Flare Fireplaces CLASS 2901 84 User manual

INSTALLER: Leave this manual with appliance

CONSUMER: Retain this manual for future reference.

Installation & servicing of this appliance MUST be performed by a qualified NFI certified technician.

MASSACHUSETTS: The piping and final gas connection must be performed by a licensed plumber gas fitter in

the state of Massachusetts.

Modern Gas Fireplaces –Linear Fireplaces

FLARE FIREPLACES | POWER VENT INSTALLATION MANUAL

[SIT CS7 SYSTEM] HIGH VOLTAGE VERSION 5.7

NOTICE

WARNING: IF THE INFORMATION IN THESE INSTRUCTIONS

ARE NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY

RESULT , CAUSING PROPERTY DAMAGE, PERSONAL INJURY,

OR LOSS OF LIFE.

-DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABEL VAPORS AND LIQUIDS IN THE VICINTY OF

THIS OR ANY OTHER APPLIANCE.

-WHAT TO DO IF YOU SMELL GAS?

•DO NOT TRY TO LIGHT ANY APPLIANCE

•DO NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT

USE ANY PHONE IN YOUR BUILDING.

•IMMEDIATELY CALL YOUR GAS SUPPLIER FROM A

NEIGHBOR’S PHONE. FOLLOW THE GAS SUPPLIERS’

INSTRUCTIONS.

•IF YOU CANNOT REACH YOUR GAS SUUPLIER, CALL

THE FIRE DEPARTMENT.

-INSTALLATION AND SERVICE MUST BE PERFORMED BY A

QUALIFIED INSTALLER, SERVICE AGENCY OR GAS

SUPPLIER.

2 | P a g e

CONTENTS

SAFTEY INFO AND WARNINGS ......................................................................................................................................................3

FLARE FIREPLACES –FRAMELSS IN EVERY WAY .............................................................................................................................4

SAFETY ........................................................................................................................................................................................4

MANUAL MODEL LIST & INFORMATION........................................................................................................................................4

POWER VENTING OVERVIEW .......................................................................................................................................................5

POWER VENT DRAWINGS.............................................................................................................................................................5

HORIZONTAL END OF LINE POWER VENT DRAWING ...........................................................................................................................5

HORIZONTAL END-OF-LINE POWER VENT FRAMING DIMENSIONS .....................................................................................................6

HORIZONTAL POWER VENT PARTS LIST ...............................................................................................................................................7

VERTICAL END OF LINE POWER VENT DRAWING .................................................................................................................................8

VERTICAL POWER VENT PARTS LIST...................................................................................................................................................10

IN-LINE POWER VENT DRAWING .......................................................................................................................................................11

IN-LINE POWER VENT PARTS LIST ......................................................................................................................................................12

VENT ADAPTER CONVERSION.....................................................................................................................................................13

CLEARANCES TO POWER VENT...................................................................................................................................................16

CLEARANCES TO VENT PIPE........................................................................................................................................................16

MINIMUM CLEARANCE TO COMBUSTIBLES FROM VERTICAL VENT..............................................................................................16

MULTIPLE VERTICAL TERMINATION POINTS................................................................................................................................17

MULTIPLE HORIZONTAL TERMINATION POINTS ..........................................................................................................................17

VENT TERMINATION CLEARANCES..............................................................................................................................................18

VENT RESTRICTOR SETUP ...........................................................................................................................................................19

VENT RESTRICTOR TROUBLESHOOTING ......................................................................................................................................19

POWER VENT ELECTRICAL CONNECTION ....................................................................................................................................20

SIT PROFLAME 2 CONNECTIONS.................................................................................................................................................22

FIREPLACE ELECTRICAL DRAWING (WITH POWER VENT –SIT PROFLAME II) .....................................................................................23

POWER VENT ELECTRICAL WIRING DRAWING.............................................................................................................................24

DOUBLE GLASS BOARD AND FAN SWITCHES .....................................................................................................................................25

STARTING UNIT..........................................................................................................................................................................26

VENTING ...................................................................................................................................................................................26

CONNECTING 3X5 PIPE...............................................................................................................................................................28

REPLACEMENT PARTS ................................................................................................................................................................29

APPENDIX ..................................................................................................................................................................................30

YEARLY SERVICE REQUIREMENTS ...............................................................................................................................................30

PILOT MAINTENANCE ........................................................................................................................................................................30

BURNER MAINTENANCE....................................................................................................................................................................31

VENT MAINTENANCE.........................................................................................................................................................................31

DOUBLE GLASS FANS .........................................................................................................................................................................31

MAINTENANCE LOG...................................................................................................................................................................32

WARRANTY POLICY ....................................................................................................................................................................33

3 | P a g e

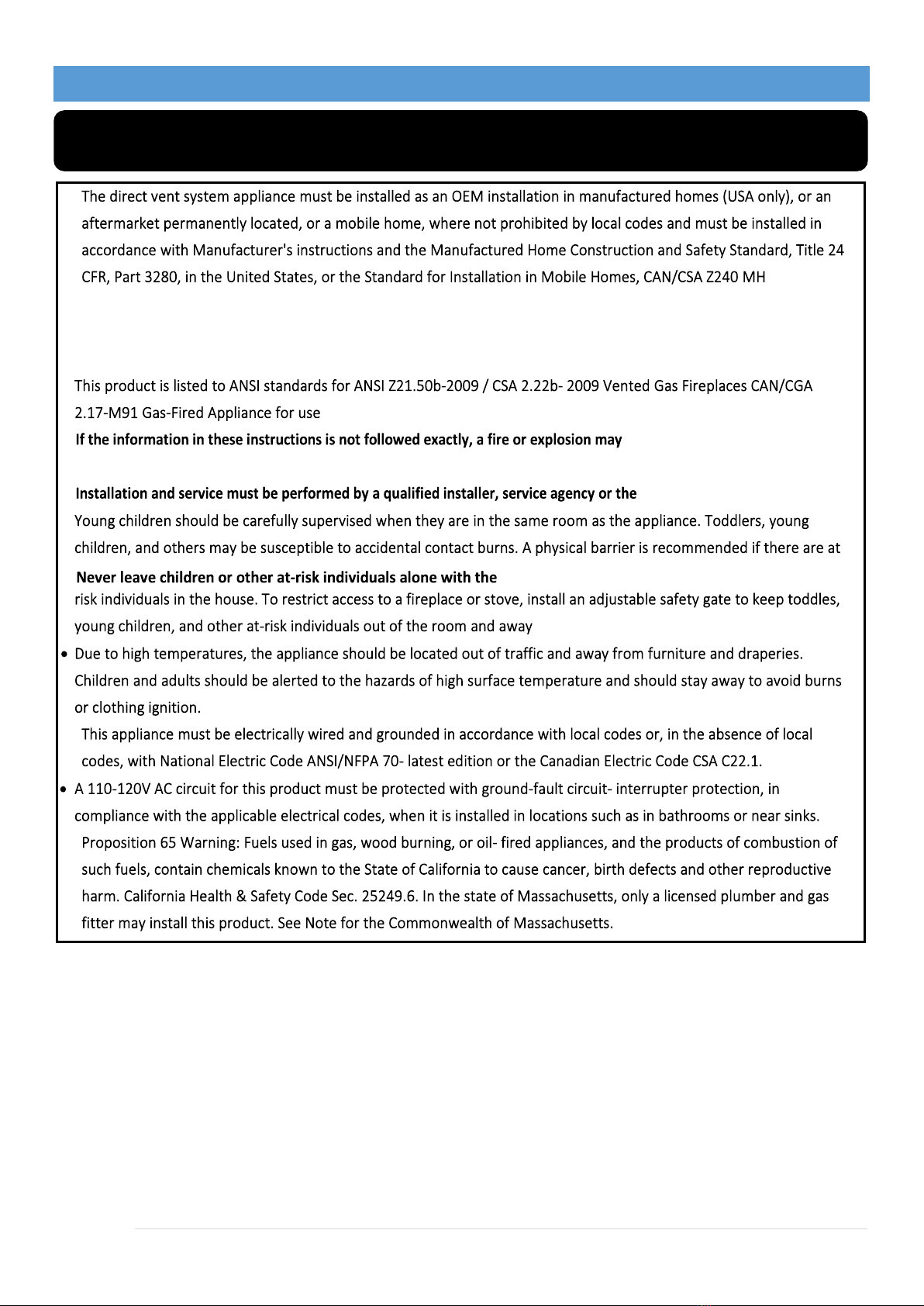

SAFTEY INFO AND WARNINGS

•

Series, in

Canada.

•This appliance is only for use with the type(s) of gas indicated on the rating plate. A conversion kit is supplied

with the appliance.

•

At High Altitude

•

from hot surfaces

•

•

•

result causing property damage,

personal injury, or loss of life.

•

supplier

.

•

appliance.

WARNING!

4 | P a g e

FLARE FIREPLACES –FRAMELSS IN EVERY WAY

Flare Fireplaces is where innovation, quality and luxury come together to form new ideas. By combining superior raw materials,

contemporary design, creative technology, and a frameless way of thinking, we have created a full line of direct-vent fireplaces

that are luxurious, simple to operate and efficient. Our Fireplaces are distinguished by their clean design, superior build quality

and unique features.

SAFETY

CSA CERTIFICATION

All our fireplaces are tested and have been certified to meet stringent CSA guidelines, ensuring optimum quality, safety, and

efficiency. All our fireplaces have been certified and tested to work with Natural Gas or Propane. Certification Information:

ANSI Z21.88/CSA 2.33-2014- Vented Gas Fireplace Heaters

CSA CLASSES:

CLASS 2901 84 / CLASS 2901 04

MANUAL MODEL LIST & INFORMATION

The Following manual should be used for Flare Fireplaces Models:

•Flare Front 30-100 “

•Flare See-Through 30-100”

•Flare Corner Right and Left 30-100”

•Flare Double Corner 30-100”

•Flare Room Definer 45-100”

To simplify the installation and operation, all models above share the same gas valve system, remote, gas connection, glass type.

All warnings and instructions apply to all models. Flare Fireplaces Power Vent system must only be connected to M&G 3x5

venting system. For detailed chimney installation information please use the M&G DuraVent direct vent installation manual:

https://www.duravent.com

Installation

MUST

comply with local,regional, state and national codesand regulations.Consult insurance carrier,

local building

inspector, fire officials or authorities having jurisdiction over restrictions, installation inspection and

permits.

This installation mustconform to local codes. In the absence of local codes, you must comply with the

National Fuel Gas Code,

ANSIZ223.1-Latest Edition inthe U.S.A.andtheCAN/CGAB149 Installation Codes in Canada.

Improper installation, adjustment,alteration, serviceor maintenance can cause injury or property damage. For

assistance or

additional information,consulta qualified service technician, service agencyor your dealer.

5 | P a g e

POWER VENTING OVERVIEW

In the event of a vent route that is unsupported based on the Gravity Vent Tables shown in the Flare Install Manual, Flare

Fireplaces may use a power vent to accommodate any extremely long, or negative degree venting routes. The 3 power vent

options allow the fireplace to operate in vent conditions that would not be possible without the powered fan. With a power-vent

you can install a 90-elbows right off the top of the fireplace. When using the power vent system, it is critical that the vent path

remain completely sealed for the power vent system to operate. The vent length and restrictor level should be set based on

number of feet, number of elbows, and the vent termination.

The system is designed and tested with DuraVent 3x5 gasket direct vent pipes. It is critical for the safety and operation of the

system to use the DuraVent 3x5 gasket system. See the link below for a DuraVent catalog & vent parts with part numbers:

https://www.DuraVent.com/docs/product/CVS_Catalog.pdf

All three Flare Power Vent systems can be installed to include 8 elbows and run up to 100ft vent run.

-A minimum length of 12ft venting is required between the Fireplace and the PV, Flare Fireplaces sizes 30”-70”. A minimum

length of 15ft,Flare sizes 80”-100”, is required between the fireplace and the PV.

-Elbows, whether 45 or 90 degrees, do not count towards the minimum distance requirements.

-Do not install any Power Vent system if the minimum length is below listed above. The three Power Vent systems can be

installed with a maximum of 5ft vent run below the fireplace.

-Do not install any of the Flare Power Vent fans inside the fireplace cavity, as this increases the risk of overheating

-Do not snake 3x5 vent pipe within cavity to achieve minimum length, as this will lead to increased heat buildup.

POWER VENT DRAWINGS

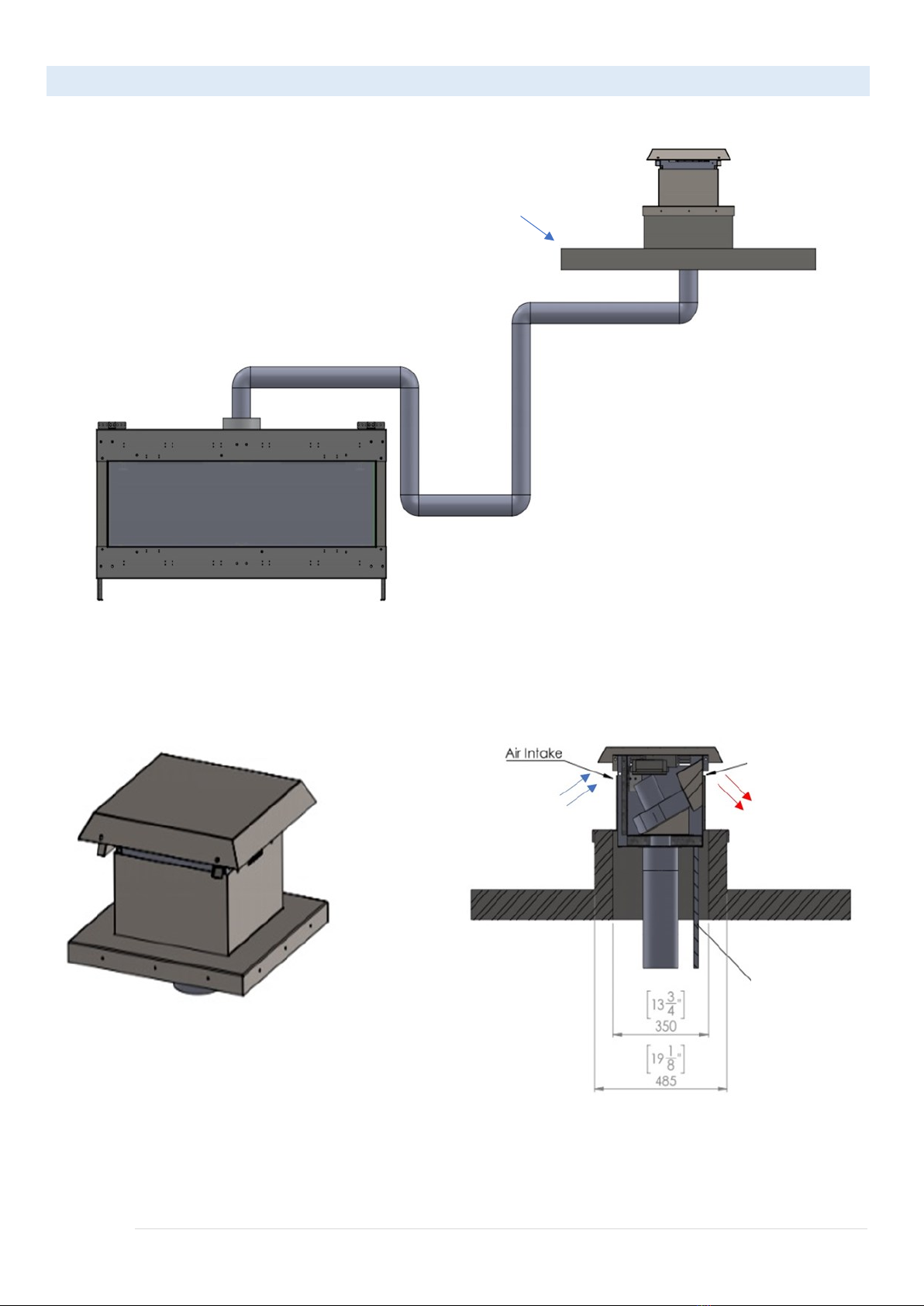

HORIZONTAL END OF LINE POWER VENT DRAWING

6 | P a g e

HORIZONTAL END-OF-LINE POWER VENT FRAMING DIMENSIONS

ROUGH OPENING CUT-OUT DIMENSIONS: 13 ½ W x 14 ½ H

7 | P a g e

HORIZONTAL POWER VENT PARTS LIST

HORIZONTAL POWER VENT PART LIST:

ITEM NUMBER

PART Name

DESCRIPTION

1

W-F-08

PV External Cover

2

W-F-14

PV Board Cover

3

Draft Switch

HUBA control to measure fan pressure

4

Elec. Holder

Electrical wiring holder

5

Motor inner cover

Internal cover motor

6

Exhaust Blower

Main Exhaust Fan

7

Housing of Exhaust Blower

PV Whole Block

8

W-F-10

Bracket for fixing PV hole.

9

Exhaust Blower Carrier

Exhaust Outlet Holder

8 | P a g e

VERTICAL END OF LINE POWER VENT DRAWING

ROOF

Exhaust Outlet

110V AC Cable

9 | P a g e

10 | P a g e

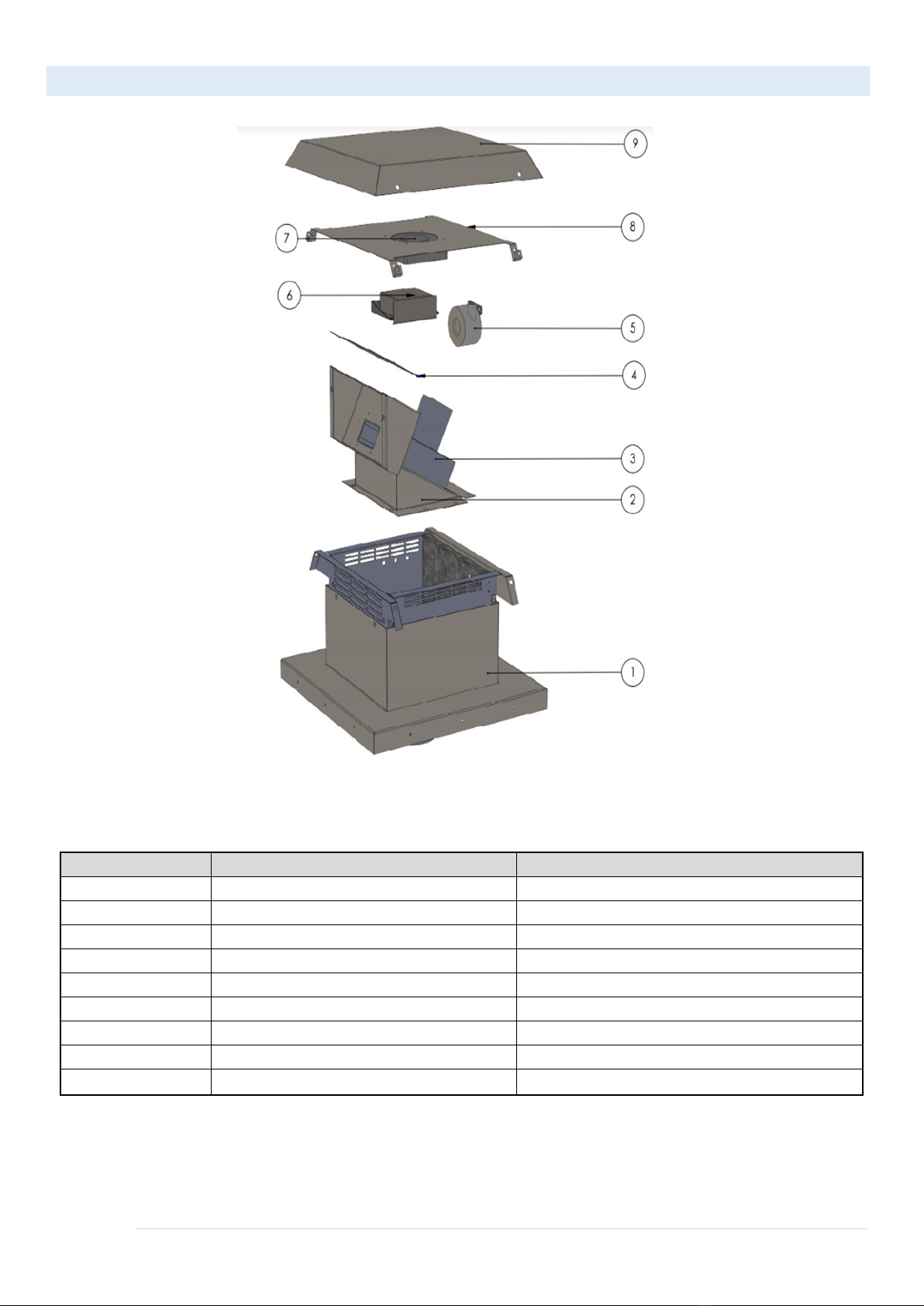

VERTICAL POWER VENT PARTS LIST

VERTICAL POWER VENT PARTS LIST:

ITEM NUMBER

PART NUMBER

DESCRIPTION

1

Housing of Exhaust Blower - Vertical

The whole block for vertical power vent

2

Fan | 03 + 04

Main Fan Holder

3

Exhaust Blower

Main Exhaust Fan

4

Fan | 08

Inner upper cover for exhaust outlet

5

Draft Switch

HUBA Control for pressure measuring

6

Electric Board

Electrical Board Cover

7

Fan

Cooling Fan

8

Fan | 12

Cooling Fan Holder

9

Fan | 06

External Upper Cover

11 | P a g e

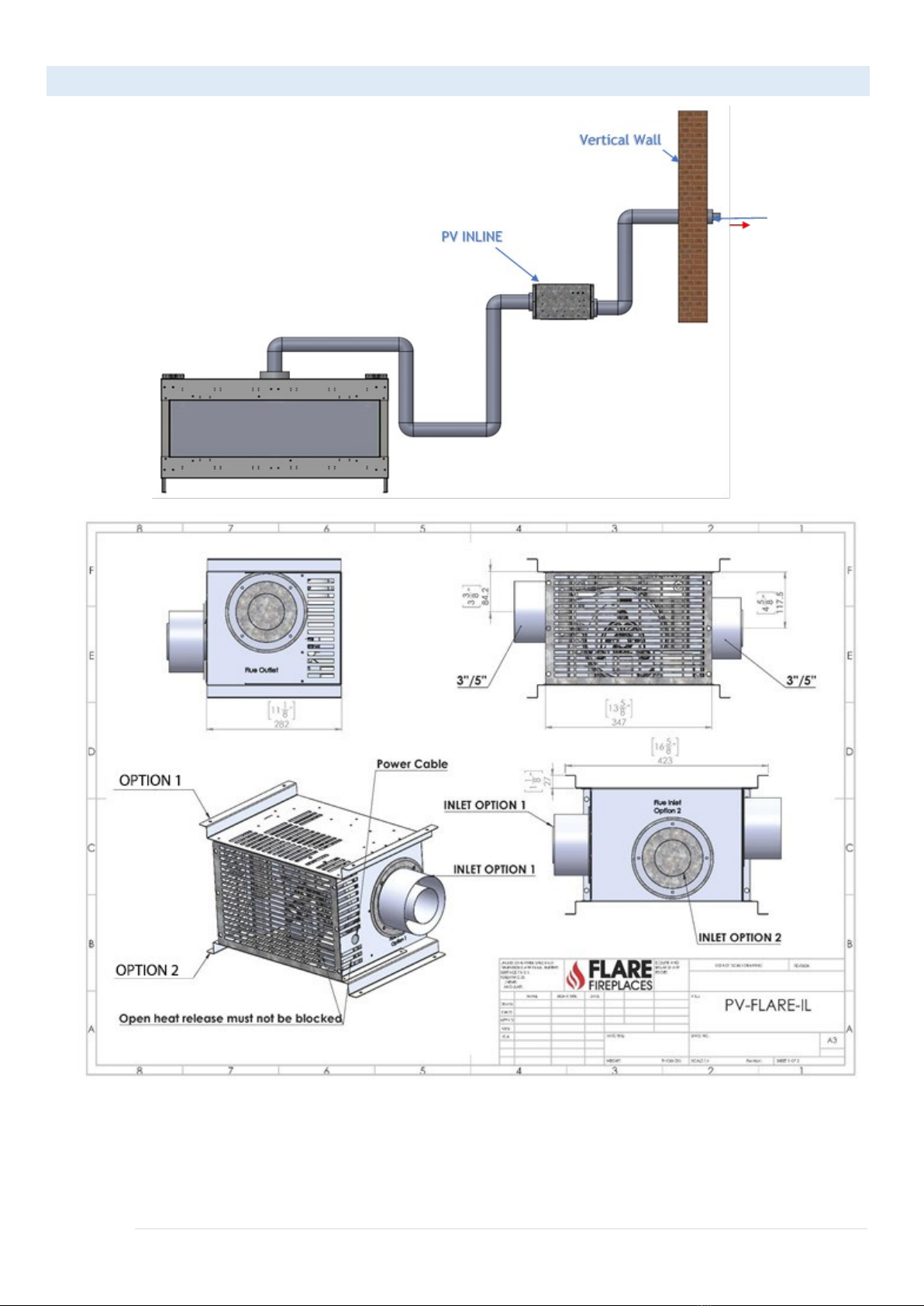

IN-LINE POWER VENT DRAWING

PLEASE NOTE THAT THE INLINE POWER VENT MUST BE MOUNTED TO A STRUCTURE AND CANNOT JUST FLOAT

USING THE VENT PIPE

12 | P a g e

IN-LINE POWER VENT PARTS LIST

IN-LINE POWER VENT PARTS LIST:

ITEM NUMBER

PART Name

DESCRIPTION

1

FanExNet

External Cover

2

C-Fan

Cooling Fan

3

Exhaust Blower

Main Fan

4

Draft Switch

(HUBA Control) Pressure Switch

5

FanExDish

Electrical Wiring Holder

6

House of Exhaust Blower In-Line

In-Line Whole Block

Part List

ITEM NUMBER

PART NUMBER

DESCRIPTION

1

FanExNet

External Cover

2

Fan

Cooling Fan

3

Exhaust Blower

Main Fan

4

Draft Switch

HUBA Control

5

FanExDish

Electronic Board Holder

6

House of Exhaust Blower In-Line

In-Line Whole Block

13 | P a g e

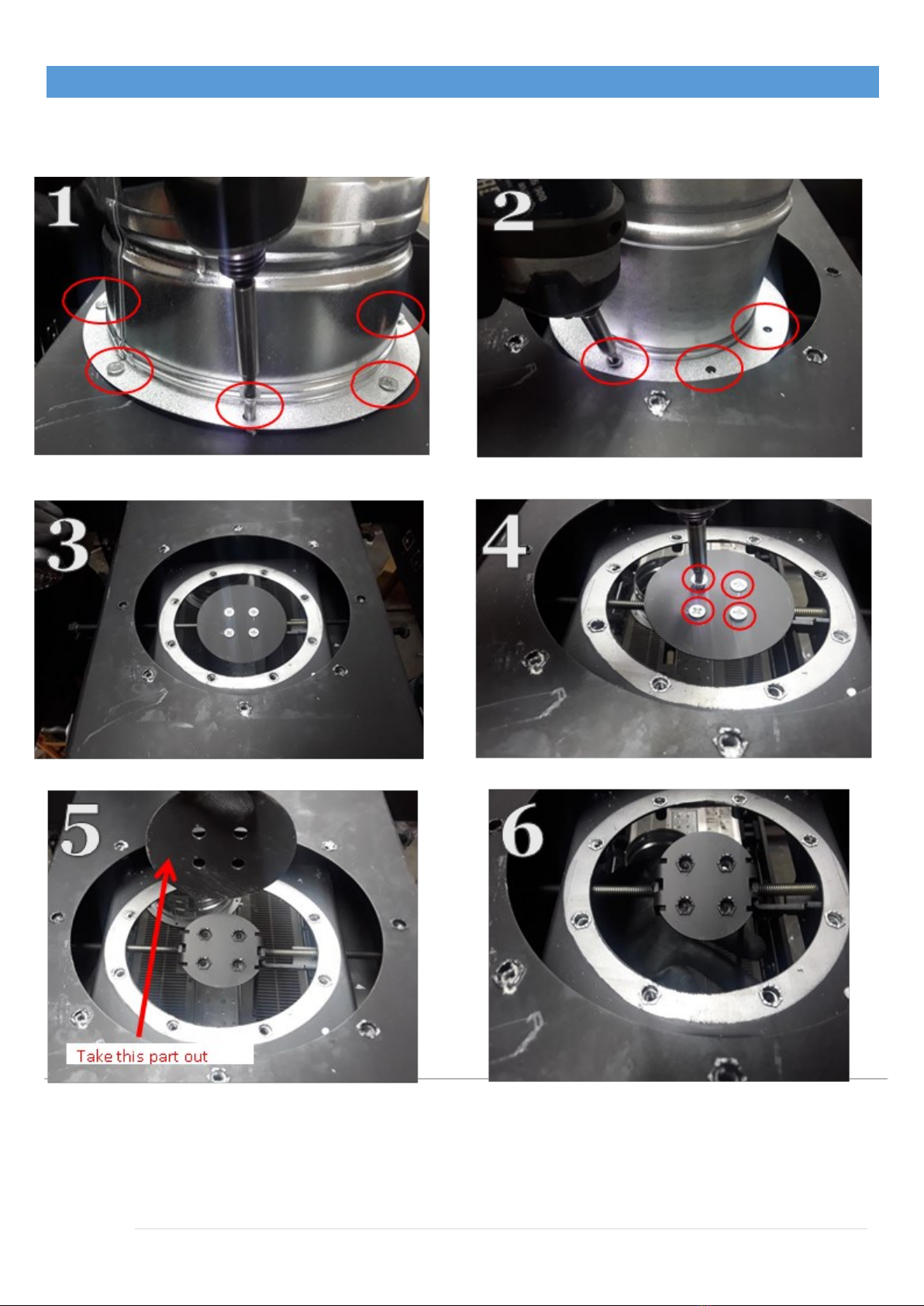

VENT ADAPTER CONVERSION

In the event a fireplace is shipped with a standard collar and needs to be converted to support a CVS 3x5 collar, follow the

steps below:

1. Remove the 4x6/5x8 Vent adapter from the top of the fireplace as shown in the pictures below:

14 | P a g e

2. Install 3x5 Vent adapter:

a. Attach the 3inch Female (inner) part first as shown in step1, then tighten the screws as shown in step 2.

b. Use 3mm ceramic fiber paper to isolate the vent adapter as shown in steps 1 and 4.

c. Step 4 shows the 5-inch male part base after using the ceramic fiber paper

15 | P a g e

3. Place the 5 Inch Male Adapter in place and tighten down screws to secure to unit.

16 | P a g e

CLEARANCES TO POWER VENT

This section describes the Flare Fireplaces Power Vent system clearance dimensions for building materials.

1. Clearance diagram is displayed below.

a. 24-inch clearance in front of access panel (Inline only) for service and removal.

b. 12-inch clearance above axillary fan for cooling (if axillary fan is part of fan box assembly).

c. 2-inch clearance on Flare Fireplaces Power Vent sides and bottom.

2. Access Panel for Flare Fireplaces Power Vent –Inline PV Only

a. Minimum 18-inch x 18-inch access panel required for service.

b. The Flare Fireplaces Power Vent must be in an area with a minimum 8 cubic feet of free air space to keep the component

operating temperature cool. In addition, the access panel must be louvered to allow for a minimum of 75 sq. inches of

free air space.

3. Flare Fireplaces Power Vent Mounting

a. Mount the Flare Fireplaces Power Vent per local code requirements, and follow the manufacturer’s instructions for

securing venting

CLEARANCES TO VENT PIPE

Clearance between the vent pipe and combustible materials must be maintained at 3” inches top and 1” for side and below.

Maintain the same clearance from the power vent box to any combustible materials.

a. HORIZONTAL VENT CLEARANCES: A minimum clearance of 3” (76mm) to the top and 1” (51mm) to the sides and bottom

of the vent pipe on all horizontal runs to combustibles is required.

b. VERTICAL VENT CLEARANCES: A minimum of 1” (25mm) all around the vent pipe on all vertical runs to combustibles is

required except for clearances in appliance enclosures.

MINIMUM CLEARANCE TO COMBUSTIBLES FROM VERTICAL VENT

POWERVENTUNIT MUSTBEINSTALLEDBYAQUALIFIEDINSTALLERINACCORDANCEWITHTHESEINSTRUCTIONS. CAUTION! FAILURETO INSTALL,

OPERATE,ANDMAINTAINTHEPOWERVENTINGSYSTEMINACCORDANCEWITHMANUFACTURER'S

INSTRUCTIONS WILL RESULTINCONDITIONS

WHICH MAYPRODUCE BODILY INJURY AND/OR PROPERTYDAMAGE

Exhaust Outlet

17 | P a g e

MULTIPLE VERTICAL TERMINATION POINTS

•If using decorative cap cover/s, this distance may need to be increased. Refer to the installation instruction supplied the

decorative cap cover.

•In a staggered installation with both gas and wood or fuel oil termination, the wood or fuel oil termination cap must be higher

than.

MULTIPLE HORIZONTAL TERMINATION POINTS

A minimum distance of 18 inches should be kept between multiple horizontal terminations.

Exhaust Outlet

18 | P a g e

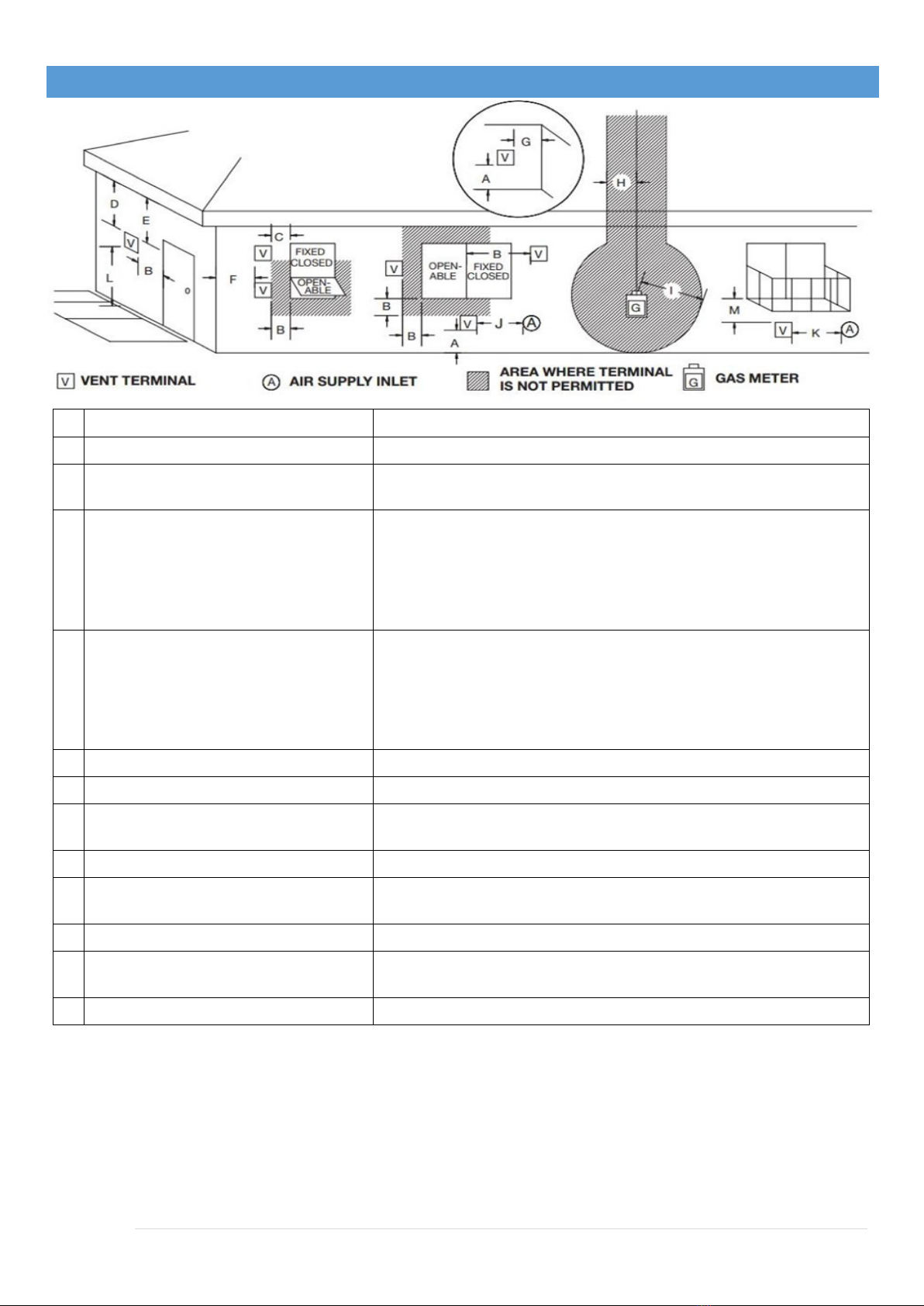

VENT TERMINATION CLEARANCES

^Vent shall not terminate directly above a sidewalk or paved driveway, located between two single family dwellings, serving both dwellings.

** Only permitted if veranda, porch, deck, or balcony is fully open on a minimum of 2 sides beneath the door.

*Clearance in accordance with local installation codes and the requirements of the gas supplier.

*As specified in CGA B149 Installation Codes, note local Codes or Regulation may require different clearances.

*For U.S.A. Installations follow the current National Fuel Gas Code, ANSI Z223.1

*** Horizontal vent termination minimum clearance to adjacent structure or fence is 48”.

**** Minimum 24” horizontal clearance to any surface (such as an exterior wall) for vertical terminations.

A

^12 inches (30 cm) min.

Clearances above grade, veranda, porch, deck, or balcony

B

**12 inches (30 cm) min.

Clearance to window or door that may be opened

C

12 inches (30 cm) min.

Clearance to permanently closed window recommended to prevent

condensation on window

D

24 inches (76 cm) min. for Flare units 80”

and 100”

18 inches (46 cm) min. for Flare units 70”

and below (vinyl surfaces require 24 inches

(61 cm) min.)

Vertical clearance to ventilated soffit located above the terminal within

a horizontal distance of 2 feet (60 cm) from the edge of the terminal

E

24 inches (76 cm) min. for Flare units 80”

and 100”

18 inches (46 cm) min. for Flare units 70”

and below (vinyl surfaces require 24 inches

(61 cm) min.)

Clearance to unventilated soffit.

F

6 inches (15 cm) min.

Clearance to outside corner

G

6 inches (15 cm) min.

Clearance to inside corner

H

3 feet (90 cm) min.

*Not to be installed above a meter/regulator assembly within 3 feet (90 cm)

horizontally from the centerline of the regulator

I

3 feet (90 cm) min.

Clearance to service regulator vent outlet

J

*12 inches (30 cm) min.

Clearance to non-mechanical air supply inlet to building or the combustion air

inlet to any other appliance

K

*6 feet (1.8 m) min.

Clearance to a mechanical air supply inlet

L

***7 feet (2.1 m) min.

Clearance above paved sidewalk or a paved driveway located on public

property

M

****20 inches (51 cm) min.

Clearance under veranda, porch, deck, or balcony

19 | P a g e

VENT RESTRICTOR SETUP

Flare Fireplace direct vent system is equipped with a vent restrictor. Use the chimney path installation planning chapter to

determine what the vent restrictor setup should be for your installation.

•The unit leaves the factory with the vent restrictor open.

•The vent restrictor is adjusted using a 10mm wrench below the front upper frame.

•The vent restrictor setting is from 1 (minimum restriction) to 6 (max restriction).

•The installer will document the restrictor setting in the end of the installation.

VENT RESTRICTOR TROUBLESHOOTING

RESTRICTOR POSITION MUST BE OPENED IF THE FLAME HAS THE FOLLOWING CHARACTERISTICS:

•Flame is excessively tall and lifting.

•Flame lacks movement.

RESTRICTOR POSITION NEEDS TO BE CLOSED MORE IF THE FLAME HAS THE FOLLOWING CHARACTERISTICS:

•Flame height is low.

•Flame has excessive movement

DOCUMENT ANYCHANGE TO THE RESTRICTOR SETTING

CONTACT FLARE FIREPLACES FOR SUPPORT IF NEEDED

20 | P a g e

POWER VENT ELECTRICAL CONNECTION

•All High Voltage Flare Fireplaces PV systems are connected to the Fireplace with 14|3 AWG 4 wire cable

Stranded CU MC (Metal Clad) armored Cable. 3 are used to power the PV and one is used to return

signaling when vacuum switch engages. The fireplace board will provide power to the power vent.

•The PV system is connected to the Fireplace control system with a high voltage with 14|3 AWG 4 wire

cable Stranded CU MC (Metal Clad) armored Cable.

•The Power Vent system will receive it’s 110V Power from the wire run from the fireplace board.

•The appliance, when installed, must be electrically grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22.1.

•Cable to be used is a minimum of 14|3 AWG 4 wire cable Stranded CU MC (Metal Clad) Armored Cable.

Cable can be ordered from Flare or sourced from any hardware store (16 AWG 5 wire can also be

installed by using just 4 from 5 wires one wire will not be used).

•Connect high voltage cable and match the colors on the terminal between the PV harness. (White to

White, Black to Black, Green to Green & red to red.)

•

•Install high voltage cable with compliance to local electrical code

Consult your electrician on the electrical safety requirement for the cable from the fireplace to the Power Ven

4 Wire cable to

PV system

Fireplac

e

110V AC

Input

Fireplace Control

box

Ignition system

cable

This manual suits for next models

1

Table of contents

Other Flare Fireplaces Remote Control manuals