Lit. No. 43894, Rev. 02 5 November 1, 2016

TABLE OF CONTENTS

Snowplow Owner Data Sheet...............................3

Preface..................................................................7

Safety....................................................................8

Vehicle Application Information...........................15

Ballast Requirements.......................................16

Getting to Know Your Snowplow.........................17

Minute Mount®2 System..................................17

Blades..............................................................18

HT Series™/SD Series/HD2™ ....................19

HDX™/MC Series/XtremeV™......................20

XV2™/XLS™ Series.....................................21

A‑Frame/T‑Frame........................................... 22

Straight Blade A‑Frames............................. 22

XLS A‑Frame............................................... 22

XtremeV/XV2 T‑Frame/Push Assembly...... 22

Headgear ........................................................ 22

Weights Table...................................................23

Mount Kits........................................................24

INTENSIFIRE™ Snowplow Headlamps...........24

Insta‑Act®Hydraulic Units................................25

System Capacity...........................................27

Pump Motor Specications ...........................27

Cab Controls....................................................28

Accessories and Options ................................... 30

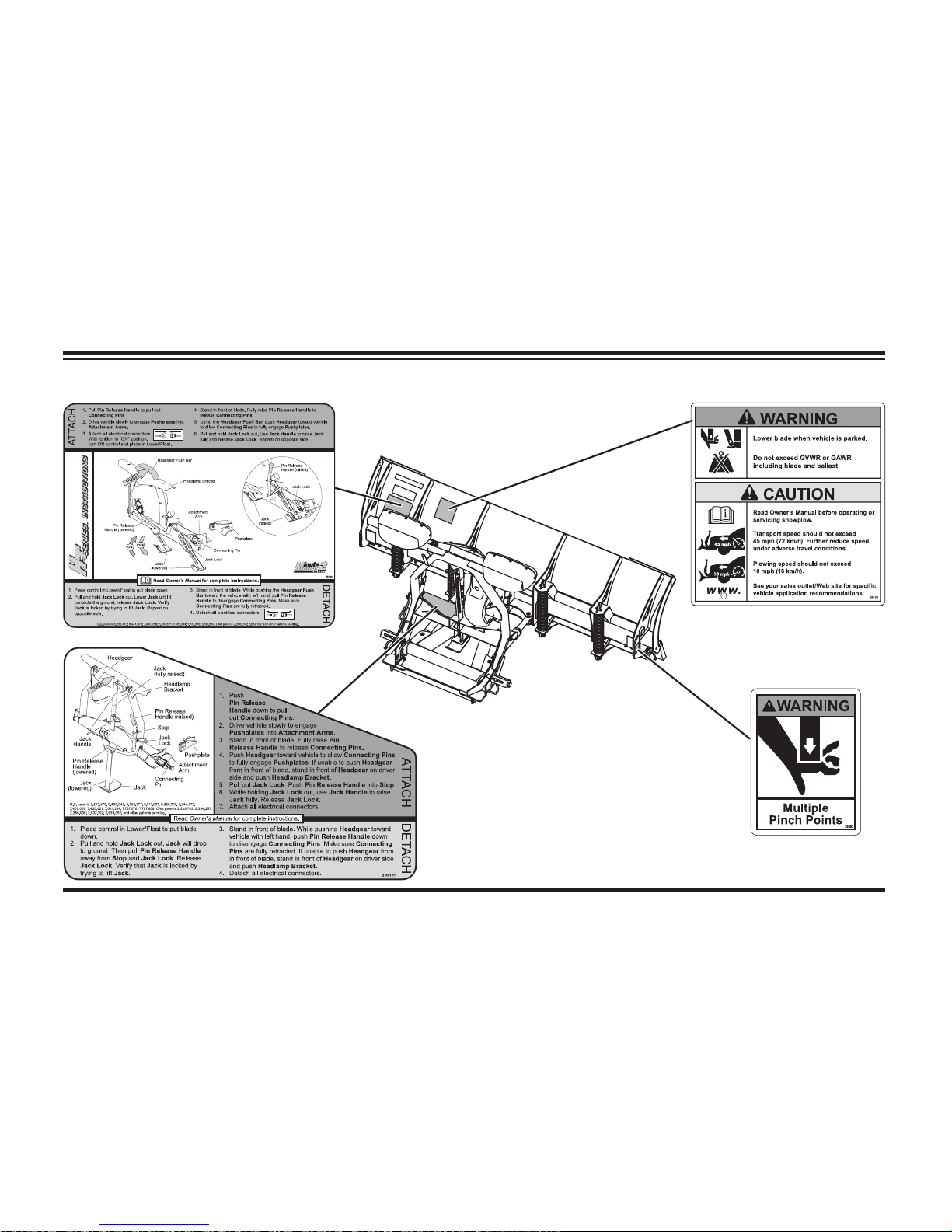

Attaching Snowplow to Vehicle.......................... 34

Operating Your Snowplow...................................37

Controls............................................................37

FLEET FLEX Electrical System................... 46

SECURITY GUARD™ System..................47

Smooth Stop/Soft Stop..............................51

One‑Touch FLOAT.....................................52

V‑Plow Blade Positions............................53

XLS Blade Positions........................................ 56

Snowplow Headlamp Check........................... 59

Antiwear Shoe Adjustment.............................. 60

Hydraulic System .............................................62

Blade Drop Speed Adjustment........................ 63

Scrape Lock Adjustment – HT Series™.......... 64

Transporting Snowplow....................................67