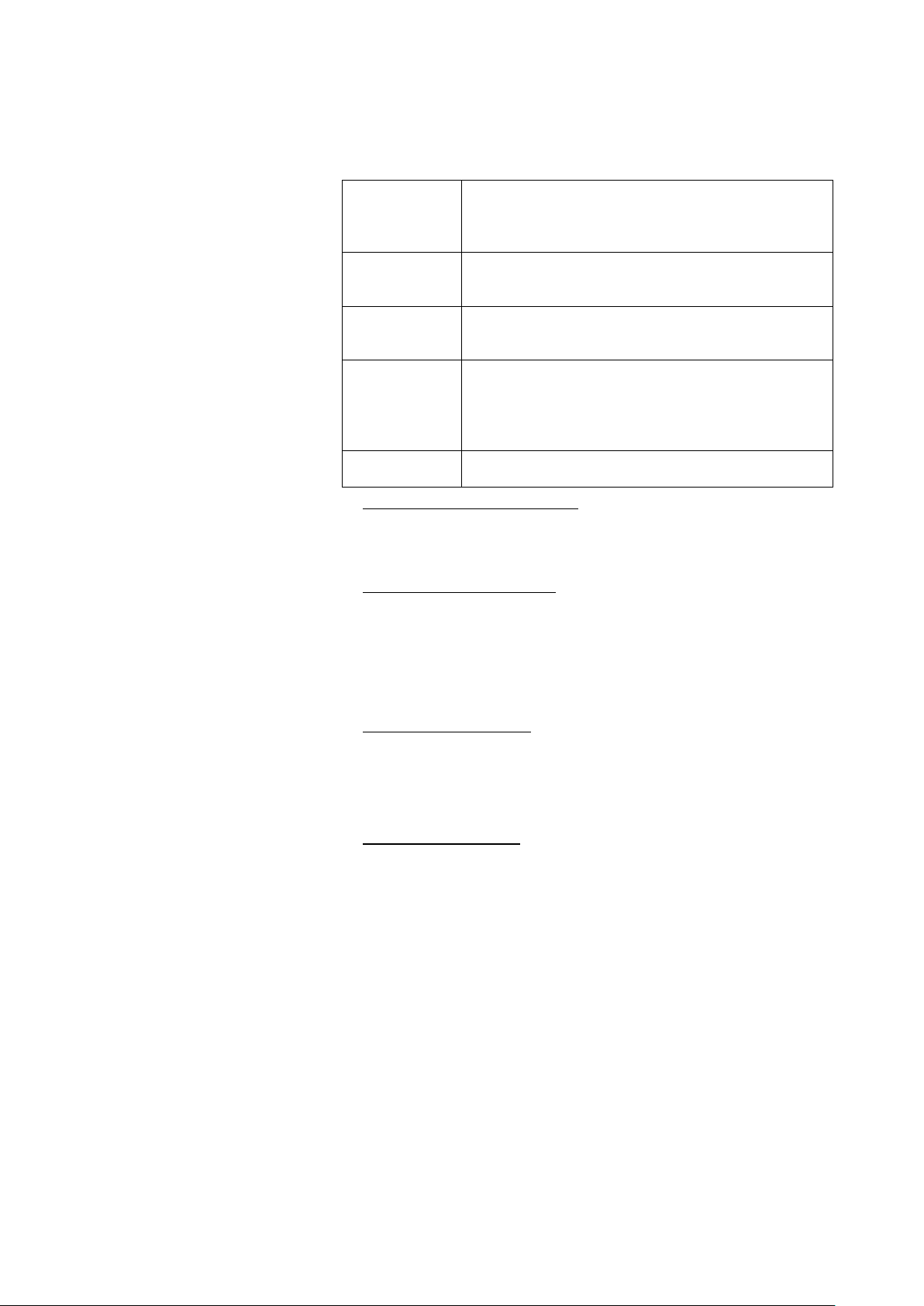

Ignoring the following cautions could cause injuries or property

damages.

Do not touch the top plate or any object near it even when the heater is

turned off. You may get burned due to residual heat.

After using this equipment, make sure to turn off the main power switch

and also to disconnect the power cord from the power outlet for the

safety of other users.

Do not place heavy objects, including this equipment, on top of the

power cord and do not strip, scratch, bend, twist, pull, or heat the power

cord. Adamaged power cord is a fire and electrical shock hazard.

Make sure to set up your instrument on a flat, stable, clean, non-slip,

dry, and fireproof surface inside a lab with proper safety measures.

Do not place any device which can be affected by the motor vibrations

near this equipment.

Do not touch the power outlet, power socket, or power cord with wet

hands. And make sure to connect the power cord directly and firmly to

the power outlet and power socket.

Do not put or insert any objects (especially if conductive or flammable)

inside this equipment.

Do not expose this equipment to any heat sources including direct

sunlight.

Mechanical shock or vibration can damage this equipment. Pay extra

attention while moving it. Damages caused by mechanical shock or

vibration may result in injury or fire.

Do not impact the heat sink. You can damage the equipment or get

injured.

Do not install this equipment near any device that generates high

frequency noise such as high frequency welding machines, high

frequency sewing machines, or SCR power controllers.

Before cleaning, make sure to unplug the power cord to avoid electric

shock or fire.

Do not use chlorine bleach, ammonia-based cleaners, abrasives,

ammonia, or metal scouring pads. Wipe with a soft damped cloth or a

sponge soaked in water or diluted neutral detergent.