FLATLIFT Slimeline 50 User manual

P.01

Operating Manual

Outperform. Outlast.

Operating Manual

YACHT AIRCRAFT HOTEL

P.02

Operating Manual

Outperform. Outlast.

CO

NTENT

S

CONTENTS

C.01 INTRODUCTION

C.02 FEATURES

C.03 PRODUCT DIMENSIONS

C.04 INITIAL PRODUCT SET-UP

C.06 PRODUCT CONTROL

C.07 TROUBLE SHOOTING

Set-up P.06

Images P.07 - P.08

Programming the remote control (S435) P.15

Resetting the receiver P.16

Connection to a room control system P.16

C.08 LEGAL NOTICE

Electric connector P.09

C.05 PRODUCT INTEGRATION

Product Integration / Covering P.10

Sample images P.11 - P.13

Complete covering P.14

P.03

Operating Manual

Outperform. Outlast.

INTR

O

DU

C

TI

O

N

INTRODUCTION

C.01:

Intended Use

The product swivels out of LCD and plasma TV equipment.

All company names and product names are trademarks of the corresponding owner. All rights reserved.

The scope of supply can vary depending on the product and the range of fixtures and fittings. Please

check that the product supplied is complete and inform us within seven days of delivery if the scope of

supply is not complete.

Safety and Hazards Recommendations

Please read this chapter carefully and follow all of the instructions provided. In this way you are able to

guarantee the reliable operation and a long lifespan for your lift system. Keep the operating manual in a

safe place.

In the event of damage which is the result of non compliance with this operating manual, all claims pertai-

ning to the guarantee are null and void. We generally accept no responsibility for secondary damage.

We accept no responsibility for damage to objects or persons which is caused by the inappropriate use of

the product or through ignoring the safety instructions. In such cases, all claims pertaining to the guaran-

tee are null and void.

Quality

In the choice of our components, our primary focus was on ensuring a high level of functionality,

straightforward use, safety and reliability.

We would like to thank you for the trust you have placed in our Flatlift brand products.

We can help you with your installation through providing individual customer care.

For safety reasons, the unauthorized conversion and/or changing of the product is not permitted. Do not

dismantle this product.

This product is not a toy and does not belong in the hands of children.

Do not allow the product to become damp or wet.

Do not leave the packaging material lying around as children may choke if they swallow it.

The product will be damaged if it is dropped, even from a low height.

Before using the product for the first time, please check that the free raising and lowering of the Flatlift

including the mounted TV equipment is possible and ensure a collision-free run.

For legal reasons and insurance purposes, your Flatlift is equipped with an ‘automatic safety

device’.

This means that the button which controls the raising and lowering must be pressed down all

the time.

The system stops and remains in the same position as soon as you let go of the button.

P.04

Operating Manual

Outperform. Outlast.

Features:

Installion dimensions Flatlift

W=1645mm D=1050mm H=200mm

opening rate 1,2°/sek

Angle of aperture 95°

Max. TV weight incl. cover 160Kg

Max. TV size 50“ (inch)

(max. TV size in mm: W=1345mm , H=800mm, D=160mm)

Power-on time 15%/h

Low noise level < 45 db

Environmental temperature from +5°C bis 40°C

4x flexible adjustable assambly brackets

Remote control 433,63MHz

Connection to room control system possible

TV switch-off if closed

Flatlift Slimline 50“

Control box

24V power supply unit

Remote control

Scope of supply:

P

R

O

D

UC

T FEAT

U

RE

S

PRODUCT FEATURES

C.02:

BUY NOW

L

I

F

E

T

I

M

E

R

e

p

a

i

r

c

o

s

t

l

i

m

i

t

5

y

e

a

r

s

f

u

l

l

s

e

r

v

i

c

e

GUARANTY

P.05

Operating Manual

Outperform. Outlast.

P

R

O

D

UC

T DIMEN

S

I

O

N

S

PRODUCT DIMENSIONS

1200

920

aa

200

920

Schnitt a-a

C.03:

Cut a-a

1645

1050

1050

200

P.06

Operating Manual

Outperform. Outlast.

Initial setting / installation

1. Unpack your Slimline Plasma ceiling TV lift and place the Slimline on a level surface.

2. Align the 4 ceiling mounting brackets with the section as shown on page 07, image 1, No. 2 in a way

that these fit your project optimally. You can displace the mounting brackets simply as you wish until

these have reached the ideal position. Afterwards, please screw the brackets to the section by means

of the screws provided (DIN 912 M8, SW6) using an Allen wrench.

3. Now, transfer the dimension of the hole centre distance of the mounting brackets to your prepared

ceiling recess (S.07, image 1, No. 1). Use a drill (d = 8mm) to drill into your ceiling material. In case

the Slimline ceiling lift is to be installed on a yacht with metal/aluminium ceiling, we recommend dril-

ling a hole having the size suitable for a screw M8 (recommended drill/core hole diameter = 6.8mm).

In case of concrete ceiling installation please use mounting anchors approved for being used with

cracked respectively non-cracked concrete. We recommend using mounting anchors of the company

Fischer. In case the installation is implemented with a wooden ceiling, you may install the Slimline lift

to the wooden ceiling using wood screws (DIN 512, d = 8mm). The anchor respectively screw length

should be at least 80mm for concrete or wooden ceiling installations.

4. Please attach your Slimline to the ceiling using the 4 mounting brackets (page 07, image 1, No. 1).

5. Now, align the 2 vertical supports in the Slimline flap with the VESA attachment dimension of your

plasma / LCD TV, as shown in figure 2. In order to be able to move the supports, you have to loosen

the DIN 912 screws using an Allen wrench (page 08, image 2, No. 3, SW 4). In doing so, the supports

can be displaced horizontally to the dimension of the hole centre distance of the TV correspondingly.

Once you have reached to desired distance, retighten the screws. Now, you transfer the hole centre

distance from the X axis to the Slimline flap. Please observe that the holes of the X axis have been

transferred to the section in a centred manner.

6. Now, you can transfer the coordinates of the Y axis of the TV mounting holes to the Slimline flap.

During this step you will have the opportunity to align the TV upwards or downwards as the customer

desires.

7. After you transferred all hole coordinates to the Slimline flap, you can centre punch the same now and

drill the holes using a drill corresponding to the size of the screws (see page 08, image 3, No. 4). As

there is no applicable standard for these mounting screws, we are not able to recommend an exact

drilling diameter. The screws for wall-mounted TV sets may vary between M6 and M10 in dependency

on the TV model. Please consult the Flatlift distribution department prior to ordering the product res-

pectively procure the suitable screws with the local screw dealer.

INITIAL PRODUCT SET UP

C.04:

P.07

Operating Manual

Outperform. Outlast.

INITIAL PR

O

DUKT

S

ET U

INITIAL PRODUKT SET UP

Image 1

2

1

C.04:

P.08

Operating Manual

Outperform. Outlast.

Image 2

Image 33

4

C.04: INITIAL PR

O

D

U

KT

S

ET

U

INITIAL PRODUCT SET UP

P.09

Operating Manual

Outperform. Outlast.

Image 4

Image 6

Image 5

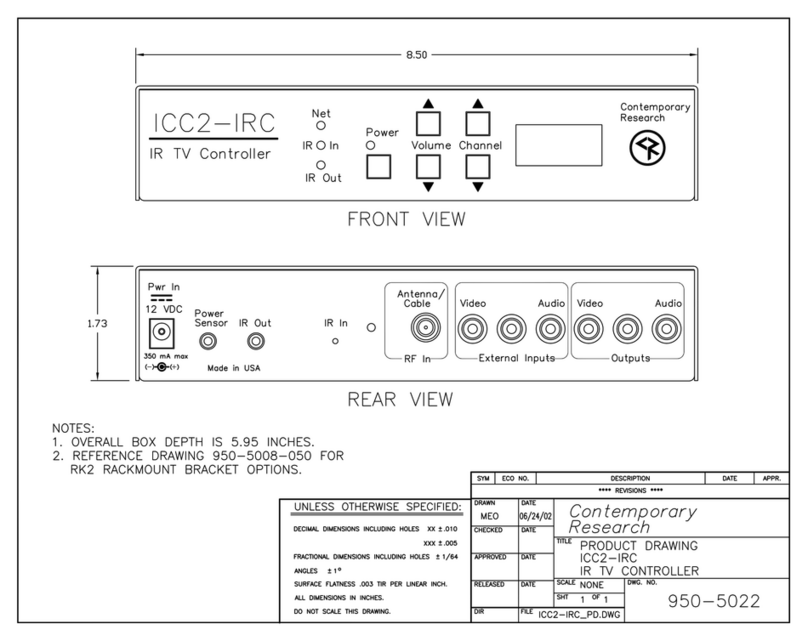

Electrical connection:

1.Connect the motors to the control box (image 4, No. 5). Now, you may connect the motors to the con-

trol box. There is no connection sequence to be observed.

2. Connect the limit switch to the control box (image 5, No. 6).

3. Connect the 24V mains adaptor (image 6, No. 7) to the control box (image 5, No. 8). Please observe

the polarity (image 6, No. 7).

4. Connect the control box (image 4, No. 9) and the 24V mains adaptor (image 6, No. 10) to the mains

supply.

5. Now, please store the control box and the mains adaptor in the suspended ceiling or in a free area of

the Slimline. Please consider planning a revision recess (see chapter 5, page 10).

6. Open and close your Flatllift Slimline once without the TV. In doing so, please observe a free pivoting

area, so that the Flatlift Slimline does not make contact with any obstructions.

7. Due to insurance purposes, your Flatlift Slimline is equipped with an automatic safety device. This me-

ans that the button for opening and closing the system has to be pressed permanently. As soon as

the button is no longer pressed, the Slimline system stops.

Minus (-) (+) Plus

5

6

7

8

9 10

C.04: INITIAL PR

O

D

U

KT

S

ET

U

INITIAL PRODUKT SET UP

P.010

Operating Manual

Outperform. Outlast.

PRODUCT INTEGRATION

PRODUCT INTEGRATION

Product integration / cover flap lining:

The Slimline cover flap may be lined in different variations. It is important to design a revision aperture

allowing you to enter into the interior or the Slimline ceiling lift in case the Slimline has a failure. This

section is to explain how the flap can be lined best.

1. Page 11, image 2, No. 1. Here, the flap of the Slimline ceiling lift is lined with the help of a 12mm MDF

board. In this example our integrator used the product Scotch 3M “Dual Lock”. Scotch 3M “Dual Lock”

is a high performance adhesive tape (similar to hook-and-loop adhesive tape). The design of this

adhesive tape allows for very high holding forces. For this, please attach the 3M tape to the Slimline

flap over a large area. Please observe that the flap of the Slimline lift has to be closed while attaching

the tape. After having attached the adhesive tape to the flap, please remove the adhesive film and

press the cover flap lining against the Slimline flap from the bottom. Please observe that the flap has

to be aligned with the ceiling recess in order to obtain a uniform image.

2. Page 12, image 3. Here, the cover lining is screwed directly to the Slimline flap. In the grooves of the

aluminium section there are 4 sliding blocks with holes of d = M6, suitable for counter-sunk screws

DIN 7991. Depending on the design of the ceiling you may fill respectively cover these DIN 7991

counter-sunk screws with the actual ceiling lining material, so that the same are no longer visible. Ac-

cording to our experience this is one of the most commonly used lining variant, which furthermore

may be implemented very easily.

3. On page 12, image 4 the cover lining is directly screwed through the flap of the Slimline TV lift. For

this, align the cover plate accordingly and drill 4-8 times directly through the centre of the aluminium

section, as shown on page 12, figure 4, No. 2. Afterwards, you can attach the cover plate using screws

of an appropriate length. (In our case study we use 12mm MDF wood. Thus, in accordance with the

thickness of the aluminium section (40mm) we use at least 45-50mm long wooden Spax screws in

order to obtain a corresponding attachment stability.

4. On page 13, image 5, No. 3 you see how the flap solution is implemented at the rear end of the

Slimline. The cover plate should project over the pivot axle of the flap by approximately 100-150mm

and should be equipped with a mitre of approximately 45° at the end. The room ceiling lining in the

recess area for the Slimline should be mitred with 45° as well. Thus, the cover flap can pivot freely at

a minimum clearance. Furthermore, this solution has the advantage of the view into the rear part of

the Slimline lift being prevented in case the Slimline is pivoted to the full extent.

5. You are free to encase your Slimline to a further extent, such as the Slimline flap with TV integrati

on, respectively the interior of the Slimline, see page 14, image 6.1 and 6.2. However, in doing so you

should observe a proper movement being provided for at any time.

C.05:

P.011

Operating Manual

Outperform. Outlast.

P

R

O

D

UC

T INTE

G

RATI

O

N

PRODUCT INTEGRATION

Image 1

Image 2

1

C.05:

P.012

Operating Manual

Outperform. Outlast.

P

R

O

D

UC

T INTE

G

RATI

O

N

PRODUCT INTEGRATION

Image 3

Image 4

2

C.05:

P.013

Operating Manual

Outperform. Outlast.

Image 5

45°

3

P

R

O

D

UC

T INTE

G

RATI

O

N

PRODUCT INTEGRATION

C.05:

P.014

Operating Manual

Outperform. Outlast.

P

R

O

D

UC

T INTE

G

RATI

O

N

PRODUCT INTEGRATION

Image 6.1

Image 6.2

Complete Covering

C.05:

P.015

Operating Manual

Outperform. Outlast.

Image 2

56

3

4

1

Image 1

P

R

O

D

UC

T

CO

NTR

O

L

PRODUCT CONTROL

2

C.06:

Programming the remote control (S435):

You can also get additional remote controllers for your Flatlift system (optional extra). As the controllers are

coded, you have to programme them.

1) To access the programming key, remove the cover (image 1, no. 1) on the receiver.

2) Press down the left hand key (image 1, no. 2). After this, an LED (image 1, no. 3) will then flash slowly.

3) Holding the programming key down, press the first key on the remote control at the same time (image

2, no. 5). On recognising the remote control, the LED (image 1 no. 3) starts to flash rapidly.

4) Release both of the keys.

5) To store a second channel, repeat the procedure starting at step 2 using the second key on the remote

control (image 2, no. 6). If your remote control has been successfully recorded, you should hear a soft

‘click’ in the receiver when you press down the key on the controller.

P.016

Operating Manual

Outperform. Outlast.

Anschluss an eine Raumsteuerung:

To assable your Flatlift Slimline to the room control

system, disconnect the contacts 2-5 (Abb.4).

Connect these cables with the relay outputs of

your room control system (Img.5).

The relays of the room control system should be

open as the case of may be close for 120 sec.

Image 3

2

3

4

1

Image 5

PRODUCT CONTROL

PRODUCT CONTROL

Image 4

Receiver contacts (Img.4):

Contact 1:

Contact 2:

Contact 3:

Contact 4:

Contact 5:

Contact 6:

Contact 7:

Contact 8:

Contact 9:

Contact 10:

unused

open outlet

open inlet

close outlet

close inlet

unused

power supply +12V

power supply 0V

unused

add on antenna

C.06:

Resetting the receiver:

It may sometimes occur that the transmitting codes stored in the receiver are lost.

In this case, the receiver must be cleared and re-programmed.

1) To access the programming key, remove the cover (image 1, no. 1) on the receiver.

2) Press down both of the programming keys (image 3, no. 2 + 4) until the LED (image 3, no. 3) rapidly

flashes. This is the signal that the memory has been successfully cleared.

3) Now re-enter your remote control (refer to P.15).

P.017

Operating Manual

Outperform. Outlast.

TROUBLE SHOOTING

TROUBLE SHOOTING

C.07:

Trouble shooting:

If your Flatlift is not working properly, please make sure you check the following things:

The Flatlift won’t move up or down

Is the power cord attached to the control box?

SCheck the main connection

Are all of the plugs properly connected to the control box? (NOTE: plugs which are not connected properly

can damage the system)

SCheck all of the connections

Is there any evidence of damage to the cables, the control box, the remote control or the Flatlift?

SDamaged components must be exchanged. Please contact us. .

The Flatlift has stopped and will only move in the wrong direction.

SIs your Flatlift fully extended already?

SIs the TV too heavy?

SRemote control command possibly deleted!

Have you, in error, attached a TV to your Flatlift which is too heavy?

STake the TV off the Flatlift and now see if the Flatlift works.

Is the remote control working?

SChange the battery in the remote control if necessary.

Is the receiver receiving the signals?

SWhen activating the remote control, the relay should ‘click’ on both channels. (If the receiver does

not ‘click’, please delete the channels and re-set them. Refer to page 16)

The lifting mechanism jerks or stutters?

SPlease check as to whether another frequency source is also transmitting at 433 Mhz in your house

(possible sources of problems: garage door opener, baby phone, alarm system or intercom). With a

frequency jammer you will have to change over to a frequency of 868 Mhz! A free changeover from

433 Mhz to 868 Mhz is only possible within the first 7 days subsequent to the date of delivery.

Please contact us if this particular point is relevant to you.

If you experience any problems setting your system up or you experience an error, you can also contact

us over the telephone or via Email:

Customer Service:

Via email: info@flatlift.de

Our telephone service time is 7.30 am - 5.30 pm. The telephone number is +49 (0) 62 41 - 97 20 10.

Please have the following information at hand / or include it in any email that you sent to us:

Your customer number

Your invoice number or delivery receipt number

The purchase date of your Flatlift

The name/model of your Flatlift system

P.018

Operating Manual

Outperform. Outlast.

p

Ou

tp

erform

.

Outlast

.

FLATLIFT References

© 2008 FLATLIFT TV LIFT SYSTEME GMBH

LI

G

AL N

O

TI

C

E

LEGAL NOTICE

C.08:

Legal Notice

FLATLIFT TV Lift Systeme GmbH

Gewerbegebiet Südwest

Niedesheimer Str. 15

67547 Worms, GERMANY

Tel.: +49 (0) 62 41 97 20 10

Fax.: +49 (0) 62 41 97 20 12

info@fl atlift.de

www.fl atlift.de

Hours of business: Mon-Fri. 7:30 am- 5:30 pm

Managing Director: Sascha Rissel

HRA Mainz: HRB 40436

USt. (VAT) ID: On request

Status of document: JULY 2008

Table of contents