Fleet Complete MGS200 User manual

MGS200InstallationGuide Feb, 10

Condential Version 1.4

MGS200 Installation Guide:

Contents:

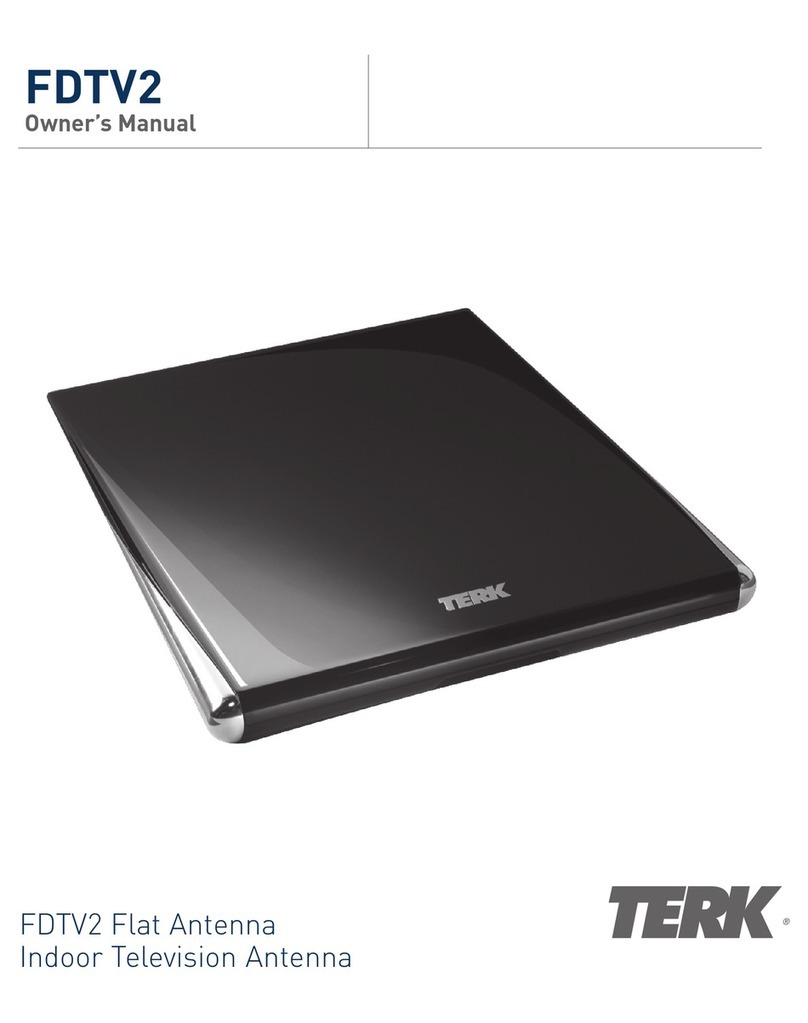

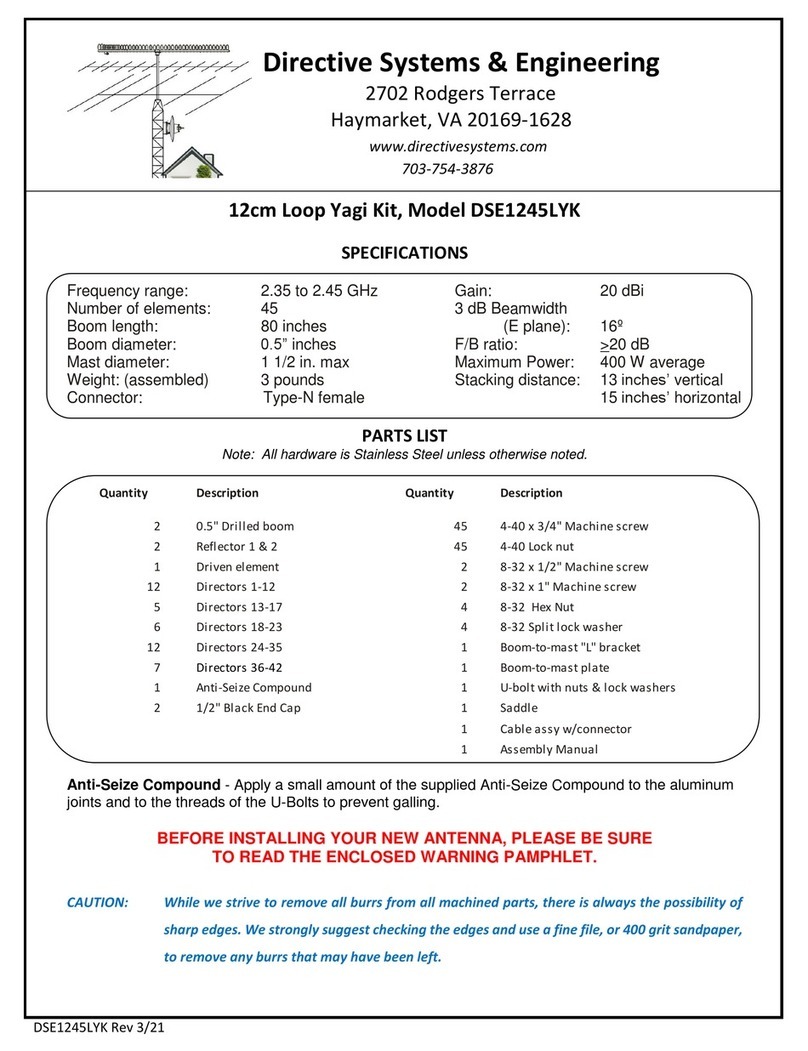

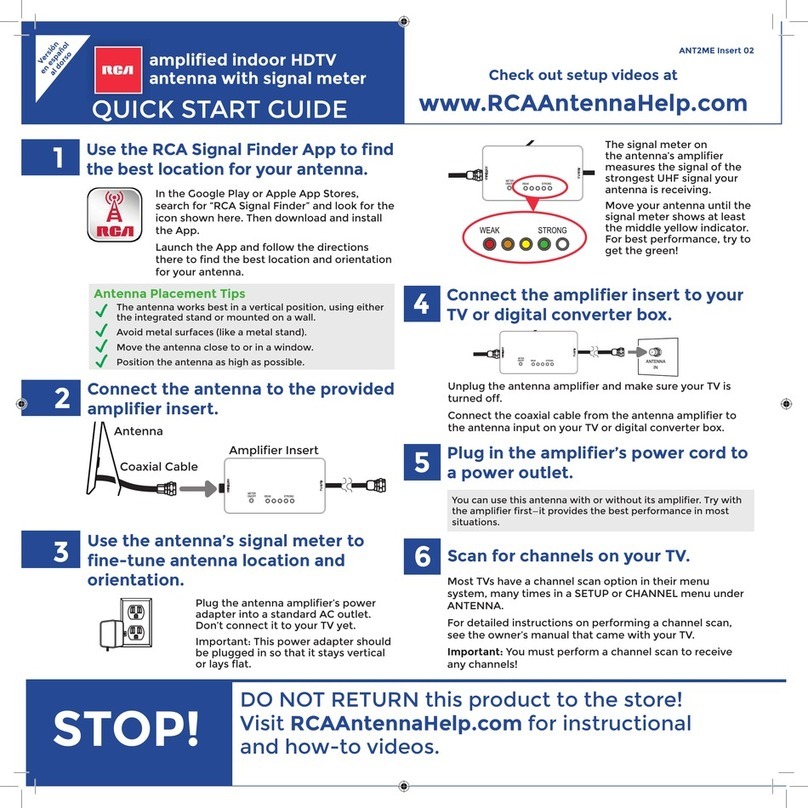

1. MGS200-G

2. Antenna pad

3. 20 pin cable

4. Antenna

5. Blue ring terminal (gound connector)

6. Fuse holder

7. Amp fuse

8. Plated steel screws

1. 2. 3.

4.

6.

8. 7. 5.

1. Contents

2. Tools / Materials required

2. Work order / System outline

2. Hardware location and preparation

3. Antenna location

3. MGS mounting

4. Power wire installation

5. Wire connections

& fusing

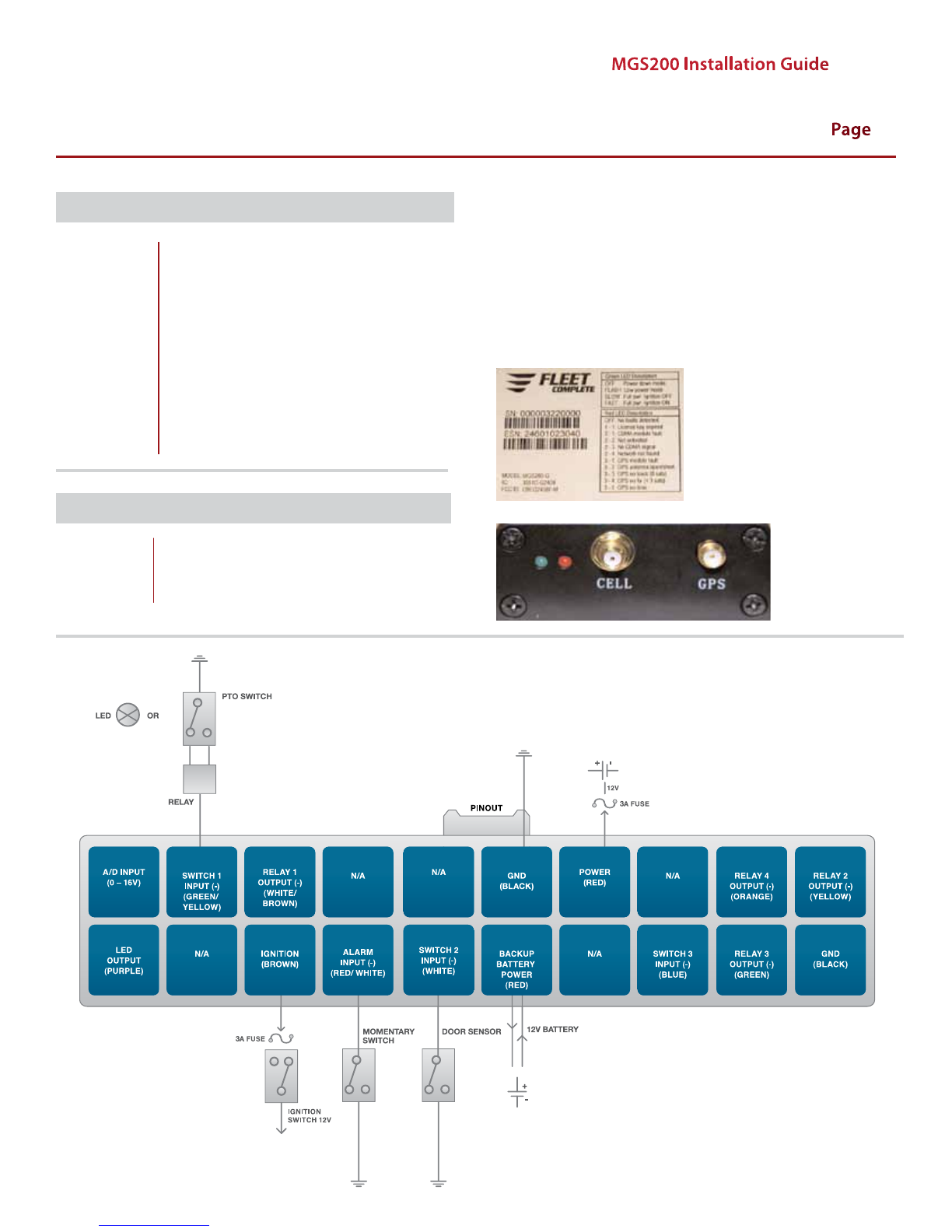

6. Installation diagram

MGS200InstallationGuide Feb, 10

Condential Version 1.4

Tools Required:

Work order/system outline:

1. Full compliment of various screw

drivers

2. Crimping tool for crimp connectors

3. Wire cutters and strippers

4. Ring, spade, splice crimp connectors

(red and blue)

5. Small spools of red and black 16

gauge wire

6. Digital multimeter

7. 7” black cable ties

8. Silicone

9. Soldering iron and solder

Verify the requirements of the installation as described in

the work order

Special instructions should be outlined on the work order

Hardware location and preparation:

Note: It is important to insulate the wires not being used on

the wire harness during the installation. Improper insulation

could result in inaccurate notications and increased usage on

monthly billing.

Find a suitable location for the MGS if one has not been

specied on the work order. The MGS is usually installed

under the vehicle’s dash.

Keep the device away from any places of high moisture i.e.

under seats, oors, etc.

Prepare all connections for the MGS, cable harness and

fuse holder prior to commencing installation.

•

•

•

Page 02

MGS200InstallationGuide Feb, 10

Condential Version 1.4

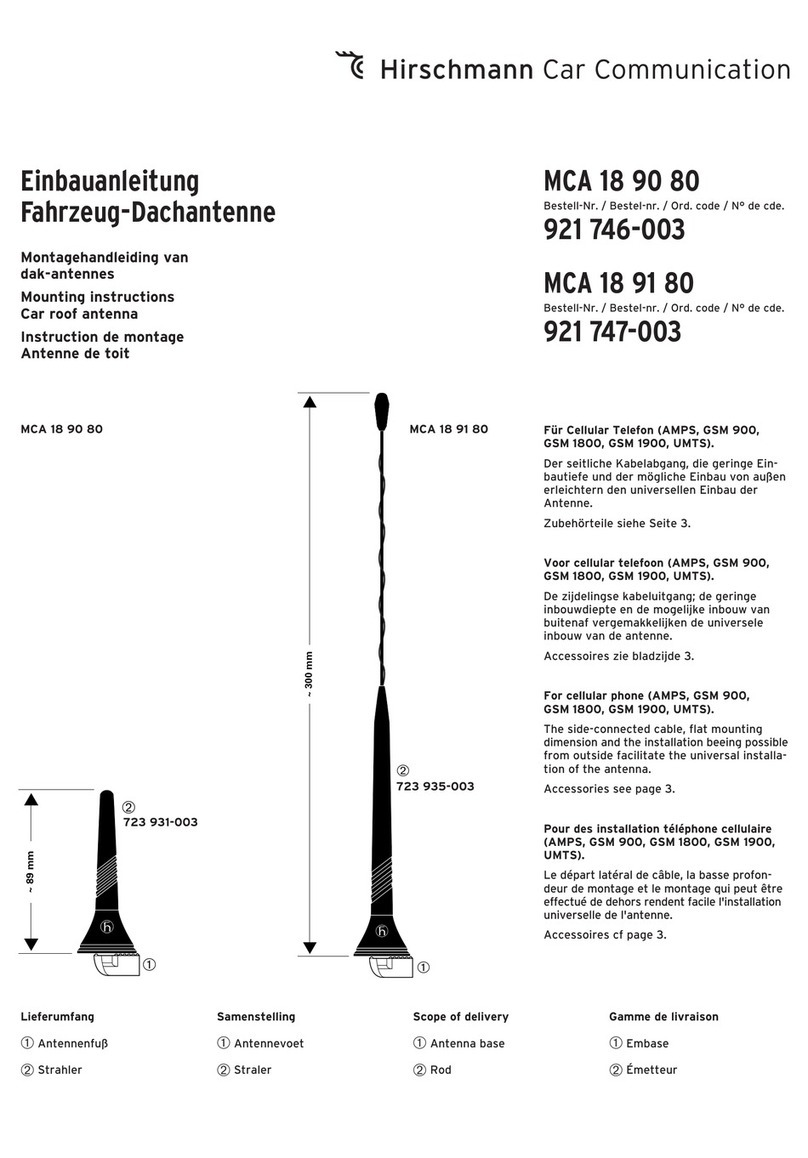

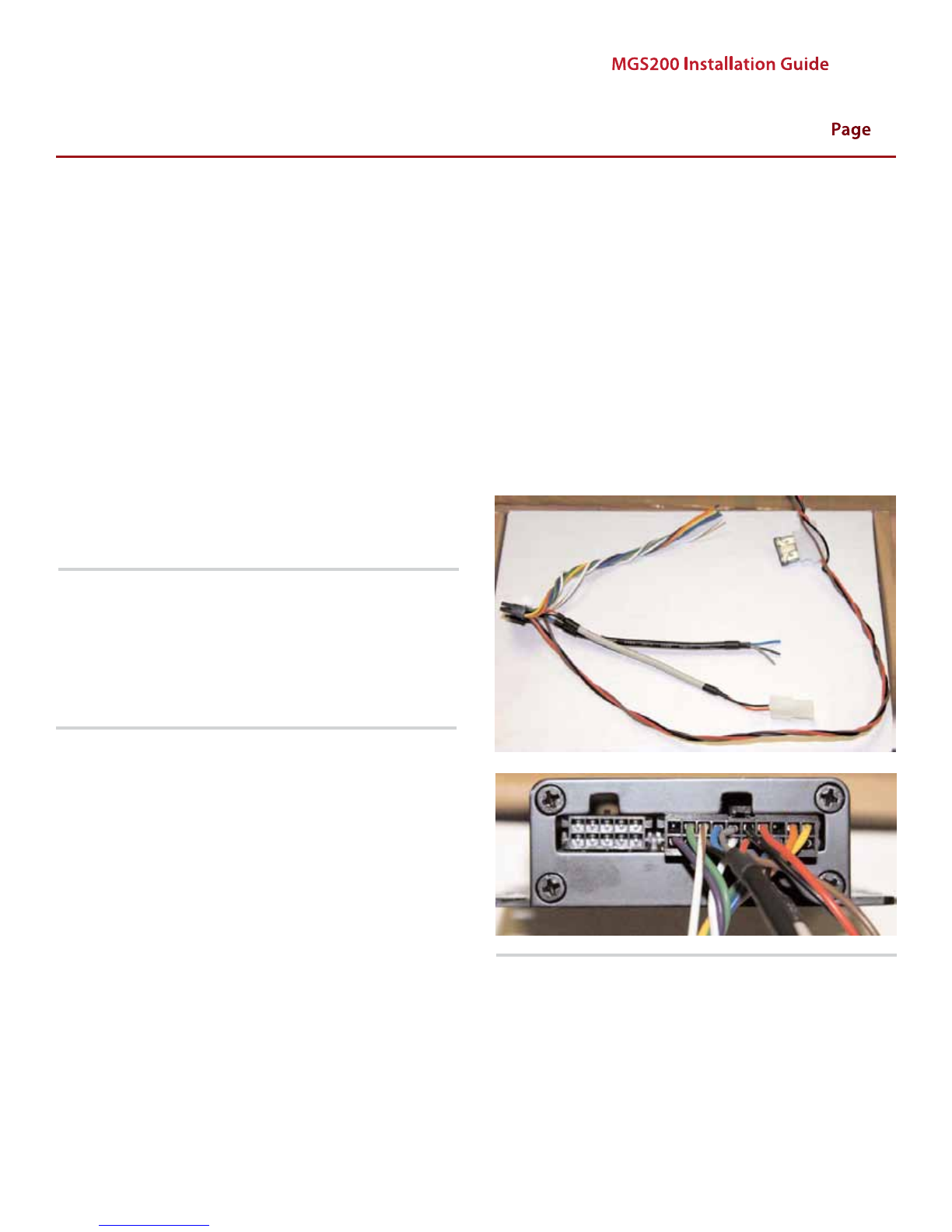

Antenna location: MGS mounting:

Note: The GPS/RF Combo antenna must be mounted at with

the GPS Receiver facing up (The letter “H” is facing up). The

ideal location is on the roof; however the antenna can be

installed on the dashboard or on the window. If the vehicle

window has a solid dark coating around the edge, do not place

the GPS antenna behind the coating. The GPS signals will travel

through the clear glass but will be reduced if the window has

any metallic coating or tint applied.

The GPS/RF Combo antenna will work best if it has a clear view

to the sky and as much of the horizon as possible. Any metallic

objects between the antenna and the GPS satellites will

degrade the signal and reduce the overall performance.

Antenna can be roof, dash or window mounted.

Find a location on the vehicle with a clear line of sight to

the sky and place the antenna on the roof/dash/window.

For dash or window mounting, to keep the wires hidden,

run the wires behind the dash.

For roof installation, run the wires into the vehicle in the

best possible way to keep the wires from being pinched.

Keep the wires tight to prevent them from slapping on the

vehicle when in motion.

If needed, drill a small pilot hole from the inside of the ve-

hicle out. Remove the nut from the antenna and feed the

wire through the hole. Place a bead of silicone around the

stem of the antenna. From inside, use the nut and lock

washer to tighten the antenna to the roof. Place a small

bead of silicone where the antenna and roof meet.

Run the antenna wires to the MGS location as you see t.

Note: The unit should be mounted so it will not be exposed to

damage from people or objects. The cables that connect to the

unit should also be routed to protect them from possible dam-

age. The MGS has a ange with four mounting holes. Normal

installation is with these four holes and #6 or #8 sheet metal

screws. The unit must be mounted where it will not be exposed

to direct sunlight or excessive heat generated by the vehicle

operation. Some examples of mounting locations include un-

der the dash above the knee bolster, under the center console,

behind the glove compartment, and in the trunk.

The MGS is equipped with slotted anges to mount on at

surfaces with #8 sheet metal screws.

If a at surface cannot be found in the desired location, it

is possible to mount the MGS using 4 cable ties around an

object under the dash. ONLY USETHIS AS A LAST RESORT!

Ensure the MGS cannot vibrate excessively and is protect-

ed from all elements.

•

•

•

•

•

•

•

•

Page 03

MGS200InstallationGuide Feb, 10

Condential Version 1.4

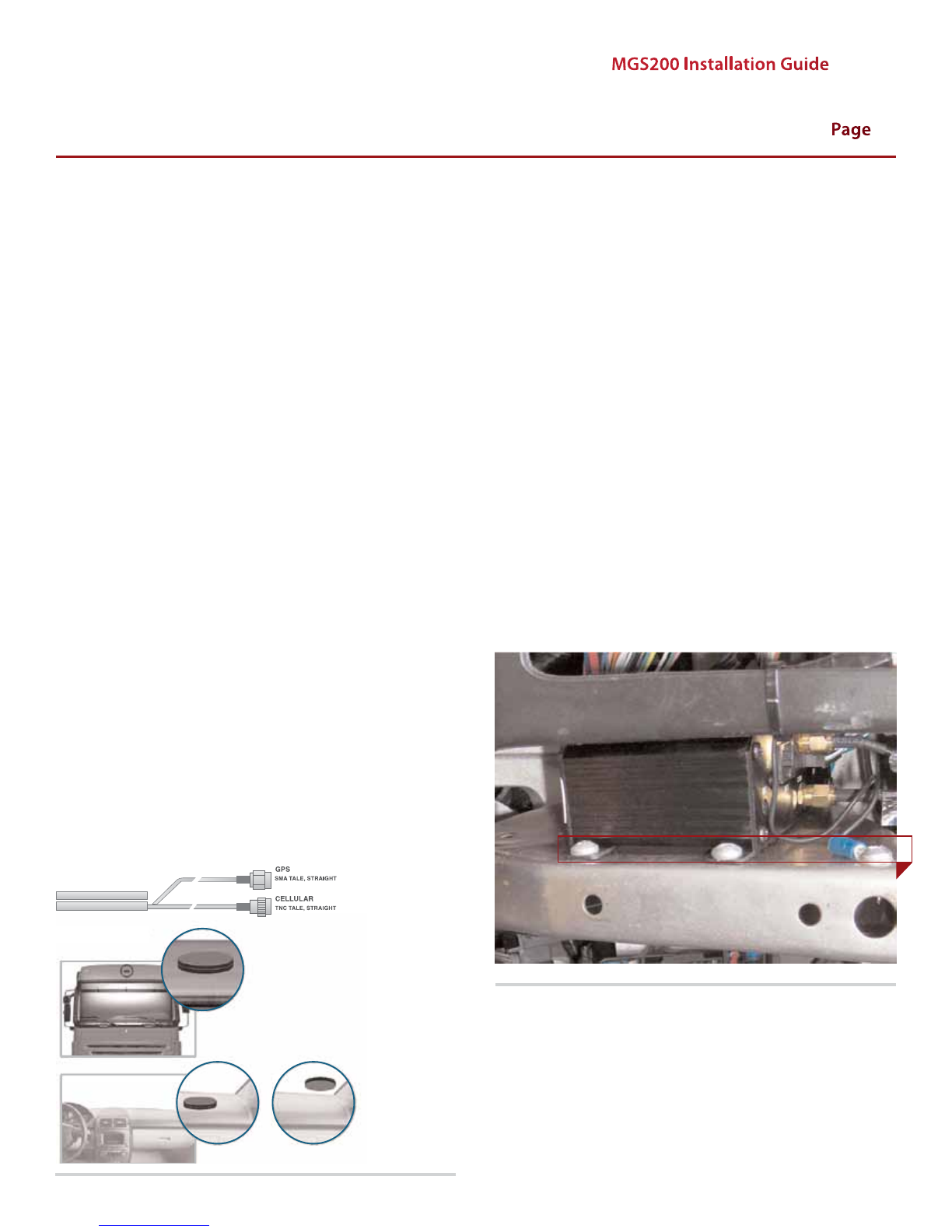

Power wire installation:

The MGS is connected directly to the vehicle’s 12-volt system.

There is no on-o switch on the unit. The installed unit oper-

ates 24 hours a day and must be powered to log vehicle events

or send data as required by the client.

The MGS is shipped with one in-line 3-amp fuse attached to

the power cable. This fuse must be installed as close as possible

to the primary 12-volt source connection. The fuse protects the

power cable should there be a short in the cable between the

fuse and the MGS. This fuse must be installed properly. If the

fuse is replaced, it should be of the same type as originally

supplied from the factory. Failure to use the proper fuse or to

install the fuse in the recommended location could cause a

vehicle re hazard. The fuse provides overload protection for

the power cable and MGS. The wiring installed between the

fuse and primary vehicle power is not protected from over-

heating if a short should occur. Use care when routing the

power cable and fuse. Route the cables where they will be pro-

tected and uses include commonly accepted install practices

for after market automotive electronic devices.

There are two acceptable methods of making a wire

connection:

Soldering your connections (recommended)

Crimp connectors (with the use of the proper crimping

tool)

Regardless of the method you choose, ensure that connection

is mechanically sound and properly insulated. Use high quality

electrical tape or shrink tubing, cheap tape will unravel in hot

weather making it a poor insulator.

Never use “t-tap” connectors (poor quality mechanical type

connection).

Never“twist and tape” without soldering your connection.

Extend the power wires on the MGS using splice crimp ter-

minals and your RED and BLACK 16 gauge Wire.

Run the ground (black) wire to a suitable chassis ground

by using the crimp ring terminal.

Run the positive (red) wire to the constant power (+12

volts DC at all times) and splice an inline fuse holder to the

end. This is to protect the wire run.

•

•

•

•

•

•

•

Splice the other side of the fuse holder to the power wire

identied in the vehicle with solder or crimp terminal.

Run the ignition switch input (brown) wire to the primary

ignition wire in the vehicle. Locate the appropriate wire

under the dash. When the ignition key is turned to the“On

or Run” position, this will show +12 Volts DC.

Page 04

MGS200InstallationGuide Feb, 10

Condential Version 1.4

Conrming proper operation:

Connect the antenna cables to the appropriate locations

on the MGS.

Check the power light on the MGS

Check for cellular connectivity light (Flushing Blue).

•

•

•

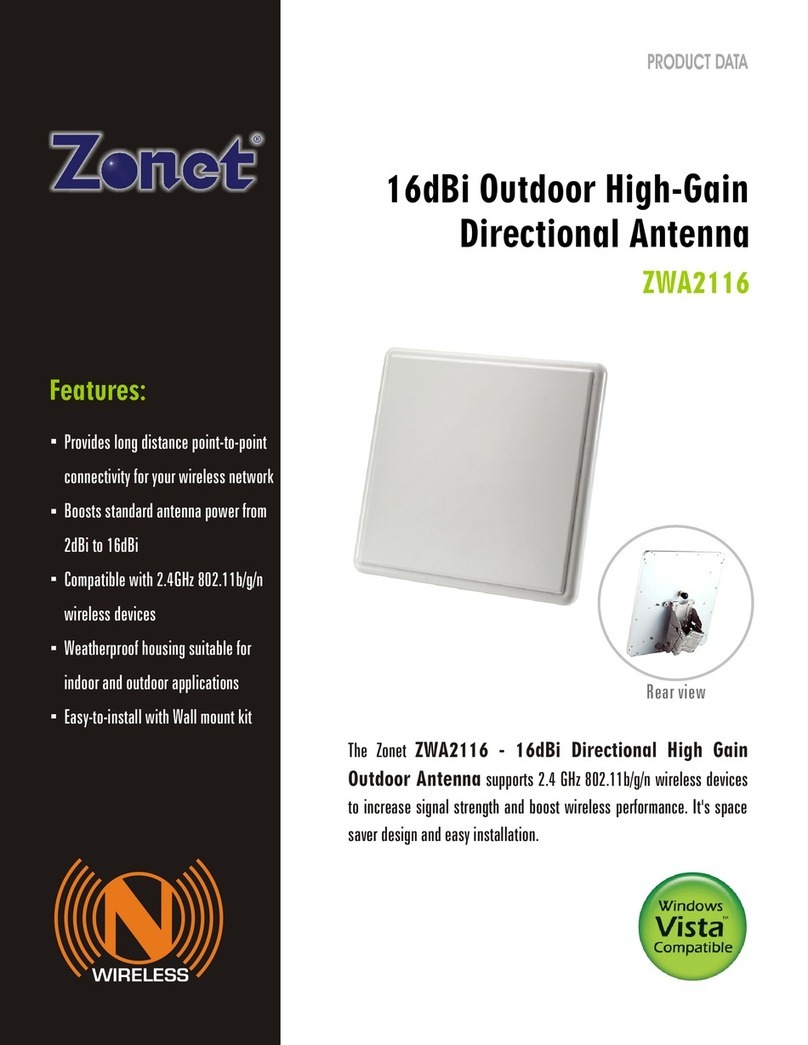

Red LED Description

Green LED Description

OFF

1 – 1

2 – 1

2 – 2

2 – 3

2 – 4

3 – 1

3 – 2

3 – 3

3 – 4

3 – 5

OFF

Flash

Slow

Fast

No faults detected

License Key Exp.

CDMA Module fault

Not Activated

No CDMA Signal

Network not found

GPS Module fault

GPS Annt. Open/Short

GPS Not track (0 Sat.)

GPS No x (<3 Sat.)

GPS No time

Power Down mode

Low power mode

Full power ignition O

Full power ignition On

Page 05

Applies to Serial #

000003259999 ( - )

MGS 200-G INPUT INSTALLATION DIAGRAM

MGS200InstallationGuide Feb, 10

Condential Version 1.4

When the ignition is rst turned on the MGS200 will power-up. The

Green LED will show solid for approximately 30 seconds. At no other

time should be green LED remain on solid for such a long period.

After 30 seconds the green LED will start to ash at the following rates:

25 times on-o every 10 seconds when the ignition is on

(this is quite rapid)

8 times on-o every 10 seconds when the ignition is o

(this is quite slow)

Very short blip once every 3 seconds when in sleep mode

The green LED will also show if there is a active input by ashing a

number of times corresponding to the input (1,2,3,4). For example

if input 4-Alarm is active then there will be 4 short ashes every 3

seconds.

•

•

•

Page 06

Applies to Serial #

000003260000 (+)

1 wIRe

DATA

TeMPeRATURe PRObe

Table of contents