Fisher-Rosemount SCS 921 User manual

Model SCS 921

Total Chlorine

Monitoring System

Instruction Manual

PN 510SCS921

March 2000

Rosemount Analytical Inc.

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 863-1181

1-800-854-8257

www.RAuniloc.com

© Rosemount Analytical Inc. 1998

WARNING

ELECTRICAL SHOCK HAZARD

Making cable connections to and servicing

this instrument require access to shock haz-

ard level voltages which can cause death or

serious injury.

Be sure to disconnect all hazardous voltage

before opening the enclosure.

Relay contacts made to separate power

sources must be disconnected before serv-

icing.

Electrical installation must be in accordance

with the National Electrical Code

(ANSI/NFPA-70) and/or any other applicable

national or local codes.

Unused cable conduit entries must be

securely sealed by non-flammable closures

to provide enclosure integrity in compliance

with personal safety and environmental pro-

tection requirements.

The unused conduit openings need to be

sealed with NEMA 4X or IP65 conduit plugs

to maintain the ingress protection rating

(IP65).

For safety and proper performance this

instrument must be connected to a properly

grounded three-wire power source.

Proper relay use and configuration is the

responsibility of the user.

No external connection to the instrument of

more than 69VDC or 43V peak allowed with

the exception of power and relay terminals.

Any violation will impair the safety protection

provided

Do not operate this instrument without front

cover secured. Refer installation, operation

and servicing to qualified personnel.

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests

its products to meet many national and international stan-

dards. Because these instruments are sophisticated tech-

nical products, you must properly install, use, and main-

tain them to ensure they continue to operate within their

normal specifications. The following instructions must be

adhered to and integrated into your safety program when

installing, using, and maintaining Rosemount Analytical

products. Failure to follow the proper instructions may

cause any one of the following situations to occur: Loss of

life; personal injury; property damage; damage to this

instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and

servicing the product. If this Instruction Manual is not

the correct manual, telephone 1-800-654-7768 and the

requested manual will be provided. Save this

Instruction Manual for future reference.

• If you do not understand any of the instructions, contact

your Rosemount representative for clarification.

• Follow all warnings, cautions, and instructions marked

on and supplied with the product.

• Inform and educate your personnel in the proper instal-

lation, operation, and maintenance of the product.

• Install your equipment as specified in the Installation

Instructions of the appropriate Instruction Manual and

per applicable local and national codes. Connect all

products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel

to install, operate, update, program, and maintain the

product.

• When replacement parts are required, ensure that qual-

ified people use replacement parts specified by

Rosemount. Unauthorized parts and procedures can

affect the product’s performance and place the safe

operation of your process at risk. Look alike substitu-

tions may result in fire, electrical hazards, or improper

operation.

• Ensure that all equipment doors are closed and protec-

tive covers are in place, except when maintenance is

being performed by qualified persons, to prevent elec-

trical shock and personal injury. WARNING

This product is not intended for use in the light indus-

trial, residential or commercial environment, per the

instrument’s certification to EN50081-2.

CAUTION

SENSOR/PROCESS

APPLICATION COMPATIBILITY

Wetted materials may not be compati-

ble with process composition and

operating conditions. Application

compatibility is entirely the responsi-

bility of the user.

DANGER

HAZARDOUS AREA INSTALLATION

Installations near flammable liquids or in haz-

ardous area locations must be carefully eval-

uated by qualified on site safety personnel.

This device is not Intrinsically Safe or

Explosion Proof.

To secure and maintain an intrinsically safe

installation, the certified safety barrier,

transmitter, and sensor combination must

be used. The installation system must com-

ply with the governing approval agency

(FM, CSA or BASEEFA/CENELEC) haz-

ardous area classification requirements.

Consult your analyzer/transmitter instruction

manual for details.

Proper installation, operation and servicing

of this device in a Hazardous Area Instal-

lation is entirely the responsibility of the user.

MODEL SCS 921 TABLE OF CONTENTS

MODEL SCS 921

TOTAL CHLORINE MONITORING SYSTEM

TABLE OF CONTENTS

Section Title Page

11..00DDEESSCCRRIIPPTTIIOONNAANNDDSSPPEECCIIFFIICCAATTIIOONNSS............................................................................................................11

Specifications............................................................................................. 1

Ordering Information .................................................................................. 2

22..00IINNSSTTAALLLLAATTIIOONN......................................................................................................................................................................................44

Unpacking and Inspection......................................................................... 4

Installation................................................................................................... 4

33..00PPRRIINNCCIIPPLLEESSOOFFOOPPEERRAATTIIOONN........................................................................................................................................66

44..00SSTTAARRTT--UUPP......................................................................................................................................................................................................77

Install the Sensor........................................................................................ 7

Install the Sample and Drain Lines............................................................. 7

Connect the Sample Conditioning Cabinet to a Power Source.................. 7

Start Sample Flow....................................................................................... 7

Start the Air Flow and Zero the Sensor....................................................... 8

Prepare and Install the Reagent................................................................. 8

Begin Operation ......................................................................................... 8

55..00CCAALLIIBBRRAATTIIOONN........................................................................................................................................................................................99

66..00MMAAIINNTTEENNAANNCCEEAANNDDTTRROOUUBBLLEESSHHOOOOTTIINNGG..........................................................................................1100

Inspection................................................................................................... 10

Sample Conditioning Reagent.................................................................... 10

Peristaltic Pump.......................................................................................... 10

Sensor......................................................................................................... 10

Troubleshooting.......................................................................................... 11

Reagent Flow Check Procedure................................................................. 11

i

MODEL SCS 921 TABLE OF CONTENTS

TABLE OF CONTENTS CONT'D.

LIST OF FIGURES

Figure No. Title Page

2-1 Recommended Arrangement of Analyzer & Sample Conditioning System. 4

2-2 Dimensions of SCS 921 Case..................................................................... 5

3-1 Schematic of Sample Conditioning System & Total Chlorine Analyzer...... 6

3-2 Sample Conditioning System ..................................................................... 6

ii

1

MODEL SCS 921 SECTION 1

DESCRIPTION AND SPECIFICATIONS

SECTION 1. DESCRIPTION AND SPECIFICATIONS

RECOMMENDED SENSORS AND ANALYZERS

Delta analyzers are obsolete; however, the SCS921 sample conditioning system

can be used with any existing Delta total chlorine analyzer.

SPECIFICATIONS -

SAMPLE CONDITIONING SYSTEM

PHYSICAL

Enclosure: Fiberglass reinforced polyester, designed

to NEMA 12 standards

Dimensions: H 20.6 in.W 13.3 in. D 6.9 in.

(H 52.3 cm W 33.7 cm D 17.5 cm)

Mounting: Wall

Ambient Temperature: 32° - 122°F (0 - 50°C)

Ambient Humidity: 0 - 90% (non-condensing)

Power: 115 Vac, 64 mA, 50/60 Hz or

230 Vac, 31 mA, 50/60 Hz

EMI/RFI: EN50081-2

EN50082-2

LVD: EN61010-1

Weight/Shipping Weight: 13 lb/16/lb (6.0 kg/7.5 kg)

SAMPLE REQUIREMENTS

Inlet Connection: 1/4 in. tubing fitting

Drain Connection: 1/4 in. tubing fitting

Inlet Pressure: <100 psig (791 kPa)

Flow: at least 100 mL/min

Temperature: 32° - 122°F (0 - 50°C)

Total Alkalinity: <150 ppm (mg/L) as CaCO3

SAMPLE CONDITIONING SYSTEM

Pressure Regulator: Adjustable, 3 to 5 psig

recommended. Do not exceed 10 psig.

Rotameter: Adjustable, 80 to 100 mL/min

recommended.

Reagent: Potassium iodide, acetic acid, and sodium

acetate solution, 1 gallon (3.785 L).

Reagent Usage: 1 gallon lasts approximately 14 days.

Reagent Pump: Fixed speed peristaltic pump,

10-11 mL/hr.

Air Source: Aquarium pump.

SPECIFICATIONS - SENSOR & ANALYZER

See Model 1054B CL and 499A CL instruction manu-

als or Model SCS921 product data sheet.

PERFORMANCE SPECIFICATIONS USING

MODEL 499A SENSOR AND MODEL

1054BCL ANALYZER

Operating Range: 0 to 20 ppm (mg/L) total residual

chlorine (as Cl2).

Linear Range: 0 to 6 ppm (mg/L) total residual chlo-

rine (as Cl2).

Linearity: For six samples at constant temperature,

more or less evenly distributed between 0 and

6 ppm, the maximum deviation of a point from

the least squares fit to the data is less than 2%

of range.

Response Time: Following a step change, the reading

reaches 95% of final value within 3 minutes.

Temperature Correction: 10-35°C (50-95°F). Possible

loss of accuracy between 0 and 50°C (32 and 122°F)

The SCS 921 is a sample conditioning and measuring system for the continuous determination of total chlorine

in water. The conditioning system continuously pumps buffered potassium iodide reagent into the sample. Free

and combined chlorine (also called total chlorine) convert the iodide to iodine. A sensor measures the concentra-

tion of iodine and sends its signal to the analyzer. The analyzer displays the concentration of total chlorine.

ANALYZER SENSOR

1054BCL-32 499ACL-02-54

Delta models 925/DC925 and 82/8325 499ACL-02-56

CODE SENSOR (optional selection)

30 Total chlorine sensor with standard cable

31 Total chlorine sensor with optimum EMI/RFI cable

ANALYZER MODEL

1054BCL-01-32 1054B CL analyzer for total chlorine, LCD display, without wall mount enclosure

1054BCL-02-32 1054B CL analyzer for total chlorine, LED display, without wall mount enclosure

1054BCL-01-20-32 1054B CL analyzer for total chlorine, LCD display, with wall mount enclosure

1054BCL-02-20-32 1054B CL analyzer for total chlorine, LED display, with wall mount enclosure

SENSOR MODEL

499ACL-02-54 Total chlorine sensor with standard cable

499ACL-02-54-60 Total chlorine sensor with optimum EMI/RFI cable

2

MODEL SCS 921 SECTION 1

DESCRIPTION AND SPECIFICATIONS

ORDERING INFORMATION AND ACCESSORIES

Model SCS 921 Sample Conditioning System. The SCS 921 is used for the continuous determination of total

chlorine in water.The SCS 921 consists of a sample conditioning system, a sensor, and an analyzer.Order reagent

separately.

CODE POWER (required selection)

11 115 V 50/60 Hz

12 230 V 50/60 Hz

CODE ANALYZER (optional selection)

21 1054B CL analyzer, LCD display, without wall mount enclosure

22 1054B CL analyzer, LED display, without wall mount enclosure

23 1054B CL analyzer, LCD display, with wall mount enclosure

24 1054B CL analyzer, LED display, with wall mount enclosure

MODEL

SCS 921 SAMPLE CONDITIONING SYSTEM

SENSOR AND ANALYZER

SCS 921 -11 -21 -30 EXAMPLE

ACCESSORIES - Sample Conditioning System

MODEL SCS 921 SECTION 1

DESCRIPTION AND SPECIFICATIONS

*Weights and shipping weights are rounded up to the nearest whole pound or 0.5 kg.

ACCESSORIES - Sensor

PN DESCRIPTION WEIGHT* SHIP WEIGHT*

9380080 Peristaltic pump for reagent, 115 Vac 2 lb (1.0 kg) 2 lb (1.0 kg)

9380086 Peristaltic pump for reagent, 230 Vac 2 lb (1.0 kg) 2 lb (1.0 kg)

23868-00 Replacement tubing for peristaltic pump, 6 ft 1 lb (0.5 kg) 2 lb (1.0 kg)

9380087 Retainer disk for peristaltic pump tubing 1 lb (0.5 kg) 2 lb (1.0 kg)

9380081 Pressure gauge, 0 to 30 psig 1 lb (0.5 kg) 2 lb (1.0 kg)

9380082 Rotameter, with valve, 10 to 100 mL/min 1 lb (0.5 kg) 2 lb (1.0 kg)

9380083 Air pump, 115 Vac 1 lb (0.5 kg) 2 lb (1.0 kg)

9380085 Air pump, 230 Vac 1 lb (0.5 kg) 2 lb (1.0 kg)

9380084 Pressure regulator, 1 to 10 psig 1 lb (0.5 kg) 2 lb (1.0 kg)

DG0301 Valve, adjustable air 1 lb (0.5 kg) 2 lb (1.0 kg)

23830-00 Low flow cell assembly, includes flow cell, sensor adapter, 1 lb (0.5 kg) 2 lb (1.0 kg)

and locking nut

9100132 Fuse, 1/8 A, Slo-blo, 3AG250V, for 115 Vac version 1 lb (0.5 kg) 2 lb (1.0 kg)

9100191 Fuse, 1/16 A, Slo-blo, 3AG250V, for 230 Vac version 1 lb (0.5 kg) 2 lb (1.0 kg)

R459-4GAL Reagent, acetic acid/acetate buffer with potassium iodide, 38 lb (17.5 kg) 40 lb (18.5 kg)

4 x 1 gallon bottles/case

PN DESCRIPTION WEIGHT* SHIP WEIGHT*

23501-02 Total Chlorine Membrane, includes one membrane 1 lb (0.5 kg) 1 lb (0.5 kg)

assembly and one O-ring

23502-02 Total Chlorine Membrane Kit, includes 3 membrane 1 lb (0.5 kg) 1 lb (0.5 kg)

assemblies and three O-rings

R434-4OZ Total Chlorine Sensor Fill Solution, includes electrolyte 1 lb (0.5 kg) 2 lb (1.0 kg)

and KI crystals to be mixed before use

(discard excess after use)

3

4

UNPACKING AND INSPECTION

Inspect the shipping containers. If there is damage, contact the shipper immediately for instructions. Save the

boxes.If there is no apparent damage, unpack the containers. Be sure all items shown on the packing list are pres-

ent. If items are missing, notify Rosemount Analytical immediately.

INSTALLATION.

See Figure 2-1. Install the grab sample point as close as possible to the sample line supplying the SCS 921. Be

sure that opening the grab sample valve does not appreciably alter the flow of sample to the instrument. If the SCS

921 is measuring dechlorinated water, provide a way of substituting a chlorinated water sample for the dechlori-

nated sample. Chlorinated water is needed to calibrate the sensor and to check its response.

The sample conditioning system uses a pressure regulator to reduce pressure to between 3 and 5 psig. The

upstream side of the pressure regulator may be at process line pressure.

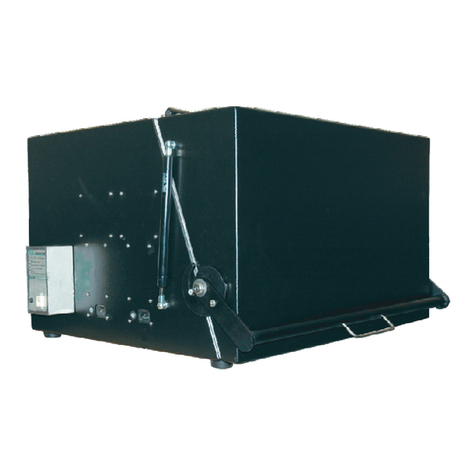

See Figure 2-2 for the dimensions of the sample conditioning system case.

See the analyzer instruction manual for analyzer dimensions and mounting instructions.

SECTION 2. INSTALLATION

MODEL SCS 921 SECTION 2

INSTALLATION

FIGURE 2-1. Recommended Arrangement of Analyzer and Sample Conditioning Cabinet.

The sensor is inside the cabinet.

CAUTION

May cause spray hazard.

Do not exceed 100 psig at

122°F (791 kPa at 50°C).

5

MODEL SCS 921 SECTION 2

INSTALLATION

FIGURE 2-2. Dimensions of SCS 921 Case

MILLIMETER

INCH

DWG. NO. REV.

4502393 B

6

SECTION 3. PRINCIPLES OF OPERATION

MODEL SCS 921 SECTION 3

PRINCIPLES OF OPERATION

See Figure 3-1. A pressure regulator and

valved rotameter control the flow of sample

through the SCS 921. From the outlet of the

rotameter the sample enters a mixing tee. A

constant speed peristaltic pump delivers

reagent to the mixing tee. The reagent,

which is a solution of potassium iodide in an

acetic acid/acetate buffer, converts total

chlorine in the sample into an equivalent

amount of iodine. The treated sample then

mixes with air and enters the flow cell. A

membrane-covered amperometric sensor in

the flow cell measures the concentration of

iodine. The analyzer (mounted outside the

cabinet holding the sample conditioning

system) receives the signal from the sensor

and displays the concentration of total chlo-

rine. The sample leaves the flow cell and

drains to waste.

Figure 3-2 shows the arrangement of com-

ponents in the sample conditioning case.

FIGURE 3-1. Schematic of Sample Conditioning System

and Total Chlorine Analyzer.

FIGURE 3-2. Sample Conditioning System

7

MODEL SCS 921 SECTION 4

START-UP

SECTION 4. START-UP

See Figure 3-1 and Figure 3-2.

INSTALL THE SENSOR

1. From inside the cabinet, thread the sensor cable through the gland on the upper-left side. Leave about one foot

of cable inside the cabinet. Remove the protective cap from the end of the sensor.

2. Wrap the sensor threads with pipe tape. Remove the locking nut and adapter from the flow cell. Slip the lock-

ing nut over the sensor and thread the adapter onto the sensor. Hand tighten only.

3. Place the sensor in the flow cell. Hand-tighten the locking nut.

4. Wire the sensor to the analyzer. See the sensor and analyzer instruction manuals for details.

INSTALL THE SAMPLE AND DRAIN LINES

1. Connect the sample line to the 1/4 in. tubing connection on the lower left hand side of the cabinet.

2. Attach a short drain line to the 1/4 in.tubing connection at the bottom of the cabinet.The drain line must empty

into a receiver open to atmosphere. See Figure 2-1.

CONNECT THE SAMPLE CONDITIONING CABINET TO A POWER SOURCE

1. Provide a switch or breaker to disconnect the analyzer from the main power supply. Install the switch or break-

er near the analyzer and label it as the disconnecting device for the analyzer.

2. Be sure power switch in sample conditioning cabinet is off.

3. Connect the sample conditioning unit to the AC power source.

START SAMPLE FLOW

1. Close the valve in the outlet of the air pump (extreme clockwise position). Do not over tighten.

2. Open the valve at the bottom of the rotameter.

3. Start the sample flow.

4. Set the pressure regulator to between 3 and 5 psig.Adjust the pressure by raising the regulator knob and turn-

ing it. Push the knob down to lock.

5. Using the valve on the rotameter, adjust the flow rate to between 80 and 100 mL/min (cc/min).

CAUTION

May cause spray hazard.

Do not exceed 10 psig at

122°F (170 kPa at 50°C).

WARNING: RISK OF ELECTRICAL SHOCK

AC connections and grounding must be in compliance with

UL 508 or local electrical code. DO NOT apply power to the

analyzer until all electrical connections are verified and secure.

MODEL SCS 921 SECTION 4

START-UP

START THE AIR FLOW AND ZERO THE SENSOR

1. Place the reagent tube in a container of water or leave in air.

2. Turn the power switch on.The peristaltic pump and the air pump will start.

3. Turn the air valve counterclockwise to start the flow of bubbles. Usually 1 1/4 turns will be adequate to cause

a steady stream of bubbles. Bubbling should not be vigorous.

4. Let the system run until the sensor current is stable. See the analyzer manual for instructions on how to dis-

play the sensor current. It may take as little as two hours or as long as overnight for the reading to stabilize.

5. Zero the analyzer. See the analyzer manual for details.

PREPARE AND INSTALL THE REAGENT

1. Add the potassium iodide crystals (PN R-459A) to the gallon bottle of buffer solution (PN R-459S).

2. Cap the bottle and invert several times to mix.

3. Insert the reagent tube in the reagent bottle and screw the cap in place. Place the bottle in the cabinet. Secure

the bottle with the strap. Close the cabinet door.

NOTE

The shelf life of the potassium iodide - buffer solution is about fifteen

days. DO NOT PREPARE THE SOLUTION UNTIL READY TO USE.

The reagent is unstable in sunlight. Keep the cabinet door closed.

BEGIN OPERATION

1. Once the flow of reagent starts, it takes about one minute for the sensor current to begin to increase. If the

concentration of total chlorine is more than about 0.5 ppm, the treated sample will be pale yellow.

2. Monitor the sensor current. Once the reading is stable, calibrate the unit. It may take an hour or longer for the

reading to stabilize. See the Model 1054B CL manual for detailed instructions.

8

9

MODEL SCS 921 SECTION 5

CALIBRATION

SECTION 5. CALIBRATION

Calibrate the system when the sensor membrane is replaced or when other maintenance is performed on the sen-

sor. Check the calibration of the system every time the sample conditioning reagent is replaced.

Calibrate by making the analyzer reading match the total chlorine level determined in a grab sample. See the ana-

lyzer instruction manual for details.For laboratory procedures refer to the most recent edition of

Standard Methods

for the Examination of Water and Wastewater

or, if data are being reported to a regulatory agency, use a proce-

dure acceptable to the agency.

See Figure 2-1 for suggested placement of the grab sample point. Be sure that opening the grab sample valve

does not appreciably change the flow to the sample conditioning system. As long as the flow is between 80 and

100 mL/min, changing the flow has almost no effect on the reading. If the flow drops below 80 mL/min, readings

begin to decrease.

Wait until analyzer readings are stable or slowly drifting before taking a grab sample for calibration. Make a note

of the analyzer reading before taking the sample.Immediately determine total chlorine in the sample.Before enter-

ing the calibration results, note the present chlorine reading. If the present reading (X) differs from the reading

when the sample was taken (Y), calculate the value to enter (C) from the following formula:

C = (X/Y)(A)

where A is the total chlorine concentration in the grab sample.

10

MODEL SCS 921 SECTION 6

MAINTENANCE AND TROUBLESHOOTING

SECTION 6. MAINTENANCE AND TROUBLESHOOTING

INSPECTION.

Periodically inspect tubing for cracks and leaks. Replace tubing if it appears to be damaged. Tubing downstream

from the reagent injection point turns yellow after a few days in service.

SAMPLE CONDITIONING REAGENT.

The sample conditioning reagent lasts about fifteen days.Do not mix the potassium iodide crystals in the small bot-

tle (PN R-459A) with the acetate buffer in the large bottle (PN R-459S) until ready to use.The reagent should be

colorless after mixing and should remain colorless for its life.

PERISTALTIC PUMP.

1. The tubing inside the pump becomes worn with usage. Pull a new section of tubing into the pump every two

months.There is six feet of extra tubing on the suction (left hand) side of the pump.

a. Remove the clear plastic cover.

b. Slide the plastic retainer on the suction side of the tubing away from

the pump about four inches (10 cm).

c. While the pump is running, pull the four inches (10 cm) of tubing

through the pump head until the retainer is snug against the pump

head.

d. Slide the retainer on the discharge side of the tubing toward the pump until it is about 3/4 inch (20 mm) from

the bottom of the pump head.

e. Replace the cover.

2. To replace pump tubing:

a. Turn off the power.

b. Remove the clear plastic cover.

c. Remove the two screws holding the pump cover in place and lift off the cover.

d. Pull the old tubing from between the pump shroud and rollers.

e. Detach the old tubing from the reagent tube and from the fitting at the mixing tee.

f. Slip off the retainer discs.

g. Prepare one end of the new tubing to feed through the holes in the retainer discs. Stretch the tubing and

hold it against a flat surface with the thumb and forefinger. Cut the stretched tubing using a straight-edged

razor blade held almost parallel to the tubing.

h. Pass the tapered end of the tubing through the discs.

i. Pull the discs along the tubing until they are about one foot (30 cm) from the tapered end. Pull the retainer

disc furthest from the end an additional five inches (13 cm) from the end. Cut the tapered end flat.

j. Insert the length of tubing between the retainer discs between the shroud and rollers. Be sure the long

end of the tubing is on the suction (left hand) side of the pump. Slide the retainer disc on the suction

side until it is snug with the bottom of the pump.Slide the retainer disc on the discharge side until it is about

3/4 inch (20 mm) from the bottom of the pump head.

k. Replace the pump cover and fasten it with the two screws.

l. Thread the ends of the tubing through the two holes in the clear plastic cover and snap the cover in place.

m. Attach the long end of the tubing to the reagent tube and attach the short end to the fitting at the mixing tee.

SENSOR.

Suspended solids in the sample slowly accumulate on the membrane. Wash the membrane every month with a

stream of water from a wash bottle.

CAUTION

Pinching hazard. Keep fingers away

from pump rollers.

11

MODEL SCS 921 SECTION 7

TROUBLESHOOTING

SYMPTOM ACTION

Sensor cannot be zeroed. 1. Allow time for readings to stabilize, particularly after doing sensor maintenance.

It may take the sensor as long as 12 hours to stabilize.

2. Examine the membrane. Replace it if it appears to be damaged. Discard and

replace the sensor electrolyte.

3. Check sensor for open and short circuits. See the sensor manual for details.

4. Verify that the sensor is correctly wired to the analyzer.

Analyzer does not respond 1. Check that sample flow is between 80 and 100 mL/min.

to changes in chlorine 2. Verify that reagent is flowing. Remove the tube from the reagent bottle and

concentration or readings see that air is drawn into the tube as the pump rollers turn. Flow rate should be

are lower than expected. 10-11 mL/hr.To measure the flow rate, see REAGENT FLOW CHECK PROCEDURE

below. If reagent flow is inadequate, move a fresh section of tubing into the pump or

replace the tubing. See PERISTALTIC PUMP above. If the pump rotor is not turning,

check the fuse. Replace the pump if necessary.

3. The reagent pump cannot pump against high pressure.Verify that the sample

pressure is between 3 and 5 psig.

4. Examine the membrane. It may be coated.If it is, rinse with the membrane with water

or replace it. See the sensor manual for details.

5. Verify that the sensor is correctly wired to the analyzer.

6. Repeat calibration.

Readings are higher than 1. Repeat calibration.

expected. 2. Check that reagent is clear and colorless. If it is pale yellow, results will be high.

To prevent the reagent from turning yellow, protect it from sunlight by keeping the

cabinet door closed.

Readings are erratic. 1. A new sensor usually takes time to stabilize. Readings should be stable after

several hours although it may take as long as 12 hours.

2. Verify that all wiring connections are tight.

3. Sample flow may be too high.Verify that flow is between 80 and 100 mL/min.

4. Check the sensor membrane. If it is loose or damaged, replace it.

5. Pressure surges in the sample line can cause erratic readings. A second pressure

regulator in the sample line may be required.

6. Mixing may be incomplete.Verify that air bubbles are in the flow cell.

Readings drift. 1. Verify that sample flow is between 80 and 100 mL/min.

2. Verify that reagent is flowing. Remove tube from the reagent bottle and see that air is

being drawn into the tube as the pump rollers turn.To measure flow rate, see

REAGENT FLOW CHECK PROCEDURE.

3. Drift can be caused by sudden changes in sample temperature. Following a step

change readings will drift for about 10 minutes while the sensor reaches sample

temperature.

4. Mixing may be incomplete.Verify that air bubbles are in the flow cell.

REAGENT FLOW CHECK PROCEDURE

1. Turn the pump off.

2. Remove the tubing from the reagent bottle.

3. Mark off two inches (51 mm) from the bottom of the tubing.

4. Let the tubing hang in air with the end even with the bottom of the reagent bottle.

5. Start the pump and verify that it takes between 26 and 30 sec for the meniscus to reach the 2-in.(51-mm) mark.

TROUBLESHOOTING

U.S. Field Service

Field Watch Response Center

1-800-654-7768

International

ARGENTINA

Emerson Argentina

Buenos Aires

54 1 780311,

795-9338

AUSTRALIA

Fisher-Rosemount

Pty. Ltd.

Bayswater, Victoria

(61)(39)721-0200

AUSTRIA

Fisher-Rosemount - AG

Neudorf

(43)(2236)607

BELGIUM

Fisher-Rosemount

N.V./S.A.

Diegem

(32)(2)716-77-11

BRAZIL

Fisher-Rosemount do

Brasil Industria e

Comercio Ltda.

Sorocada

(55)(11)228 3788

CANADA

Rosemount Instruments

Ltd.

Calgary

(800) 268-1151

CHINA

Fisher-Rosemount

Pudong, Shanghai

(86)(215)899-4415

CROATIA

Fisher-Rosemount

Croatia

Zagreb

(385)(1)305 071

CZECH REPUBLIC

Fisher-Rosemount

Praha

(420)(2)81002666-7

DENMARK

Fisher-Rosemount A/S

Alleroed

(45)48-17-03-33

ENGLAND

Fisher-Rosemount

Limited

Bognor Regis

(44)(1243)863-121

FINLAND

Oy Valment-Rosemount

AG

ESPOO

(358)(9)549-541

FRANCE

Fisher-Rosemount S.A.

Lyon

(33)(7)215-98-00

GERMANY

Fisher-Rosemount

GmbH & Co.

D-63549 Hasselroth

(49)(6055)884-0

HUNGARY

Fisher-Rosemount

Budapest

(36)(1)4624001

INDIA

Fisher-Rosemount

(India) Ltd.

New Bombay

(91)(22)762-9191/9200

ITALY

Fisher-Rosemount

Italia s.r.l.

Milan

(11)(39)(39)27021

JAPAN

Fisher-Rosemount Japan

Co., Ltd.

Tokyo

(81)(3)5403-8529

KOREA

Fisher-Rosemount

Korea Ltd.

Seoul

(82)(2)515-2321

MIDDLE EAST

Fisher-Rosemount

Middle-East Dubai,

United Arab Emirates

(971)(4)835235

MALAYSIA

Rosemount Instruments

SDN BHD

Kuala Lumpur

(60)(3)244-5688

MEXICO

Fisher-Rosemount S.A.

de C.V.

Tlalnepantla

(011)(525)728-0885

NEW ZEALAND

Fisher-Rosemount

Auckland

(64)(9)444-1646

NORWAY

Fisher-Rosemount A/S

Porsgrunn

(47)35-55-5600

POLAND

Fisher-Rosemount

Warszawa

(48)(22)857 3856/

647 3865

PORTUGAL

Fisher-Rosemount

Portugal Instrumentos

Limitada

Alfragide

(351)(1)472 88 50

PUERTO RICO

Fisher-Rosemount Inc.

Guaynabo

(787)782-9955, 9956,

or 9957

ROMANIA

Fisher-Rosemount

Bucharest

40 1230 4149/50/59

RUSSIA

Fisher-Rosemount

Moscow

7095 245 86 86

SINGAPORE

Fisher-Rosemount

Singapore

Pte, Ltd

(65)777-8211

SLOVAK REPUBLIC

Fisher-Rosemount scr

Bratislava

42 17 761 973

SPAIN

Fisher-Rosemount S.A.

Madrid

(34)(1)358-91-41

SWEDEN

Fisher-Rosemount AB

Karlstad

(46)(54)19-0090

SWITZERLAND

Fisher-Rosemount AG

Baar

(41)(41)768 62 60

THE NETHERLANDS

Fisher-Rosemount BV

Rijswijk

(31)(70)413-6542

TURKEY

Fisher-Rosemount

Proses Kontrol Ltd. Sri

Istanbul

(90)(216)49 240 42-46

A Worldwide Network of Sales and Service

The Rosemount customer sales and service organization comprises a network of fully equipped support centers strategical-

ly located throughout the world. From many of these locations, the Rosemount Group provides support, distribution of fin-

ished products, repair facilities, and training for our customers.

Immediate, Reliable Analytical Support

Now there’s a way to quickly get the right answers for your liquid analytical instrumentation

questions: the Analytical Customer Support Center.

Our staff of trained professionals are ready to provide the information you need. If you are

placing an order, verifying delivery, requesting application information, or just want to con-

tact a Rosemount Analytical representative, a toll-free call to 1-800-854-8257 will provide

you with the right people, the right answers, right now.

The right people, the right answers, right now.

WARRANTY

Goods and part(s) (excluding consumables) manufactured by Seller are warranted to be free from defects in work-

manship and material under normal use and service for a period of twelve (12) months from the date of shipment by

Seller. Consumables, pH electrodes, membranes, liquid junctions, electrolyte, O-rings, etc. are warranted to be free from

defects in workmanship and material under normal use and service for a period of ninety (90) days from date of ship-

ment by Seller. Goods, part(s) and consumables proven by Seller to be defective in workmanship and / or material shall

be replaced or repaired, free of charge, F.O.B. Seller's factory provided that the goods, parts(s), or consumables are

returned to Seller's designated factory, transportation charges prepaid, within the twelve (12) month period of warranty

in the case of goods and part(s), and in the case of consumables, within the ninety (90) day period of warranty. This war-

ranty shall be in effect for replacement or repaired goods, part(s) and consumables for the remaining portion of the peri-

od of the twelve (12) month warranty in the case of goods and part(s) and the remaining portion of the ninety (90) day

warranty in the case of consumables. A defect in goods, part(s) and consumables of the commercial unit shall not oper-

ate to condemn such commercial unit when such goods, parts(s) or consumables are capable of being renewed,

repaired or replaced.

The Seller shall not be liable to the Buyer, or to any other person, for the loss or damage, directly or indirectly, arising

from the use of the equipment or goods, from breach of any warranty or from any other cause. All other warranties,

expressed or implied are hereby excluded.

IN CONSIDERATION OF THE STATED PURCHASE PRICE OF THE GOODS, SELLER GRANTS ONLY THE ABOVE STAT-

ED EXPRESS WARRANTY. NO OTHER WARRANTIES ARE GRANTED INCLUDING, BUT NOT LIMITED TO, EXPRESS

AND IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

RETURN OF MATERIAL

Material returned for repair, whether in or out of warranty, should be shipped prepaid to:

Rosemount Analytical Inc.

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606

The shipping container should be marked:

Return for Repair

Model

_______________________________

The returned material should be accompanied by a letter of transmittal which should include the following information

(make a copy of the "Return of Materials Request" found on the last page of the Manual and provide the following there-

on):

1. Location type of service, and length of time of service of the device.

2. Description of the faulty operation of the device and the circumstances of the failure.

3. Name and telephone number of the person to contact if there are questions about the returned material.

4. Statement as to whether warranty or non-warranty service is requested.

5. Complete shipping instructions for return of the material.

Adherence to these procedures will expedite handling of the returned material and will prevent unnecessary additional

charges for inspection and testing to determine the problem with the device.

If the material is returned for out-of-warranty repairs, a purchase order for repairs should be enclosed.

Rosemount Analytical Inc.

Uniloc Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 863-1181

http://www.RAuniloc.com

© Rosemount Analytical Inc. 1998

Credit Cards for U.S. Purchases Only.

UNILOC DIVISION

CUSTOMER SUPPORT CENTER

1-800-854-8257

The right people, the right answers, right now.

ON-LINE ORDERING NOW

AVAILABLE ON OUR WEB SITE

http://www.RAuniloc.com

$10.00 U.S. Dollars

Table of contents

Other Fisher-Rosemount Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Solmetric

Solmetric PVA-1500S user guide

Fukuda

Fukuda CardiMax Series Service manual

Beta

Beta 682 Operation manual and instructions

PCB Piezotronics

PCB Piezotronics IMI SENSORS HT625B01 Installation and operating manual

ETS-Lindgren

ETS-Lindgren 5225 Series manual

Anritsu

Anritsu VNA Master MS2024B Maintenance manual

Tenmars

Tenmars TM-730 user manual

Endress+Hauser

Endress+Hauser Levelflex M FMP40 Description of Device Functions

Hesai

Hesai PandarQT user manual

Tektronix

Tektronix PRISM MPI2-10 instructions

Watts Clever

Watts Clever EW4008 instruction manual

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS FMM-P-L Installation and maintenance instruction