7.2.3 Correcting faults.....................................................................................................................40

7.2.3.1 Replacing wearing parts.........................................................................................................40

7.2.3.2 Correcting the changed alignment.........................................................................................41

8 Servicing.....................................................................................................................................................43

8.1 Maintenance intervals............................................................................................................43

8.2 Maximum permissible torsional backlash...............................................................................44

8.3 Replacing wearing parts.........................................................................................................45

8.4 Removing the coupling...........................................................................................................46

9 Service and support....................................................................................................................................49

9.1 Contact...................................................................................................................................49

10 Disposal......................................................................................................................................................51

11 Spare parts.................................................................................................................................................53

11.1 Ordering spare parts..............................................................................................................53

11.2 Spare parts drawing and spare parts list................................................................................54

11.2.1 Types A and ADS...................................................................................................................54

11.2.2 Types B and BDS...................................................................................................................55

A Technical data............................................................................................................................................57

A.1 Speeds, geometry data and weights......................................................................................57

A.1.1 Type A....................................................................................................................................57

A.1.2 Type B....................................................................................................................................59

A.1.3 Type ADS...............................................................................................................................60

A.1.4 Type BDS...............................................................................................................................61

A.2 Shaft misalignment values during operation..........................................................................62

A.3 Tightening torques and widths A/F.........................................................................................63

A.4 Tightening procedure.............................................................................................................64

A.5 Flexible elements (12)............................................................................................................64

A.5.1 Use and storage of flexible elements (12)..............................................................................64

A.5.2 N-EUPEX flexible elements (12)............................................................................................65

A.5.3 N-EUPEX DS flexible elements (12)......................................................................................66

B Quality documents......................................................................................................................................67

B.1 Declaration of Conformity.......................................................................................................67

Tables

Table 2-1 General warnings........................................................................................................................11

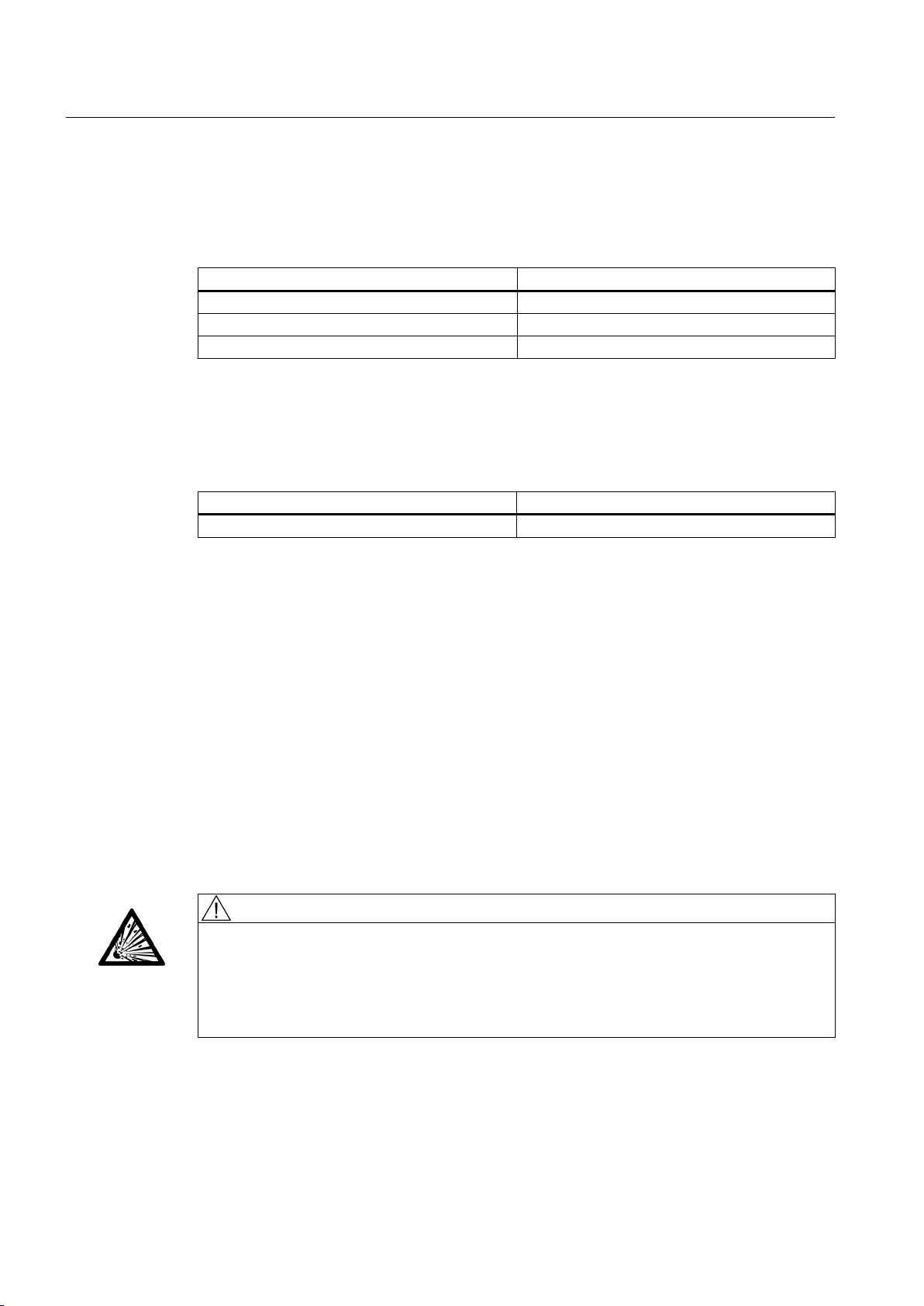

Table 2-2 Temperature classes (TX) for explosive atmospheres as a result of gases, vapours or mists......16

Table 2-3 Maximum surface temperature (TX) for an explosive atmosphere as a result of dust/air

mixtures.......................................................................................................................................16

Table 4-1 Types of preservative agents for long-term storage....................................................................22

Table 5-1 Recommended assigned fits for bores with parallel key connection...........................................24

Table of contents

N-EUPEX / N-EUPEX DS 3100en

6Operating Instructions 10/2017