FISNAR VD510-SS User manual

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

DISPENSING VALVE

MODEL VD510-SS

◀INSTRUCTION MANUAL▶

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-2-

CONTENTS

1

Introduction

page 3

2

Specifications

page 3

3

Part Description

page 4

4

Operation Principles

page 5

5

Operating Procedure

page 6

5-1 Setup

page 6

5-2 Maintenance

page 9

6

Sectional Drawing & Dimension

page 11

7

Exploded View & Parts List

page 12

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-3-

1. INTRODUCTION

The VD510-SS is a diaphragm valve designed for precise flow control of low to medium viscosity

materials (under 10,000 cps). The valve head is made of Stainless Steel appropriate for use in

medical grade applications. Shot sizes may be fine tuned by turning the stroke adjustment knob at

the top of the valve.

2. SPECIFICATIONS

Operating Air Pressure

4.0~6.0kgf/㎠(60-90)

Material Delivery Pressure

Max 5.0kgf/㎠

Maximum Number of Cycle

500 cylces or more/min

Flux (KV value)

0.3ℓ/min

Minimum Shot Size

0.001 (material dependant)

Valve Structure

Diaphragm Valve

Weight

76g (2.7oz)

Driving Part Materials

Body : AL(Hard coated, Black)

Piston : SUS303

Piston Seal : NBR

Wetted Part Materials

Valve Head : SUS303

(option :Teflon, PEEK, Acetal)

Diaphragm : UHMW-PE

Connecting Ports

Operating Air Inlet: M5xP0.8

Material Inlet: BSPT1/8"

Material Outlet: Luer Lock

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-4-

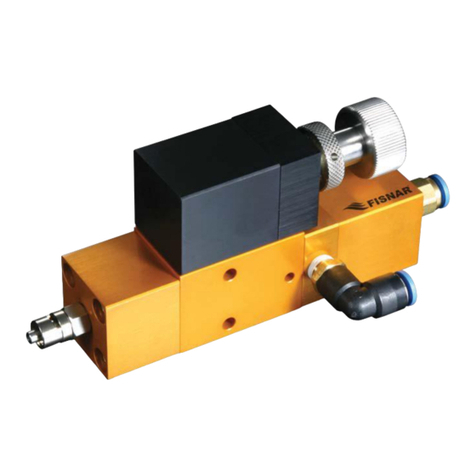

3. PART DESCRIPTION

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-5-

4. OPERATION PRINCIPLES

Dispensing OFF

Dispensing ON

short

Stroke

long

small

Shot Volume

large

In the “Normal”state (air off), the diaphragm

is closed –material is not dispensed.

When air is applied, the diaphragm is opened and

material is dispensed.

Because "Air" is not entering into the driving

parts, the diaphragm is closed. In this case,

the material path is closed, so material is

not dispensed.

If air is applied to the valve, the diaphragm will open.

At this time material will be dispensed.

You can increase or decrease the shot volume by

adjusting the stroke (shot volume control knob).

Notice

The maximum stroke length is 0.6mm (1

rotation). There is no effect after turning the knob

more than (1) rotation.

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-6-

5. OPERATING PROCEDURE

5-1. Setup

▶example for general installation

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-7-

5-1-1) Fasten the valve firmly using mount hole.

(M5*P0.8*D98)

5-1-2) Connect air hose to Air In Port and Controller.

Valve driving pressure is Min 4.0kgf/㎠or more.

5-1-3) Connect fitting for material supply hose to the inner port (BSPT1/8")

Notice

Do not insert fitting too deeply (7 ㎜or more).

5-1-4) Connect a suitable sized needle to the outer port.

5-1-5) Adjust the material pressure (max 5.0kgf/㎠).

When dispensing low viscosity materials (like water, solvent) set material pressure at 0.5kgf/㎠. For

high-viscosity materials, set material pressure at 2.0kgf/㎠.

Increase or decrease pressure as needed.

5-1-6)

At the time of delivery, the scale of shot volume control knob is being initiated

to point 3(½of full stroke). Increase or decrease the number as needed.

Maximum length of stroke is 0.6 ㎜.

(This is corresponding to the amount when shot volume control knob makes 1 round).

Notice

If you make 2 or more revolutions counterclockwise, the tensile strength of spring

is weaker and the valve becomes open state all the time. In this way liquid can

be dispensed.

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-8-

5-1-7)

After steady mode in controller and reducing pressure of pressure container,

make dispensing the liquid come out slowly.

(This is to remove bubble and dispense the first liquid from valve)

5-1-8)

Choose "timer" or "steady" mode of controller according to the state of dispensing.

5-1-9)

You can control dispensing amount by selecting 1 of following 4 options.

▶4 options

By increasing or decreasing pressure to

container

Pressure increase →Dispensing amount increase

Pressure decrease →Dispensing amount decrease

Thickness of Needle

Thick Needle →Dispensing amount

increase (Improvement of tendency to pause)

Thin Needle →Dispensing amount decrease

(Worse of tendency to pause)

Flux Control Knob

Long stroke →Dispensing amount increase

Short stroke →Dispensing amount decrease

Dispensing Time

Long dispensing time →Dispensing amount increase

Short dispensing time →Dispensing amount decrease

*Choose the way of controlling dispensing time preferentially to get proper dispensing amount.

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-9-

5-2. Maintenance

5-2-1) Washing

①Wash valve thoroughly after using if dispensed liquid has tendency to be stiff

or has possibility to damage liquid contacting part.

②First of all dispense all liquid entirely from pressure container,

liquid supply hose and liquid contacting part until sufficient air comes out.

③Wash liquid inside of valve with a little of proper solvent.

④Then wash thoroughly in order of air→solvent→air→solvent.

5-2-2) Disassembly

①In case of disassembly for washing or replacing part,

Refer to "7.Exploded View & Parts List".

②In case of washing valve head with sharp pin or

others, try not to scratch needle or seat part. If

damaged you need to replace parts because of

leakage.

5-2-3) Assembly

①Diaphragm Assembly

ⓐLoosen stroke control knob by turning twice counterclockwise.

ⓑSeparate valve head.

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-10-

ⓒRemove diaphragm by turning counterclockwise.

ⓓScrew new diaphragm carefully to become horizontal to piston road screw-thread.

- 7 -

Notice

If it isn't fit thread properly leakage may occur.

ⓔAfter fixing diaphragm at regular intervals(0.4mm) like the picture,

for matching cylinder body and mount screw, please turn to the

location that you want using a screwdriver like next picture.

ⓕTo reinstall valve head fasten L(hexagon)-wrench bolt firmly.

ⓖFasten stroke control knob until it is closed.

Then open it again until stroke is appropriate.

Notice

Scale may not indicate to ‘0’of reference mark. In this case refer to relative scale.

(No problem to use)

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-11-

6. SECTIONAL DRAWING & DIMENSIONS

▶Cross-sectional View

▶Dimension

- Measurements shown in millimeters.

Rev. A Jul 07

VD510-SS INSTRUCTION MANUAL

Part # 562148-SS

-12-

7. EXPLODED VIEW & PARTS LIST

▶Exploded View

▶Parts List

Part No

Description

Q'TY

Part No

Description

Q'TY

VD510-7

WASHER

1

VD510-1-SS

CHAMBER

1

VD510-8

O-RING(P4)

1

VD510-2

CYLINDER

BODY

1

VD510-9

O-RING(AS016)

1

VD510-3

CYLINDER CAP

1

VD510-10

SPRING

1

VD510-4

COLLAR

1

VD510-11

O-RING(P15)

1

VD510-5

DIAPHRAGM

1

VD510-12

BOLT(M3*20)

2

VD510-6

PISTON

1

561964

FITTING

1

Table of contents

Other FISNAR Control Unit manuals

Popular Control Unit manuals by other brands

Block

Block PC-1024-050-0 manual

Caroma

Caroma QUIET FLOW installation instructions

Mitsubishi Electric

Mitsubishi Electric AJ65VBTS32-16DT user manual

Midian

Midian ID-1 manual

Advanced Micro Controls Inc.

Advanced Micro Controls Inc. SMD17E2 user manual

CALEFFI

CALEFFI Altecnic SATK40103 Installation, operation & maintenance instructions