2.3 Colorimeter Source Lamp Inspection........................................................................ 31

10.2.4 Interference Filter Cleaning........................................................................................ 31

10.2.5 Sample Intake Tubing Replacement ......................................................................... 31

11 Troubleshooting........................................................................................................ 32

11.1.1 Symptom Chart........................................................................................................... 32

11.1.2 Test Functions............................................................................................................. 33

12 Repair and Service................................................................................................... 34

12.1 Colorimeter.................................................................................................................34

12.1.1 Source Lamp Replacement....................................................................................... 34

12.1.2 Interference Filter Replacement................................................................................. 34

12.1.3 Sample Flow Cell Replacement................................................................................. 34

12.2 Pump and Reaction Vessel Assembly....................................................................... 35

12.2.1 Pump Tubing Harness Replacement......................................................................... 35

12.2.2 Reaction Vessel Replacement................................................................................... 37

12.3 Circuit Boards............................................................................................................. 37

12.4 Fuses .......................................................................................................................... 37

13 Appendix ................................................................................................................... 38

Wiring Diagram........................................................................................................... 38

Help Sheet.................................................................................................................. 39

Specific Chemistries................................................................................................... 41

14 Ordering Information................................................................................................ 43

14.1 Reagents ....................................................................................................................43

14.2 Replacement Parts and Accessories........................................................................ 43

15 Specifications ........................................................................................................... 44

TABLE OF CONTENTS (CON’T)

iv

CHEMPURE MANUAL TABLE OF CONTENTS

LIST OF FIGURES

FIGURE TITLE.......................................................................................................................... PAGE

3-1 Analyzer Front View.................................................................................................... 3

3-2 Keypad Panel............................................................................................................. 4

3-3 Electronics Panel........................................................................................................ 5

3-4 CPU Board.................................................................................................................. 6

3-5 Fault/Analog Board..................................................................................................... 6

3-6 Colorimeter Assembly................................................................................................ 7

3-7 Pump Assembly Components................................................................................... 8

3-8 Back of Analyzer ........................................................................................................ 9

3-9 Input/Output Panel ..................................................................................................... 10

3-10 Computer Interface Ports........................................................................................... 10

3-11 Overflow Sampler Assembly...................................................................................... 11

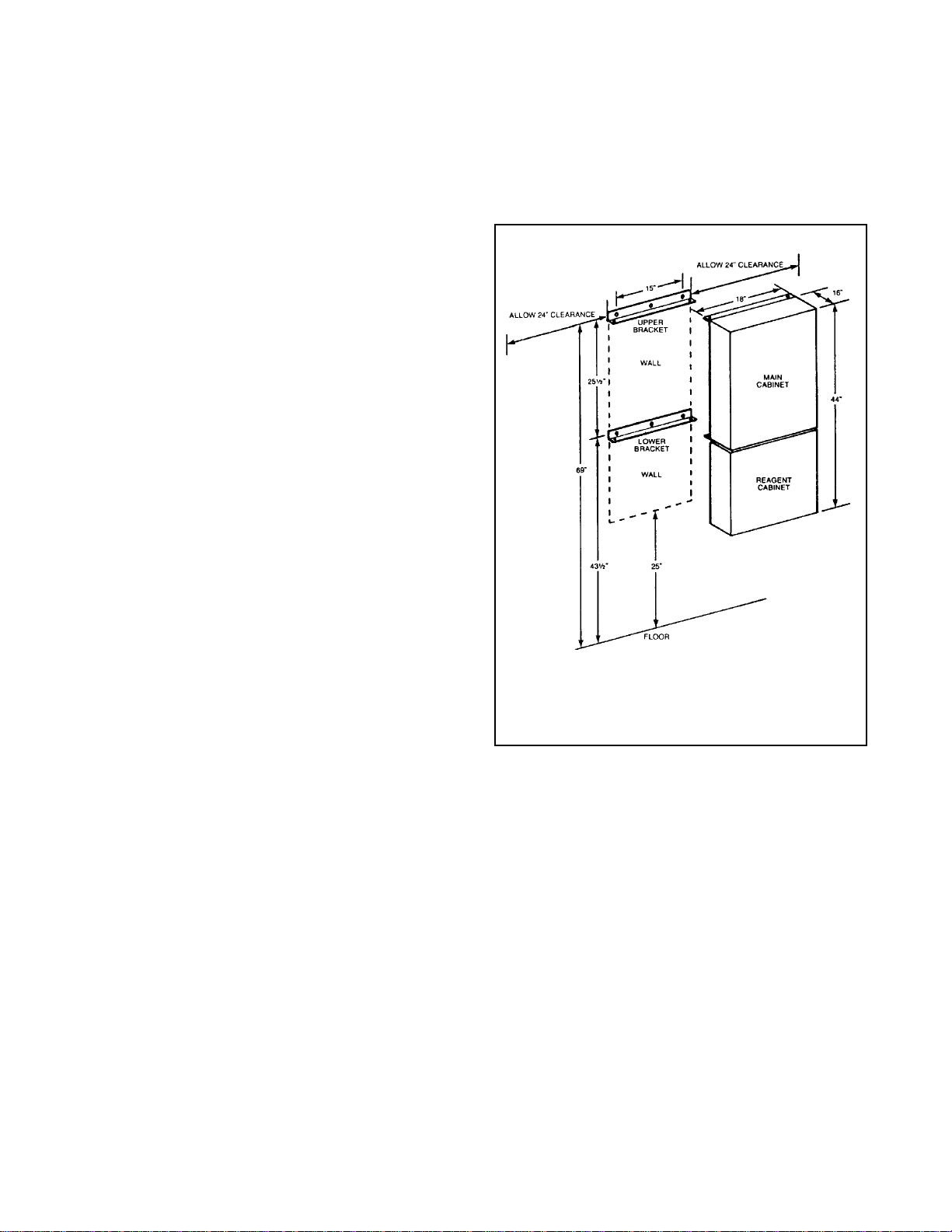

4-1 Mounting Main and Reagent Cabinets...................................................................... 12

4-2 Overflow Sampler Assembly...................................................................................... 13

4-3 Pump and Reaction Vessel Assembly....................................................................... 14

4-4 Pump Platen Removal................................................................................................ 14

4-5 Heating Bath and Pump Connectors......................................................................... 15

4-6 Installation of Pump Tubing Harness......................................................................... 16

4-7 Solenoid Valves #1 and #2......................................................................................... 16

4-8 Solenoid Valve #3....................................................................................................... 16

5-1 Basic Functional Diagram.......................................................................................... 18

9-1 Trace Recording......................................................................................................... 22

9-2 Typical 6 Stream Tracer Recording With Stream Markers and Values..................... 23

9-3 Multi-Stream Circuit Board......................................................................................... 24

12-1 Source Lamp Replacement....................................................................................... 34

12-2 Interference Filter and Flow Cell Replacement......................................................... 35

12-3 Pump Platen Removal................................................................................................ 36

12-4 Installation of Pump Tubing Harness......................................................................... 36

12-5 Circuit Boards............................................................................................................. 37

13-1 Wiring Diagram........................................................................................................... 38

LIST OF TABLES

TABLE TITLE.......................................................................................................................... PAGE

9-1 Stream Identification BLIPs........................................................................................ 23

9-2 Normal Data Output Format....................................................................................... 26

9-3 Data Configuration ..................................................................................................... 27

9-4 RS232-C Pin Configuration........................................................................................ 27

9-5 RS232-C Function Commands.................................................................................. 27

9-6 Printer Pin Configuration ............................................................................................ 28

TABLE OF CONTENTS (CON’T)

1

CHEMPURE MANUAL SECTION 1

INTRODUCTION

SECTION 1

INTRODUCTION

The Rosemount Analytical Chempure Series analyz-

ers are designed for minimal maintenance and maxi-

mum reliability. The touch of a button starts the micro-

processor-controlled program, calibrates the analyz-

er, keeps it calibrated, and reports results directly –

unattended – for a month or more. Maintenance is

simplified by a modular design with quick disconnect

fittings and color coded components.

The Chempure Series includes analyzers for many

common chemical parameters, including: silica,

phosphate, nitrate, chrome, iron, chloride, cyanide,

alkalinity, and ammonia. Sample concentration is

clearly indicated on the digital display panel, and out-

put signals are provided to drive recorders, alarms, or

other external devices such as printers or computers.

This instruction manual describes installation, opera-

tion, and maintenance of the Chempure Series ana-

lyzers. The specific chemistry of your individual ana-

lyzer is discussed in the accompanying CHEMISTRY

SECTION located in the Appendix.

SECTION 2

UNPACKING

When you receive your new Chempure analyzer, care-

fully unpack and verify the following items:

Item Part No.

Main Cabinet 180-2005-01

Reagent Cabinet 180-2010-01

Mounting Brackets 180-2004-01

Overflow Sampler 180-1300-01

Assembly (Single stream analyzer)

180-1300-02

(Dual stream analyzer)

180-1300-03

Three stream analyzer)

180-1300-04

(Four stream analyzer)

180-1300-05

(Five stream analyzer)

180-1300-06

Six stream analyzer)

Pump Assembly 180-S007-01

Item Part No.

Colorimeter 180-S008-01

Pump Tubing (Part No. dependent on

Harness chemistry)

Waste Tube 180-1346-01

Accessories Pack MISC.

Start-Up Reagents (Part No. dependent on chem-

istry)

Instruction Manual Input our Manual p/n here or

leave blank.

If any of the above items are missing or damaged, con-

tact:

Rosemount Analytical, Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606 USA

TEL (800) 854-8257

(949) 863-1181

FAX (949) 474-7250

2

CHEMPURE MANUAL SECTION 3

INSTRUMENT DESCRIPTION

SECTION 3

INSTRUMENT DESCRIPTION

3.1 ANALYZER FRONT VIEW

3.1.1 MAIN CABINET

Part Function

Main Cabinet Splash-proof enclosure protects

analyzer.

Reagent Cabinet Splash-proof enclosure protects

reagents and solenoid valves.

Door Hinges Pin hinges mount doors on main

and reagent cabinets.

Door Latch Secures cabinet door.

Keypad Panel Contains touch buttons for con-

trolling analyzer, digital display,

and status panels.

HB Lamp Indicates when power is ON to

heating bath.

1/2 Amp 1/2 amp fuse for heating bath.

LAMP PS 1 Amp 1 amp fuse for power supply to

colorimeter lamp.

PUMP 1 Amp 1 amp fuse for pump.

XFMR 1 Amp 1 amp fuse for transformer.

Pump On/Off Lighted switch controls power to

pump.

Pump Norm/Hi Switch selects pump speed.

On/Off Main power switch supplies

power to electronics, trans-

former, and heating bath.

Colorimeter Colorimeter assembly Assembly

measures absorbance of the

reacted sample solution.

Waste Drain Pan Drain pan directs waste solu-

tions to waste tube.

Pump Connector Positive fit connector connects

pump to main cabinet electron-

ics.

Heating Bath Positive fit connector connects

Connector heating bath to main cabinet

electronics.

Solenoid Valve #3 Redirects reagent flow to waste

tube during baseline correction

(dependent on chemistry).

Part Function

Pump Assembly Positive displacement, peristaltic

pump moves sample and

reagents through analyzer.

Reaction Vessel Contains chemistry module,

Assembly heating bath, and thermometer.

Chemistry Module Tubing which carries sample

Tubing and reagent into chemistry mod-

ule.

Quick-Disconnect Connects chemistry module tub-

ing and pump tubing harness.

Pump Tubing Tubing which carries sample

Harness and reagents through pump.

Waste Tube Carries waste solutions to drain.

Leak Detector Senses leakage of solutions in

main cabinet, shut pump off, and

activates leak LED.

3.1.2 REAGENT CABINET

Part Function

Cabinet Light Light with on/off switch for view-

ing reagent cabinet.

Solenoid Valve “Phone” jack connectors for

Power Connectors solenoid valve power.

Sample Solenoid Solenoid valve which directs

Valve #1 flow of sample.

Baseline/Standard Solenoid valve which directs flow

Solenoid Valve #2 of baseline solution and fullscale

standard.

Multi-Stream Two to six solenoid valves

Valve Panel mounted on a panel for control

of multiple analysis streams

(Multi-Stream analyzer only).

Multi-Stream Positive fit connector connects

Connector Multi-Stream valve panel to main

cabinet electronics.

Bulkhead Fitting Fitting that directs individual

sample stream to sample valve.

3

CHEMPURE MANUAL SECTION 3

INSTRUMENT DESCRIPTION

FIGURE 3-1 ANALYZER FRONT VIEW

(2X)

4

Button/LED Function

auto multi-stream Press to begin automatic Multi-

Stream analysis (Multi-Stream

analyzer only).

man. baseline Press to begin manual baseline

setting procedure.

set multi-stream Press to program analysis time

for each sample stream (Multi-

Stream analyzer only).

hi alarm Press to set high alarm limit.

dec. loc. Press to set decimal point location.

low alarm Press to set low alarm limit.

power When lit indicates power ON to

circuitry.

rec. f/s Press to output fullscale signal to

external device such as a

recorder.

tube reset Press to display hours before rec-

ommended monthly mainte-

nance.

rec. zero Press to output zero signal to ex-

ternal device such as a recorder.

leak LED When lit indicates leak in main

cabinet.

calibration LED When lit indicates calibration in

progress.

lamp LED When lit indicates colorimeter

source lamp failure.

pump tube LED When lit indicates monthly main-

tenance should be performed.

3.2 KEYPAD PANEL

3.2.1 PANEL

Part Function

Thumbscrews Attaches keypad to analyzer and

secures door to electronics panel.

Digital Display Liquid crystal display reads out

in four digits with adjustable deci-

mal point.

Status Panel Four LEDs indicate leak, calibra-

tion, lamp failure, and hours re-

maining to monthly maintenance.

Sample Stream LEDs indicate sample stream

Indicator currently being sampled and

stream currently being displayed

(Multi-Stream analyzer only).

3.2.2 KEYPAD

Button/LED Function

man. multi-stream Press to manually choose sample

stream (Multi-Stream analyzer only).

/\ Press to increase displayed

value.

enter Press to accept numeric entries or

terminate a procedure.

\/ Press to decrease displayed

value.

auto cal Press to begin automatic calibra-

tion of analyzer.

man. fullscale Press to begin manual fullscale

calibration of analyzer.

CHEMPURE MANUAL SECTION 3

INSTRUMENT DESCRIPTION

FIGURE 3-2 KEYPAD PANEL

5

CHEMPURE MANUAL SECTION 3

INSTRUMENT DESCRIPTION

3.3 ELECTRONICS PANEL

The electronics panel is located directly behind the key-

pad. Access electronics panel by removing thumb-

screws from right side of keypad panel and opening

hinged door.

3.3.1 ELECTRONIC PANEL

Part Function

Keypad Panel Door Opens to access electronics

panel.

Display Board Circuit board contains electron-

ics for keypad and

LCD display.

CPU Board Central processing circuit board

processes the signal fed to the

digital display and any external

devices. Clips are color coded

yellow.

Part Function

Multi-Stream and Circuit board controls Stream

Multi-RS-232C accessory and Interface Board

RS-232C interface. Clips are

color coded purple.

Fault/Analog Circuit board converts Board

signals from analog to digital

and processes signals from

“fault” detectors. Clips are color

coded orange.

Power Board Supplies voltages to electrical

circuitry. Clips are color coded

blue.

FIGURE 3-3 ELECTRONICS PANEL

6

CHEMPURE MANUAL SECTION 3

INSTRUMENT DESCRIPTION

3.3.2 CPU BOARD

Part Function

20 mA Adjust For adjustment of fullscale

Set Screw recorder output signal when

recorder has no span adjust-

ment.

4 mA Adjust For adjustment of zero

Set Screw recorder output signal when

recorder has no span adjust-

ment.

5 V Adjust For adjustment of fullscale

Set Screw recorder output signal when

recorder has no span adjust-

ment.

0 V Adjust For adjustment of zero

Set Screw recorder output signal when

recorder has no span adjust-

ment.

Computer Memory Clears microprocessor

Reset Switch memory.

3.3.3 FAULT/ANALOG BOARD

Part Function

Leak Detector Adjusts sensitivity of leak

Adjust Set Screw detector.

FIGURE 3-4 CPU BOARD FIGURE 3-5 FAULT/ANALOG BOARD

7

CHEMPURE MANUAL SECTION 3

INSTRUMENT DESCRIPTION

3.4 COLORIMETER

Part Function

Colorimeter Contains and protects Housing

colorimeter and electronics

which measure the absorbance

of the reacted sample solution.

Source Lamp Provides light source for col-

orimeter.

Interference Selects desired wavelength of

Filter Assembly light from source lamp beam.

Sample Flow Cell Sample flows through cell for

analysis.

Sample Flow Sidearm of flow cell which Cell

Inlet receives sample.

Colorimeter Connector for electronic

Connector connection to analyzer.

FIGURE 3-6 COLORIMETER ASSEMBLY

(SEE FIGURE 12-1)

8

Part Function

Quick-Disconnect Male half of tubing Connector

connector which mates with

pump tubing harness.

Colorimeter Inlet Tubing carries sample, after

Tubing appropriate chemical reaction,

to colorimeter.

Thermometer Displays temperature in heating

bath.

Pump Drip Tray Catches any leaks and directs

them to the leak detector.

3.5 PUMP AND REACTION VESSEL

ASSEMBLY

Part Function

Pump Housing Contains and protects pump

and reaction vessel assembly.

Pump Positive displacement, peristaltic

pump moves sample and

reagents through the analyzer.

Platen Assembly Maintains pressure on tubing to

ensure consistent flow of sam-

ple and reagents.

Reaction Vessel Contains chemistry module,

Assembly heating bath, and thermometer.

Chemistry Tubing which carries sample

Module Tubing and reagent into chemistry in

reaction vessel assembly.

CHEMPURE MANUAL SECTION 3

INSTRUMENT DESCRIPTION

FIGURE 3-7 PUMP ASSEMBLY COMPONENTS

9

CHEMPURE MANUAL SECTION 3

INSTRUMENT DESCRIPTION

3.6 BACK OF MAIN CABINET

In the back of the main cabinet are a number of elec-

tronic components and connectors.

FIGURE 3-8 BACK OF ANALYZER WITH COVER REMOVED

INPUT/OUTPUT

PANEL

SOLENOID

VALVE #3 CON-

NECTOR

10

CHEMPURE MANUAL SECTION 3

INSTRUMENT DESCRIPTION

3.7 INPUT/OUTPUT PANEL

The input/output panel is located on the upper, left side

of the analyzer.

3.8 COMPUTER INTERFACE

The computer interface ports are located on the lower,

left side of the analyzer.

Part Function

Printer Interface For connection of printer cable.

Relay Output Optional relay contact (Multi-

Stream analyzer only).

RS-232C For connection of computer or

Interface other accessories.

FIGURE 3-9 INPUT/OUTPUT PANEL

FIGURE 3-10

COMPUTER INTERFACE PORTS

11

CHEMPURE MANUAL SECTION 3

INSTRUMENT DESCRIPTION

3.9 OVERFLOW SAMPLER ASSEMBLY

The overflow sample assembly is located is on the

lower right side of the Analyzer (See Figure 3-1)

Part Function

Intake/Regulating Regulates flow of sample into

Valve overflow sampler assembly.

Overflow Tube Assures adequate supply of

sample and reproducible results

by eliminating positive pressure

from sample stream.

FIGURE 3-11

OVERFLOW SAMPLER ASSEMBLY

Part Function

Sample Inlet Tube Tubing which carries sample

from overflow tube to sample

solenoid valve #1.

Air Vent Allows air to escape overflow

tube as it fills with sample.

Overflow Vent Allows excess sample to

escape.

Waste Pipe Carries waste to drain.

12

CHEMPURE MANUAL SECTION 4

INSTALLATION

SECTION 4

INSTALLATION

After the analyzer has been unpacked and all parts

accounted for, install as described in the following

chapter.

4.1 MAIN CABINET MOUNTING

4.1.1 GENERAL RECOMMENDATIONS:

• Mount the cabinet on a wall or other suitable verti-

cal surface, at least 66" (168cm ) wide and 43 1/2"

(111cm ) off the floor.

• Allow two feet of clearance at the left side of the

analyzer for access to the input/output panel, and

allow for swing of main and reagent cabinet doors.

• Allow 2 feet at the right side for access to the filter

and overflow tube assembly.

• Mount cabinet level or with a slight backward tilt for

proper leak detector operation.

• Mounting surface must be able to support 200

pounds.

• If the analyzer is to be installed out of doors, it must

be suitably sheltered to maintain the following envi-

ronmental conditions: Temperature: 50°F to 90°F,

regulated ±10°F Humidity:

10 to 80%.

To mount the main cabinet, proceed as follows:

1. Drill 6 holes in wall for mounting brackets, as indi-

cated in Figure 4-1.

2. Securely attach “L” brackets to wall using suitable

hardware. (Brackets must be anchored properly to

support 200 pounds.)

3. Attach main cabinet to “L” brackets using four

3/8" x 3/4" bolts, 3/8" split ring washers, and 3/8"

hex nuts.

4.2 REAGENT CABINET MOUNTING

To mount the reagent cabinet, proceed as follows:

1. Loosen the four bolts in bottom of

main cabinet,

leaving approximately 1/4" between washer and

cabinet.

2. Lift reagent cabinet and attach to main cabinet by

placing heads of bolts into the keyhole slots in top

of reagent cabinet and sliding reagent cabinet

back.

3. Tighten screws to attach reagent cabinet to main

cabinet.

4.3 WASTE TUBE INSTALLATION

To install the waste tube, proceed as follows:

1. Guide waste tubing through main cabinet into

reagent cabinet and out the side of reagent cabi-

net.

2. Secure plastic waste tube in clamp in lower right of

main cabinet. See Figure 3-1.

FIGURE 4-1 MOUNTING MAIN AND

REAGENT CABINETS

13

CHEMPURE MANUAL SECTION 4

INSTALLATION

4.4 OVERFLOW SAMPLER ASSEMBLY

To mount overflow sampler assembly, proceed

as follows:

1. Mount overflow sampler assembly on outer, right

side of reagent cabinet using four bolts provided.

See Figure 4-2. (If using IF-100 In-Line Filter see

instruction sheet enclosed with filter for complete

installation instructions.)

2. Place ends of the air vent tubing and overflow

waste tubing into waste pipe.

3. Connect waste pipe to drain.

4. Supply sample stream to regulating/intake valve

with 1/4" tubing (plastic or steel) as follows:

a. Loosen and remove nut and compression fitting

from bottom of regulating intake valve.

b. Slide nut and compression fitting over end of

sample stream tubing.

c. Seat end of tubing in nipple of valve and secure

by firmly tightening nut.

4.5 ELECTRICAL CONNECTIONS

Electrical connections are made to and from the analyz-

er at the input/output panel, located on the left side of

the analyzer. See Figure 3-9.

FIGURE 4-2

OVERFLOW SAMPLER ASSEMBLY

14

CHEMPURE MANUAL SECTION 4

INSTALLATION

FIGURE 4-3 PUMP AND REACTION VESSEL ASSEMBLY

FIGURE 4-4 PUMP PLATEN REMOVAL

This manual suits for next models

12

Table of contents

Other Fisher-Rosemount Measuring Instrument manuals